Production method of polyurethane spray product with hole

A production method, polyurethane technology, applied in the production field of polyurethane spray products, to achieve the effect of simple operation, low development cost, and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

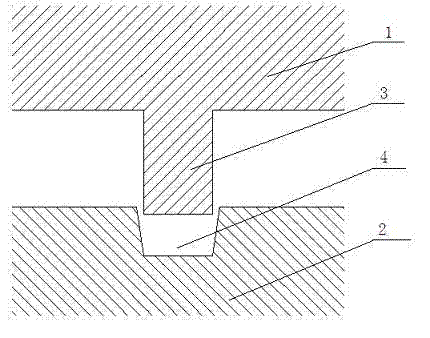

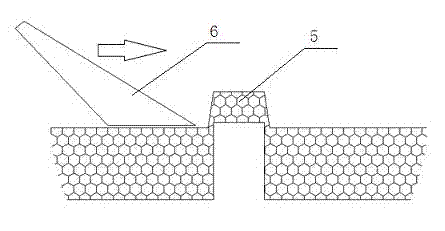

[0014] Embodiment 1, the product is an example with a glass fiber reinforced polyurethane material with a honeycomb paper sandwich, a product thickness of 10mm, and several small holes with a diameter of 5mm on the product; see figure 1 , 2 , the forming mold is a punch 1 on one side and a die 2 on one side. The punch 1 has a boss 3 with a diameter of 5 mm and a height of 11 mm; the die 2 has a pit 4 with a depth of 3 mm, and the diameter of the pit mouth is 6 mm. The diameter of the bottom of the pit is 5 mm; when the mold is closed, the boss 3 on the punch 1 falls into the pit 4 on the die 2, and there is a gap between the boss 3 and the pit 4; The product, the scrap 5 in the pit can be cut 6 with a flat knife with a width of 6~10mm.

Embodiment 2

[0015] Embodiment 2, the product is a natural fiber reinforced polyurethane material with a honeycomb paper sandwich, and the product thickness is 8mm, with several small holes with a diameter of 5mm on the product; see figure 1 , 2 , the forming mold is a punch 1 on one side and a die 2 on one side; the punch 1 has a boss 3 with a diameter of 5 mm and a height of 10 mm; the die 2 has a pit 4 with a depth of 4 mm, and the diameter of the pit mouth is 6 mm. The diameter of the bottom of the pit is 5.5 mm; when the mold is closed, the boss 3 on the punch 1 falls into the pit 4 on the die 2, and there is a gap between the boss 3 and the pit 4; after molding For the product, the waste material 5 in the pit can be cut off with a flat knife 6 with a width of 6-10mm.

Embodiment 3

[0016] Embodiment 3, the product is a glass fiber reinforced polyurethane material with a honeycomb paper sandwich, and the product thickness is 12mm, with several small holes with a diameter of 8mm on the product; see figure 1 , 2 , the forming mold is a punch 1 on one side and a die 2 on one side; the punch 1 has a boss 3 with a diameter of 8 mm and a height of 14 mm; the die 2 has a pit 4 with a depth of 4 mm, and the diameter of the pit mouth is 14 mm. The diameter of the bottom of the pit is 12 mm; when the mold is closed, the boss 3 on the punch 1 falls into the pit 4 on the die 2, and there is a gap between the boss 3 and the pit 4; Product, the waste material 5 in the pit can be cut off with the flat knife 6 of width 6~10mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap