Non-uniformity compensation winding of slender non-moment coil and compensation method

A technology for compensating windings and non-uniformity, which is applied in the field of electromagnetic fields, can solve the problems of high cost of magnetic shielding tubes, achieve the effects of wide application range, reduce thermal conductivity, reduce magnetic flux noise and thermal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

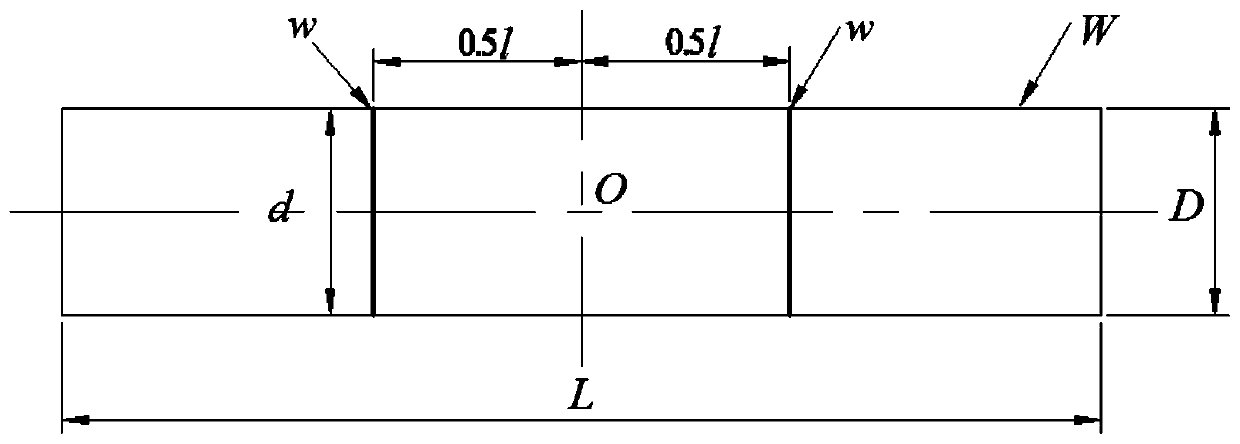

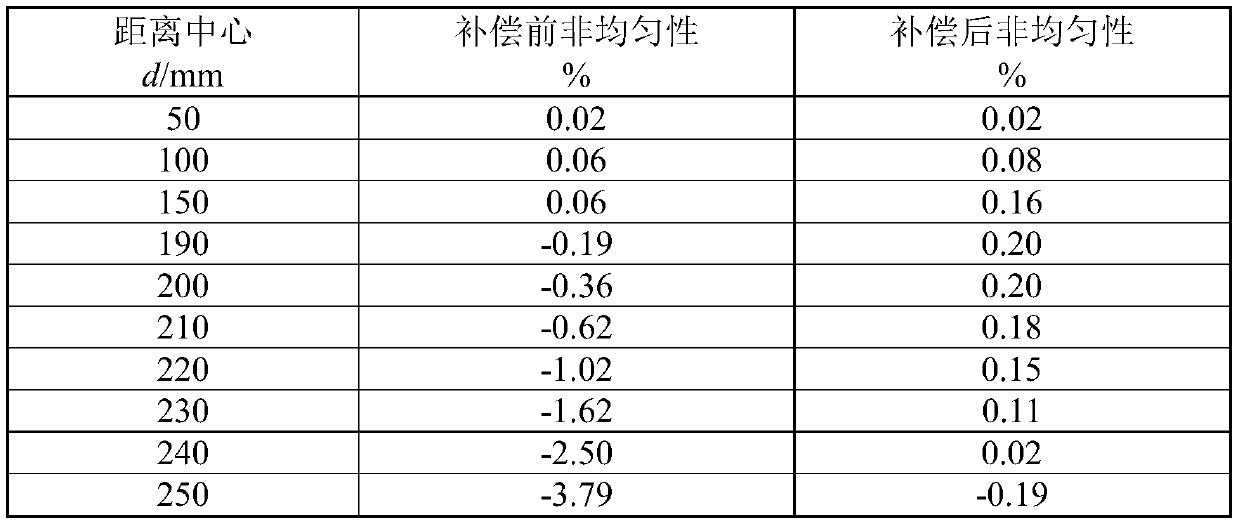

[0015] This embodiment provides a non-uniformity compensation winding for a slender momentless coil, which is suitable for a slender momentless coil, and its aspect ratio is 7-10. Such as figure 1 As shown, symmetrically adding compensation windings at both ends of the momentless coil can reduce the length of the momentless coil while ensuring the overall non-uniformity of the magnetic field, thereby reducing the cost of the low-frequency weak magnetic field test system.

[0016] The length of the external winding of the slender momentless coil is L, the outer diameter is D, the number of turns is W, the distance between the compensation windings at both ends is l, the diameter is d, and the number of turns is w, while satisfying the following relationship:

[0017] 1) The diameter of the compensation winding d=D;

[0018] 2) Number of turns w=1;

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com