3D protective film and preparation process thereof

A preparation process and technology of protective film, applied in the field of 3D protective film and its preparation process, can solve the problems of low production efficiency, poor tensile strength, lack of availability, etc., to improve the repair effect, lasting antibacterial properties, and reduce the coefficient of friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

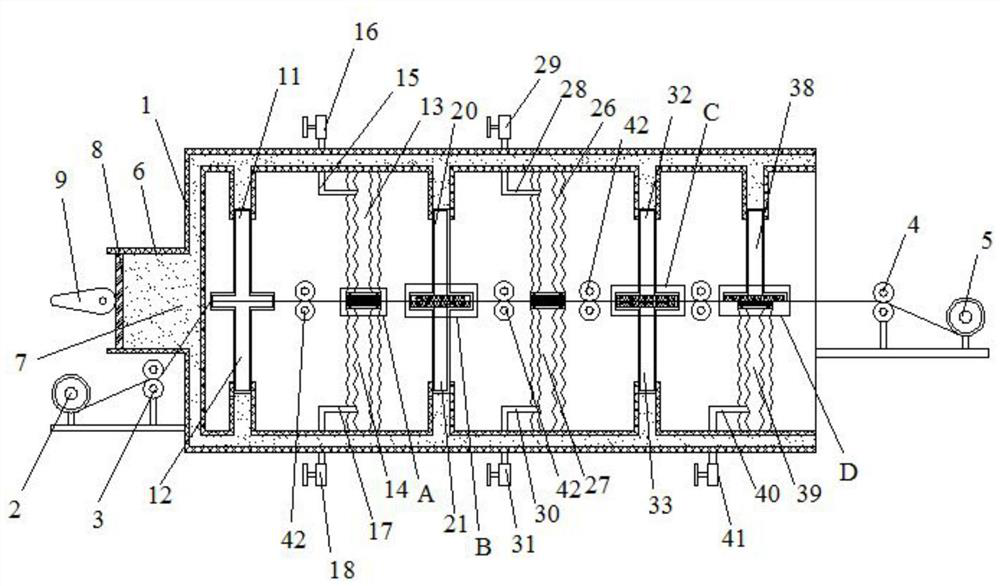

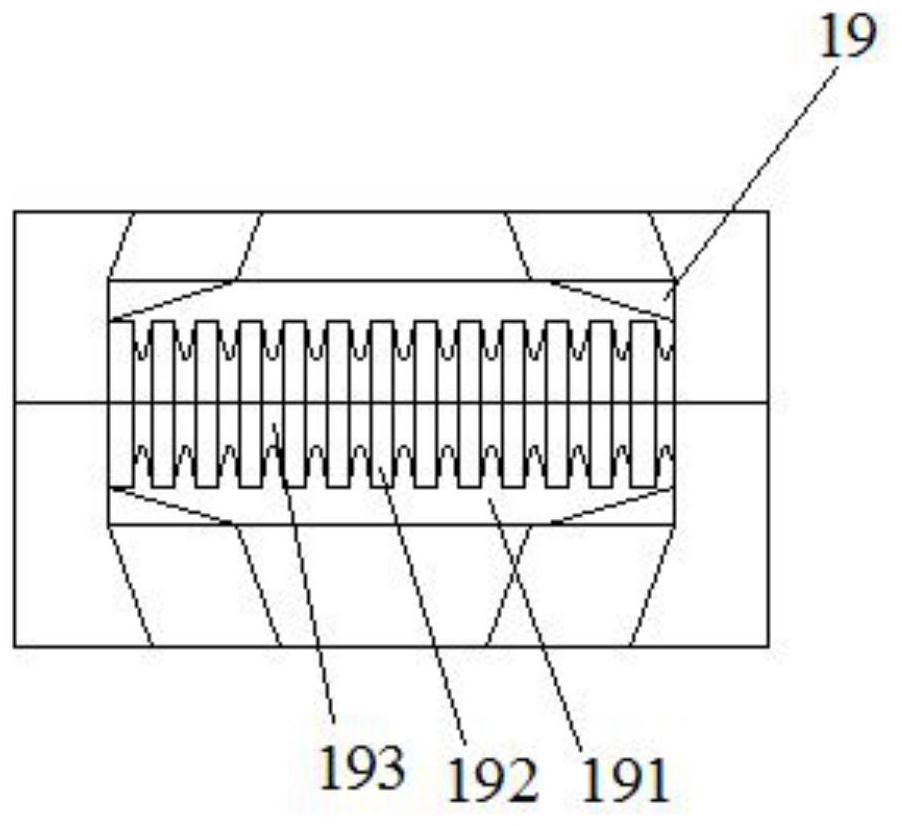

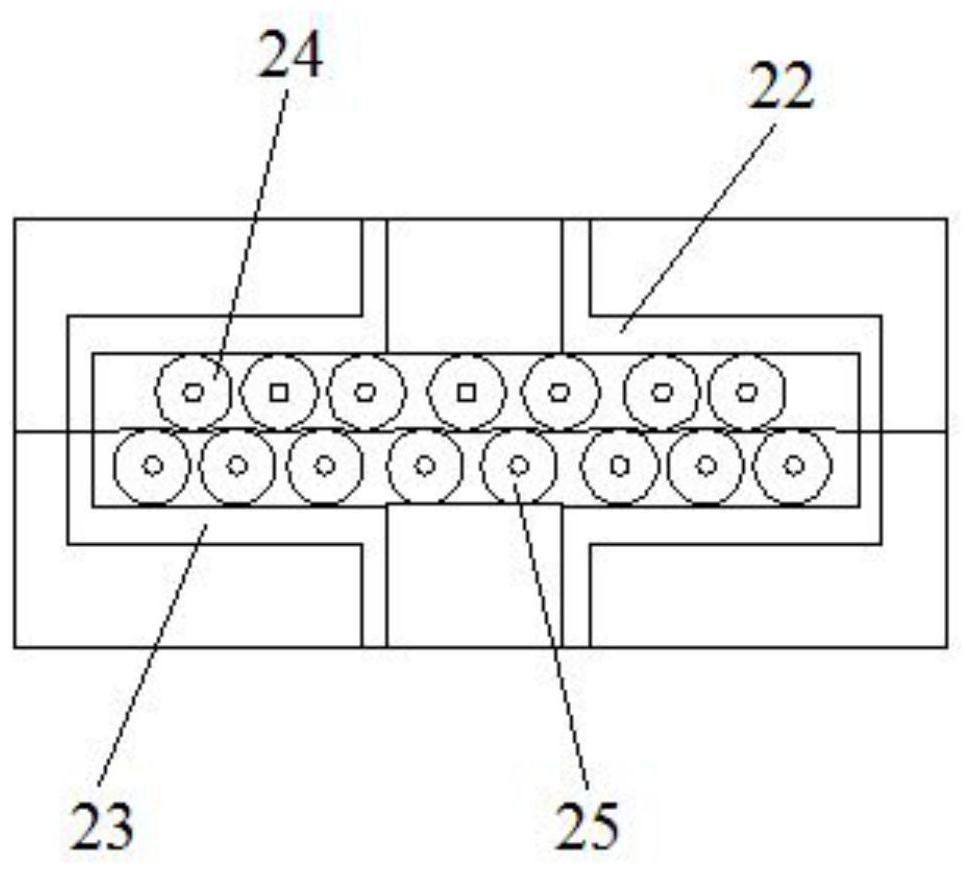

[0034] refer to Figure 1-5 As shown, a 3D protective film of this embodiment includes a dumb film layer from top to bottom, a first OCA adhesive layer, a grating layer, a self-repairing TPU film layer, a second OCA adhesive layer, a high-viscosity silica gel layer, a fluorine Plain release film; the thickness of the dumb film and fluorine release film is 40-60 μm, the thickness of the first OCA adhesive layer and the second OCA adhesive layer is 15-18 μm, and the thickness of the self-healing TPU film is 100 -160μm, the thickness of the high-viscosity silicone layer is 18-25μm, and the grating layer is grid-like stripes arranged evenly.

[0035] The self-healing TPU film layer is obtained by coating and solidifying the self-healing TPU mixture. The preparation method of the self-healing TPU mixture is as follows: according to parts by weight, 95 parts of hot-melt grade TPU, 7 parts of white carbon black, and 7 parts of propylene glycol butyl Add ether, 0.6 parts of molybdenu...

Embodiment 2

[0049] refer to Figure 1-5 As shown, a 3D protective film of this embodiment includes a dumb film layer from top to bottom, a first OCA adhesive layer, a grating layer, a self-repairing TPU film layer, a second OCA adhesive layer, a high-viscosity silica gel layer, a fluorine Plain release film; the thickness of the dumb film and fluorine release film is 40-60 μm, the thickness of the first OCA adhesive layer and the second OCA adhesive layer is 15-18 μm, and the thickness of the self-healing TPU film is 100 -160μm, the thickness of the high-viscosity silicone layer is 18-25μm, and the grating layer is grid-like stripes arranged evenly.

[0050] The self-healing TPU film layer is obtained by coating and solidifying the self-healing TPU mixture. The preparation method of the self-healing TPU mixture is as follows: according to parts by weight, 88 parts of hot-melt grade TPU, 6 parts of white carbon black, 9 parts of propylene glycol butane Add ether, 0.7 parts of molybdenum d...

Embodiment 3

[0055] refer to Figure 1-5 As shown, a 3D protective film of this embodiment includes a dumb film layer from top to bottom, a first OCA adhesive layer, a grating layer, a self-repairing TPU film layer, a second OCA adhesive layer, a high-viscosity silica gel layer, a fluorine Plain release film; the thickness of the dumb film and fluorine release film is 40-60 μm, the thickness of the first OCA adhesive layer and the second OCA adhesive layer is 15-18 μm, and the thickness of the self-healing TPU film is 100 -160μm, the thickness of the high-viscosity silicone layer is 18-25μm, and the grating layer is grid-like stripes arranged evenly.

[0056] The self-healing TPU film layer is obtained by coating and solidifying the self-healing TPU mixture. The preparation method of the self-healing TPU mixture is as follows: according to parts by weight, 90 parts of hot-melt grade TPU, 8 parts of white carbon black, and 9 parts of propylene glycol butyl Add ether, 0.7 parts of molybdenu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com