Extrusion device and 3D printer

A technology of extrusion device and adjustment mechanism, which is applied in the field of 3D printing, can solve the problems such as obstacles to the development of multi-nozzle 3D printing technology, the volume is difficult to meet the demand, and the extrusion mechanism is large in size, so as to achieve high-speed and high-precision multi-nozzle 3D printing, The effect of increasing the speed and reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

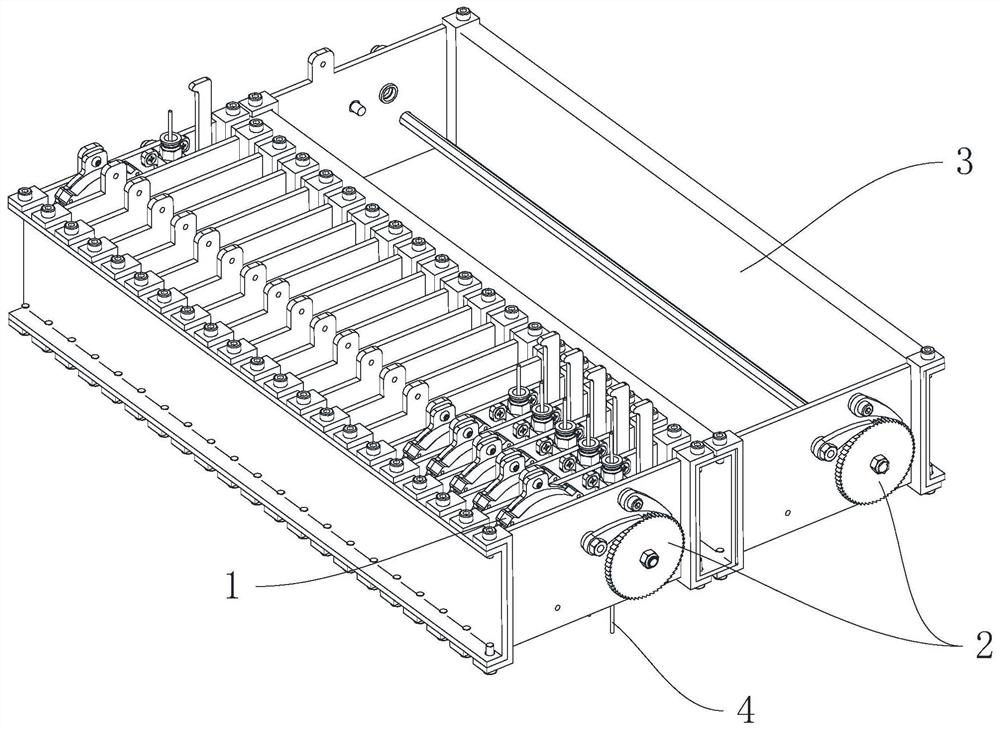

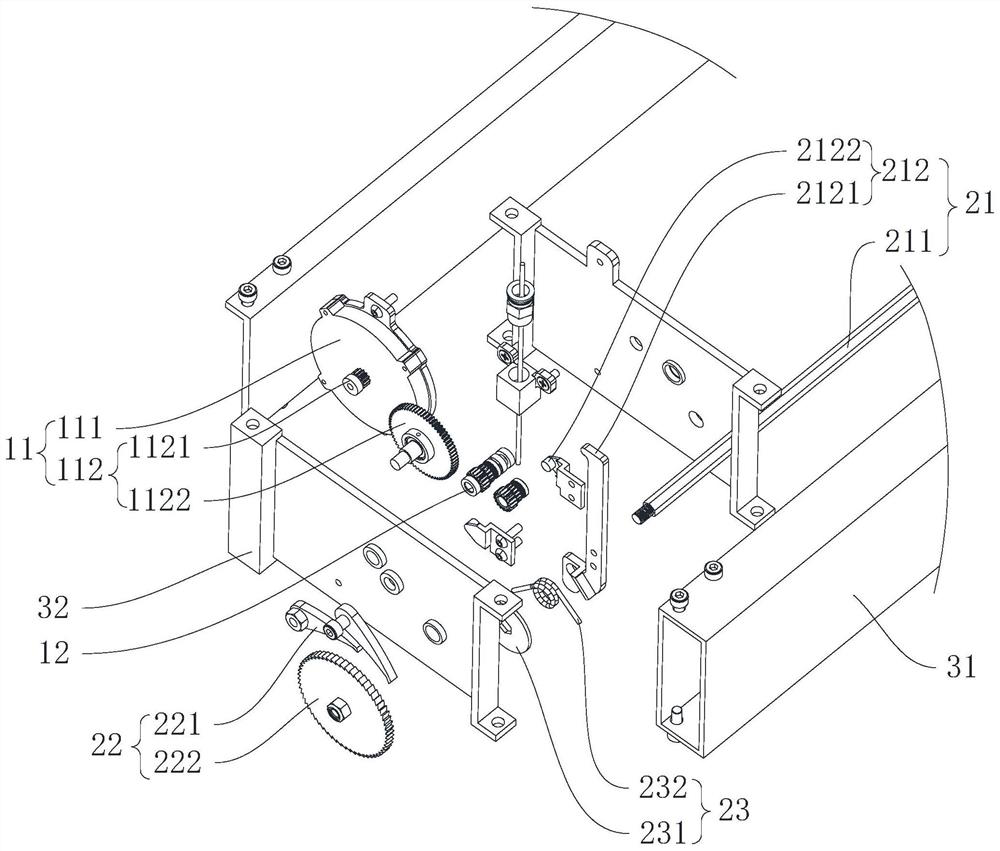

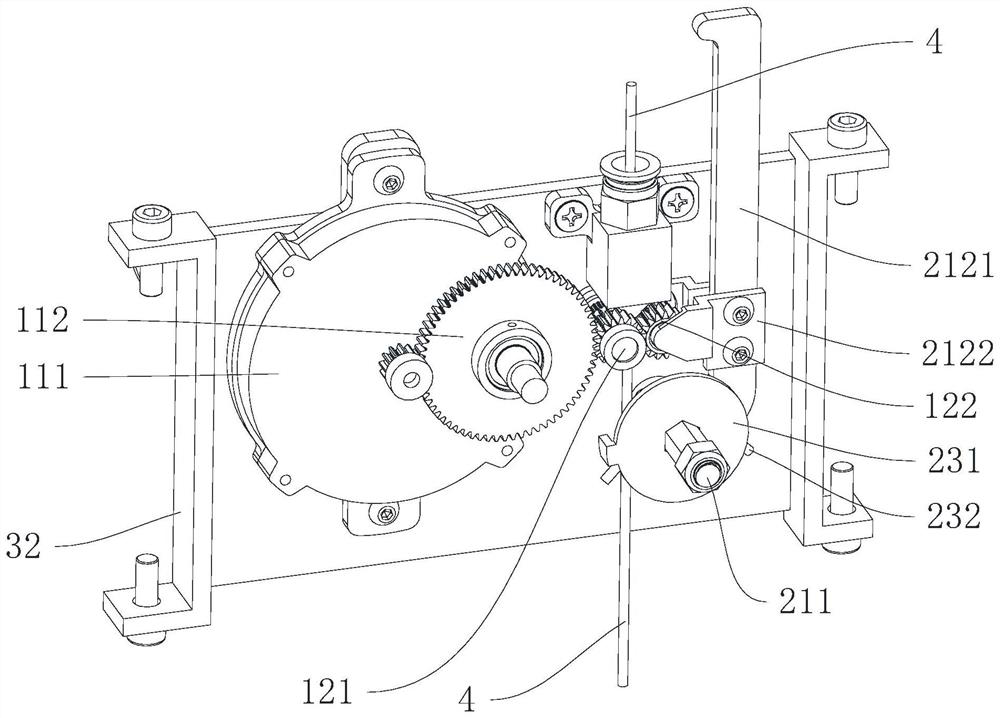

[0031] refer to Figure 1-Figure 3 The specific structure of the extrusion device of the embodiment of the present invention will be described.

[0032] Such as figure 1 An embodiment of an extrusion device is shown, which includes a plurality of extrusion mechanisms 1 and adjustment mechanisms 2 distributed in arrays. The extrusion mechanism 1 includes a driving assembly 11 and a feeding assembly 12 , the feeding assembly 12 is connected to the output end of the driving assembly 11 , the feeding assembly 12 is used for extruding consumables 4 , and the driving assembly 11 includes an ultra-thin motor 111 . The adjusting mechanism 2 is connected with a plurality of feeding components 12 , and the adjusting mechanism 2 is used to adjust the pressing force of the feeding components 12 on the consumables 4 .

[0033]Because the feeding assembly 12 generally has a smaller volume, the main driving structure of the driving assembly 11 can significantly reduce the volume of the ext...

Embodiment 2

[0061] The invention also discloses a 3D printer, which includes an extrusion device. Wherein, the extruding device is the extruding device described in embodiment 1, thus having the advantages described in any one of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com