Three-dimensional printing method and three-dimensional display panel

A technology of three-dimensional printing and three-dimensional display, applied in the field of printing, can solve the problems of lack of three-dimensional sense, inability to display pattern layers and depths in multiple directions, and inability to present 3D three-dimensional effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

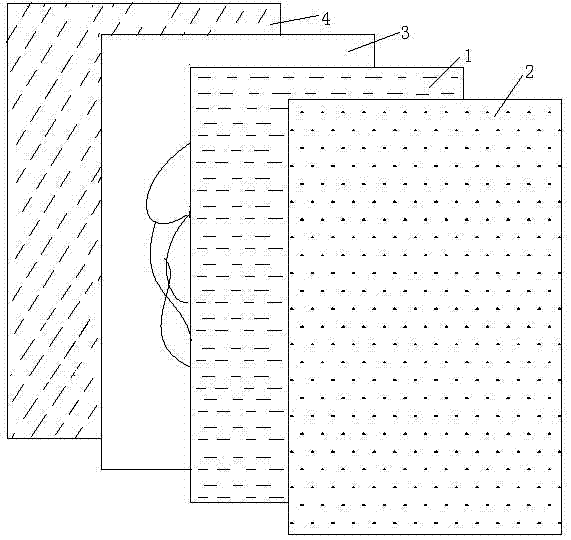

Image

Examples

Embodiment Construction

[0031] The invention provides a three-dimensional printing method, which is to print a pattern on a transparent panel base material, the transparent panel base material has a first surface and a second surface, which comprises the following steps:

[0032] First of all, the present invention determines an executable project plan to design pattern textures suitable for the home appliance industry. In this plan, the original manuscript, pixel data and printed image are always consistent with the grating pitch, so as to avoid the difference in the finished product due to the difference in data. Interference fringes are generated in the image, affecting the visual effect.

[0033] Then, customize a suitable transparent panel base material. In this embodiment, a piece of air-conditioning panel with 3D stereo printing effect is made, and a PC transparent base material with a size of 766MM*150MM and a thickness of 2mm is used to carry out the process on the PC transparent base materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com