Visual system and working method for high-voltage hot-line operating robot

A technology for working robots and high-voltage electrification, which is applied in manipulators, manufacturing tools, and program-controlled manipulators. It can solve problems such as high technical requirements and difficult training, and achieve the effects of reducing labor intensity, improving automation, and good stereoscopic visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

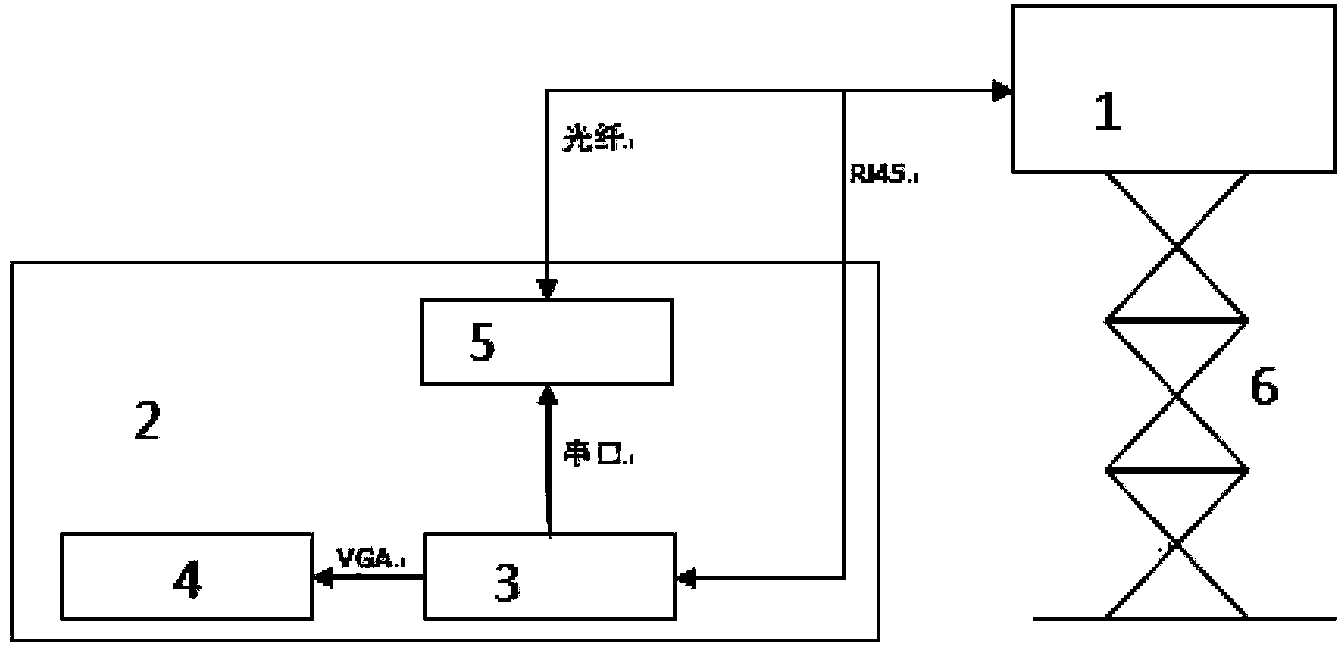

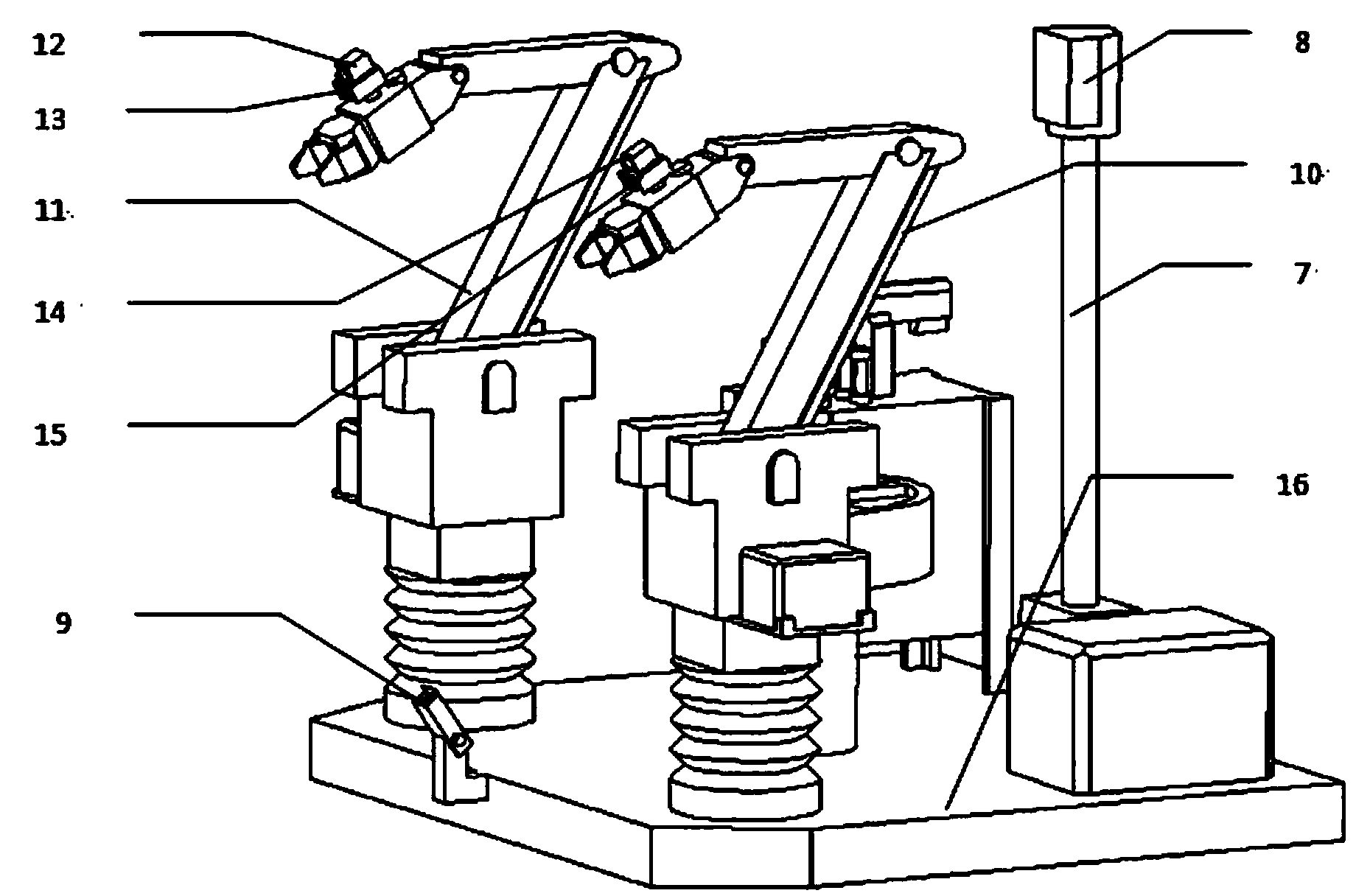

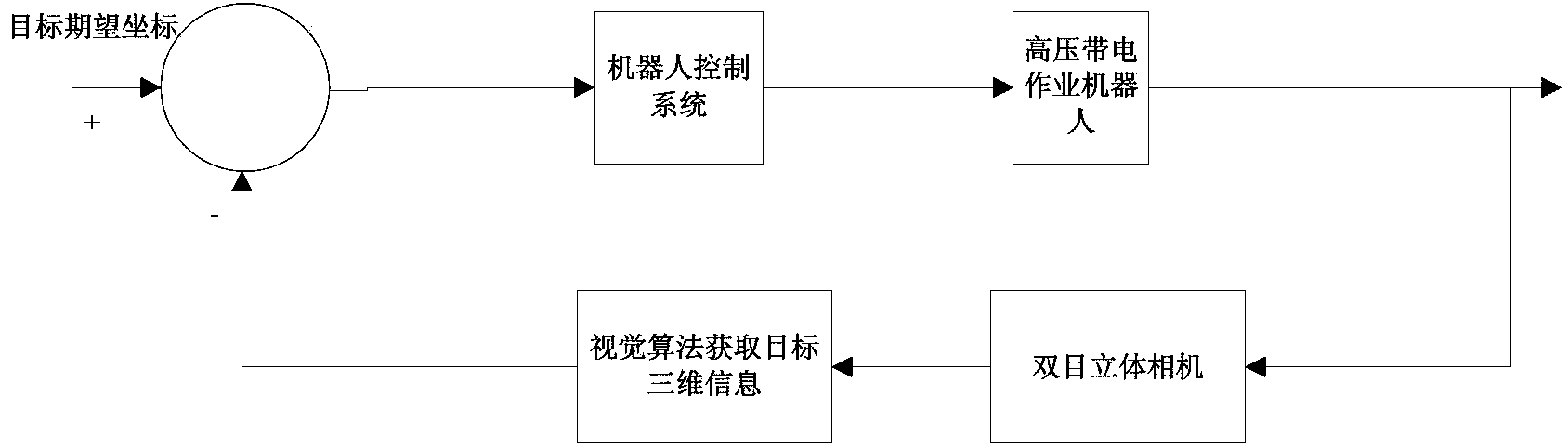

[0048] like figure 1 , figure 2 As shown, a vision system for a high-voltage live working robot includes a visible light camera II8 and a visible light camera I9 at the operating end 1, a left stereo camera 15 and a right stereo camera 13, a left stereo camera 14 and a right stereo camera 12, located at The high-performance video processor 3, the man-machine interface 4, and the robot control system 5 of the ground remote control terminal 2.

[0049] The high-voltage live working robot is the robot described in the patent No. 201210095860 "a high-voltage live working master-slave control robot operating platform" invented by Shandong Electric Power Research Institute. The robot includes a hydraulic lifting platform 6, a robot control system 5 and an insulating bucket. 16.

[0050] Described visible light camera II8 and visible light camera I9 adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com