Handheld cutting machine and grooving machine

A cutting machine and slotting machine technology, applied in stone processing tools, working accessories, manufacturing tools, etc., can solve the problems of affecting heat dissipation effect, unreasonable fan design, short service life, etc., and achieve reasonable air inlet and outlet, Improve the effect of ventilation and heat dissipation, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

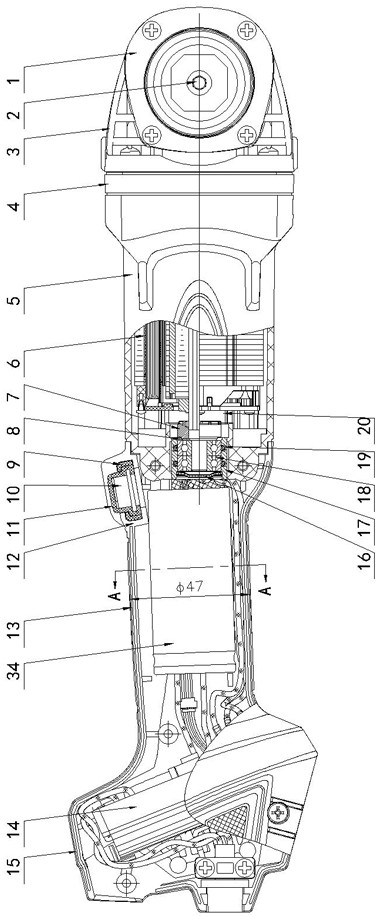

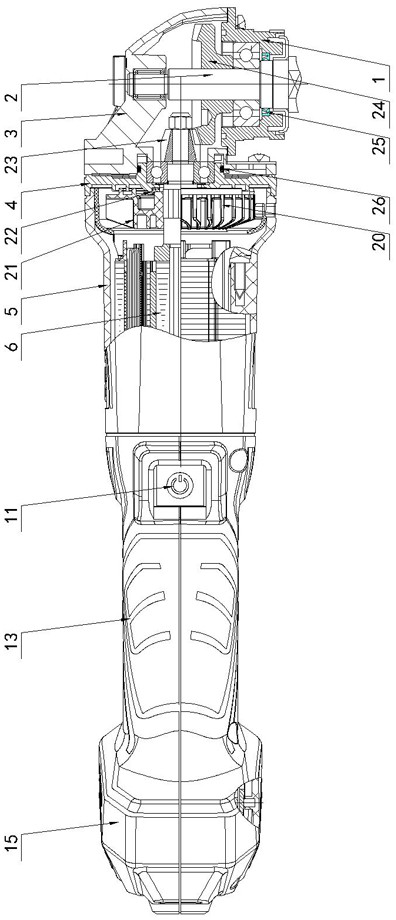

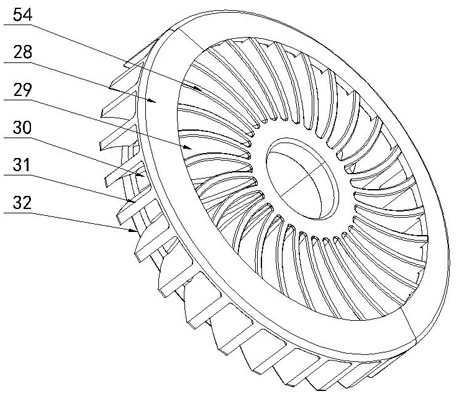

[0028] Figure 1 to Figure 7As shown, the present invention creates a specific embodiment of a hand-held cutting machine and slotting machine, which includes a main machine and a cutting device, and the main machine includes a rear handle 13, a casing 5, a brushless motor 6, an intermediate cover 4, and a transmission mechanism , the motor shaft 20 is fixed with a fan 21, the rear side wall of the casing 5 is provided with a metal bushing 17 connected by injection molding, and the metal bushing 17 is provided with a double bearing 18 through a first sealing ring 19 structure, the front end of the motor shaft 20 is rotatably set on the middle cover 4 through a single bearing structure, the rear end of the motor shaft 20 is rotatably set on the metal bush 17 through a double bearing 18 structure, and the rear end of the metal bush 17 The rubber dustproof cover 16 that is provided with seal fit is fixed on the motor shaft 20 with the dustproof and waterproof plastic ring 7 positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com