Belt conveyor for feeding of grinder

A belt conveyor and pulverizer technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of difficult adjustment, weak climbing ability, easy rollover, etc., and achieve good climbing ability, improve stability, and improve transportation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

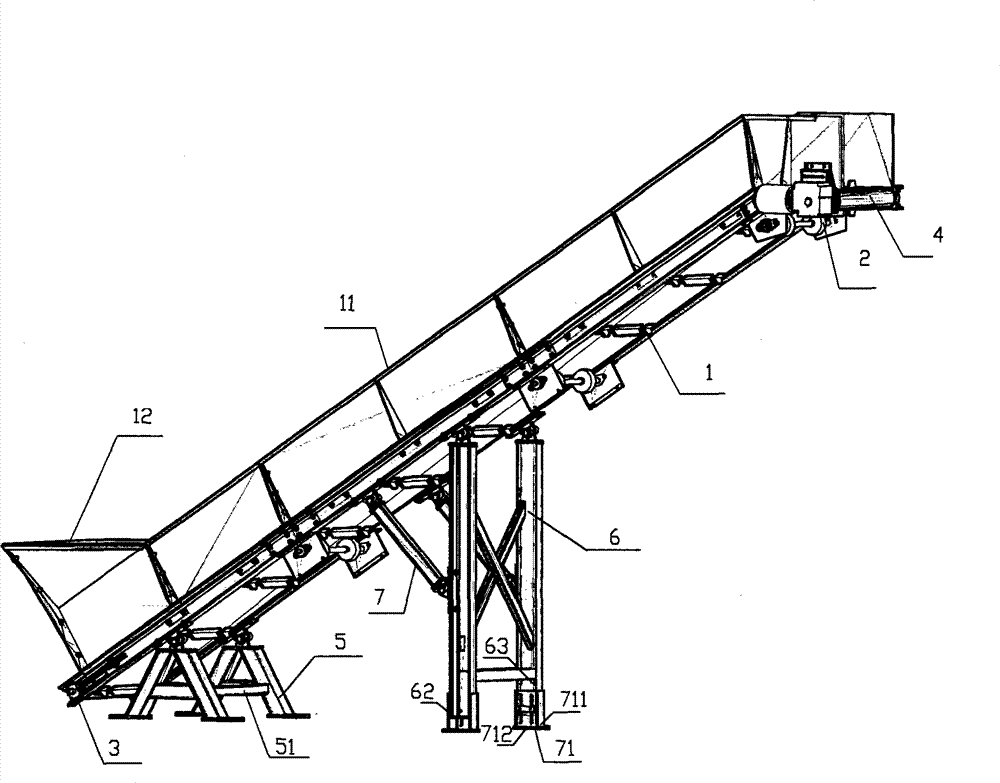

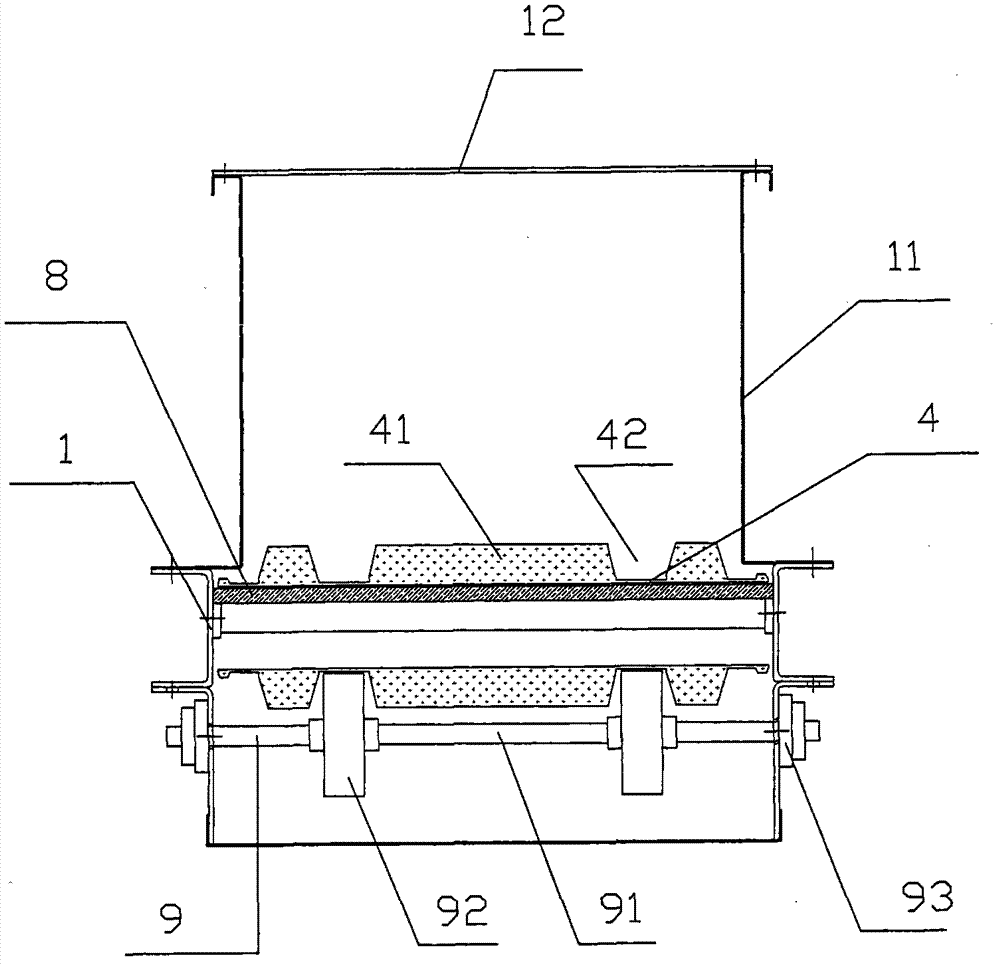

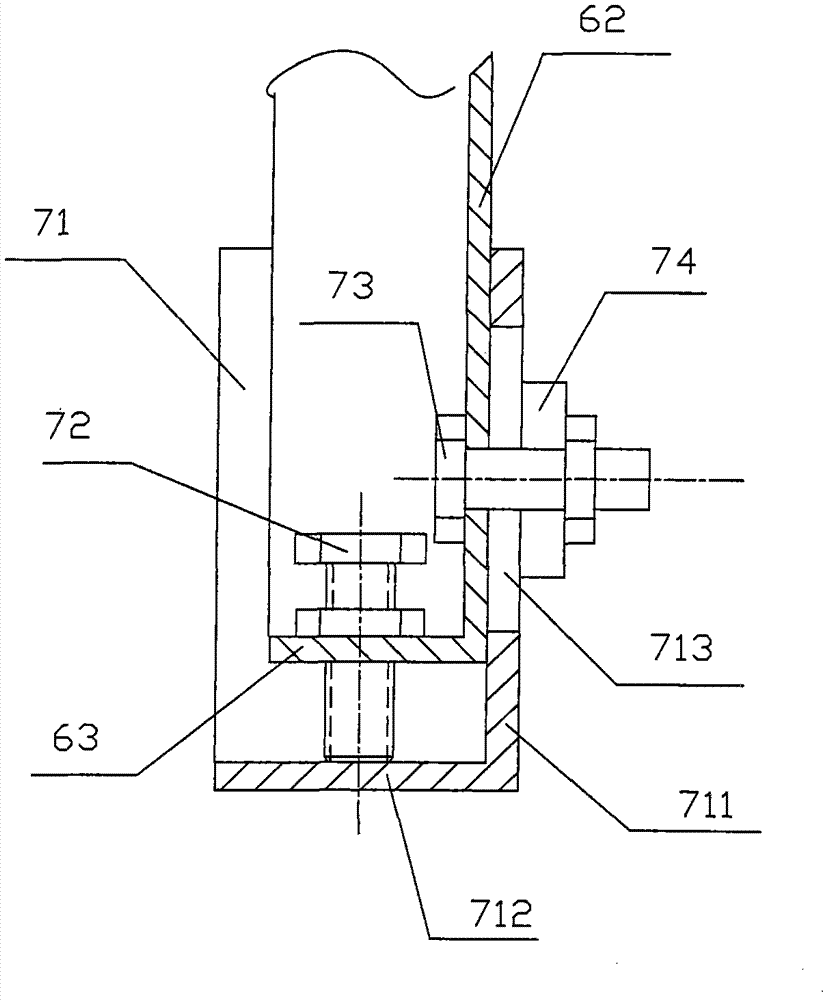

[0013] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 A schematic diagram of the structure of the embodiment of the present invention is given. In the figure, a belt conveyor for pulverizer feeding includes a frame 1, a driving roller 2 and a driving device, a driven roller 3, a conveyor belt 4, a frame support structure, and a conveyor belt support structure. The frame supporting structure is composed of A-shaped tailstock 5, H-shaped front legs 6 and diagonal braces 61. The A-shaped tailstock 5 is composed of two A-shaped frames connected by transverse rods 51. The conveyor belt supporting structure is composed of The wooden backing plate 8 installed on the upper end surface of the frame 1 and several lower idlers 9 on the lower end surface of the frame 1 are composed of the lower idler roller shaft 91, the roller 92 installed on the lower idler roller shaft, the lower idler roller The idler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com