Patents

Literature

31results about How to "Won't jump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

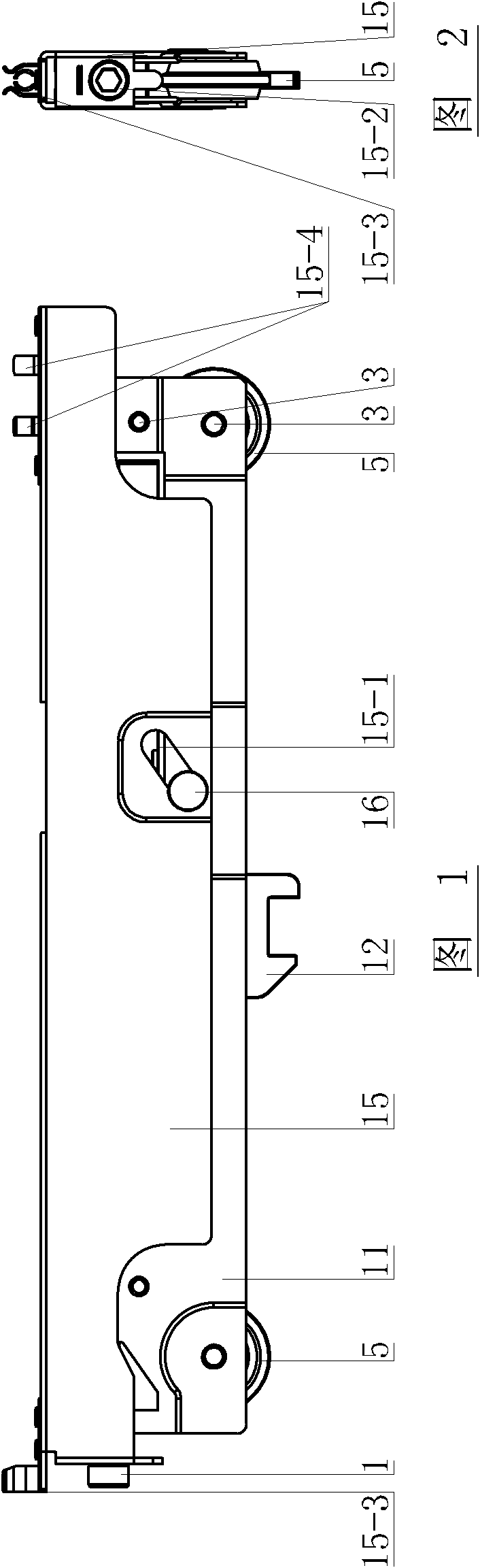

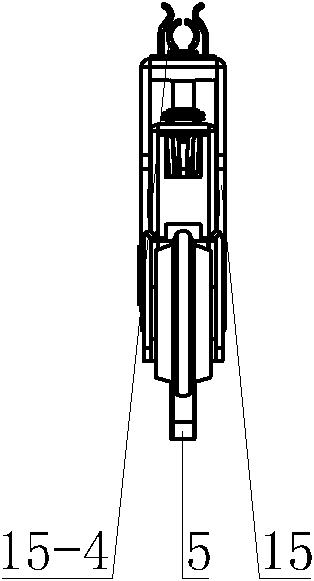

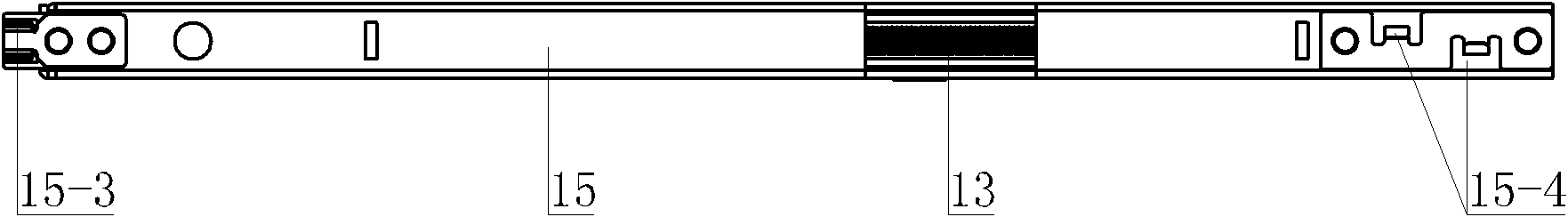

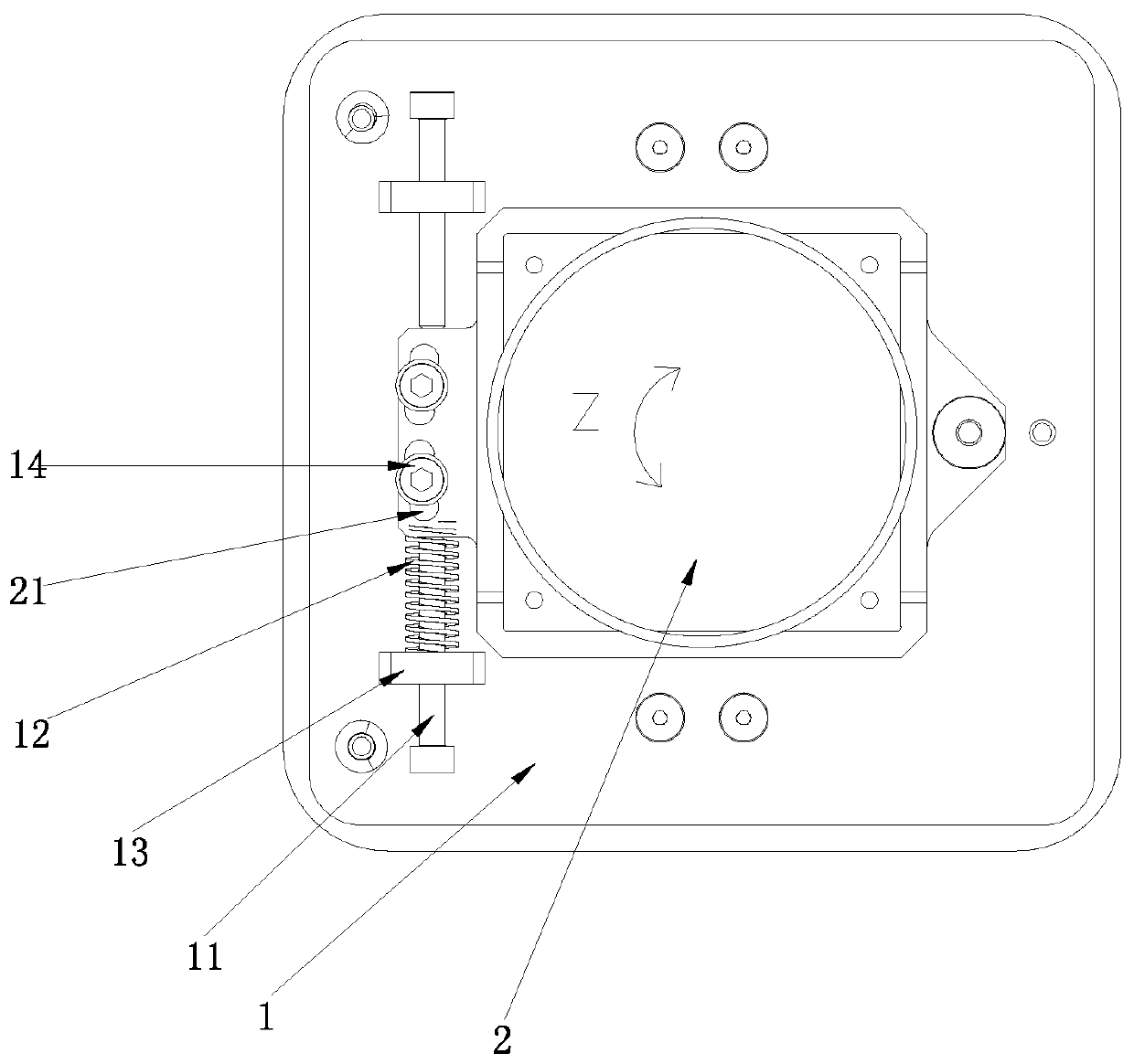

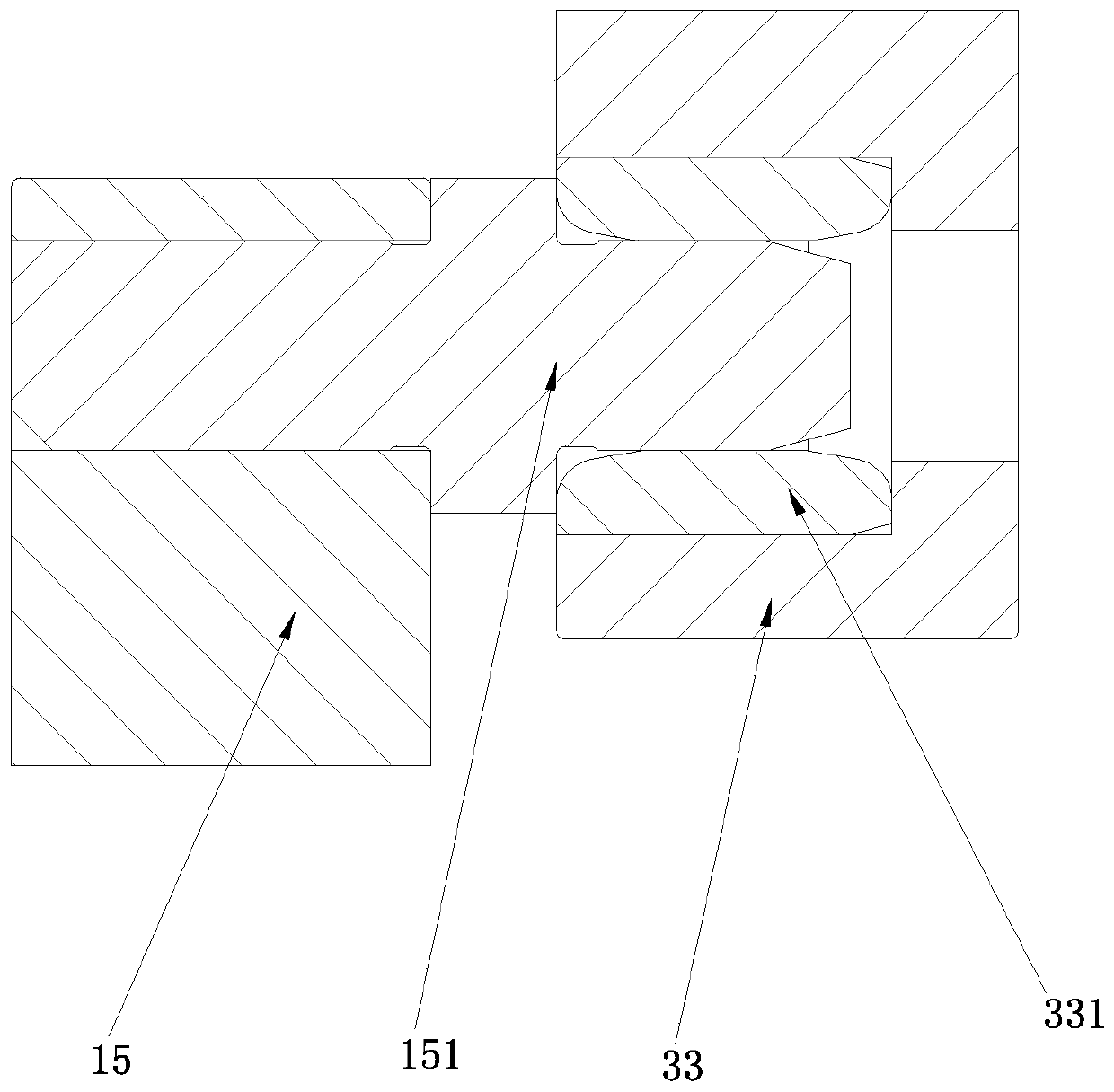

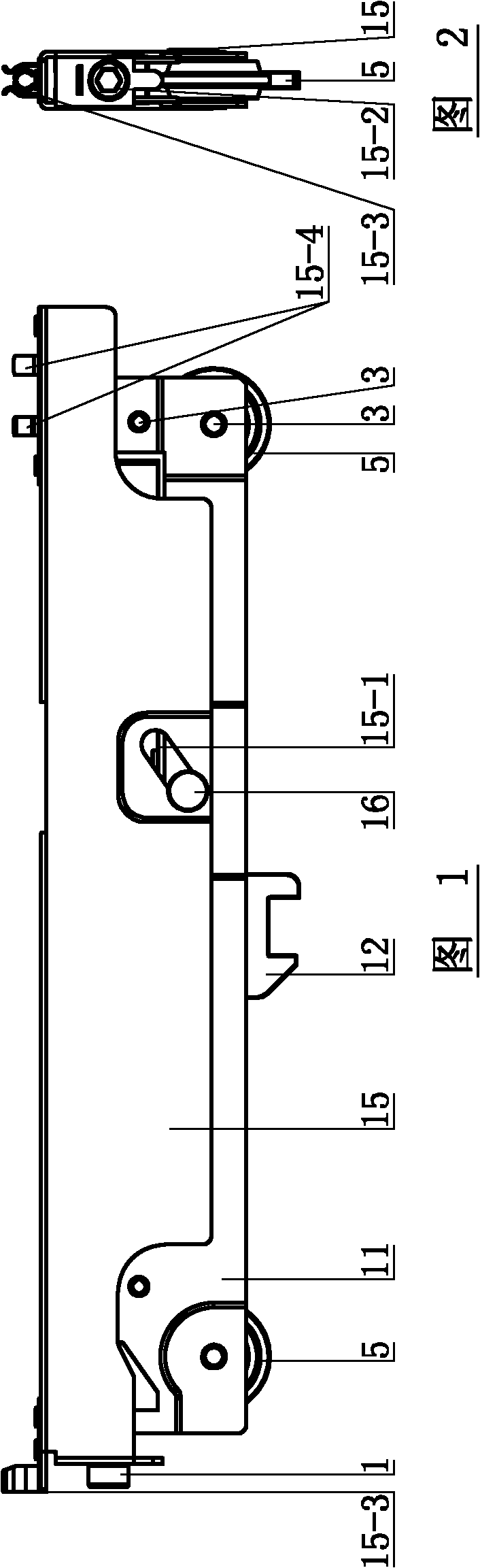

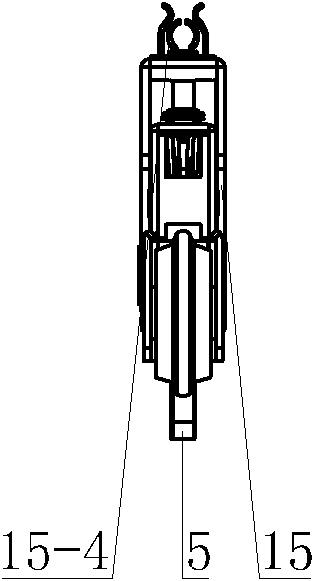

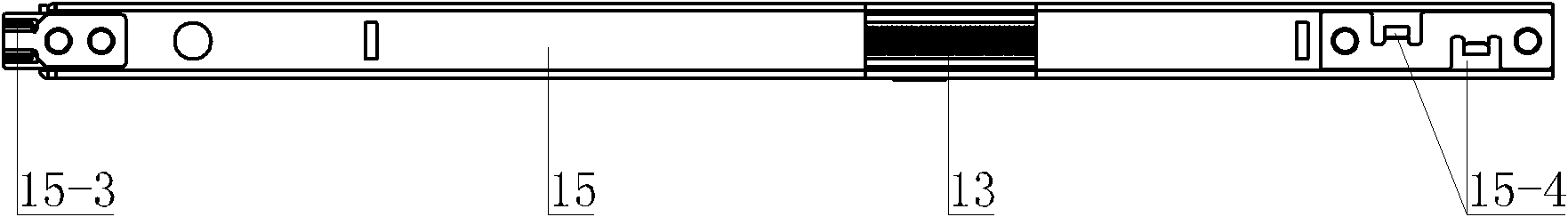

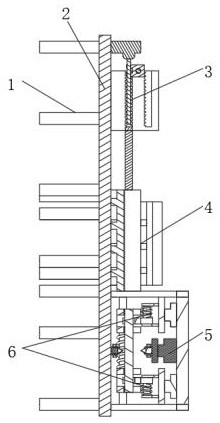

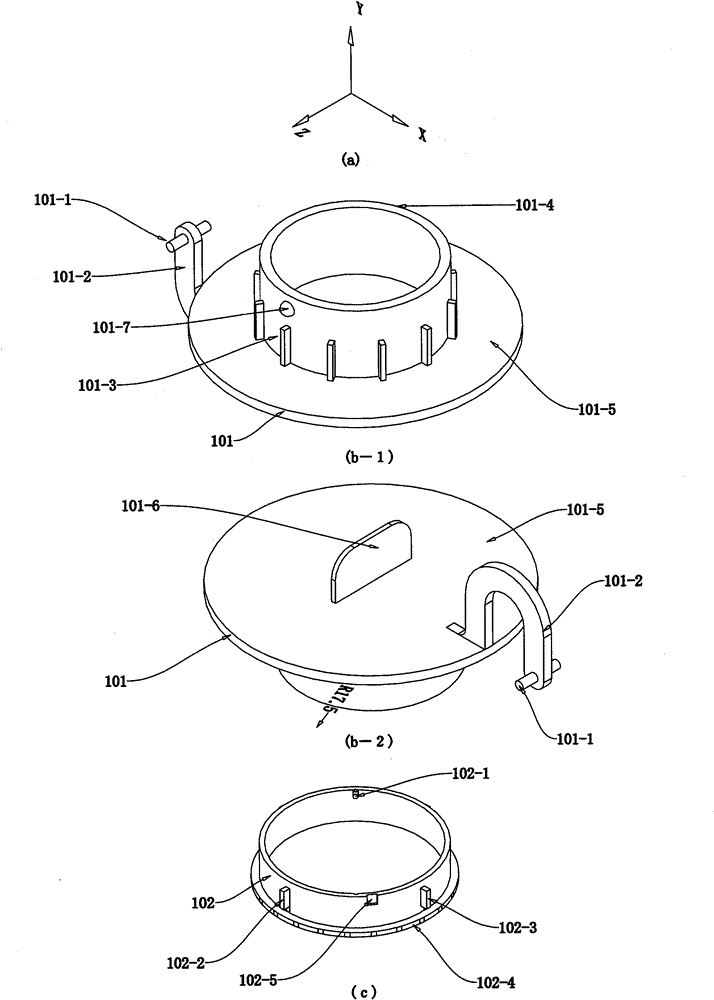

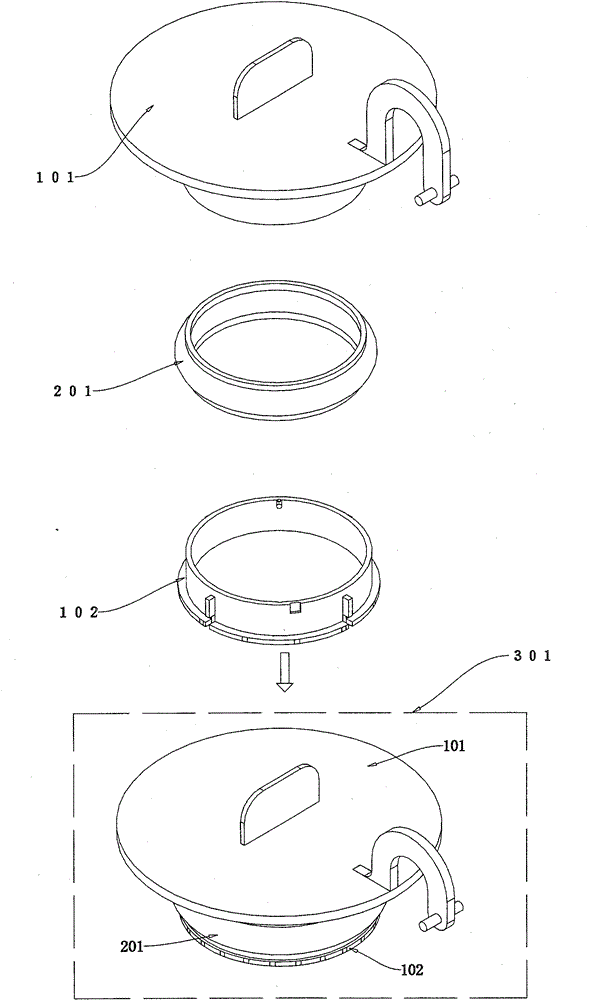

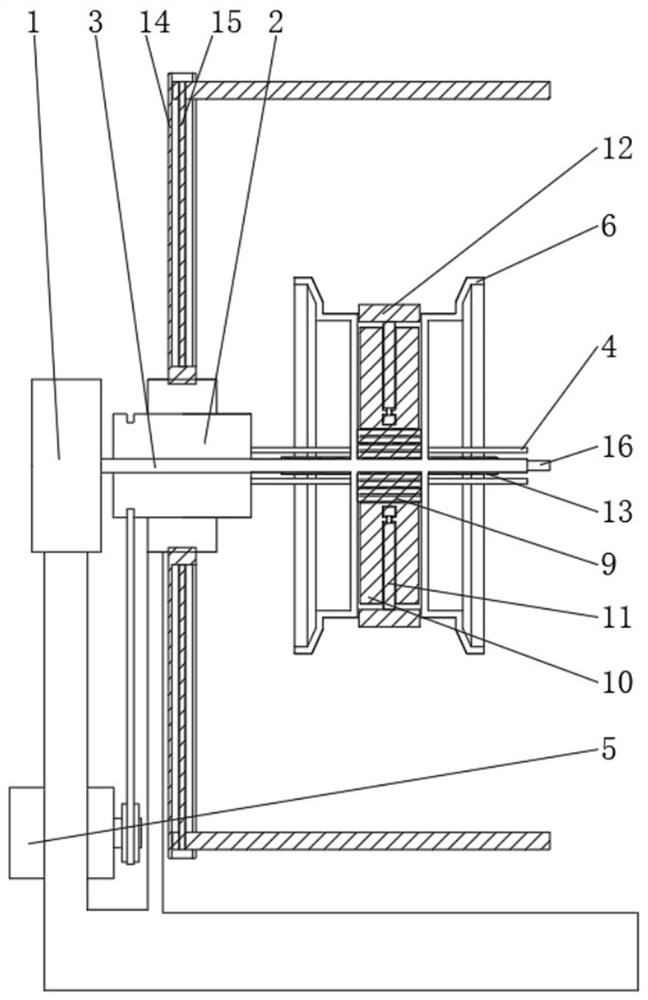

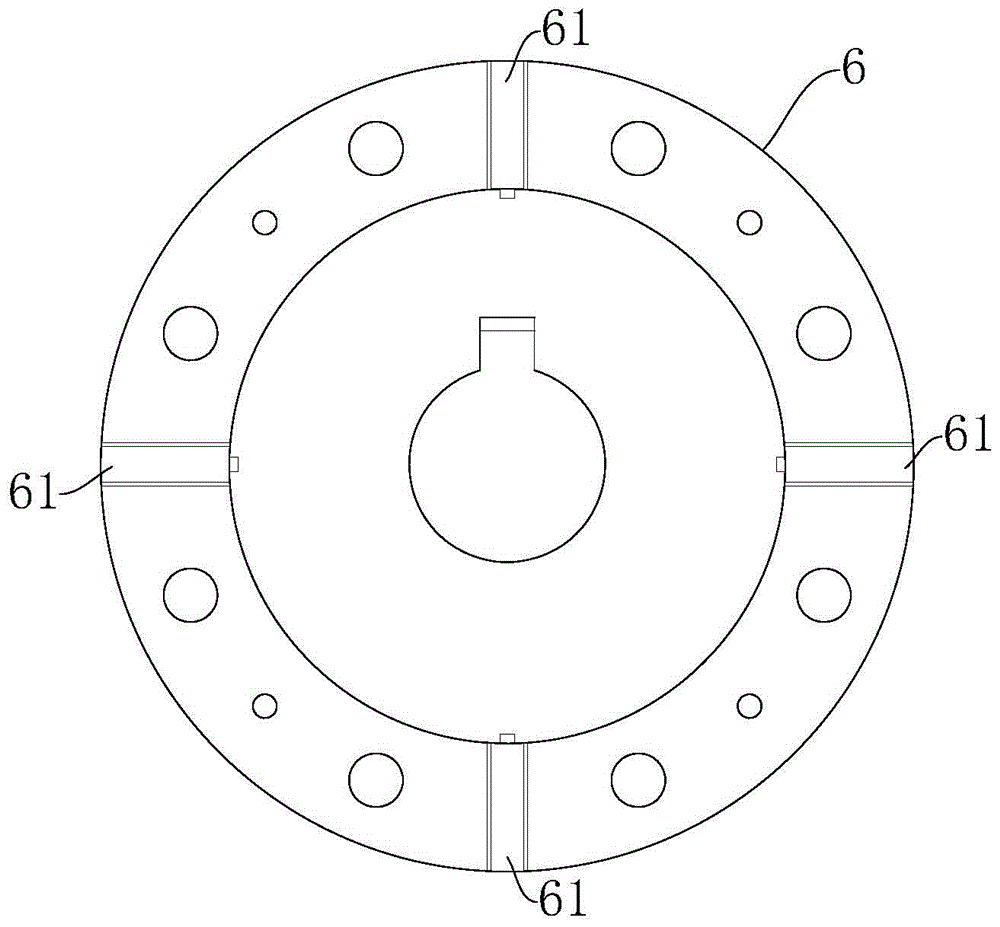

Damper-including sliding wheel assembly under wall cabinet door

ActiveCN102305002AIncrease dampingInnovative designBuilding braking devicesWing openersManufacturing technologyEngineering

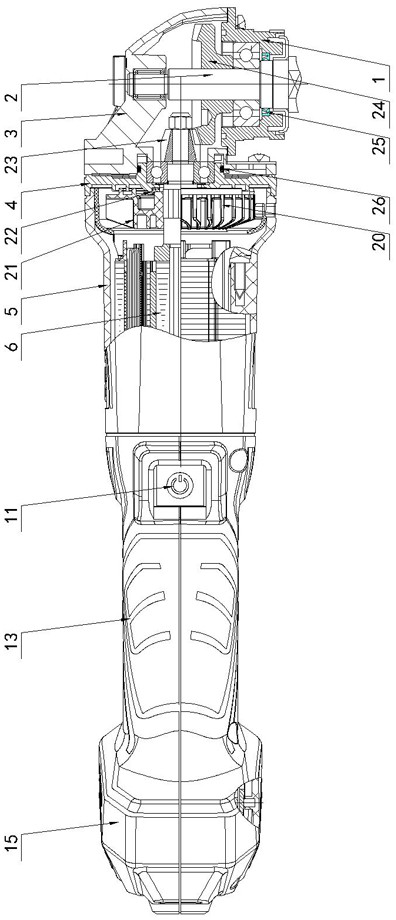

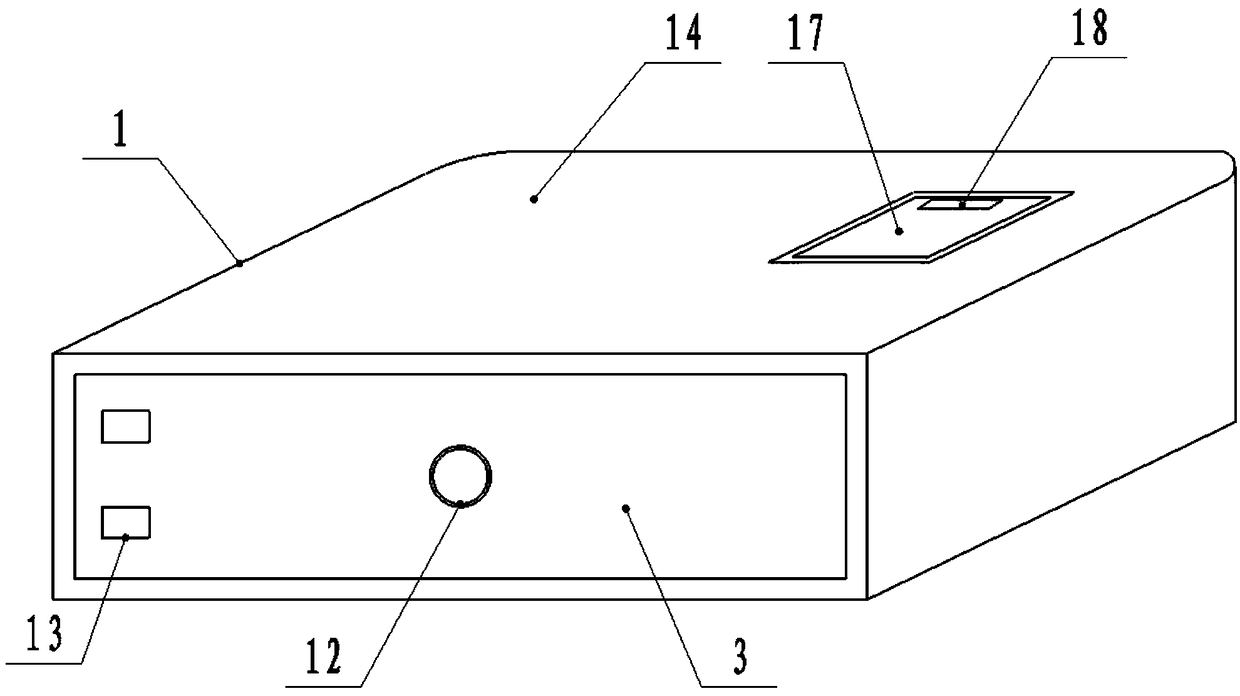

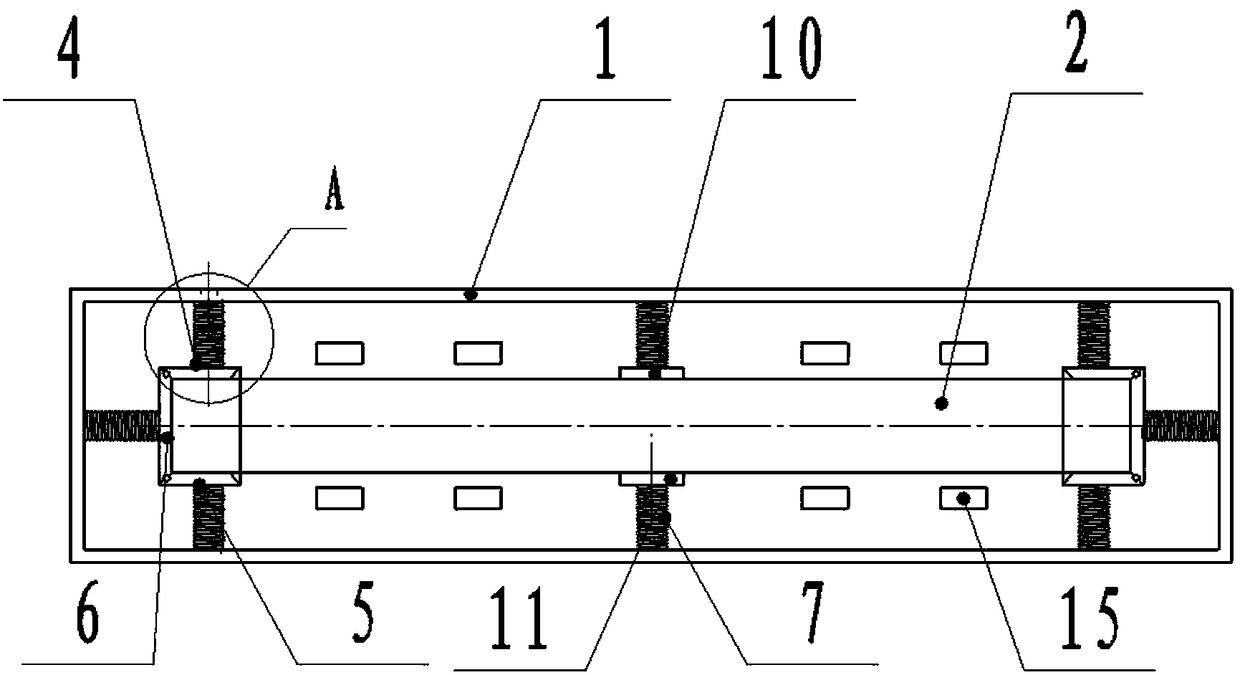

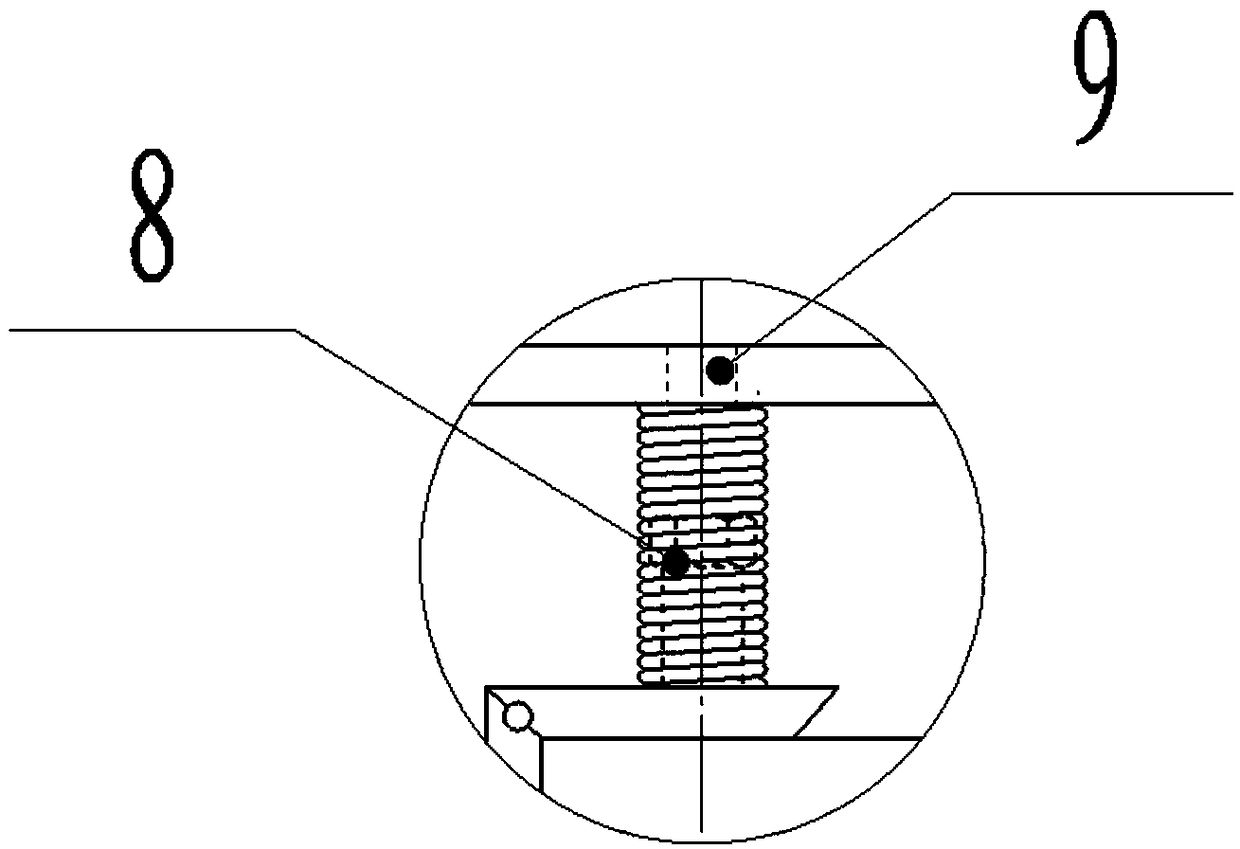

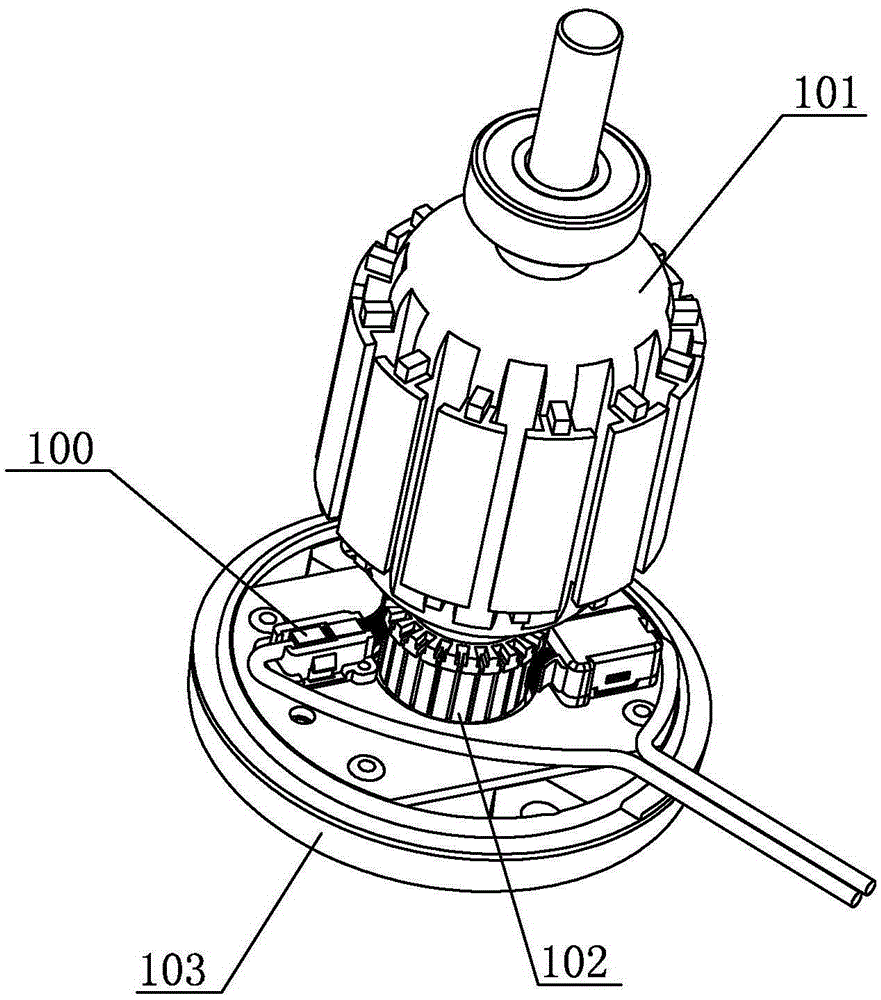

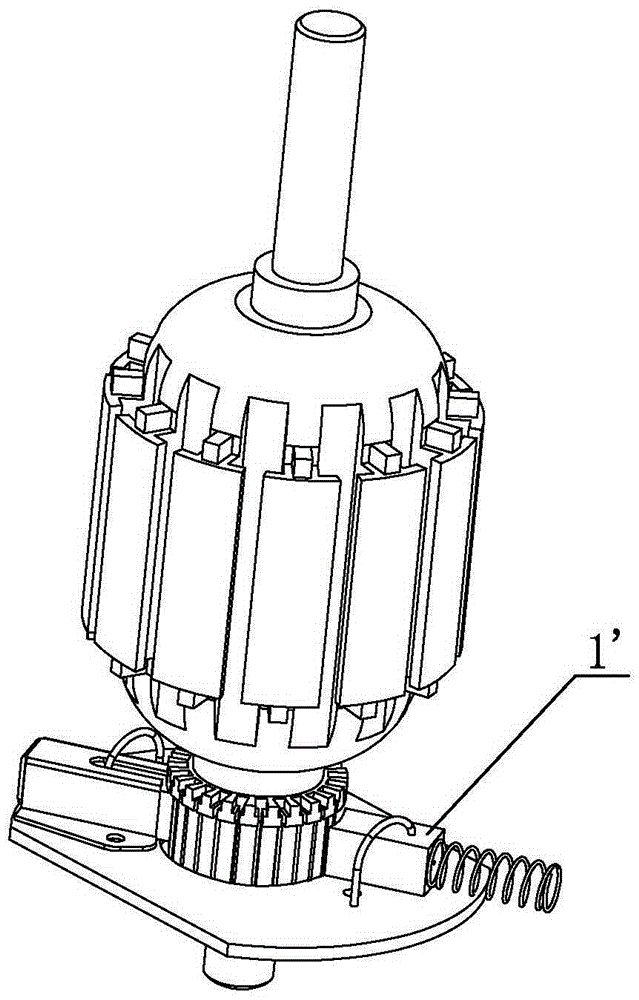

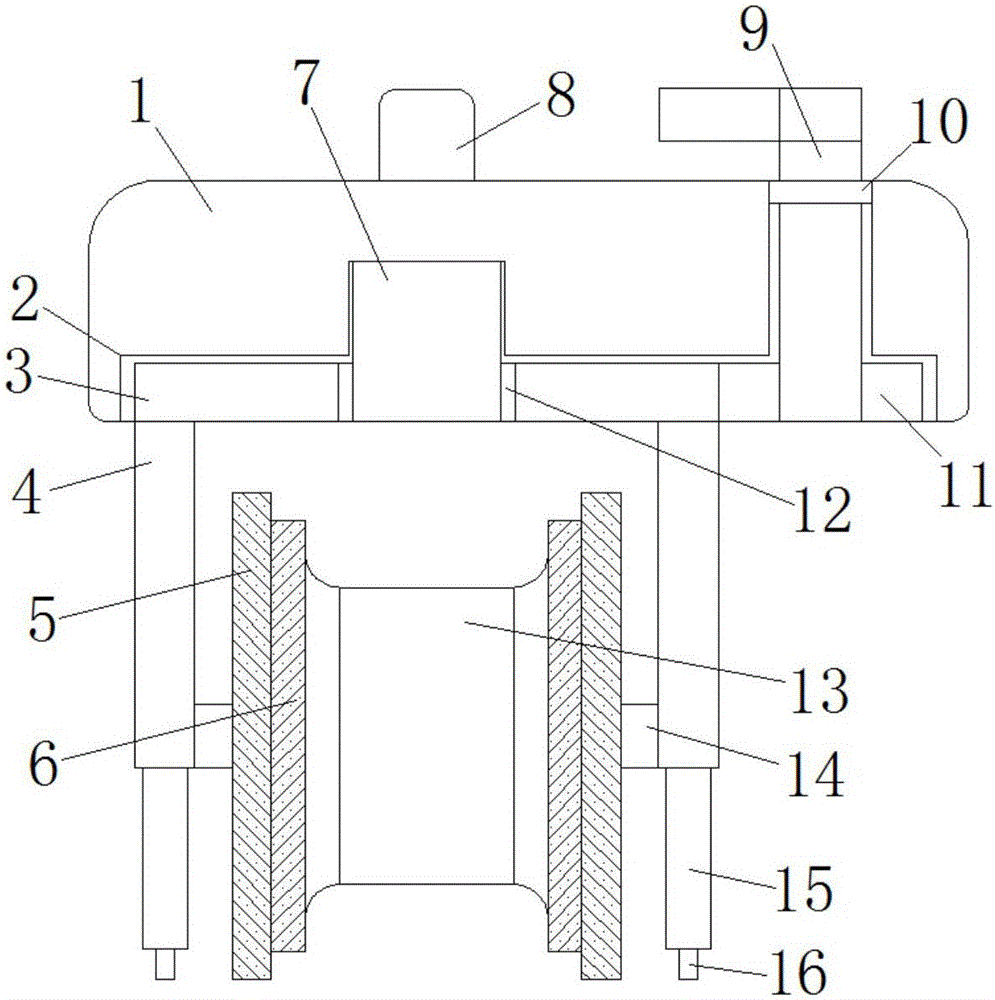

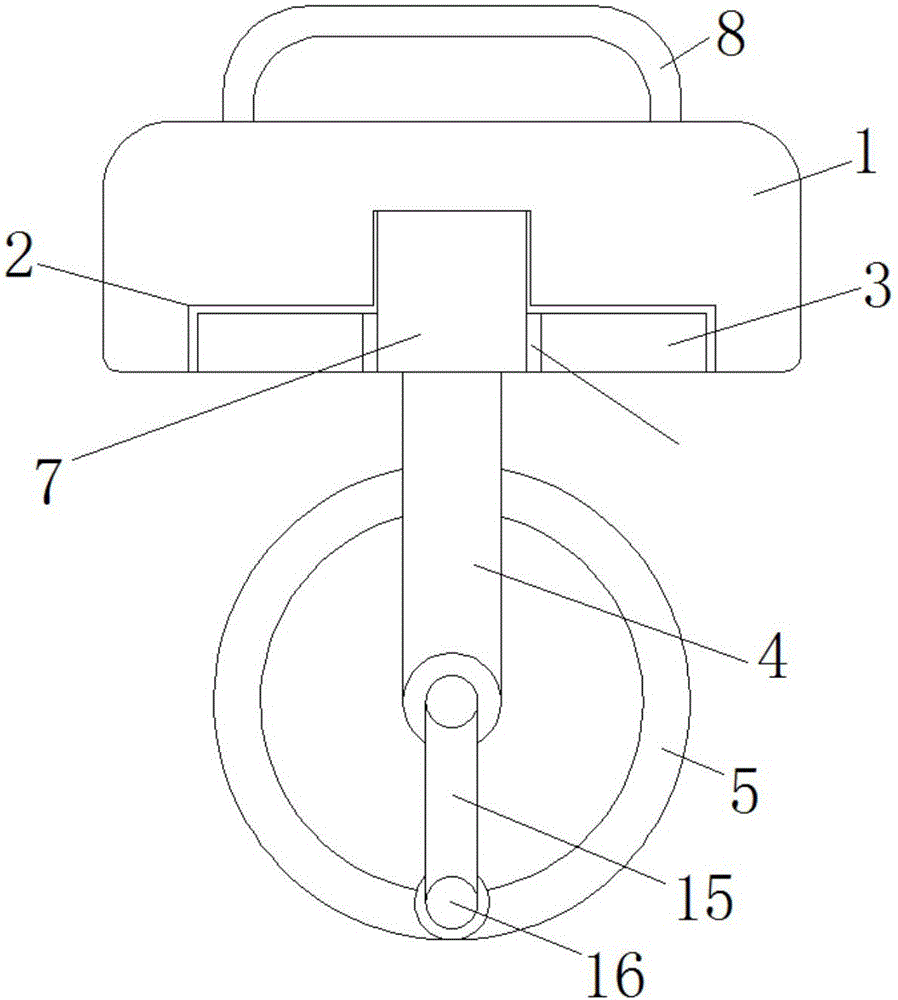

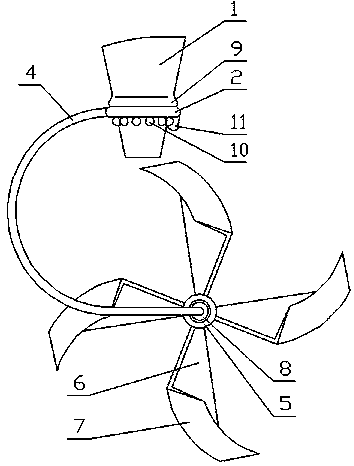

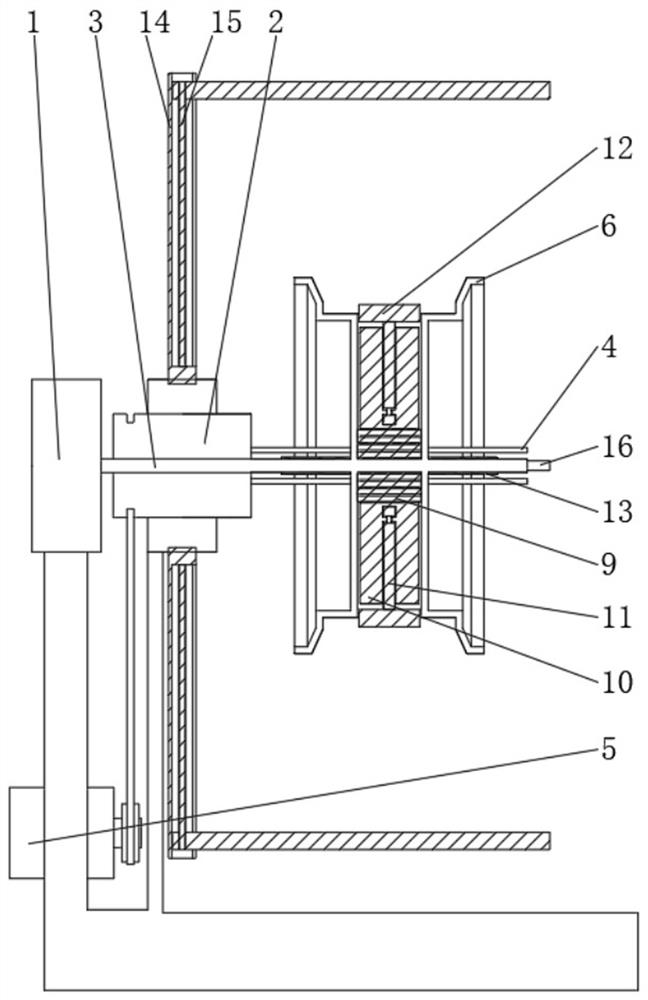

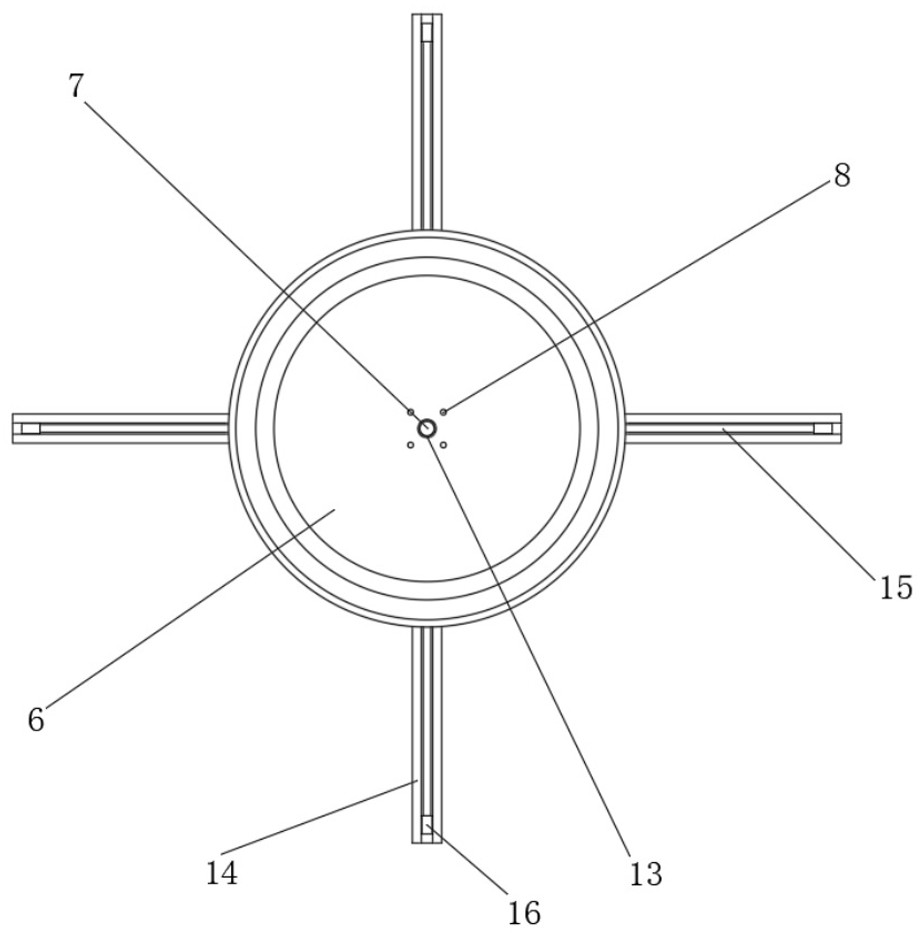

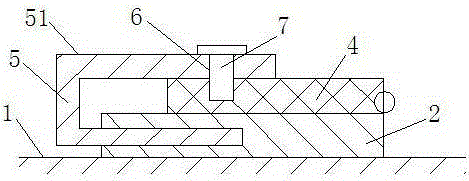

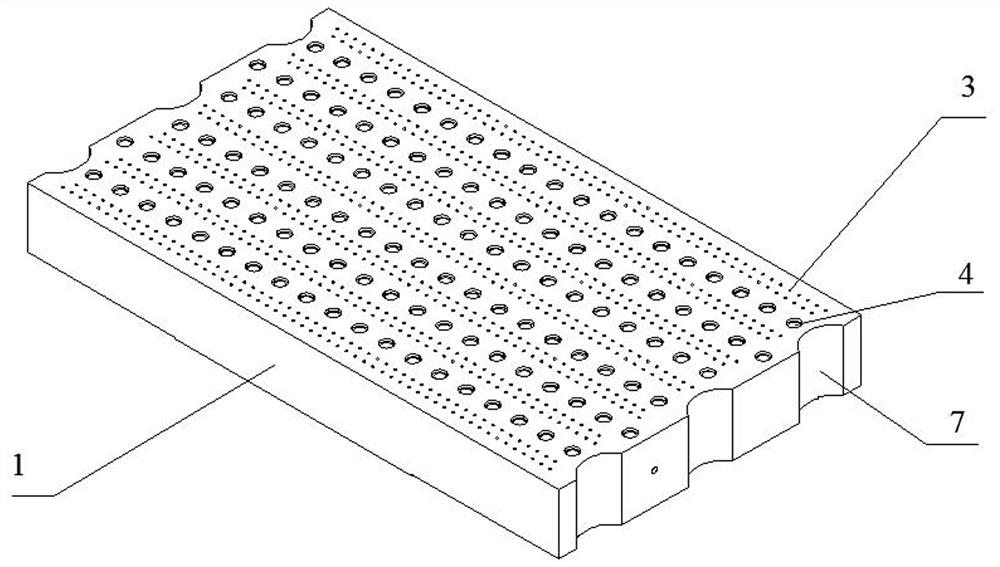

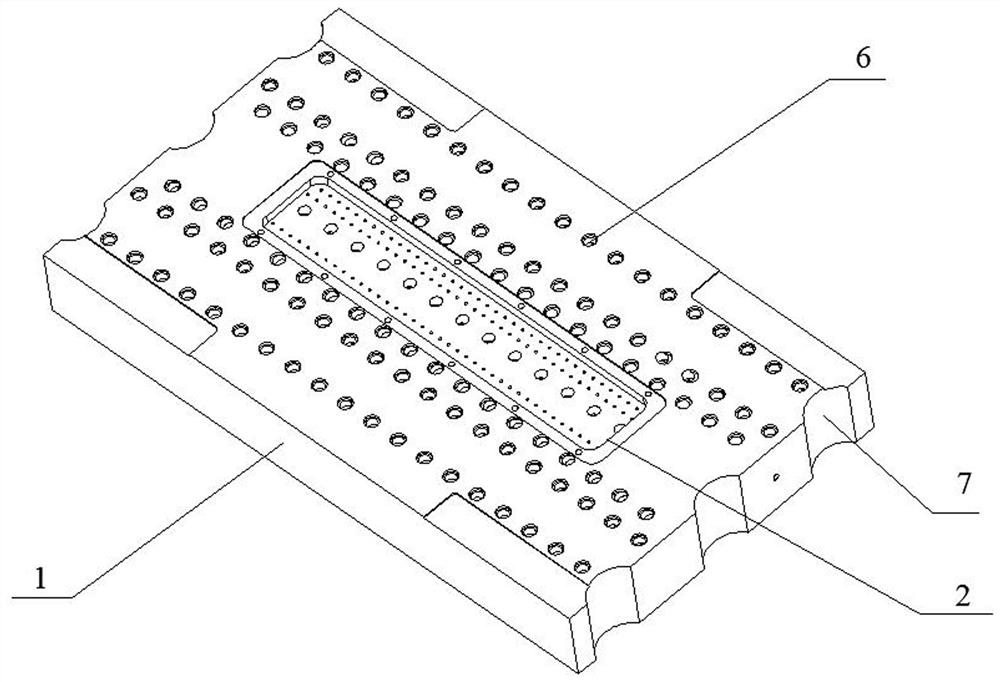

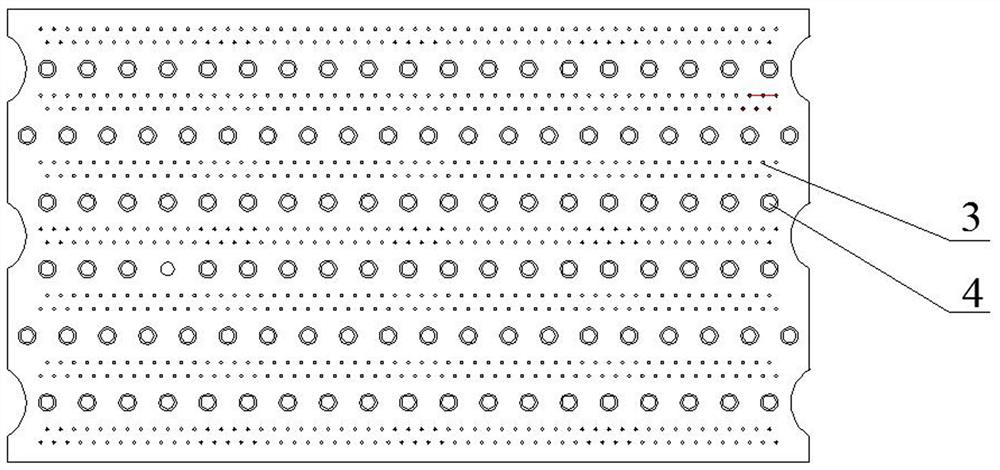

The invention relates to a sliding wheel assembly with a damper under a wall cabinet door and belongs to technologies of manufacturing architectural ornament accessories. The assembly is formed by three jackets which are in sleeve connection, wherein the innermost layer is a damper assembling clip on which the damper, a damper poking piece and a supporting spring are arranged; the middle layer is a movable jacket on which a sliding wheel is assembled; the outermost layer is an external support clip; the external support clip, the movable jacket and the damper assembling clip are connected to a whole through a waist-shaped hole by utilizing a movable rivet; and the assembly is arranged at the bottom end of a wall cabinet door leaf and a better damping effect is produced through coordinating with a hook hanged plate on a lower track. The assembly has the advantages of novel design, reasonable structure, remarkable effect and simpleness and convenience for adjusting. The assembly provided by the invention comprises an adjusting bolt (1), the supporting spring (2), the wall cabinet door leaf (6) and the lower track (7) and is characterized by comprising the three jackets which are in sleeve connection, wherein: (1) the innermost layer is the damper assembling clip (10); (2) the damper assembling clip (10) is hidden and wrapped in the movable jacket (11); and (3) both the damper assembling clip (10) and the movable jacket (11) are wrapped in the external support clip (15).

Owner:许姜德

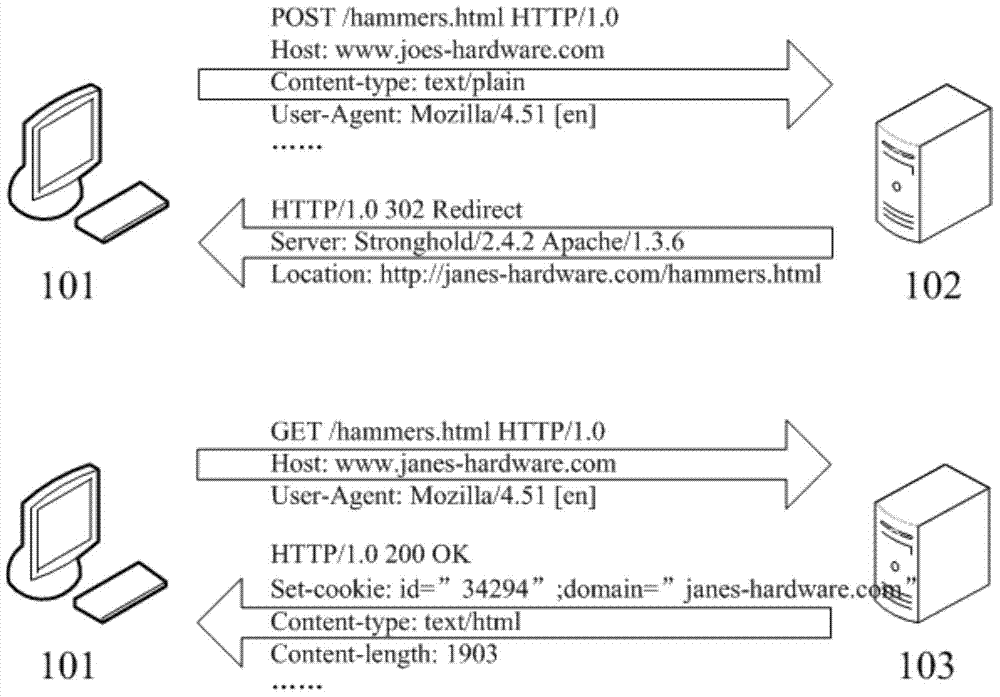

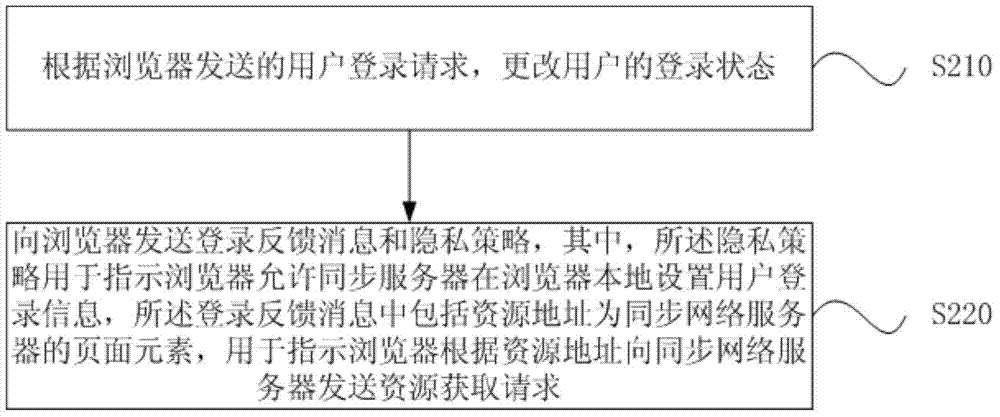

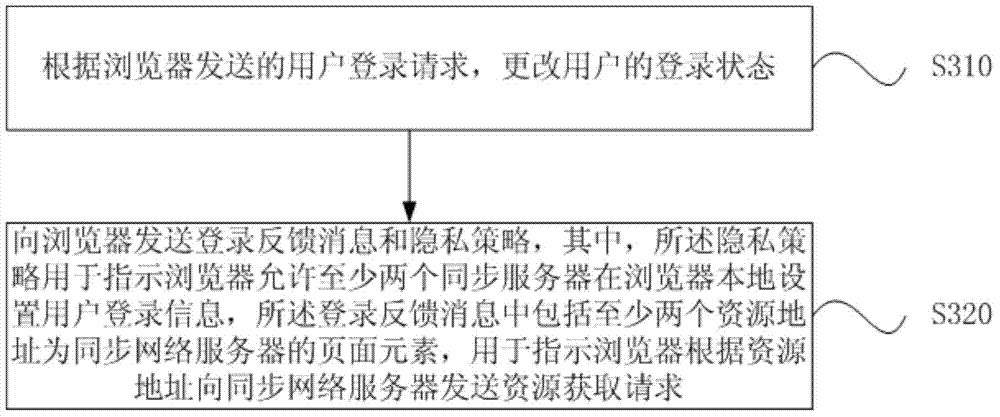

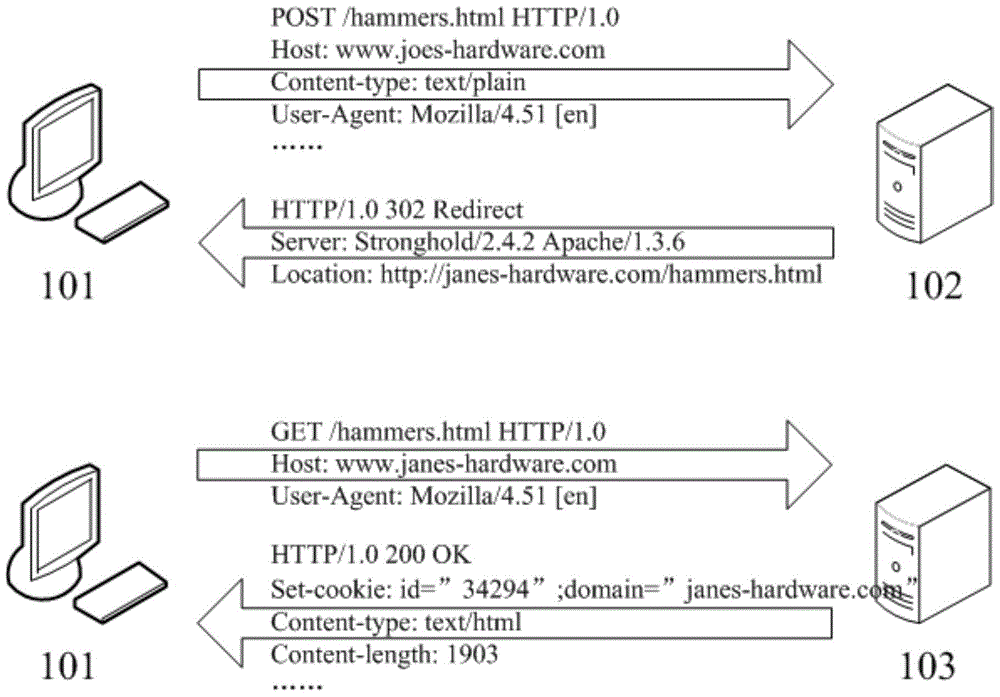

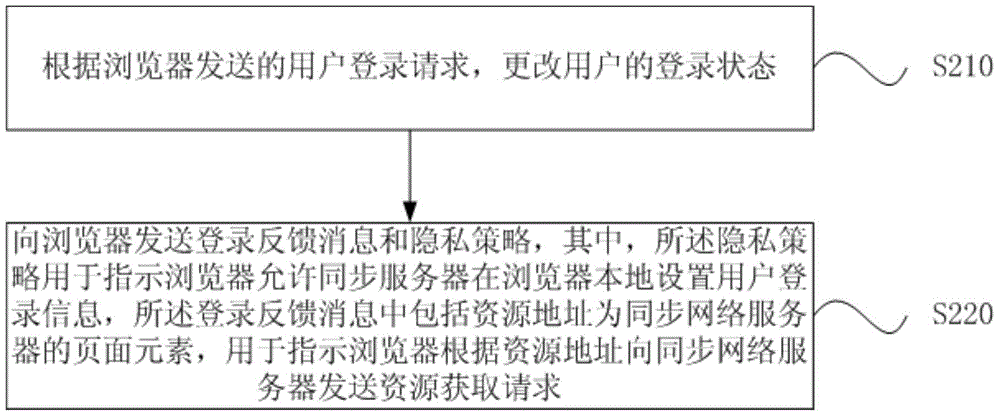

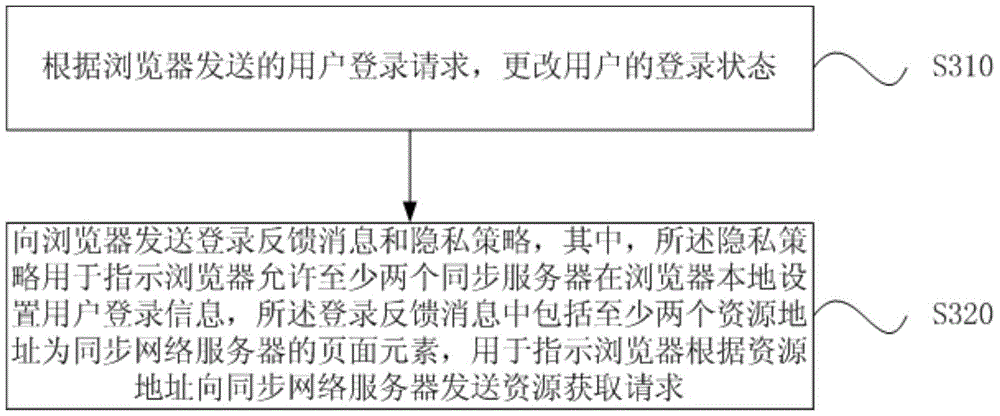

Login information synchronization method, synchronized network servers and synchronizing network servers

The invention discloses a login information synchronization method, synchronized network servers and synchronizing network servers. The login information synchronization method comprises the steps that the logging status of users is changed by the synchronized network servers; the synchronized network servers send login feedback messages and privacy policies to browsers; the synchronizing network servers feed back resources requested by the browsers to the browsers; the synchronizing network servers acquire the user login information that the users have access to the synchronized network servers; the synchronizing network servers configure the user login information; the synchronizing network servers carry out the login operation on the synchronized network servers according to the configured user login information. According to the login information synchronization method, the synchronized network servers and the synchronizing network servers, resource addresses are added to the feedback messages as page elements of the synchronizing network servers, and page skipping cannot happen to the browsers between synchronizing websites when the user login information is synchronized between a plurality of network servers.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

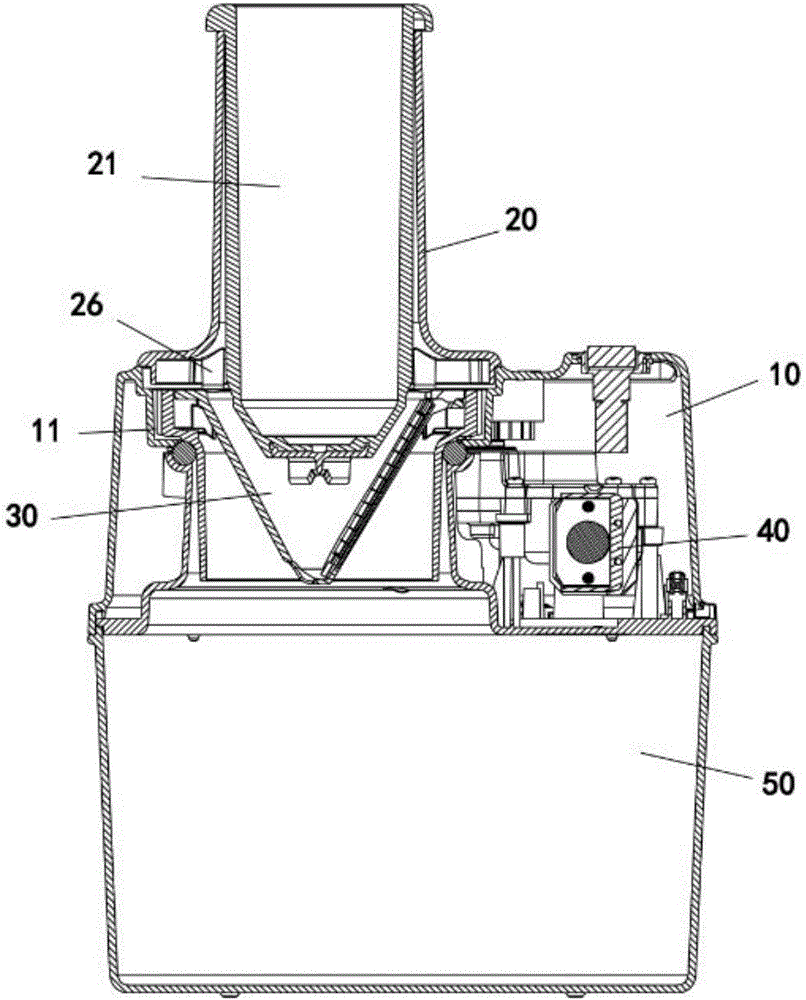

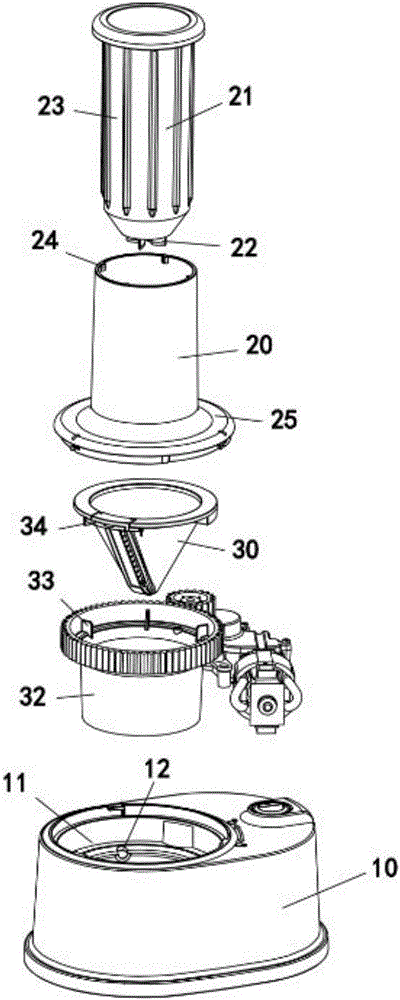

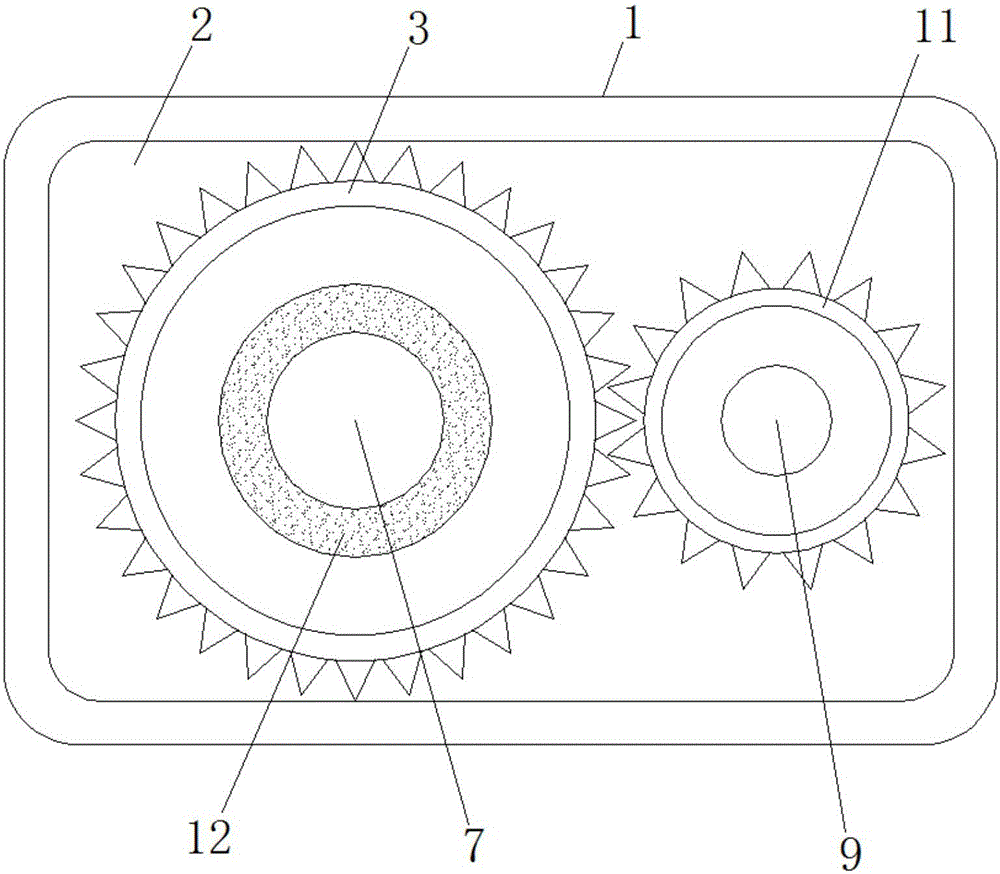

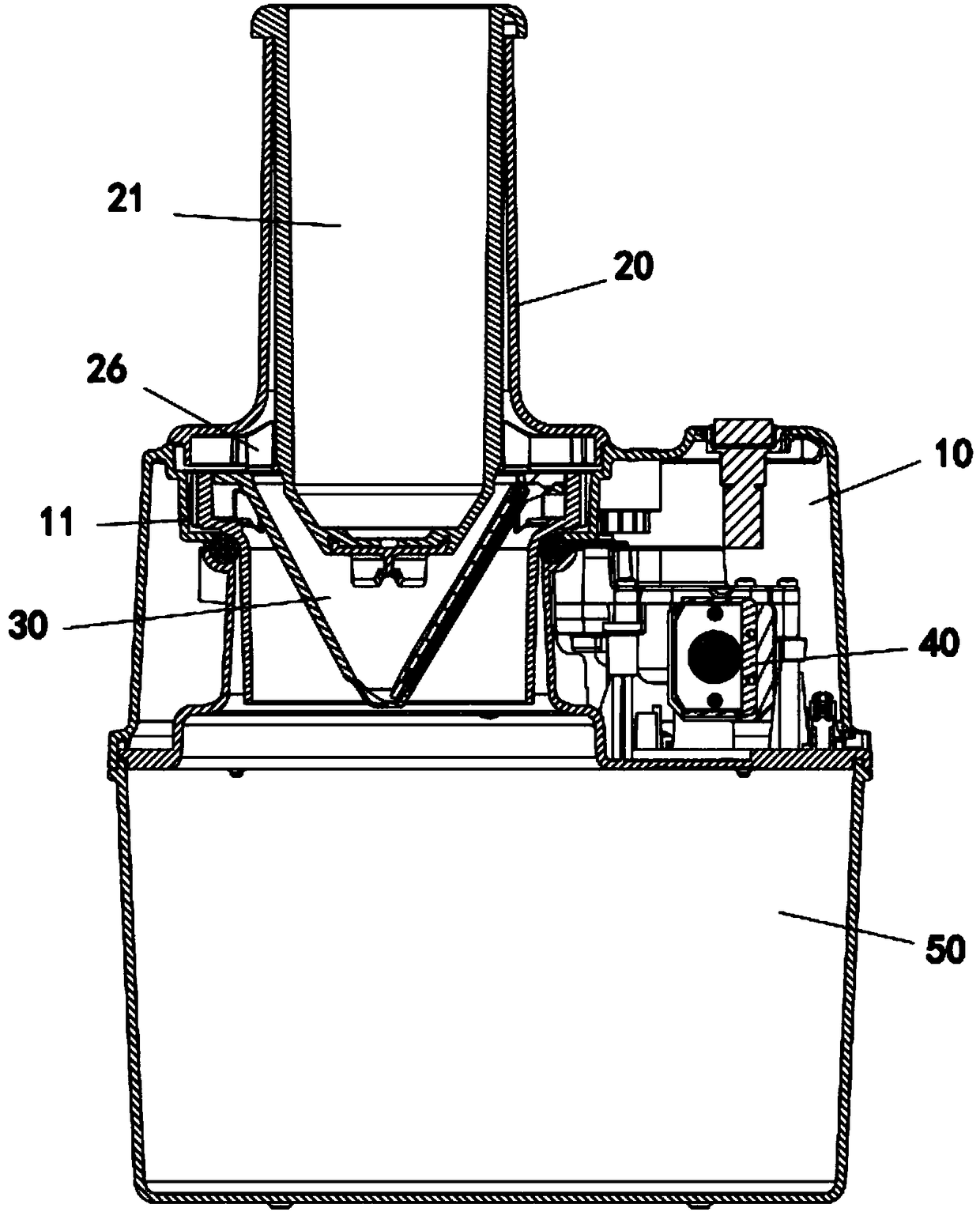

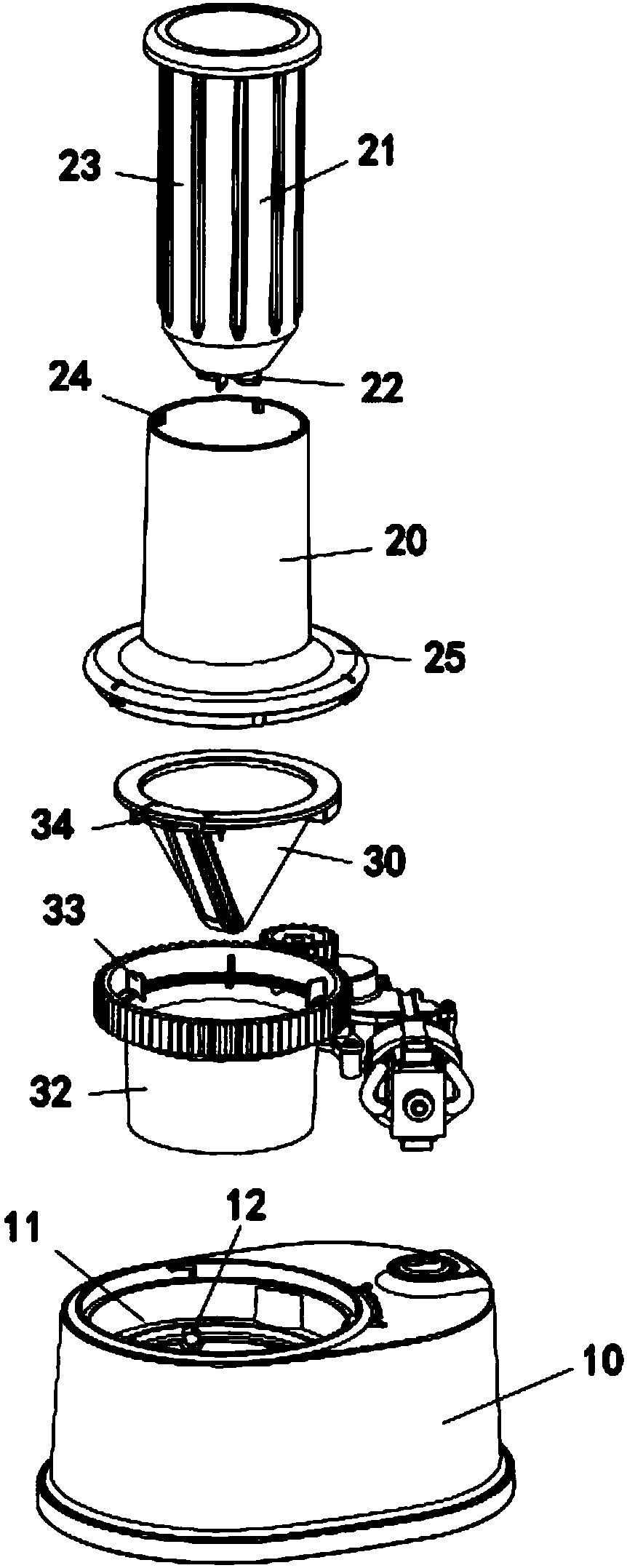

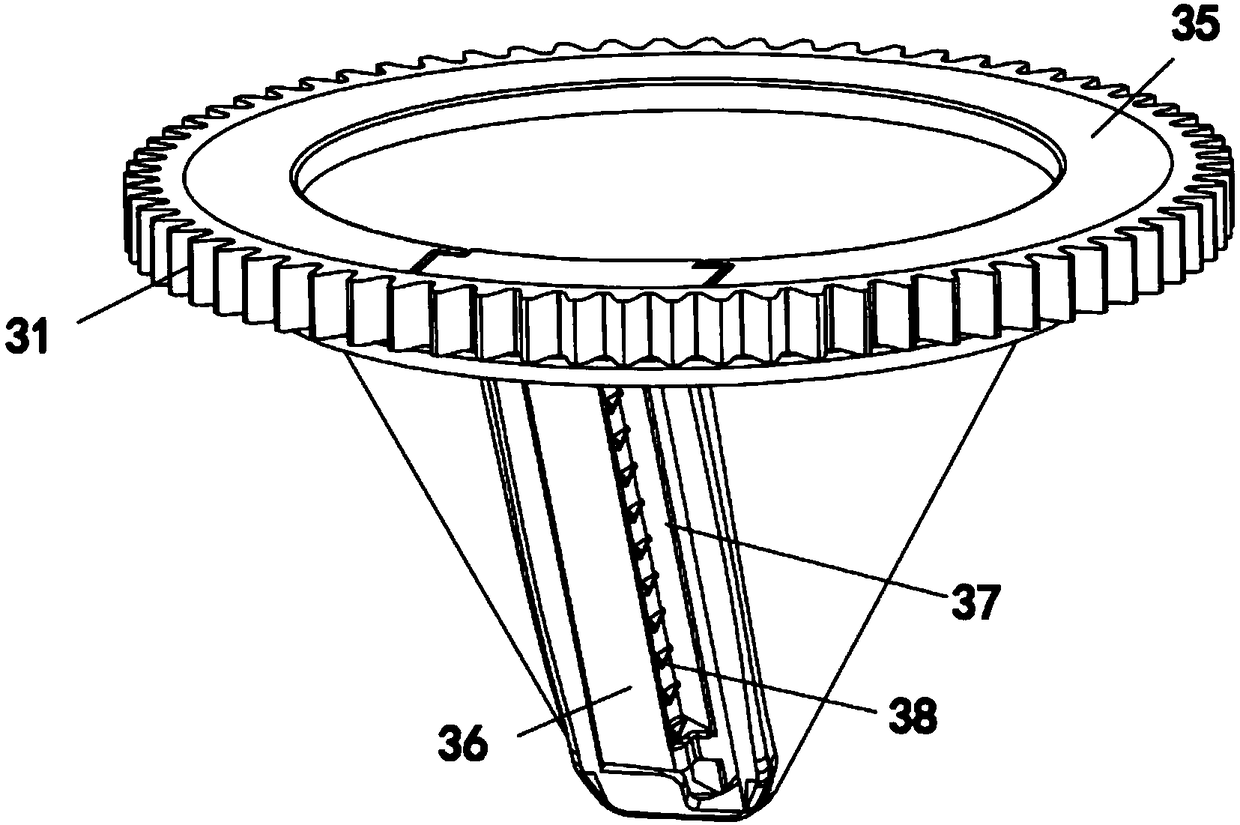

Shredding and slicing equipment

ActiveCN105965579AReduce product costReduce product volumeMetal working apparatusEngineeringFood processing

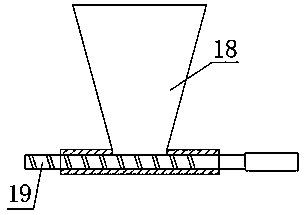

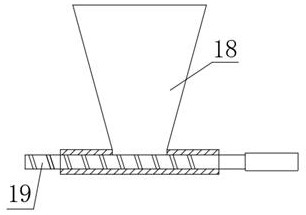

The invention relates to the technical field of food processing electric appliances, in particular to shredding and slicing equipment. The shredding and slicing equipment comprises a main machine, a feeding pipe is mounted on the main machine, a planer tool and a drive device are arranged in the main machine, the planer tool is located below the feeding pipe and is driven by the drive device to operate, and the equipment is characterized in that a large cup used for supporting the main machine is arranged below the main machine, a food material outlet of the planer tool faces an opening in the top of the large cup, and therefore the large cup is used for containing and storing food materials obtained after planing; and the feeding direction of the feeding pipe is arranged along a planing rotating shaft of the plane tool. Super-long shredded or sliced food can be cut, a product is small and exquisite in size, use convenience is high, and the manufacturing cost is low.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

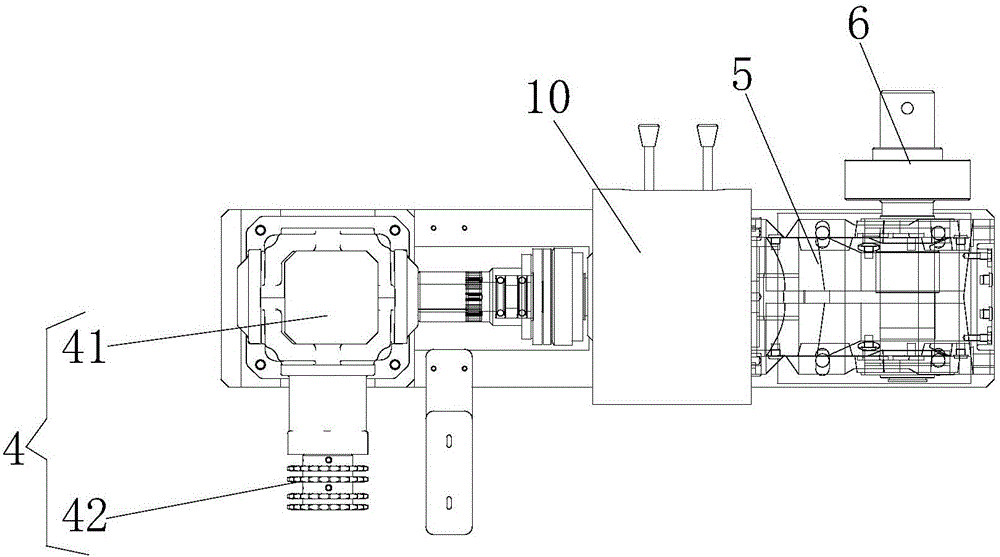

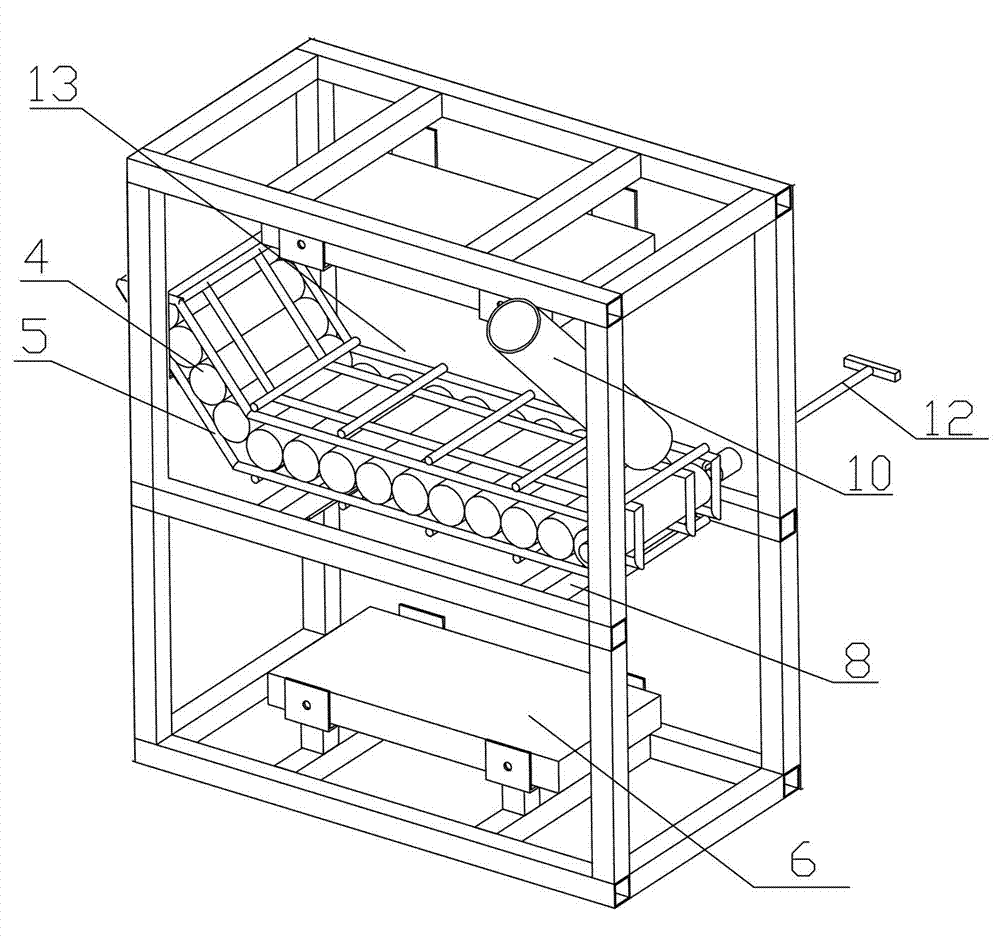

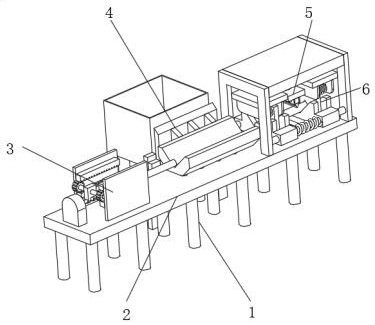

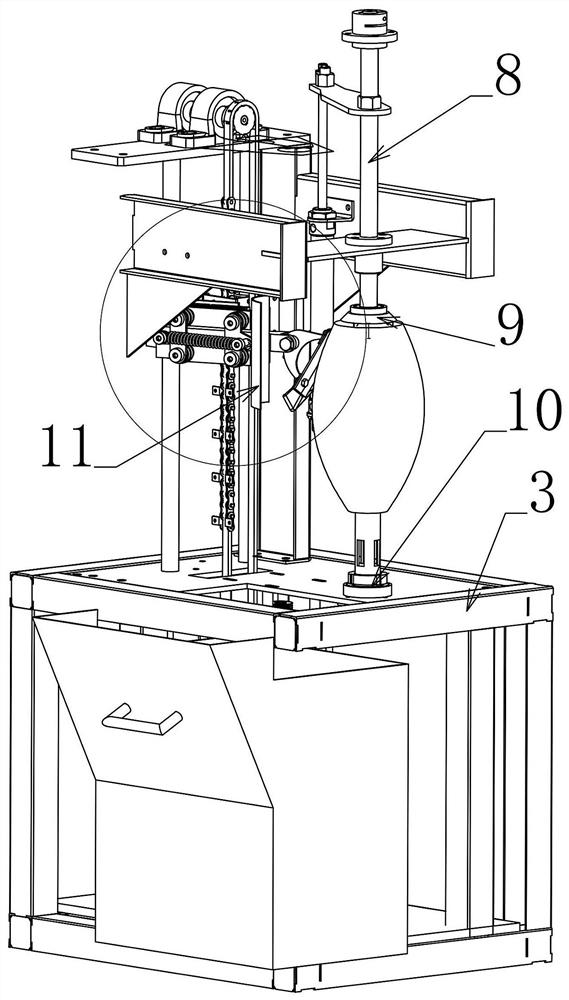

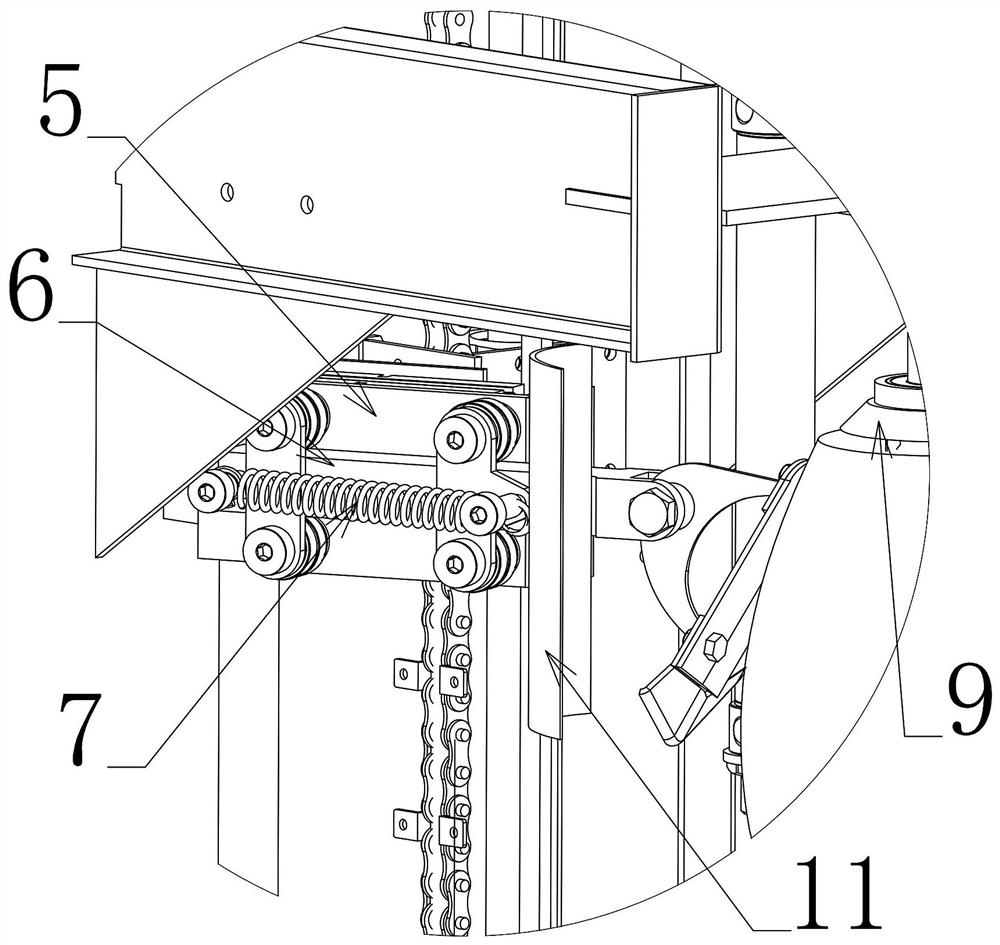

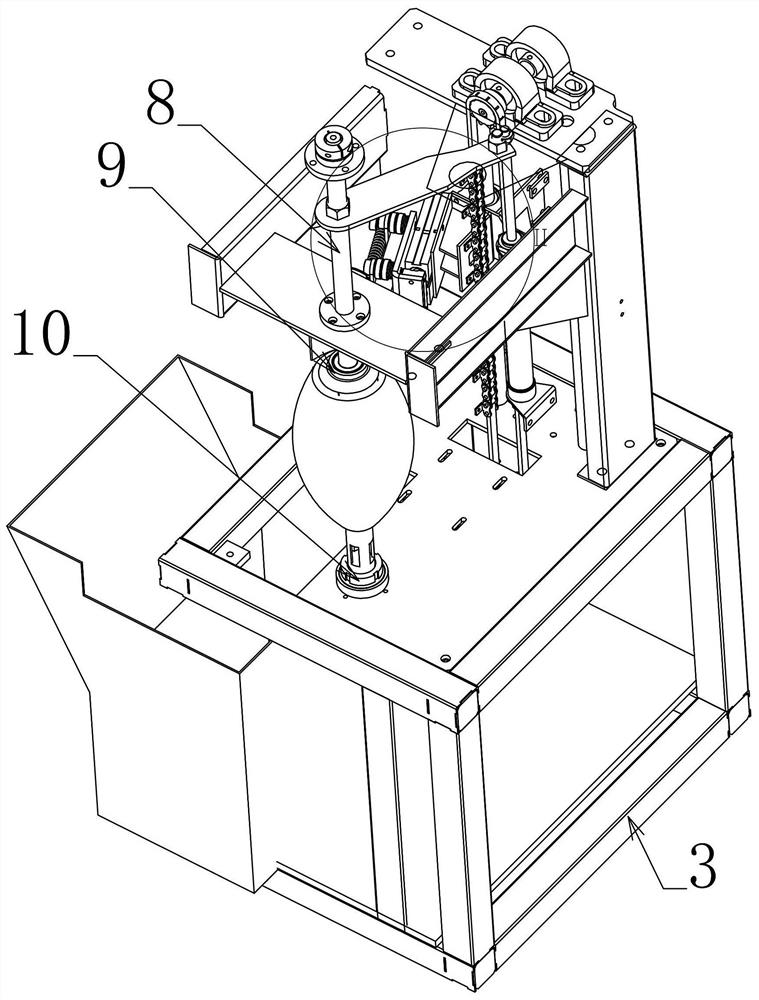

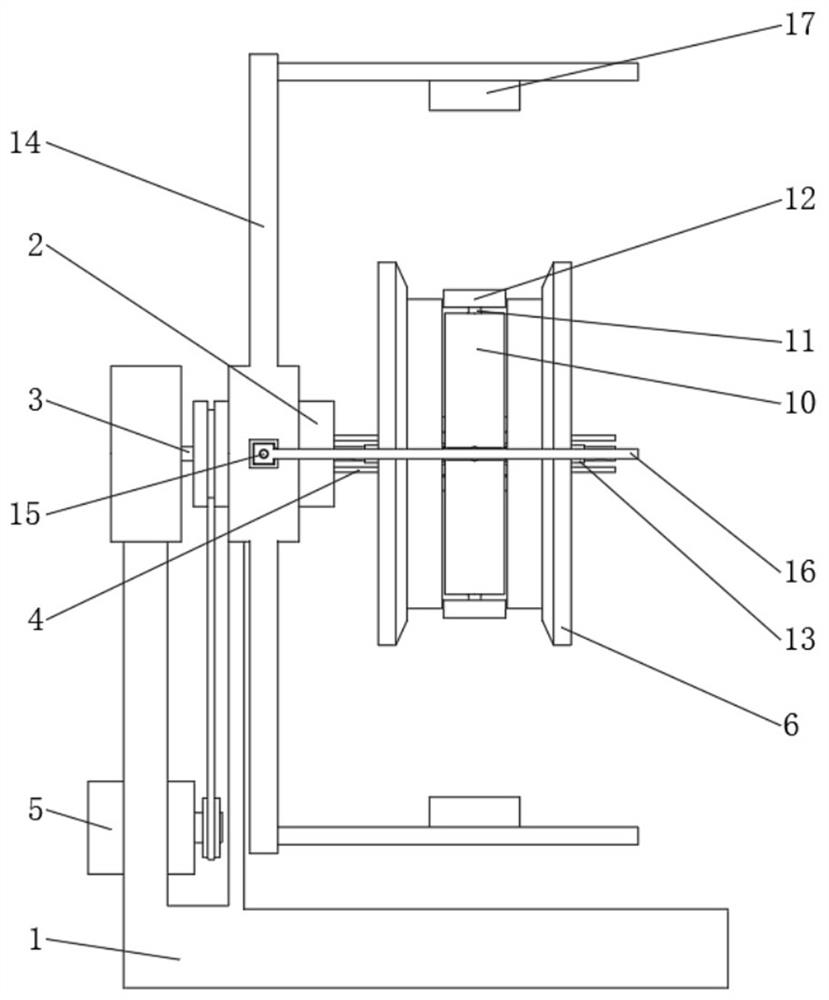

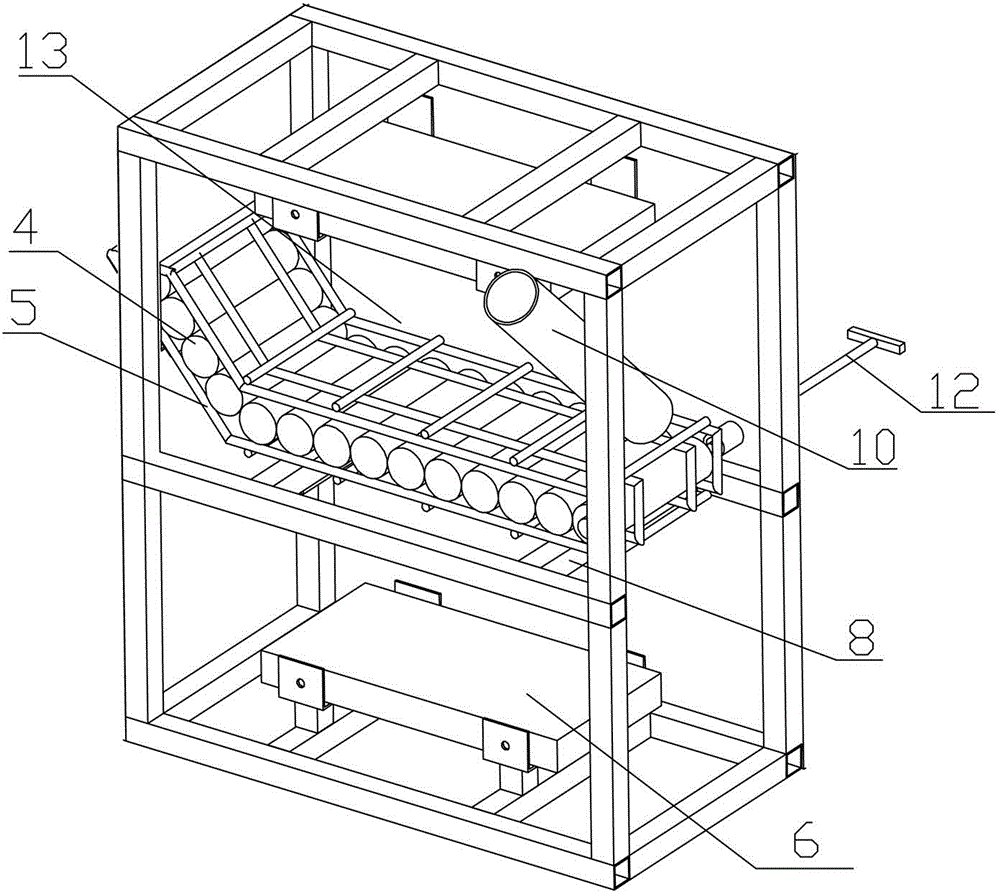

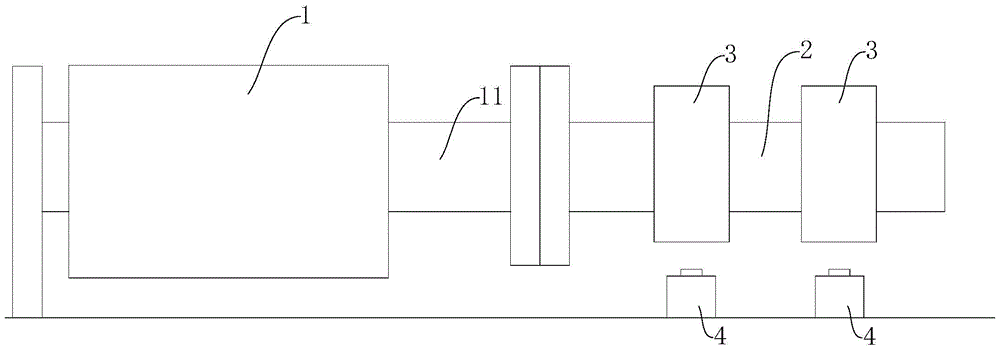

Interval flower color dovetail groove pipe head sucking pipe machining production line

ActiveCN110341159AConvenient distanceImprove cooling and shaping effectMetal working apparatusProduction lineEngineering

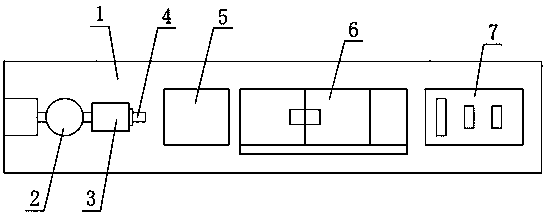

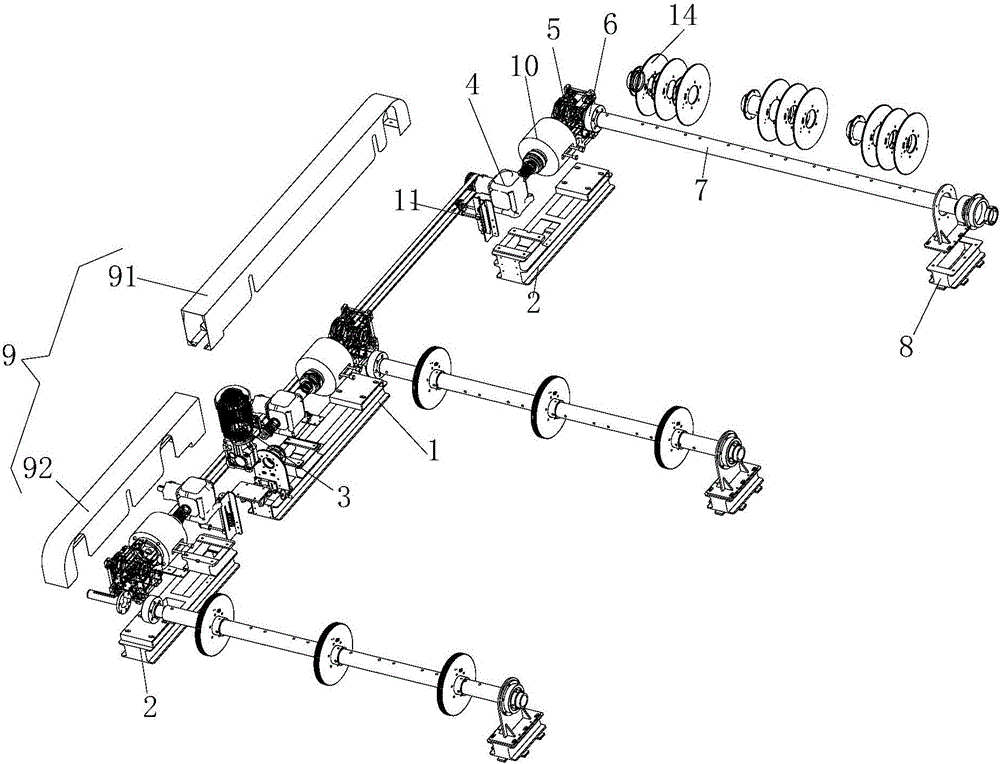

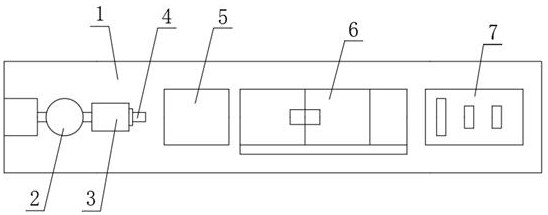

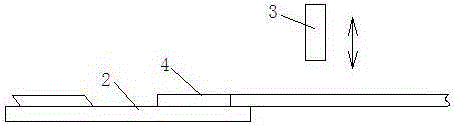

The invention discloses an internal flower color dovetail groove pipe head sucking pipe machining production line which comprises a rack (1), and a feeding device (2), a heating device (3), an extrusion molding die (4), a vacuum foam removing device (5), a cooling plastic device (6) and a cutting discharging device (7) which are sequentially arranged on the rack (1). The cooling plastic device (6)comprises a cooling box (8) fixedly connected with the rack. The two ends of the cooling box (8) are provided with a sealing feeding opening (9) and a sealing discharging opening (10) correspondingly, wherein the sealing feeding opening (9) and the sealing discharging opening (10) are the same in height. A partition plate (11) is arranged in the cooling box (8) and provided with a sealing transition opening (12). The height of the sealing transition opening (12) is the same as that of the sealing feeding opening (9). The production line is convenient to operate, and has the advantages of being low in cost, uniform in coloring, high in working efficiency and good in product quality.

Owner:义乌市城西机械有限公司

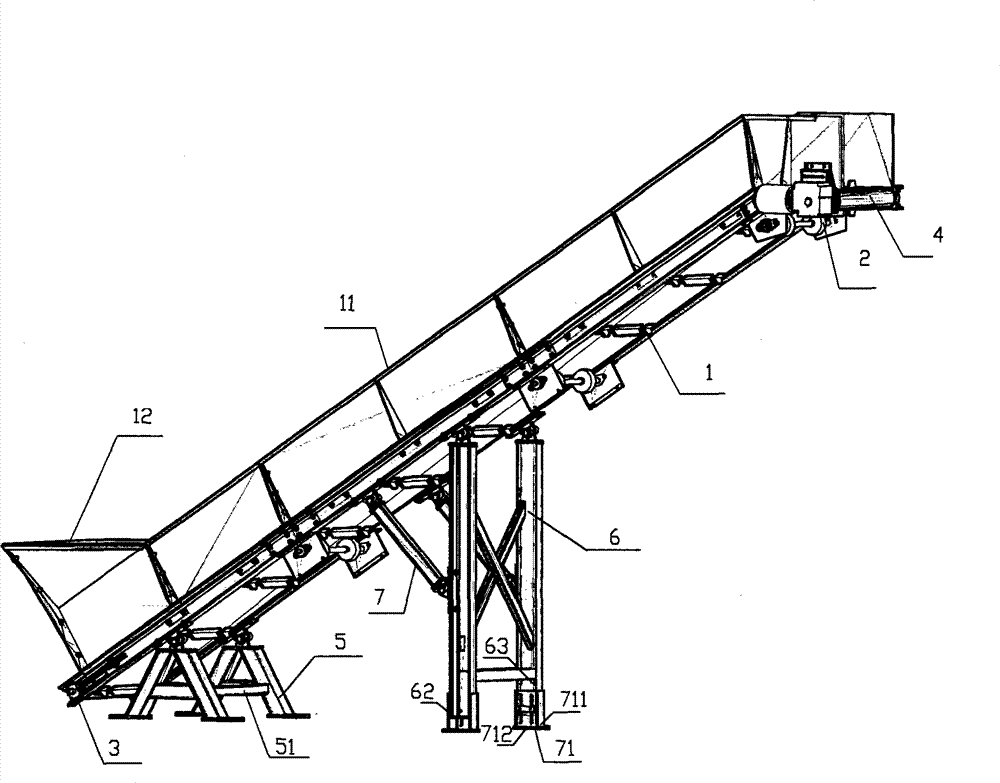

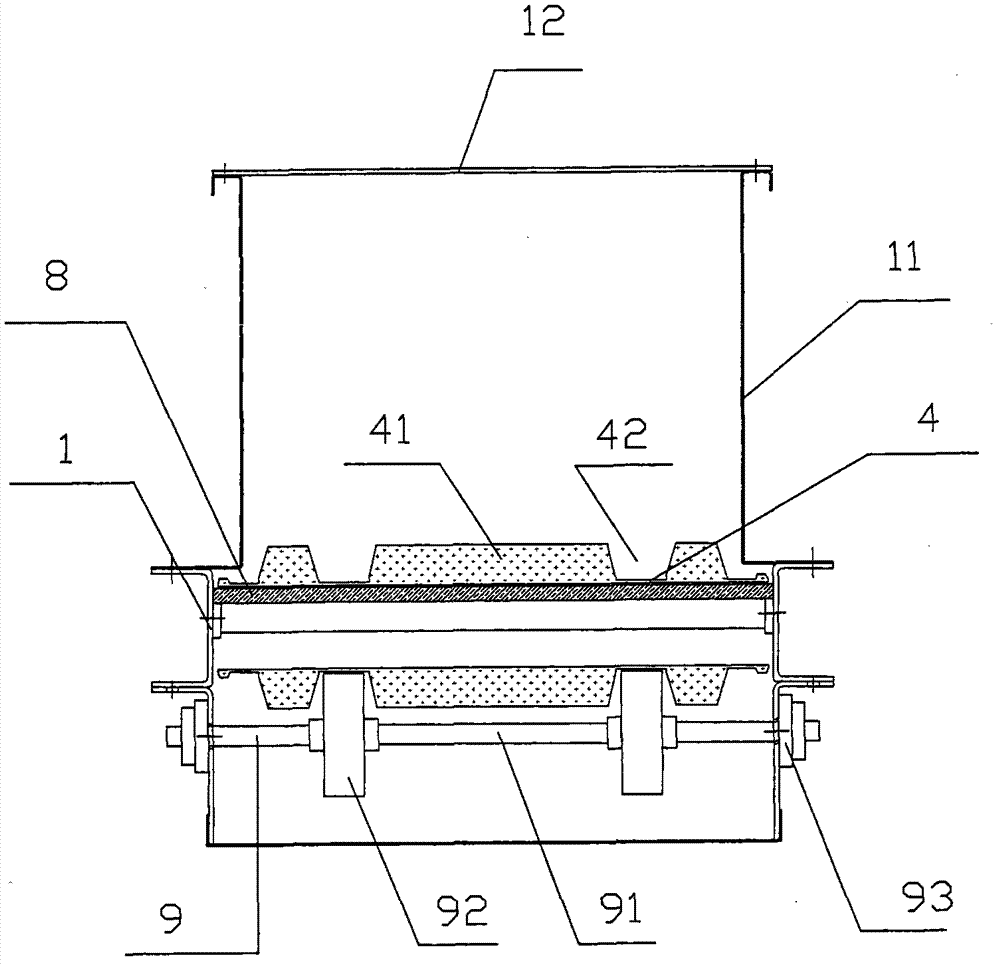

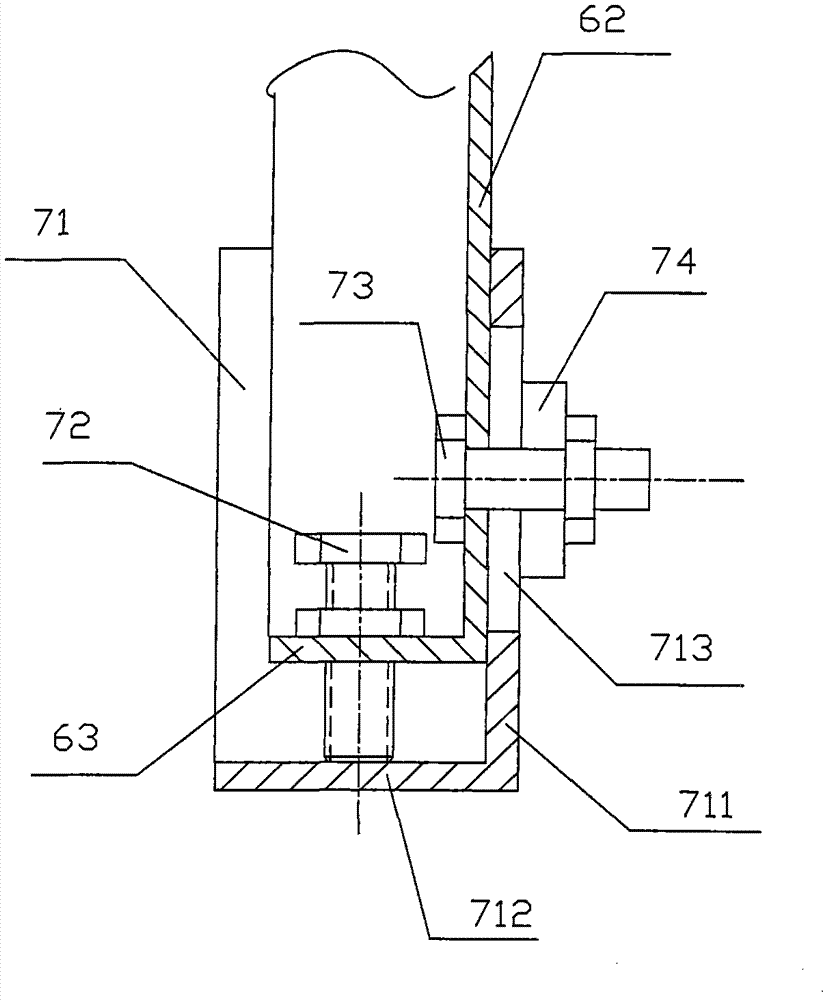

Belt conveyor for feeding of grinder

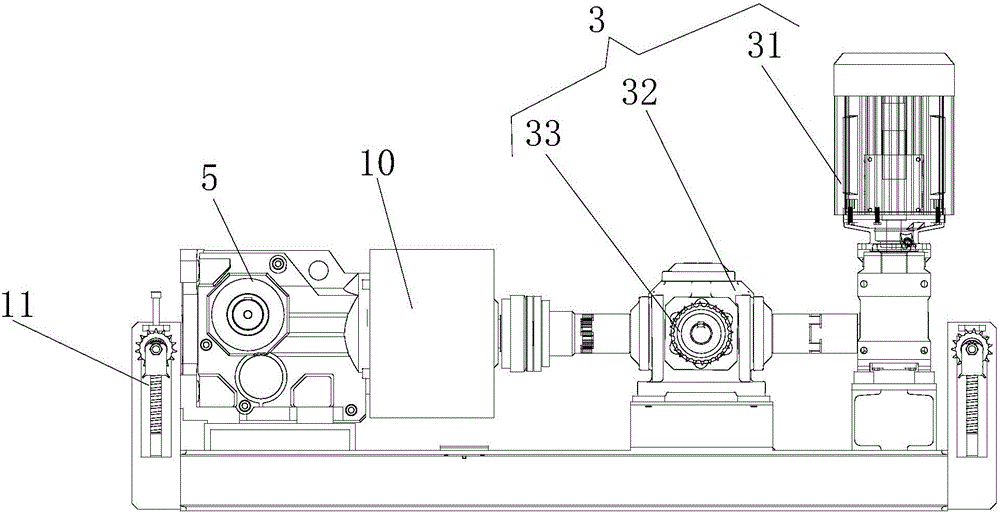

The invention relates to a belt conveyor for feeding of a grinder. The belt conveyor comprises a frame, a driving drum, a drive device, a driven drum, a conveying belt, a frame support structure and a conveying belt support structure. The frame support structure is composed of an A-type tailstock, an H-type front supporting leg and an inclined strut, the conveying belt support structure is composed of a wood footplate mounted at the upper end face of the frame and a plurality of lower touch rolls mounted on the lower end face of the frame, the A-type tailstock, the H-type front supporting leg and the frame are in hinged connection, one end of the inclined strut is hinged on the frame while the other end of the same is hinged on the H-type front supporting leg, the inner side surface of a conveying belt bearing section is attached onto the wood footplate on the upper end face of the frame, and the outer surface of a conveying belt no-load back-turning section contacts with rollers of the lower touch rolls. The belt conveyor for feeding of the grinder has the advantages that the conveying belt bearing section operates on the wood footplate in an attaching manner, so that transportation is stable, and waste materials cannot be jittered; and the conveyor frame is hinged with the A-type tailstock and the H-type front supporting leg, and stability of the whole conveyor is improved as the A-type tailstock is low in gravity center.

Owner:SHANGHAI DEPEI SAFETY TECH CO LTD

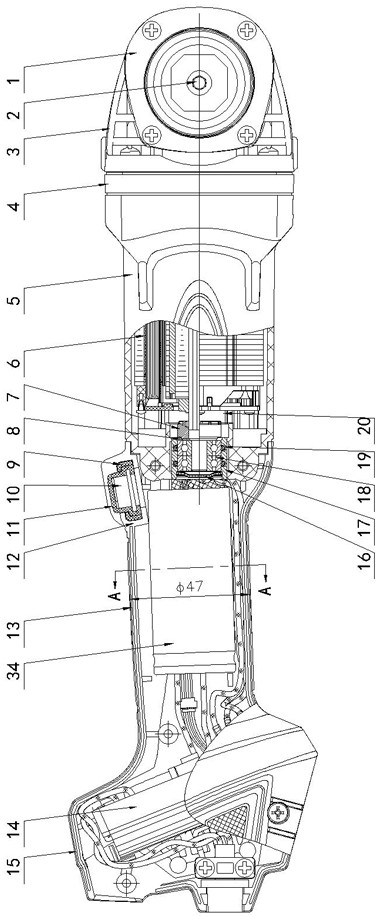

Handheld cutting machine and grooving machine

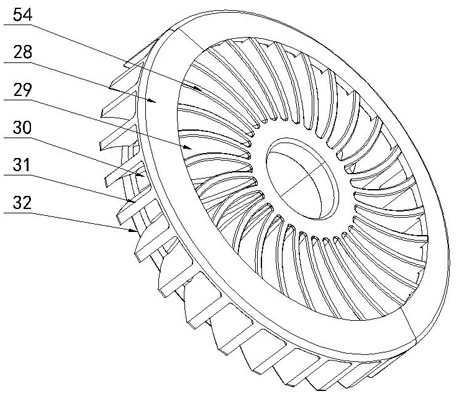

PendingCN112720877AExtended service lifeImprove output power stabilityWorking accessoriesStone-like material working toolsBrushless motorsImpeller

The invention discloses a handheld cutting machine and grooving machine. The handheld cutting machine and grooving machine comprises a main machine and a cutting device, wherein the main machine comprises a rear handle, a machine shell, a brushless motor, a middle cover and a transmission mechanism, a fan is fixed to a motor shaft, a metal bush connected into a whole through injection molding is arranged on the rear side wall of the machine shell, a double-bearing structure is arranged in the metal bush through a first sealing ring, the front end of the motor shaft is arranged on the middle cover through a single-bearing structure, the rear end of the motor shaft is arranged on the metal bush through a double-bearing structure, a rubber dustproof cover in sealing fit is arranged at the rear end of the metal bush, a plastic impeller located on the front side of the metal bush is fixed to the motor shaft, and centrifugal blades are uniformly distributed on the plastic impeller. After the structure is adopted, the handheld cutting machine and grooving machine has the advantages of simple and reasonable structure, convenience in operation and use, stability in work, good ventilation and heat dissipation effects, dust prevention, water prevention, reliability, long service life and the like.

Owner:ZHEJIANG BODA IND

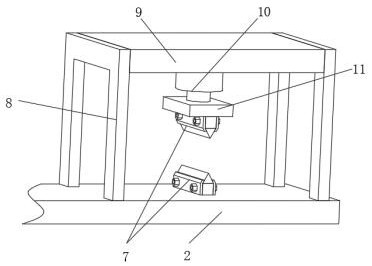

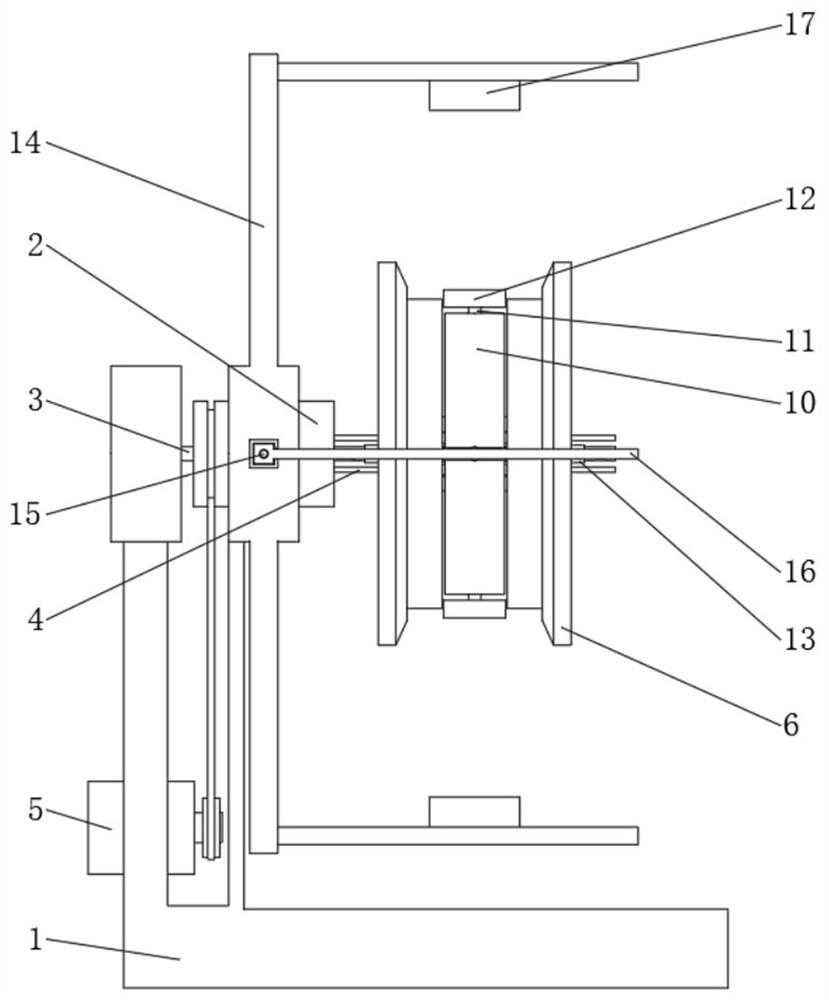

Three-shaft matrix hanging system for studio

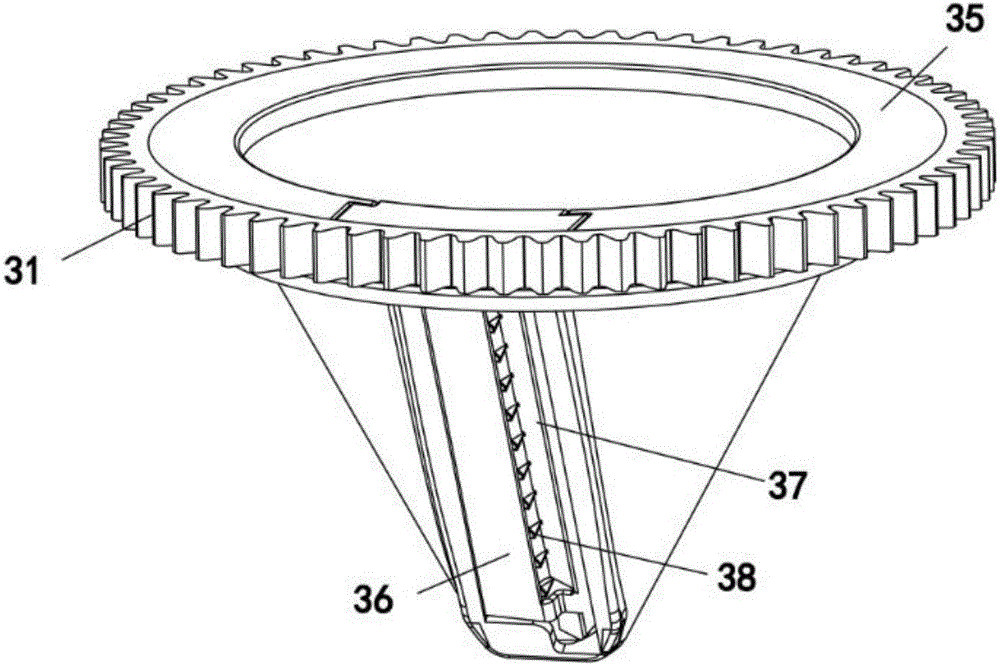

InactiveCN105910072AEnsure safetyEnsure that it does not slip when carrying weight to ensure safetyLighting support devicesWinding mechanismsEngineeringDISC assembly

The invention discloses a three-shaft matrix hanging system for a studio. The three-shaft matrix hanging system comprises a first mounting underframe and two second mounting undeframes, wherein the two second mounting undeframes are respectively arranged on the two sides of the first mounting undeframe; a brake mechanism is fixedly mounted at the top of the first mounting undeframe; the brake mechanism is in transmission connection with transmission mechanisms arranged on the two sides of the brake mechanism through chains; the two transmission mechanisms are fixedly mounted at the tops of the two second mounting undeframes respectively; the brake mechanism and the transmission mechanisms are fixedly connected with speed shifting devices; the speed shifting devices are fixedly connected with rotating shafts through floating connecting heads which are fixedly connected on the speed shifting devices; and three rope disc assemblies are connected on each of the three rotating shafts in a sleeving manner. The three-shaft matrix hanging system for the studio has the characteristics that the safety coefficient is high and the utilization is flexible and convenient, rope discs and hanging points are convenient to adjust, the utilization requirement of large props is met, the braking and transmission are quite stable, and operation and utilization of users are facilitated.

Owner:GUANGDONG HUACHEN FILM & TELEVISION STAGE PROJECT CO LTD

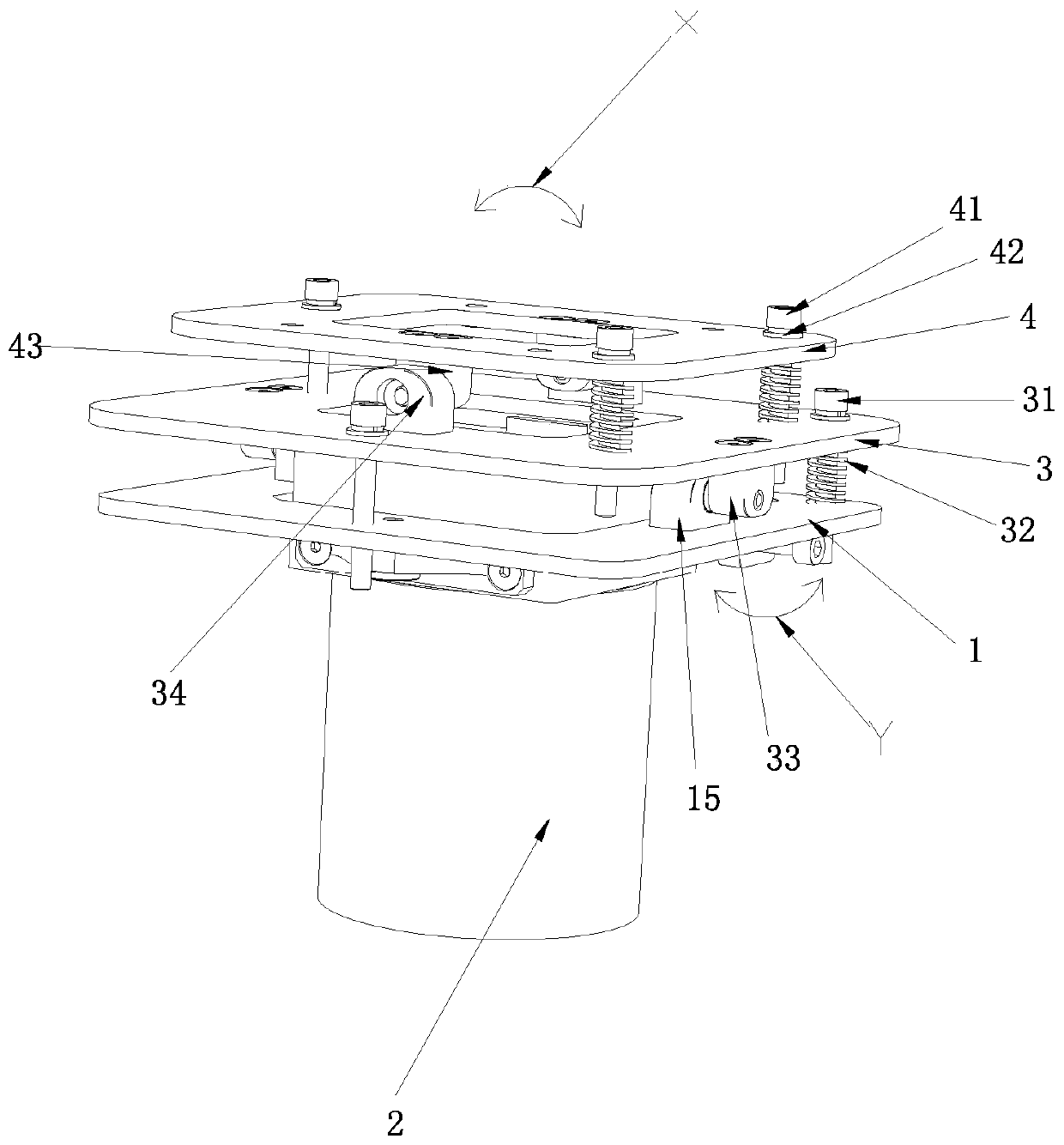

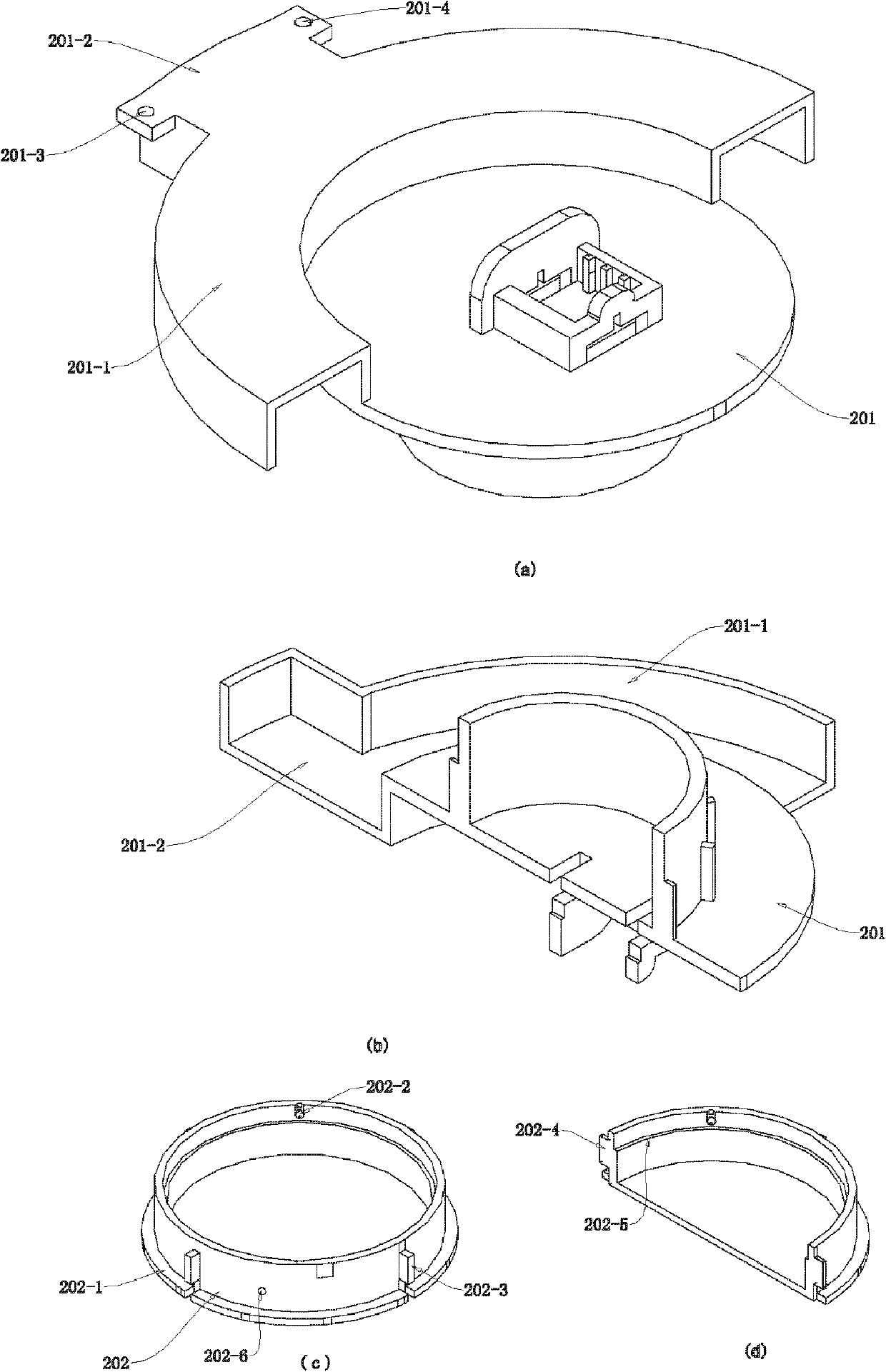

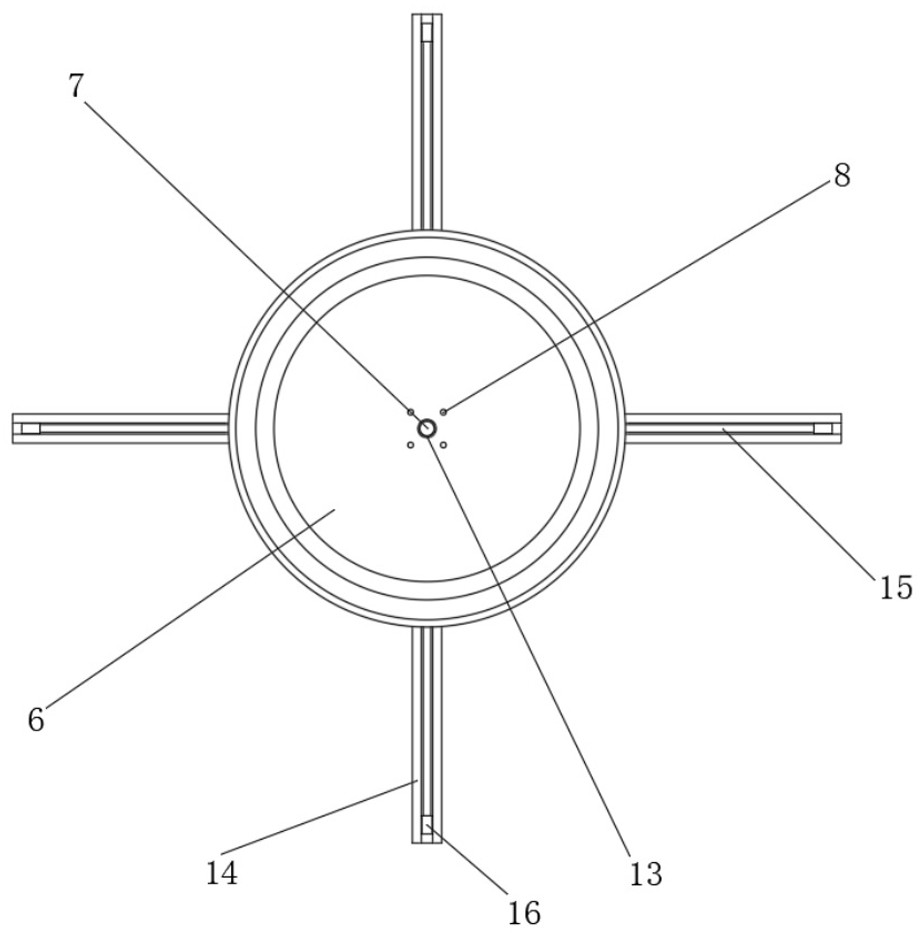

Rotary regulating mechanism

PendingCN110645455APrecisely control the amount of rotationNo shakingStands/trestlesCamera body detailsElastic componentMachine

The invention discloses a rotary regulating mechanism, and is applied to the field of regulating machines. The rotary regulating mechanism comprises a first bottom plate and working equipment; the first bottom plate is movably provided with two opposite first regulating rods; each of the two first regulating rods has a stroke that the regulating rods move in the axial direction of the first bottomplate; one end of the working equipment is rotatably arranged on the first bottom plate; the other end of the working equipment is connected between the two first regulating rods; at least one of thefirst regulating rods is sleeved with a first elastic component; and the at least one first elastic component is arranged between the corresponding first regulating rod and the working equipment in an abutted manner. The rotary regulating mechanism is simple in structure, high in regulating precision and high in stability.

Owner:湖南讯目科技有限公司

Damper-including sliding wheel assembly under wall cabinet door

ActiveCN102305002BIncrease dampingInnovative designBuilding braking devicesWing openersManufacturing technologyEngineering

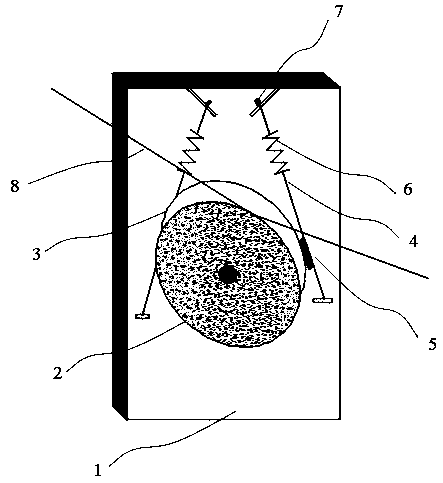

A pulley assembly with a damper comprises a damper assembling clip (10), a movable clip sleeve (11), and an outer support clip (15) arranged in sequence from the interior to the exterior. A damper assembly is mounted in the damper assembling clip (10). The damper assembly comprises a fixed base (1), a damper (2), and an extension spring (3). A damper pulling sheet (12) is mounted in a radial through groove (10-4) of the fixed base (1). The damper pulling sheet (12) extends out of a lower end of the damper assembling clip (10) and is provided with a 7-shaped fixed hook (12-2). The pulley assembly implements synchronous damping, ensures smooth running of a wall cabinet door page, and avoid shaking and bouncing.

Owner:许姜德

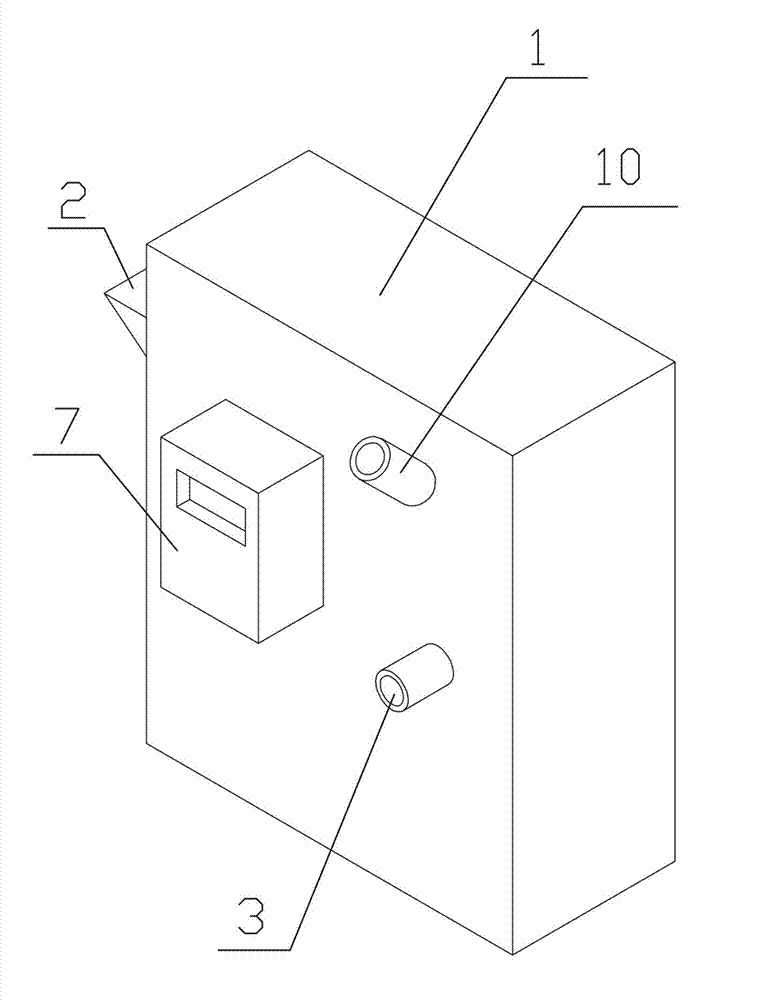

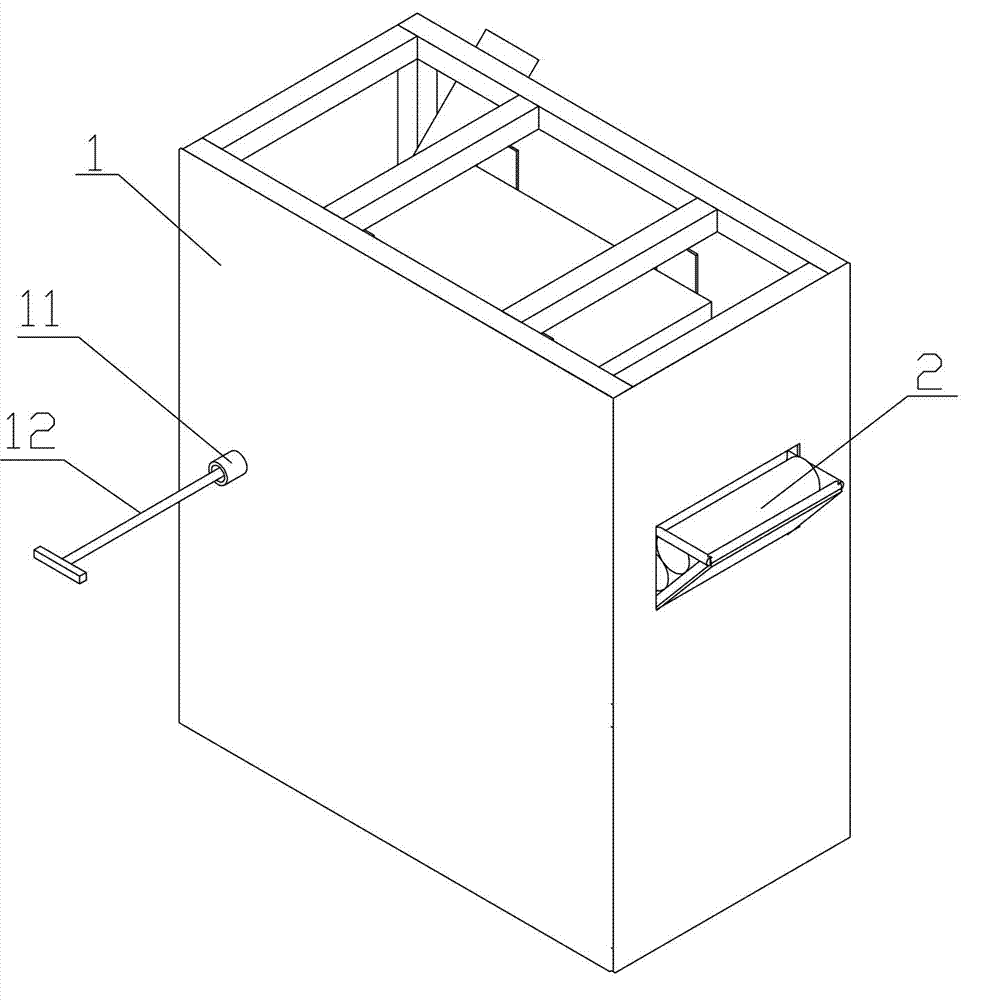

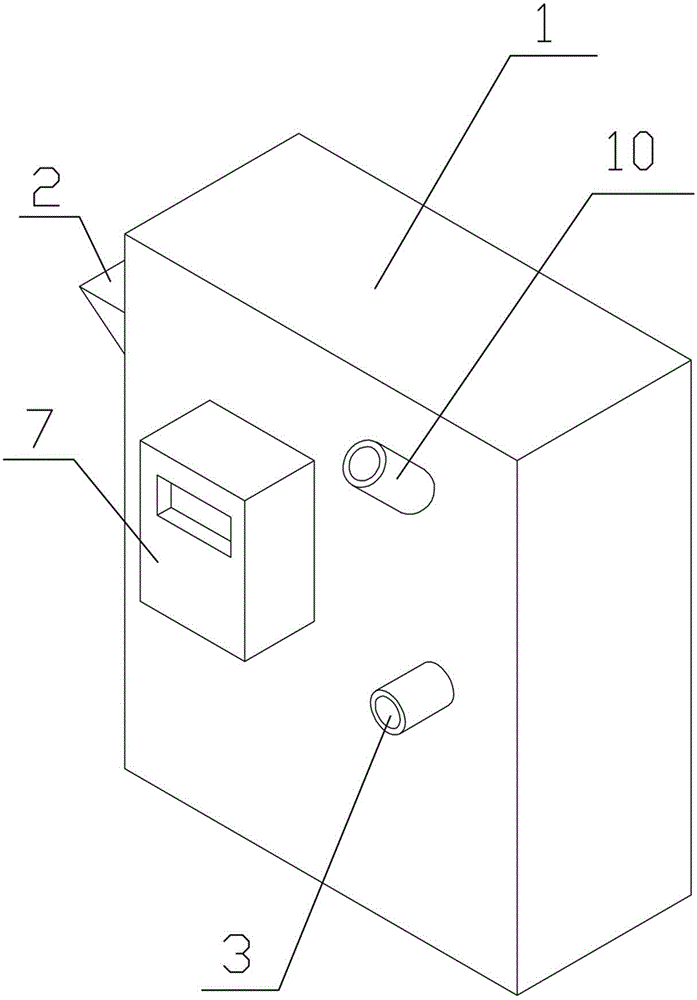

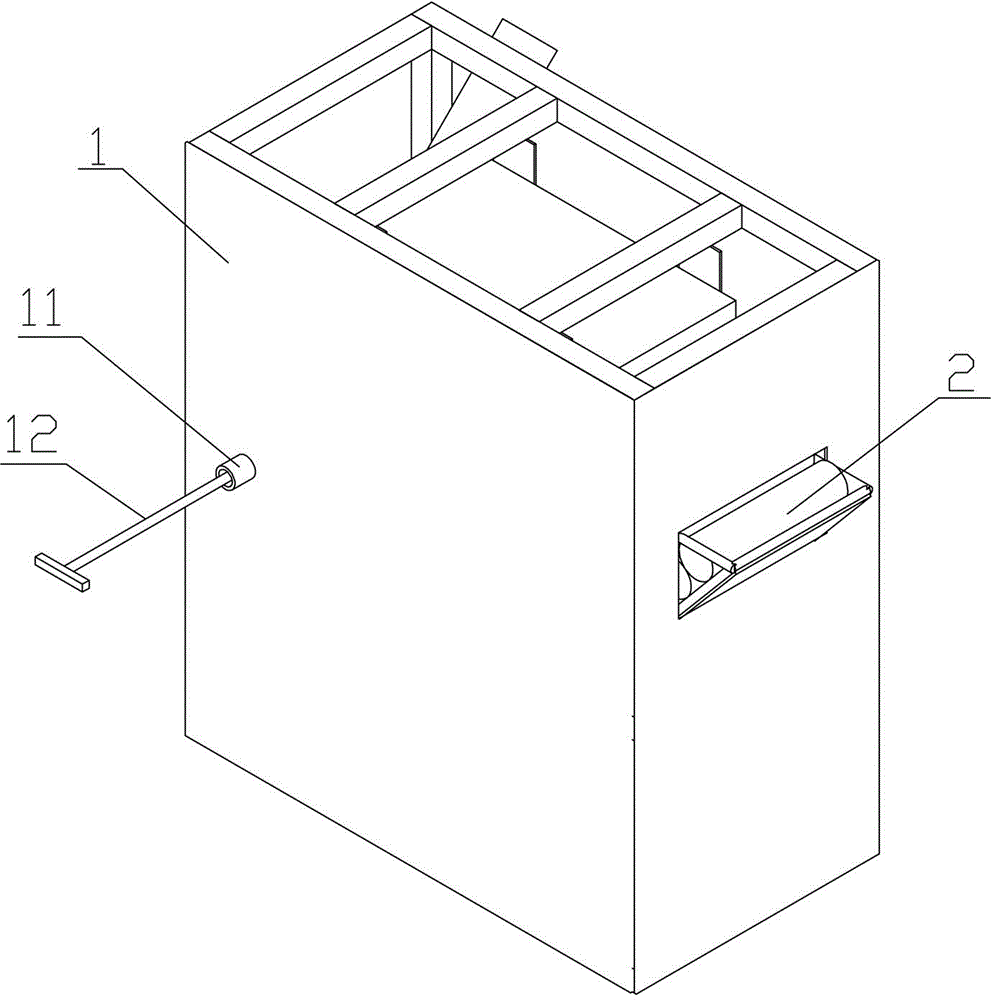

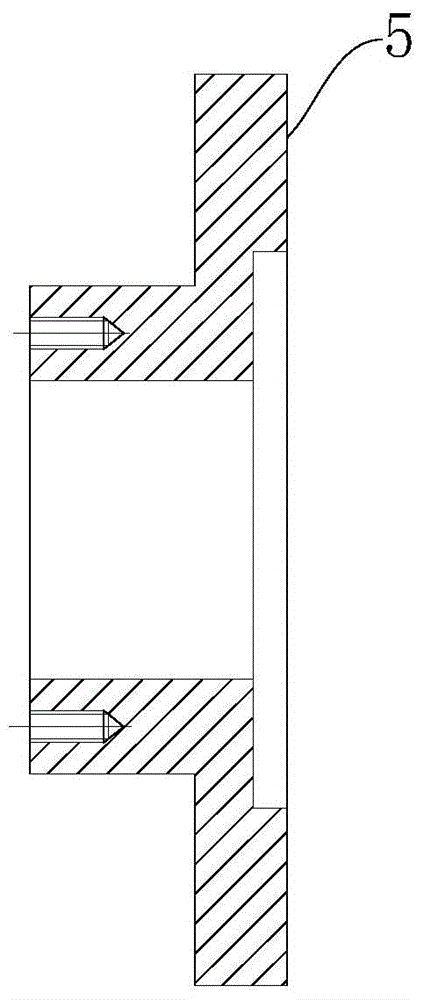

Heating box for cylindrical solid sols

InactiveCN102814263ANormal extrusionSimple structureLiquid surface applicatorsCoatingsEngineeringColloid

The invention discloses a heating box for cylindrical solid sols. The heating box comprises a box body of a cuboid structure, the box body is provided with an internal hollow cavity, a guide inlet communicated with the hollow cavity is arranged on the wall of the box body, a guide outlet communicated with the hollow cavity is arranged on the other non-bottom wall of the box body, the height of the guide outlet is smaller than or equal to that of the guide inlet, a guide rail for bearing the cylindrical solid sols is fixed in the hollow cavity and extends from the guide inlet to the guide outlet, and electric-heating elements are fixed in the hollow cavity. By the heating box for the cylindrical solid sols, the cylindrical solid sols can be heated on line in batches in cold environments and can be guaranteed to be squeezed out normally in use. The heating box is simple in structure, convenient to operate and applicable to heating of various cylindrical solid sols.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

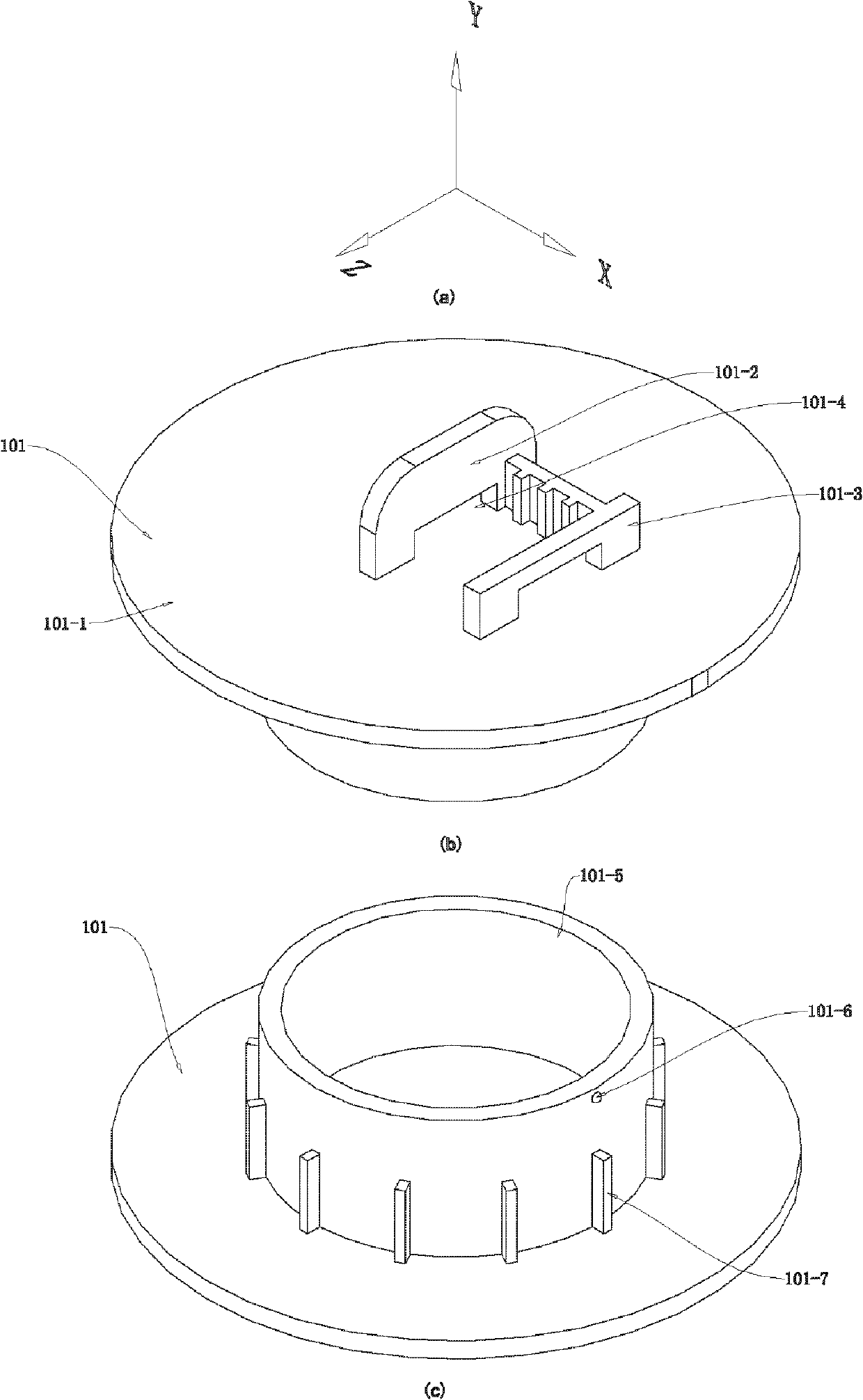

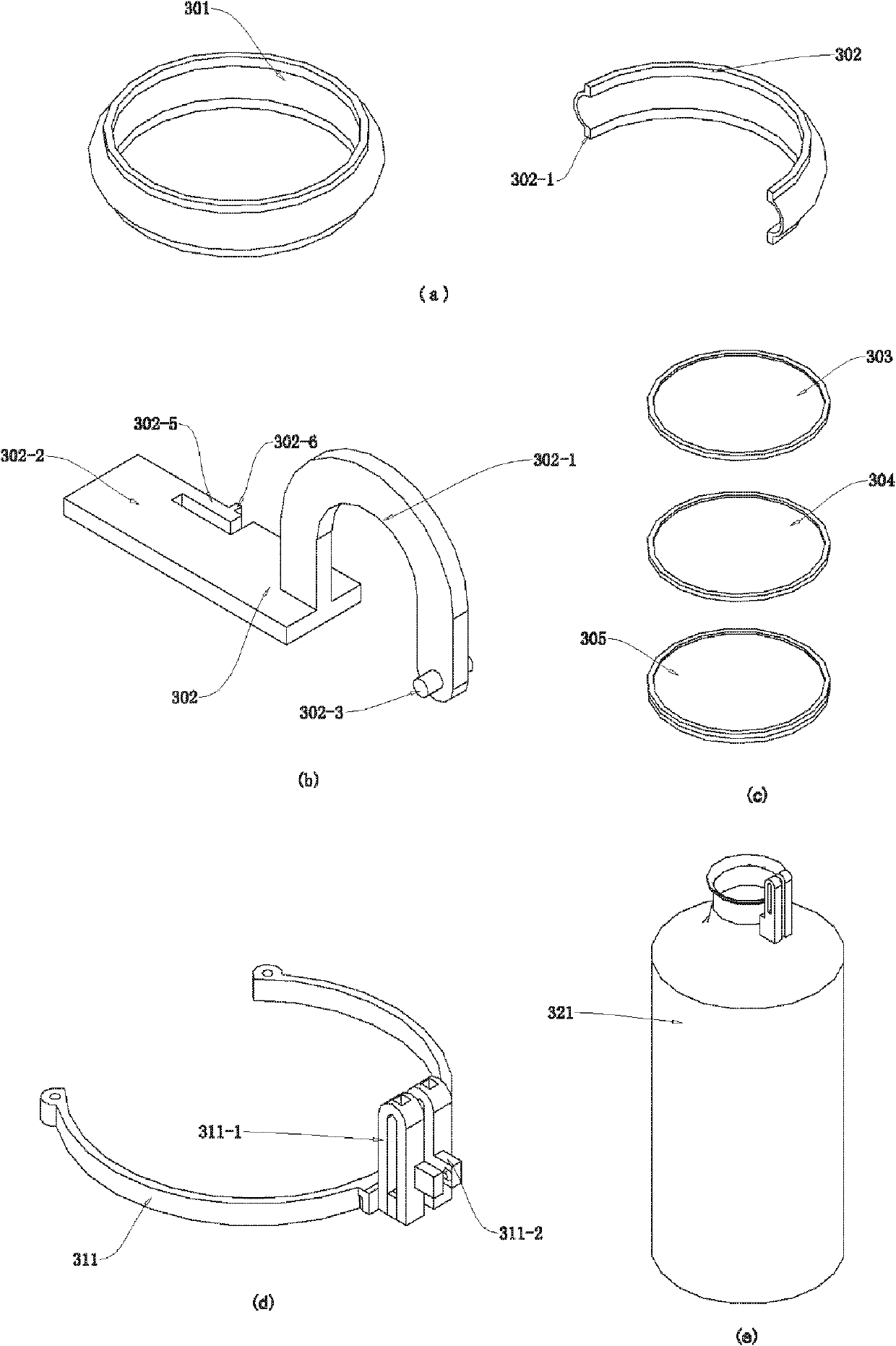

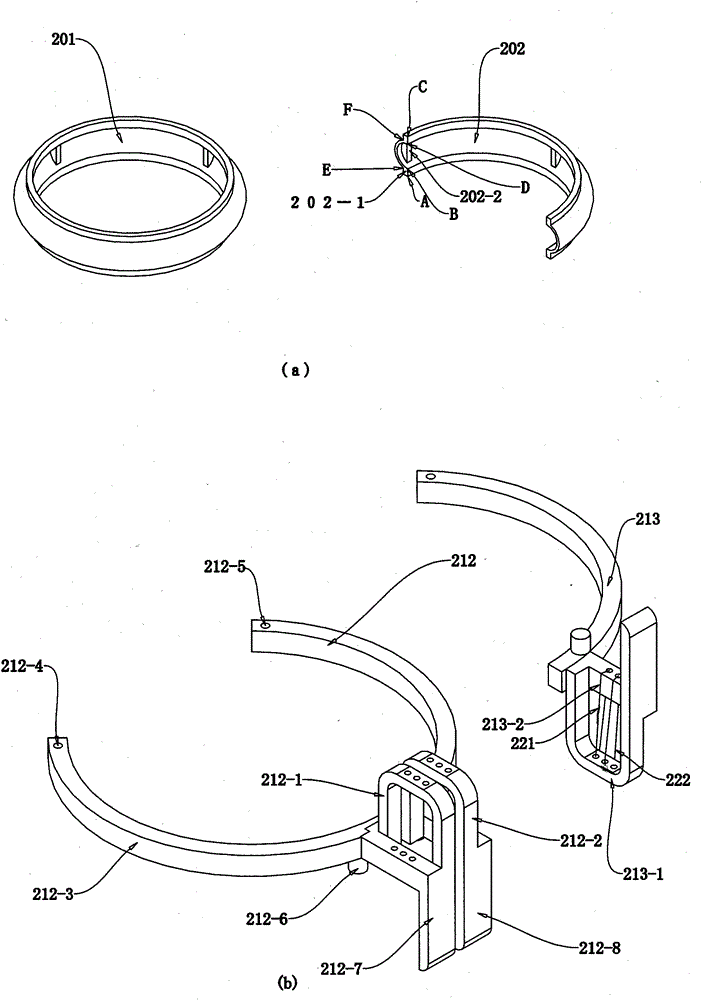

Flip type thermos bottle cork

InactiveCN102232802AImprovement of core functionsImprove heat preservation functionNon-pressured vesselsPolymer scienceCork

The invention provides a flip type thermos bottle cork. By adopting the flip type thermos bottle cork, the following shortcomings are overcome: the existing thermos bottle corks are poor in heat insulation effect, poor in adaptability and easy to fall out in winter, and can accidentally drop and fall to the ground at any time, etc. In the bottle cork, three air layers playing the heat insulation role are arranged in a cork column of a cork body, and two heat insulation layers are arranged between the outer wall of the cork column and the inner wall of a bottle neck of a bottle liner; the free end of a long plate section 302-2 of a transfer strip 302 is clamped between an auxiliary bayonet and a main bayonet, and symmetrical rotating shafts at the free end of an arch-shaped section 302-1 are respectively clamped into two mutually symmetrical clamping rings in a cork seat; a heat insulation sheet 305 tight fit in a lower cork barrel 202 is clamped between an annular heat insulation sheet ridge of the lower cork barrel 202 and the end of an upper cork barrel; and a seal ring 301 with semi-circular-arc-shaped radial section is arranged around the outer wall of the lower cork barrel 202 through tight fit. By adopting the flip type thermos bottle cork, the heat insulation function of a thermos bottle can be significantly improved, the consumption of raw materials is reduced, and the flip type thermos bottle cork can be matched with the thermos bottles from different manufacturers and is easy to popularize.

Owner:王华

Full-automatic reinforcing steel bar cut-to-length shearing device

The invention discloses a full-automatic reinforcing steel bar cut-to-length shearing device, relates to the technical field of reinforcing steel bar processing, and aims to solve the problem of service life of a tool. The full-automatic reinforcing steel bar cut-to-length shearing device specifically comprises a worktable fixed to the ground through a supporting leg I, wherein a feeding mechanism, a loading mechanism and a shearing mechanism are successively arranged on the outer wall of the top of the worktable; the shearing mechanism comprises two tool assemblies and a hydraulic cylinder, two portal frames are fixed to the outer wall of the top of the worktable through bolts, a top plate is fixed to the outer walls of the tops of the portal frames through bolts, the hydraulic cylinder is fixed to the outer wall of the bottom of the top plate through bolts, a lifting rack is fixed to the outer wall of a telescopic end of the hydraulic cylinder through bolts, and one tool assembly isfixedly mounted on the outer wall of the bottom of the lifting rack. By arranging the tools in normal triangular prism structures and processing a cutting edge in each edge, when one edge is worn, cutting edges of other edges still can perform shearing work, so that the service life of the single tool is prolonged and the using cost is lowered.

Owner:广西吉长旺新材料科技有限公司

Heat dissipating and damping system of power amplifier

InactiveCN108337584AWon't destroyGuaranteed working conditionTransducer casings/cabinets/supportsEngineeringAmplifier

The invention discloses a heat dissipating and damping system of a power amplifier. The system comprises a power amplifier chassis and a power amplifier main body, wherein a front baffle is arranged at a front end of the power amplifier chassis, power amplifier U-shaped clamp blocks are arranged on both sides in the power amplifier chassis, the power amplifier main body is clamped in the two poweramplifier U-shaped clamp blocks, each power amplifier U-shaped clamp block comprises an upper clamp plate, a lower clamp plate and a side clamp plate, the upper clamp plate is hinged with the upper end of the side clamp plate, the lower clamp plate is hinged with the lower end of the side clamp plate, the upper clamp plate, the lower clamp plate and the side clamp plate are connected with the power amplifier chassis through damping springs, connecting screws are arranged at the connection sites of the damping springs with the upper clamp plate, the lower clamp plate and the side clamp plate,and adjustment holes are formed in the power amplifier chassis corresponding to the connecting screws. Heat dissipating holes are formed in the power amplifier chassis, a movable baffle is arranged atthe heat dissipating holes on the power amplifier chassis, the movable baffle is slidably connected to the power amplifier chassis, and the sliding of the movable baffle can block the heat dissipating holes and open the heat dissipating holes.

Owner:CHENGDU DIMAN TECH CO LTD

Bus duct assembling manufacturing flow process

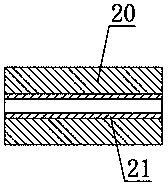

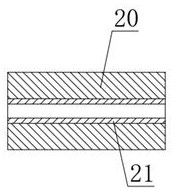

InactiveCN104184063AEasy to useImprove overload capacityTotally enclosed bus-bar installationsCable installation apparatusCopper wirePulp and paper industry

The invention discloses a bus duct assembling manufacturing flow process which comprises the following steps: preparing copper bars in a bus duct, and trimming the length of the copper bars according to the dimensions in a list; punching connection holes at the two ends of the standard-length copper bars respectively; welding the copper bars needing welding; brush plating length of the copper bars in the bus duct being 12-15 cm; preparing a heat shrink tube sleeve pipe, and copper bars, the length of which is 3 m for example, and cutting 2.95 cm of the length of the sleeve pipe; after the thermal shrinkage, cutting the two ends of a heat shrink tube by 6-8 cm; cutting the 1.2-1.3 cm place of the heat shrink tube; during side plate assembling, the piece with a housing being connected with a screw; during bus assembling, preparing copper bars 1-4 cm long and 2-3 cm housing, and cutting the two ends of the bus to enable the copper wires to be exposed for 14-16 cm; and the copper bars in the bus duct being 40-170 cm wide and the side plate being configured to be 90-190 cm wide. The bus duct is convenient to use; and the plug-in type bus duct branches the power source of a trunk line to a branch line by utilizing a plug-in manner, so that convenient branching is achieved.

Owner:JIANGSU HAIWEI GROUP

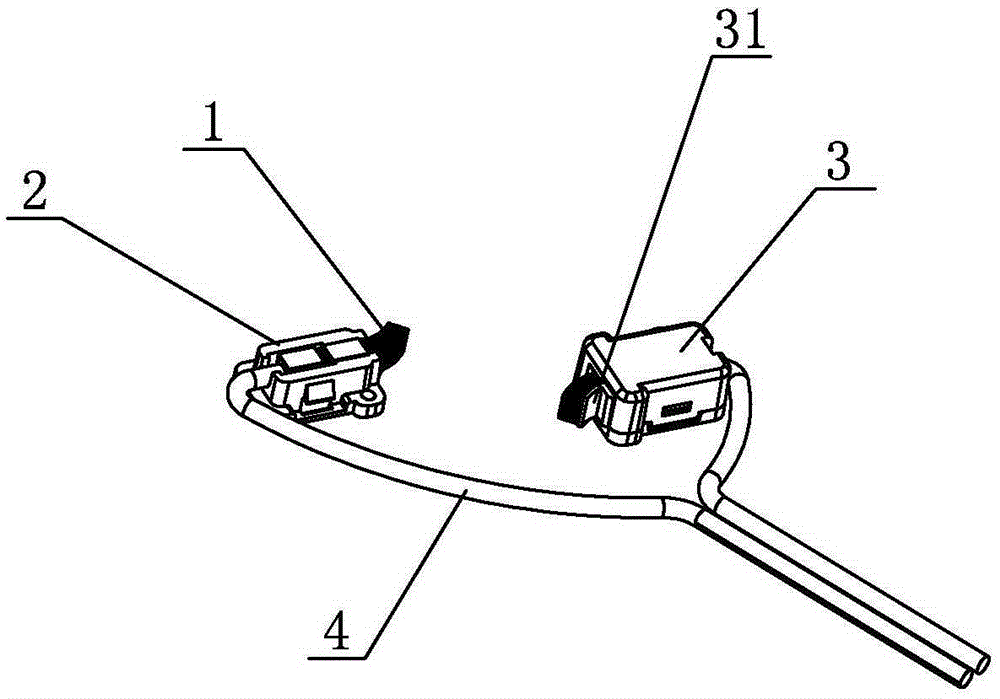

Carbon fiber brush

The present invention discloses a carbon fiber brush. The carbon fiber brush comprises a brush fixed base; and the brush fixed base is provided with brush of kernel made of conductive carbon fibers, one end of the brush of kernel extends out of the brush fixed base, and the other end of the brush of kernel is connected with wires. According to the invention, brush of kernel made of conductive carbon fibers is capable of heat resistance, soft and wear resistant, and is in soft contact with a commutator. When the carbon fiber brush and the commutator of a rotor are relatively running, the soft brush of kernel is close to the commutator and bends along the rotation direction of the commutator. The brush of kernel is not able to bounce and is not reliable to generation of spark, the friction generated between the brush of kernel and the commutator is very small without any noise, therefore the friction loss of the brush of kernel is greatly reduced, the carbon fiber brush is not reliable to wearing, and the service life of a motor is prolonged.

Owner:陈锦霞

Press-fit device for decoration strip

The invention relates to the technical field of decoration, and particularly relates to a press-fit device for a decoration strip. The press-fit device comprises an installation plate, wherein a gear groove is formed in the lower surface of the installation plate; a first gear and a second gear are arranged in the gear groove; a second bearing is installed at the middle part of the first gear; a fixed column is arranged in the second bearing in an insertion manner; a fixing groove is formed in the middle part close to the first gear, of the gear groove; a rolling wheel is installed on a rotary shaft; press-fit sheets are installed at the two sides of the rolling wheel; a location sheet is arranged at one side away from the rolling wheel, of each of the two press-fit sheets; a through hole is formed in the centre close to the second gear, of the installation plate, and a first bearing is installed at the top of the through hole; a connection rod is installed in the first bearing; and an adjustment rod is arranged at the top of the connection rod. The press-fit device disclosed by the invention effectively improves the press-fit effect, ensures one-process forming, and ensures no jump of the decoration strip after press-fit, thereby greatly improving the installation quality of a decoration part.

Owner:管大海

Flip-type thermos stopper

The invention relates to a flip-type thermos stopper which overcomes the defects of easy falling in winter, drop on the ground by mistake at any time, poor temperature preserving effect, poor adaptability and the like. The thermos stopper of type 1 or type 2 is clamped outside a thermos neck of a thermos 501 by a circular arc clamping strip of a stopper base; in the thermos stopper of type 1, arch plug ears on a stopper body 301 of style I are clamped into two symmetrical frame-shaped clip rings in the stopper base of style I and clipped between the two frame-shaped clip rings of a stopper base 212 of style I in a tight fit way; in the thermos stopper of type 2, a stopper body of style II is connected with the stopper base of style II into a whole by a transfer strip 402; and a sealing ring with a C-shaped radial section is circled on the outer wall of a stopper barrel under the stopper body in a tight fit way. The thermos stopper can not fall in the thermos in winter or drop on the ground by mistake, and has better temperature preserving effect, good adaptability and certain dustproof effect.

Owner:王华

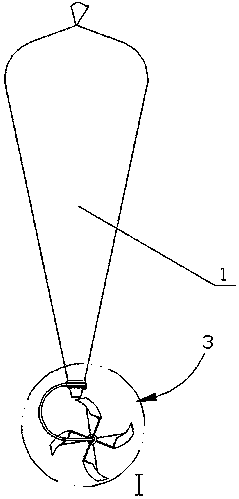

Peeling machine for specially removing rotary type melons and fruits

PendingCN113208395AFix unevennessWon't jumpVegetable peelingPeelersEngineeringMechanical engineering

The invention provides a peeling machine for specially removing rotary type melons and fruits, the problem that the surfaces of the peeled melons and fruits are uneven due to the uneven surfaces of the melons and fruits in the peeling process of the surfaces of the melons and fruits is solved; a multi-point contact method is adopted to relieve or avoid the jumping action of uneven surfaces of melons and fruits on a cutter, so that the surfaces of the melons and fruits subjected to peeling treatment are smoother, meanwhile, residues obtained after peeling treatment can be guided and collected, and centering can be assisted in the melon and fruit fixing process. According to a solution scheme, the peeling machine comprises a peeling knife, the peeling knife is characterized in that the peeling knife comprises a guide limiting knife rest, one end of the guide limiting knife rest is fixedly connected with a linear cutting edge, the linear cutting edge is obliquely arranged facing the axis of a melon or fruit, and the peeling machine can be attached to the melon or fruit all the time in the peeling process.

Owner:郑州顺鹏科技有限公司

Convenient-to-cook bagged mashed shrimps

PendingCN108556000ASimple structureReasonable designMetal working apparatusFood sciencePrawnEngineering

The invention discloses convenient-to-cook bagged mashed shrimps. A mashed shrimp cutting mechanism is arranged and provided with a circular shaft and a sleeve connection element, and the sleeve connection element is provided with a spiral piece and a cutting piece. When the mashed shrimps are extruded, the mashed shrimps are automatically cut, and other operations are omitted. A body and the mashed shrimp cutting mechanism are independent and are combined during use, the lower end of the body is provided with a mounting structure which is composed of a baffle ring and a protrusion and used for being connected with the mashed shrimp cutting mechanism, and the mashed shrimp cutting mechanism is provided with a first ring to be connected with the body. According to the scheme, the structureis simple, the design is reasonable, the mashed shrimps are naturally formed and convenient and quick to use, and the remaining mashed shrimps are kept in a bag and are sanitary and convenient to store; in use, the mashed shrimps can be extruded and cut into strips with one hand, and the other hand can stir the mashed shrimps in a pot and the like.

Owner:刘飞

A production line for processing pipettes with dovetail grooves at intervals

ActiveCN110341159BConvenient distanceImprove cooling and shaping effectMetal working apparatusMouth pieceProcess engineering

Owner:义乌市城西机械有限公司

A shredding and slicing device

The invention relates to the technical field of food processing electric appliances, in particular to shredding and slicing equipment. The shredding and slicing equipment comprises a main machine, a feeding pipe is mounted on the main machine, a planer tool and a drive device are arranged in the main machine, the planer tool is located below the feeding pipe and is driven by the drive device to operate, and the equipment is characterized in that a large cup used for supporting the main machine is arranged below the main machine, a food material outlet of the planer tool faces an opening in the top of the large cup, and therefore the large cup is used for containing and storing food materials obtained after planing; and the feeding direction of the feeding pipe is arranged along a planing rotating shaft of the plane tool. Super-long shredded or sliced food can be cut, a product is small and exquisite in size, use convenience is high, and the manufacturing cost is low.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

A vehicle tire grinding device

ActiveCN114505739BGuaranteed flatnessWon't jumpGrinding carriagesRevolution surface grinding machinesElectric machineryTire rotation

The invention belongs to the technical field of grinding equipment, and discloses a vehicle tire grinding device, which comprises a base, a rotating shaft is movably sleeved in the middle part above the base, and the upper part of the base extends to the right through the rotating shaft and is fixedly installed with a fixed Axle 1, a fixed shaft 2 is fixedly installed on the right end face of the rotating shaft in a circumferential array, a belt motor is fixedly installed on the lower part of the base, and a belt is connected between the belt motor and the rotating shaft, and the right end of the fixed shaft 1 is movable Set with support rim. In the present invention, the fixed shaft 1 is fixedly installed with the base. After the supporting rim rotates, the fixed shaft 1 rotates relative to the supporting rim, thereby driving the transmission teeth to rotate, and driving the rotating sleeve to rotate, so that the supporting plate slides on the inner surface of the tire, and the supporting plate is always maintained. Support in the original position, that is, the grinding block 1 and the grinding block 2 are always supported by a support plate in the grinding part of the tire during the rotating grinding process of the tire, which ensures the smoothness of the tire surface grinding.

Owner:SHANDONG LINGLONG TIRE +1

Heating box for cylindrical solid sols

InactiveCN102814263BNormal extrusionGuaranteed heating effectLiquid surface applicatorsCoatingsEngineeringColloid

The invention discloses a heating box for cylindrical solid sols. The heating box comprises a box body of a cuboid structure, the box body is provided with an internal hollow cavity, a guide inlet communicated with the hollow cavity is arranged on the wall of the box body, a guide outlet communicated with the hollow cavity is arranged on the other non-bottom wall of the box body, the height of the guide outlet is smaller than or equal to that of the guide inlet, a guide rail for bearing the cylindrical solid sols is fixed in the hollow cavity and extends from the guide inlet to the guide outlet, and electric-heating elements are fixed in the hollow cavity. By the heating box for the cylindrical solid sols, the cylindrical solid sols can be heated on line in batches in cold environments and can be guaranteed to be squeezed out normally in use. The heating box is simple in structure, convenient to operate and applicable to heating of various cylindrical solid sols.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

Vehicle tire polishing device

ActiveCN114505739AGuaranteed flatnessWon't jumpGrinding carriagesRevolution surface grinding machinesElectric machineryTire rotation

The invention belongs to the technical field of grinding equipment, and discloses a vehicle tire grinding device which comprises a base, the middle of the upper portion of the base is movably sleeved with a rotating shaft, the upper portion of the base extends rightwards to penetrate through the rotating shaft to be fixedly provided with a first fixing shaft, and second fixing shafts are fixedly installed on the right end face of the rotating shaft in the circumferential direction in an array mode. A belt motor is fixedly installed on the lower portion of the base, the belt motor is connected with the rotating shaft through a belt, and the right end of the first fixing shaft is movably sleeved with a supporting rim. According to the device, the first fixing shaft and the base are fixedly installed, after the supporting rim rotates, the first fixing shaft rotates relative to the supporting rim, so that transmission teeth are driven to rotate, a rotating sleeve is driven to rotate, a supporting plate slides on the inner surface of a tire, and the supporting plate is always kept at the original position for supporting, that is, in the rotating and grinding process of the tire through a first grinding block and a second grinding block; and the ground part of the tire is always supported by the supporting plate, so that the ground flatness of the surface of the tire is ensured.

Owner:SHANDONG LINGLONG TIRE +1

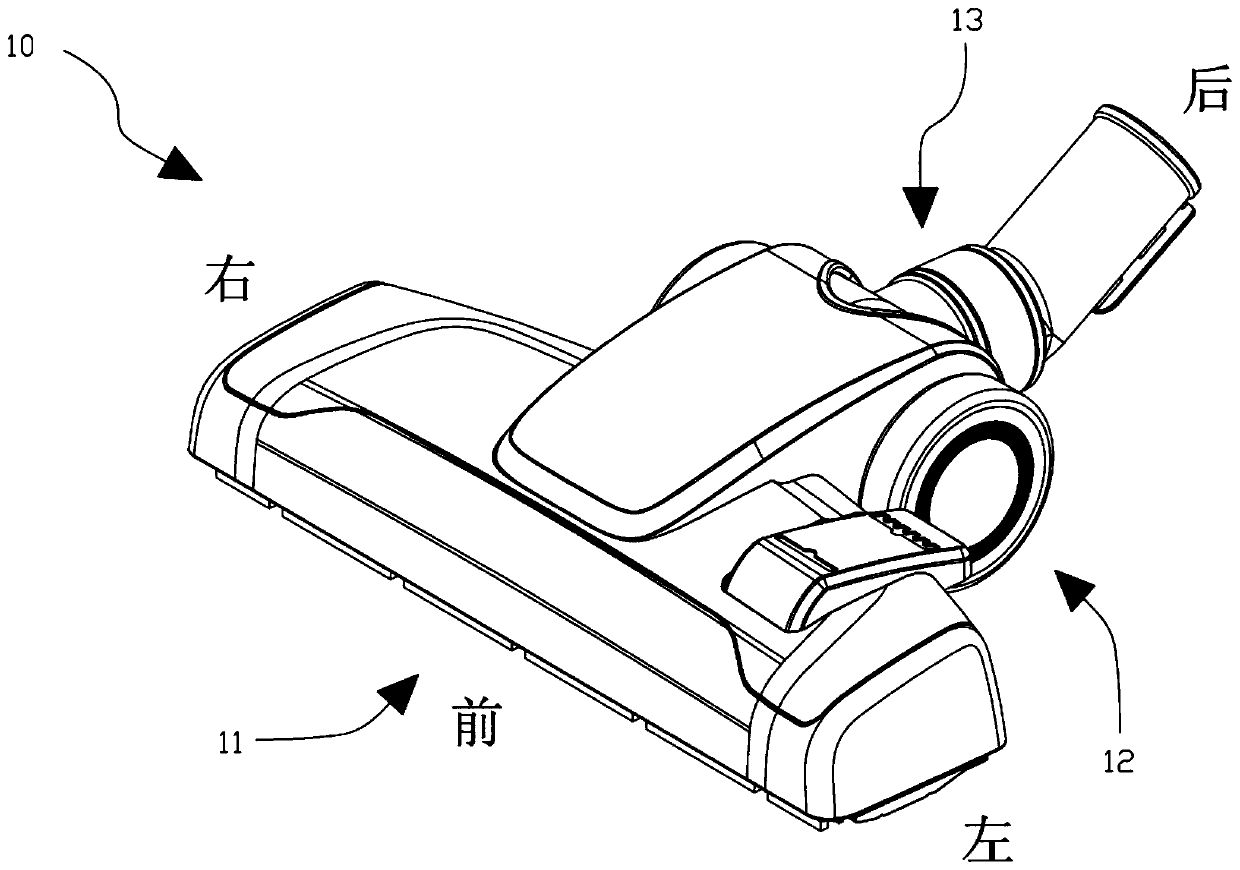

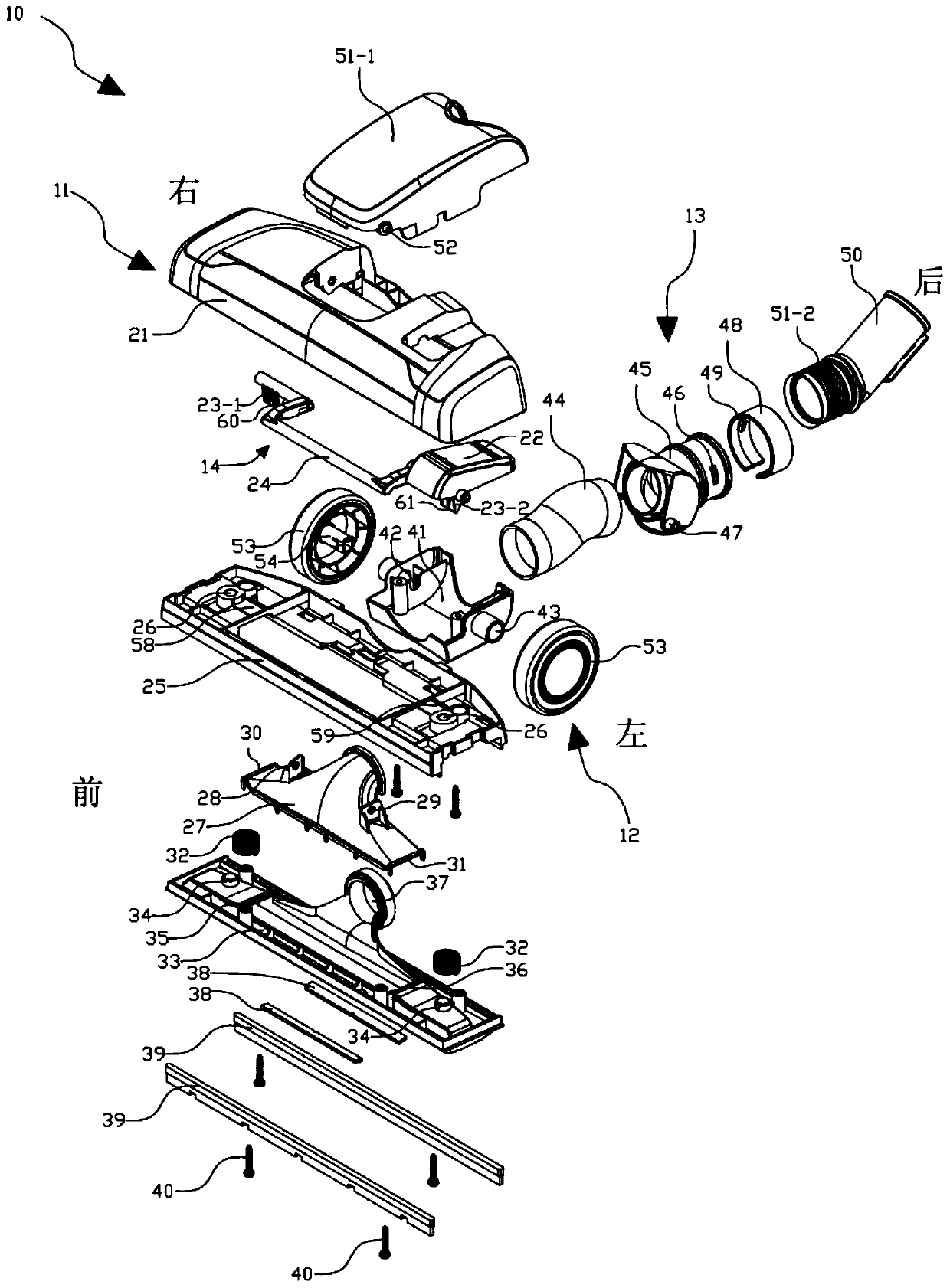

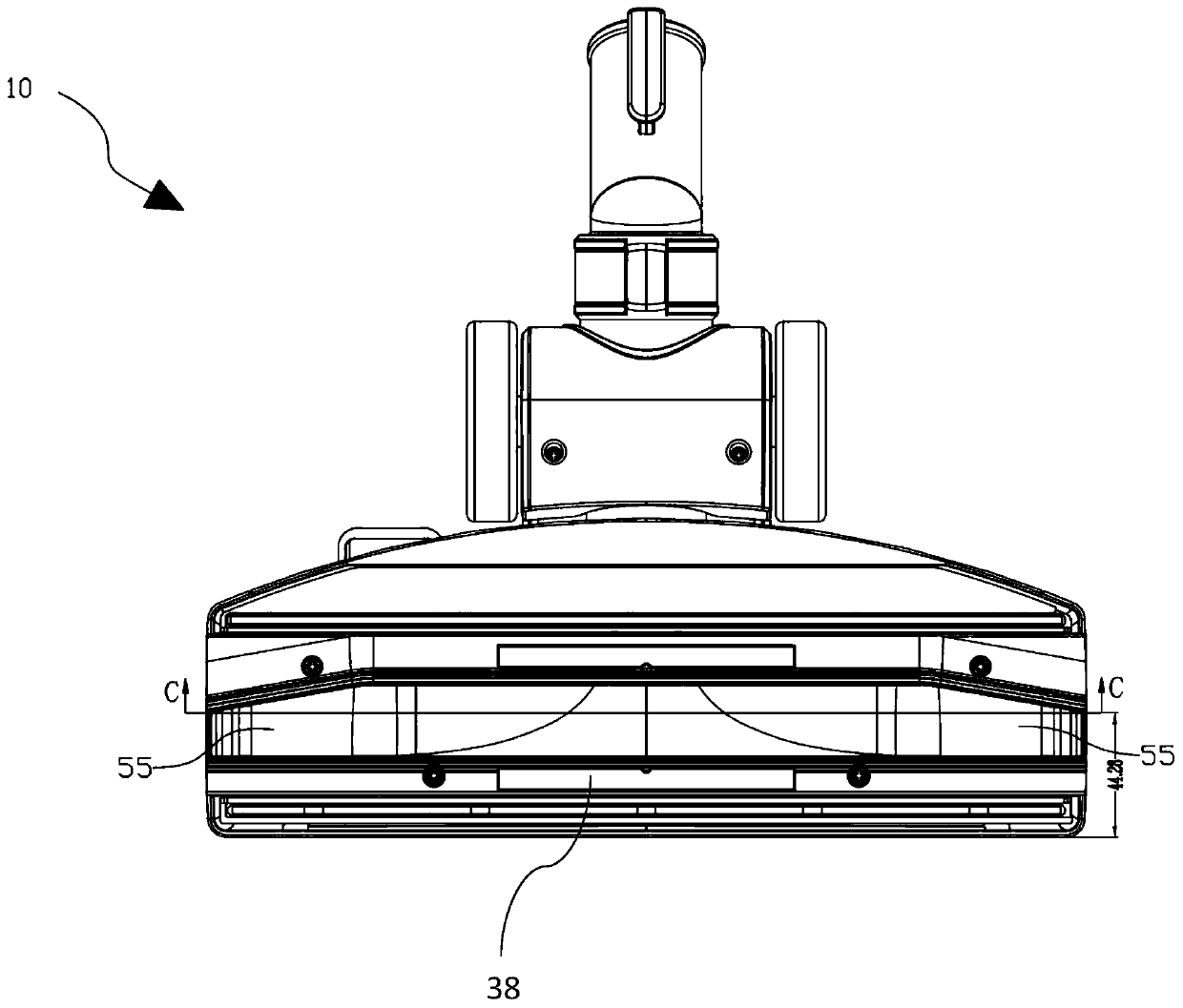

Floor brushes and vacuum cleaners

A floor brush (10) and a vacuum cleaner comprising the floor brush (10). The floor brush (10) is used for cleaning a ground surface in cooperation with an air duct assembly of the vacuum cleaner, and has the following features: a main body component (11); an air duct component (12), comprising a soft tube (44); a soft tube cover plate (51-1) disposed on a top cover (21) and above the soft tube (44), a front end of the soft tube cover plate rotationally connected, by means of a first rotation hinge (52), to an upper portion of an air channel plate (27); a bent tube socket bottom cover (41) located under the location of a connection between the soft tube (44) and a bent tube sleeve (45) and fixedly connected to a rear end of the soft tube cover plate (51-1), the bent tube sleeve (45) being rotationally connected, by means of a second rotation hinge (47), with the bent tube socket bottom cover (41); and a roller wheel component (13). When the floor brush (10) is positioned horizontally and two roller wheels (53) are pressed against the ground surface, the first rotation hinge (52) and the second rotation hinge (47) become parallel to the ground surface. A perpendicular distance between the first rotation hinge (52) to a bottom plate (33) is set as D1, and a perpendicular distance from the second rotation hinge (47) to the bottom plate (33) is set as D2, wherein the first rotation hinge (52) is set higher than the second rotation hinge (47), and D1 = D2 + X, where X is any distance within a range of 4.3 mm to 6.3 mm.

Owner:SUZHOU VACS ELECTRICAL

Wire passing apparatus for increasing tensile force

The invention provides a wire passing apparatus for increasing tensile force and relates to the field of a steel wire unwinding apparatus. The wire passing apparatus comprises a pedestal, a wire passing wheel, a friction wheel, a chain and a friction block; the wire passing wheel and the friction wheel are fixed to the pedestal; the friction block is arranged in the circumferential direction of the friction wheel; the chain is fixed to the upper surface of the friction block; one end of the chain is fixed to the pedestal; the other end of the chain is connected with a spring; one end of the spring is connected with a regulating screw; and the regulating screw is fixed to the pedestal through a regulating screw fixing plate. According to the wire passing apparatus provided by the invention,the friction block is additionally arranged on the circumference of the friction wheel; the friction force of the friction block and the friction wheel is adjustable; and the tensile for intertwininga steel wire is further increased. As the wire passing wheel is fixed, the tensile force is not fluctuating, and the uniformity of the tensile force is guaranteed.

Owner:JIANGSU FUERTE METAL PROD CO LTD

Perforating device

Owner:扬州市邗江科达涂装有限公司

Login Information Synchronization Method, Synchronized and Synchronized Web Server

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Comprehensive off-line test platform for generator rotor insulation measurement device

ActiveCN104007386BWon't jumpSolve the problem of grounding protection false alarmDynamo-electric machine testingMeasurement deviceElectric machine

The invention discloses a comprehensive off-line test platform for a motor rotor insulation measuring device, which includes a rotating test platform and a console connected to the rotating test platform. The rotating test platform includes a motor installed on the rotating test platform, a slip ring shaft, a slip ring and First carbon brush. The slip ring shaft is connected to the drive shaft of the motor, and the slip ring is sleeved on the slip ring shaft and rotates with the slip ring shaft. During the test, the motor reaches the rated speed, and the first carbon brush contacts the slip ring by lifting the brush and outputs an electrical signal. The console includes motor power distribution and control circuit, carbon brush power distribution and control circuit, and oscilloscope. During the test, use the oscilloscope to record waves to confirm that the waveform of the input electrical signal has no clutter, so as to ensure that when the motor reaches the rated speed, the first A carbon brush is always in contact with the slip ring and the first carbon brush does not jump on the surface of the slip ring. After testing, it can be guaranteed that the first carbon brush will not jump on the surface of the slip ring, thereby solving the problem of false alarm of the generator rotor grounding protection.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +1

An air-floating ceramic tile

ActiveCN107572765BSolve the technical problem that rolling is easy to produce obvious rolling marksImprove product qualityGlass transportation apparatusGlass tempering apparatusThin glassExhaust pipe

The invention discloses an air flotation type ceramic tile. The air flotation type ceramic tile comprises a ceramic tile body of a hollow structure, wherein an air inlet connecting hole matched with an air inlet pipe is formed in the lower surface of the ceramic tile body; a plurality of air outlet holes are formed in the upper surface of the ceramic tile body; a plurality of exhaust inlets are formed in the periphery of the air outlet holes; the exhaust inlets are connected with one end of an exhaust pipe arranged in an inner cavity of the ceramic tile body; the other end of the exhaust pipeis connected with an exhaust outlet formed in the lower surface of the ceramic tile body. According to the air flotation type ceramic tile disclosed by the invention, the technical problem in the traditional technology that solar thin glass rolls in a high-temperature state and easily produces an obvious roll mark due to the adoption of roller transport is solved, and the product quality of the solar thin glass is improved.

Owner:YICHANG CSG POLYSILICON CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com