Heating box for cylindrical solid sols

A sol, cylindrical technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as difficulty, expensive glue guns, and the inability of cylindrical solid sols to be extruded normally. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

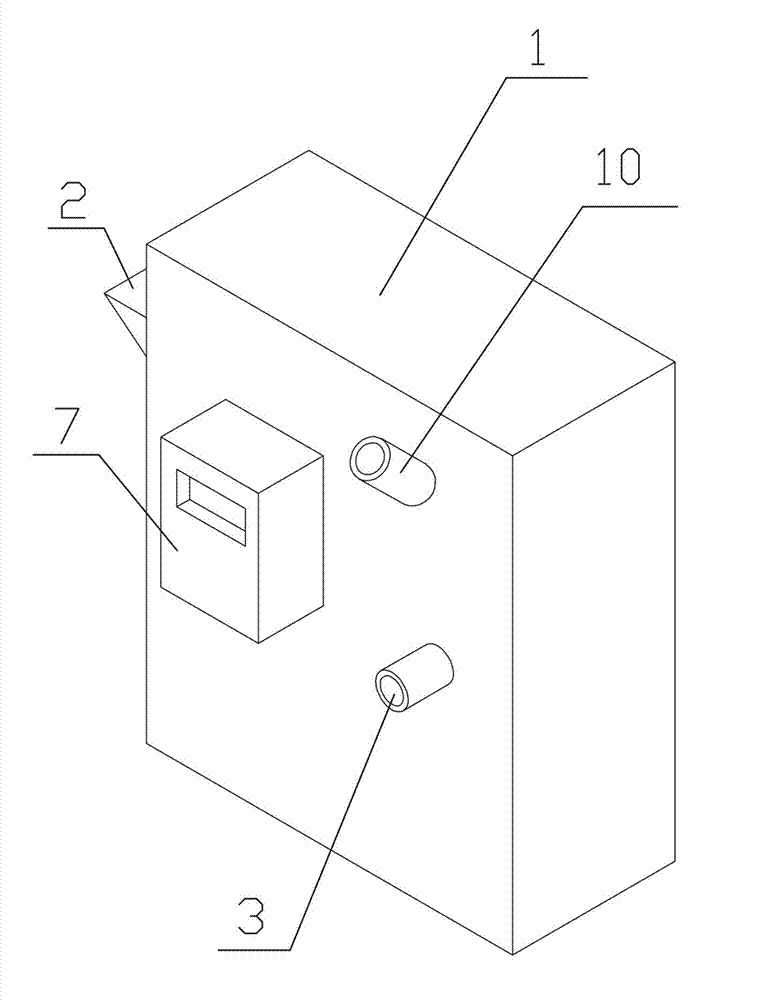

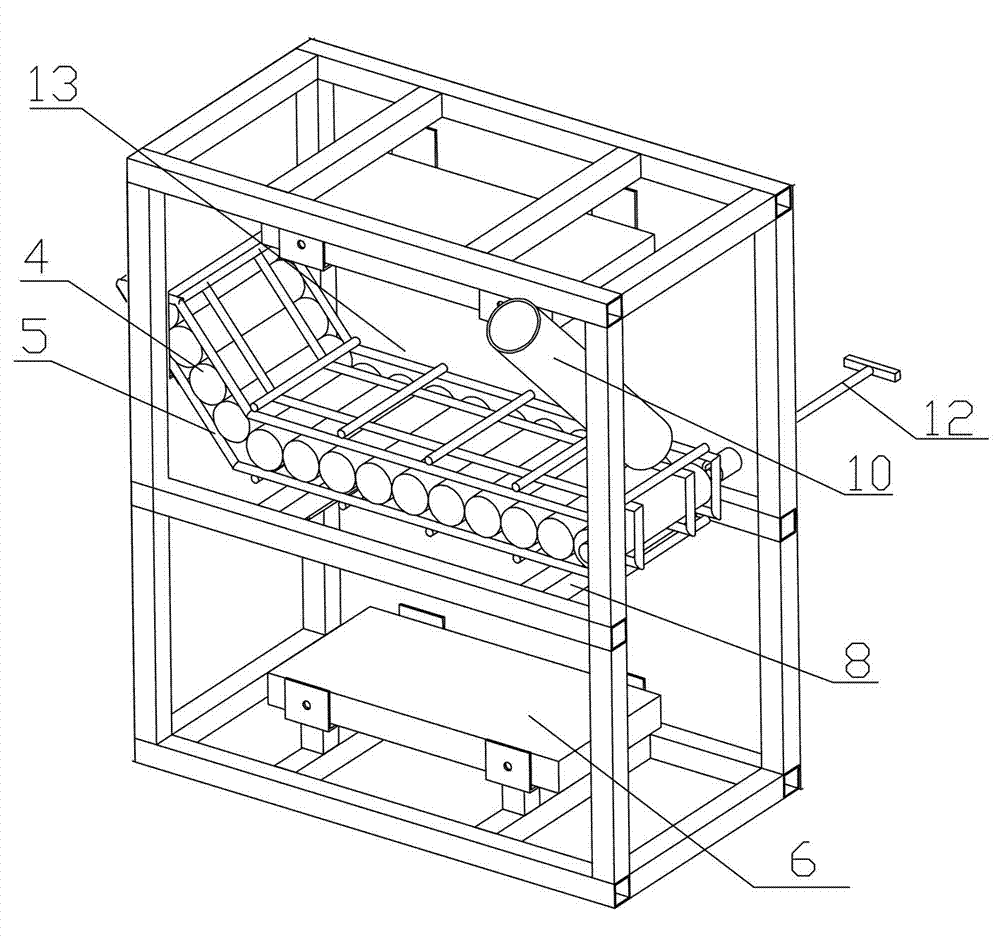

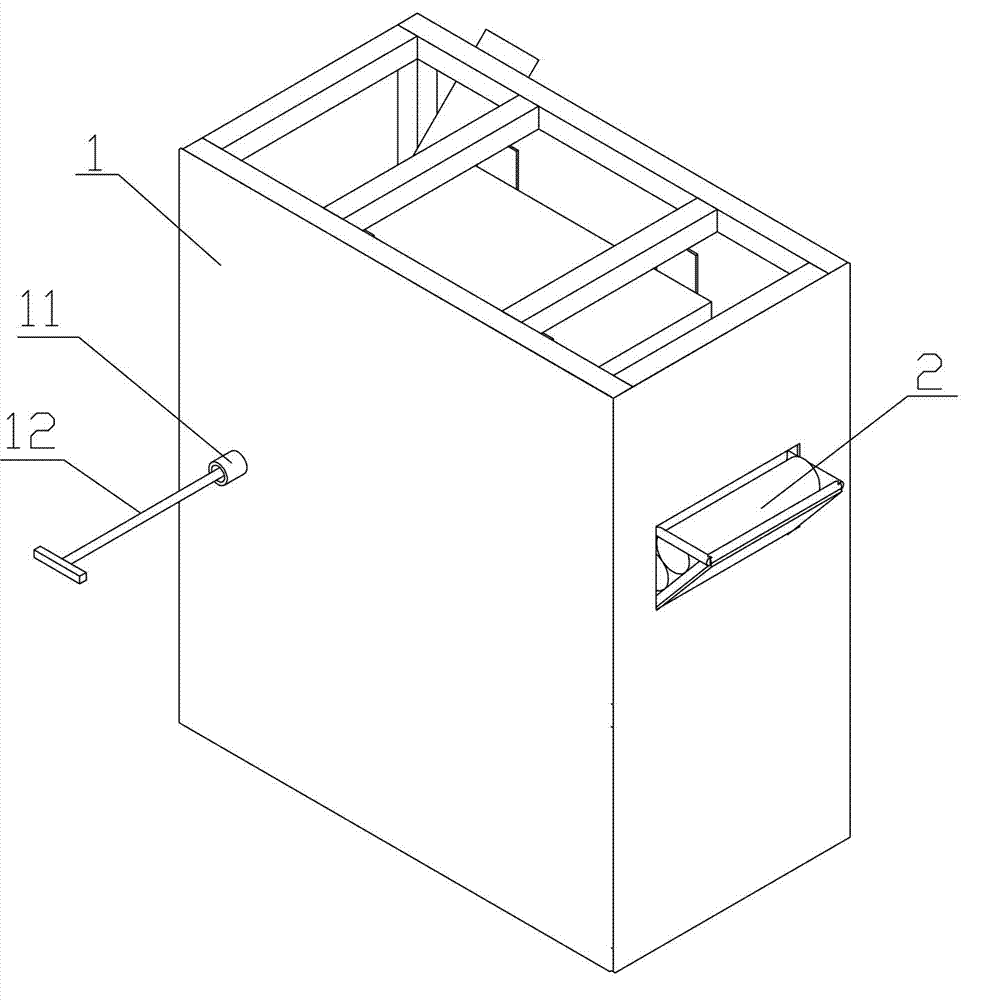

[0037] This example figure 1 As shown, it is a cylindrical solid solution colloidal heating box, which includes a box body 1 with an inner hollow cavity 13, and the main structure of the box body 1 is in the shape of a cuboid.

[0038] The left side wall of the box body 1 is provided with an inlet 2, and the front wall is provided with an outlet 3, and the height of the outlet 3 is lower than that of the inlet 2.

[0039] A support frame 8 arranged horizontally is fixed in the middle of the vertical direction in the hollow cavity 13 , and the upper end of the support frame 8 is fixedly connected with a guide rail 5 for carrying a cylindrical solid solution colloid 4 .

[0040] The left end of the guide rail 5 is arranged at the lower side of the inlet 2 , and the right end is provided with a stopper and is adjacent to the right inner wall of the box body 1 .

[0041] The guide rail 5 extends obliquely downward from the left end and then extends horizontally to the right end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com