A production device for extruded film

A production device and film technology, which is applied in the field of extrusion film production devices, can solve the problems of unstable film product quality, difficult winding and traction operation, and inability to stabilize film bubbles, etc., and achieve good stabilization effect, simple structure, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

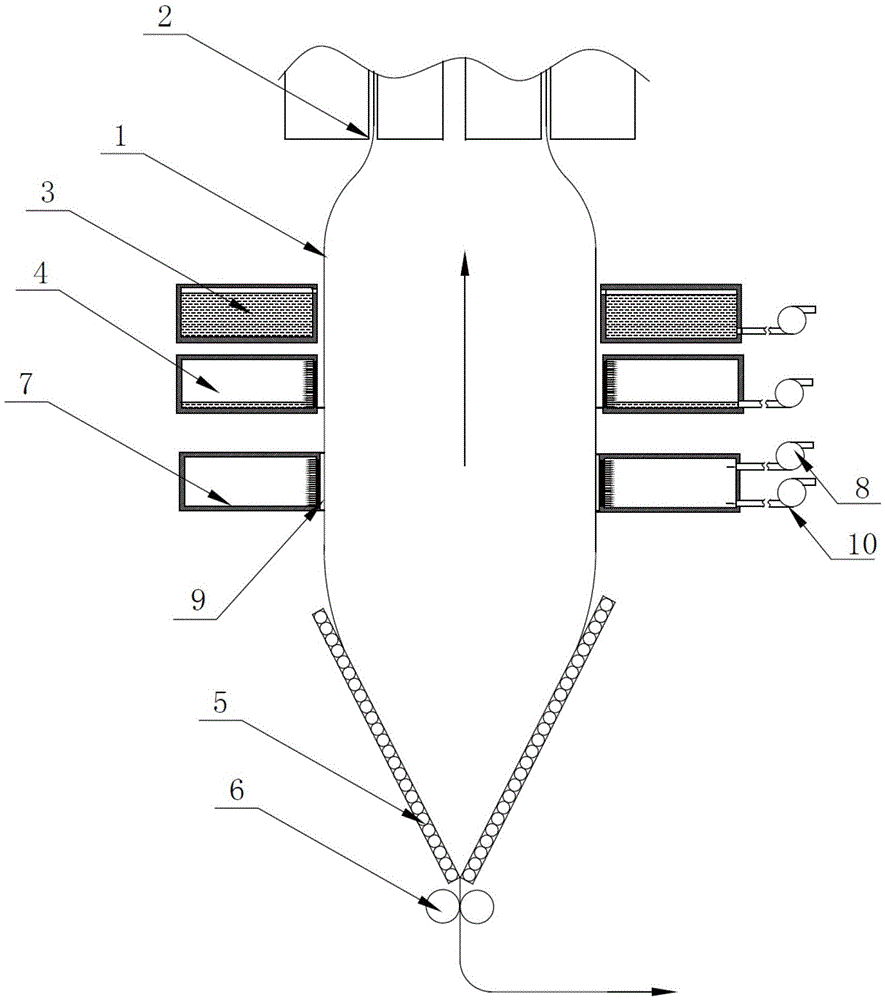

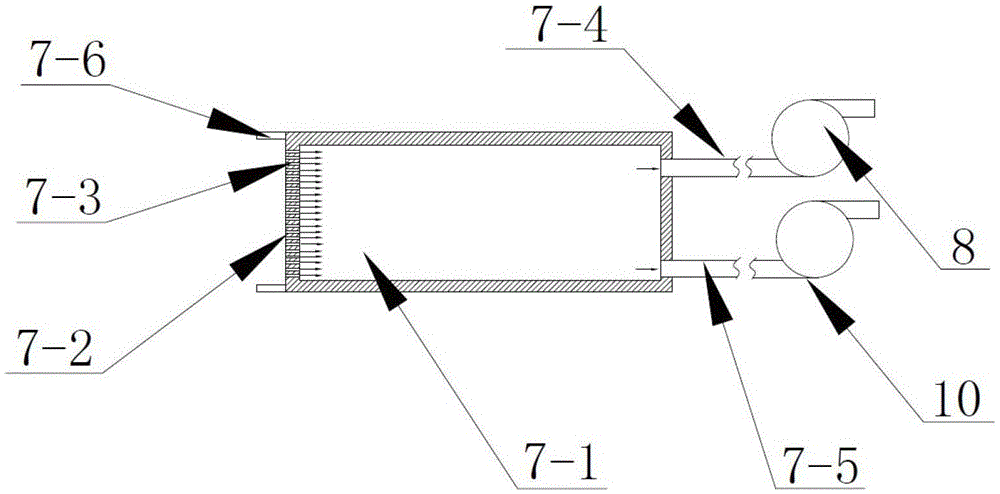

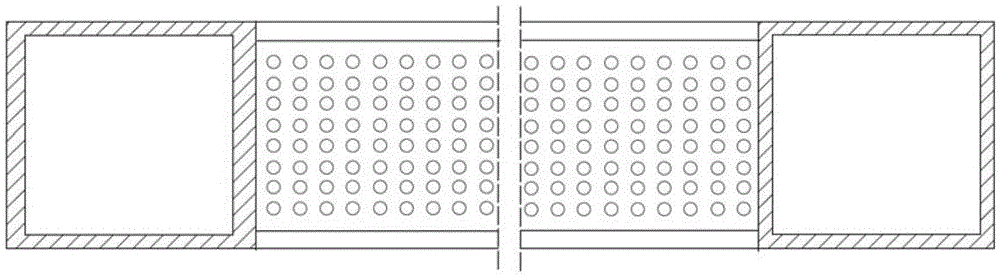

[0027] Such as Figure 1 to Figure 5 Shown, the present invention is a kind of production device of extruding film, and this device is used for the processing of annular downward extruding water-cooled casting film. The extrusion die 2, the water inlet ring 3 for cooling and forming the bubble 1, the return water ring 4 for recycling the cooling water, the guide structure 5 for pressing the bubble 1 into a folded film, and the drawing and blowing ring The traction mechanism 6 for continuous film forming, at least one vacuum bubble stabilizer 7 is provided between the return water ring 4 and the guide structure 5 so that the partial annular outer surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com