Carbon fiber brush

A carbon fiber and conductive carbon fiber technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of high noise, easy to jump, wear, etc., to reduce friction loss, prolong service life, and not easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

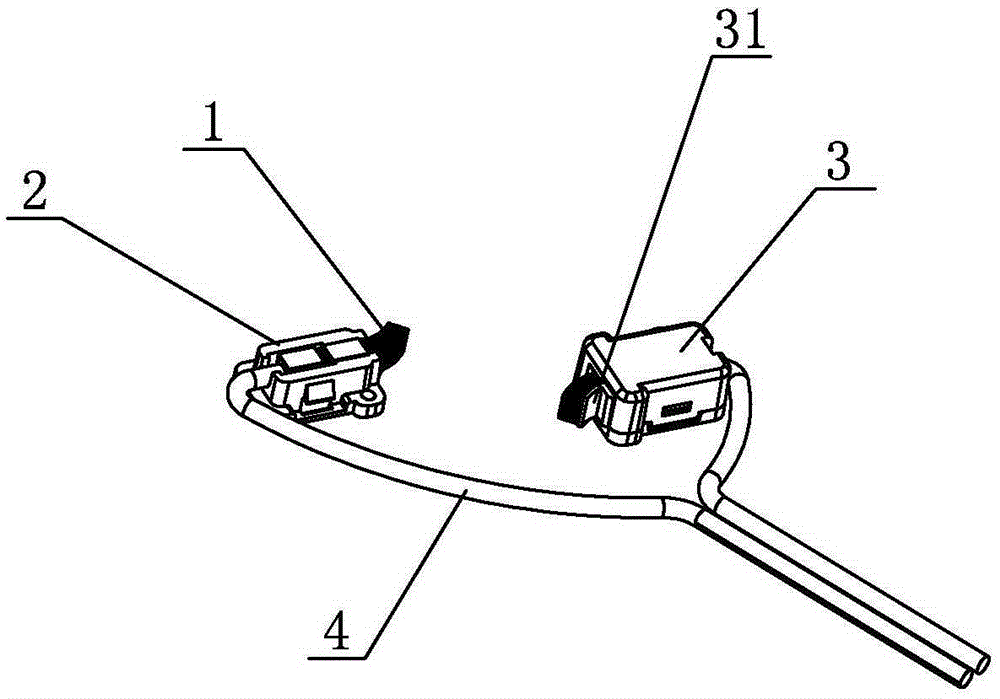

[0015] refer to figure 1 , the present invention provides a carbon fiber brush, comprising a brush holder 2, the brush holder 2 is provided with bristles 1 made of conductive carbon fibers, the brush holder 2 is provided with a casing 3, and the casing 3 An arc-shaped limiting edge 31 is arranged on the top, and one end of the bristle 1 protrudes from the outlet of the limiting edge 31 to the brush holder 2 , and the other end is connected to a wire 4 .

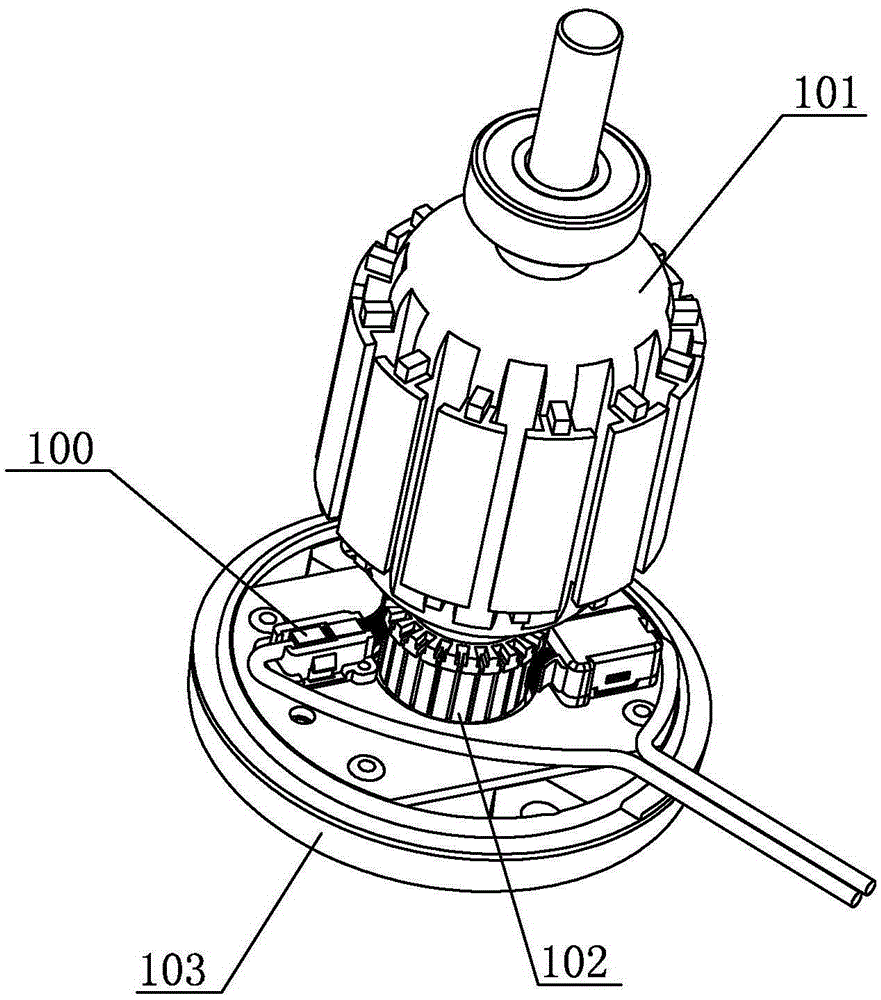

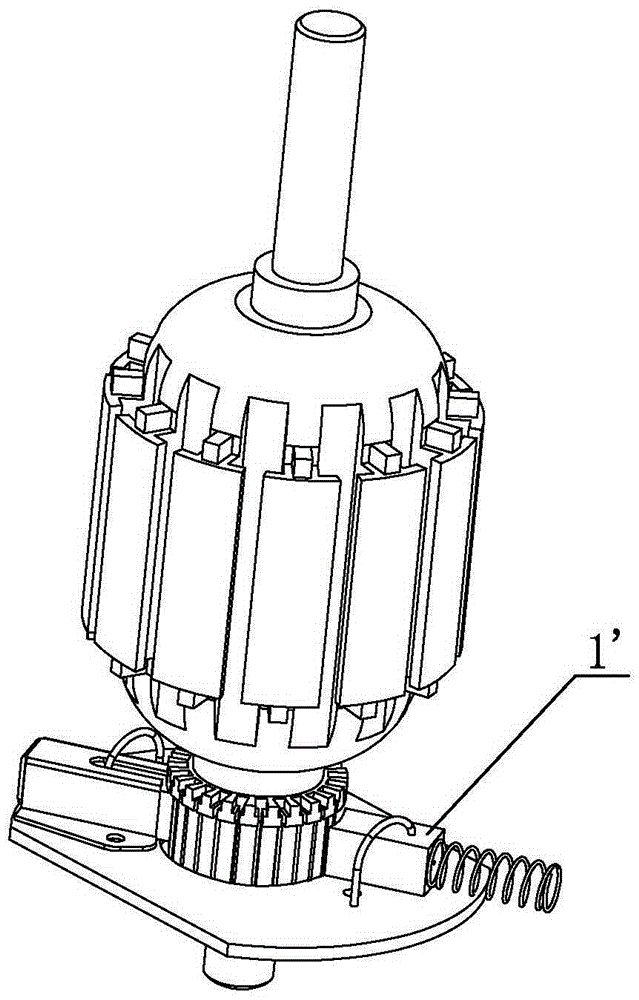

[0016] refer to figure 2 , is a schematic diagram of applying the carbon fiber brush of the present invention to a motor, the motor includes a rotor 101 , a stator (not shown in the figure) and a motor housing 103 , and a commutator 102 is arranged on the rotor 101 . The carbon fiber brush 100 is fixed on the motor housing 103 through the brush holder 2, the bristles 1 of the carbon fiber brush 100 are close to the commutator 102, and the limit side 31 is located outside the bristles 1, so that the bristles 1 are in contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com