Perforating device

A drilling device and blind hole technology, which is applied in boring/drilling, drilling/drilling equipment, and drilling templates for workpieces, etc., can solve the problems of inaccurate positioning and high cost of positioning devices, and achieve good results. Use effect, good positioning, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

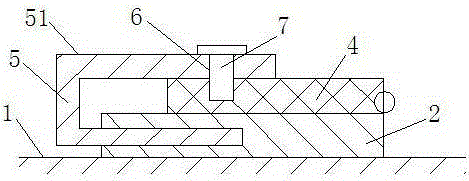

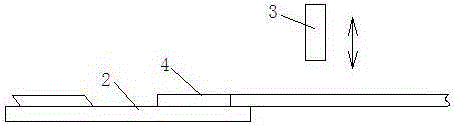

[0017] The present invention includes a frame 1 and a positioning guide rail 2 arranged on the frame 1, the frame 1 is provided with a tool 3 on the upper part of the positioning guide rail 2;

[0018] The positioning guide rail 2 is provided with hinges 4 at intervals, and the hinges 4 can interfere with the positioning guide rail 2 when rotating.

[0019] The side of the positioning guide rail 2 is provided with a blind hole inwardly, and a positioning plate 5 with a U-shaped cross section is provided to penetrate into the blind hole. The upper plate 51 of the positioning plate 5 faces the positioning guide rail 2, and the upper plate The gap formed between 51 and the positioning guide rail 2 accommodates the hinge 4 .

[0020] An elastic layer is provided on the inner wall of the upper plate 51 .

[0021] A positioning hole 6 is provided at the corresponding position of the upper plate 51 and the hinge 4 , and a positioning member 7 is provided to pass through the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com