Multi-station stamping processing equipment and turnover mechanism thereof

A technology of stamping processing and turning mechanism, which is applied in the direction of metal processing equipment, forging/pressing/hammering machinery, manufacturing tools, etc. It can solve the problems of low workpiece processing efficiency, workpiece inability to turn over, and workpiece turning over, so as to achieve convenient design and processing, Simple structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

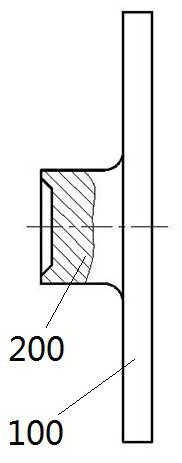

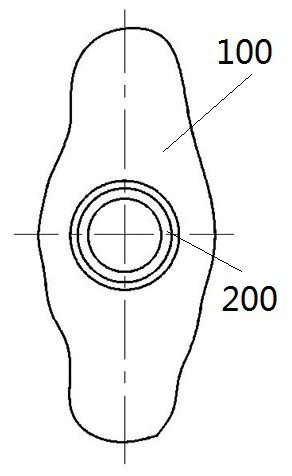

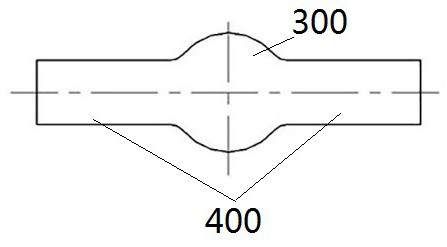

[0097] Taking the turning mechanism installed on a multi-station cold heading machine as an example, the turning mechanism for multi-station stamping processing equipment of the present invention is introduced in detail. Such as Figure 5 and Figure 6 As shown, the turning mechanism includes a die 1 and a punch 2. The die 1 includes a die body 10, a slider 11, a bar body 12 and an ejector 13. The die body 10 is used to be installed in the die body of a cold heading machine. cavity, such as Figure 7 and Figure 8 As shown, the die body 10 is provided with an overturn cavity 101, a guide hole 102, an avoidance hole 103 and a step hole 104. The overturn cavity 101 runs through the die body 10 along the left and right directions. The ejector 13 can move left and right and is assembled on the right side of the turning cavity 101; the guide hole 102 extends along the left and right directions, and the slider 11 is guided and slidably assembled in the guide hole 102; into the s...

specific Embodiment 2

[0112] The difference between it and the above-mentioned embodiment 1 mainly lies in that in the above-mentioned embodiment 1, a stopper rod body is provided on the die body, and a pusher is provided on the punch body, and the pusher pushes the lower part of the stopper rod body into the turning cavity The stamping parts to be stamped are stopped by the lower part of the stop rod body, so as to avoid the obstruction of the turning process of the stamping parts to be stamped. In this embodiment, there is no stop rod body on the die body, and no pusher on the punch body. At this time, by improving the machining accuracy of the turning cavity and setting the size of the turning cavity reasonably, the turning process of the stamped parts can be avoided. blocked by the flip chamber.

specific Embodiment 3

[0114] The difference between it and the above-mentioned embodiment 1 mainly lies in that in the above-mentioned embodiment 1, sliders are installed on the left and right guiding activities of the concave mold body, and the pusher pushes the slider, and pushes the stop rod body through the slider. In this embodiment, no slide block is assembled on the die body, and a matching inclined surface is directly arranged on the head of the stop rod, and the pusher is used to push the matching inclined surface, so that the stop rod body moves downward. Of course, in other embodiments, a matching slope can also be provided at the left end of the push piece, so that the stop rod body moves downward when the push piece pushes the stop rod body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com