Full-automatic reinforcing steel bar cut-to-length shearing device

A fixed-length cutting and fully automatic technology, applied in the field of steel bar processing, can solve the problems of edge wear, material waste, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

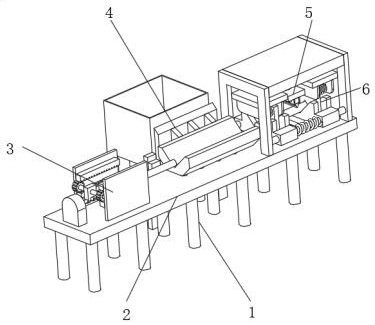

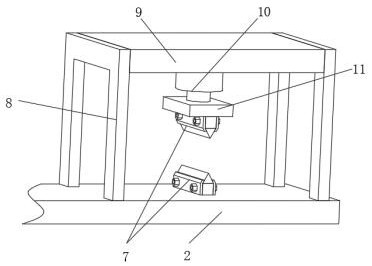

[0038] A fully automatic steel bar fixed-length shearing device, such as Figure 1-4 As shown, it includes a workbench 2 fixed on the ground by a leg-1, and the top outer wall of the workbench 2 is provided with a feeding mechanism 3, a feeding mechanism 4 and a shearing mechanism 5 in sequence, and the shearing mechanism 5 includes Two sets of cutter assemblies 7 and hydraulic cylinders 10, the top outer wall of the workbench 2 is fixed with two gantry frames 8 by bolts, the top outer wall of the gantry frame 8 is fixed with a top plate 9 by bolts, and the hydraulic cylinder 10 is fixed on the top plate 9 by bolts On the bottom outer wall of the hydraulic cylinder 10, the outer wall of the telescopic end of the hydraulic cylinder 10 is fixed with a lifting frame 11 by bolts, wherein one set of cutter assemblies 7 is fixedly installed on the bottom outer wall of the lifting frame 11, and the other set of cutter assemblies 7 is fixed on the bottom outer wall of the lifting frame...

Embodiment 2

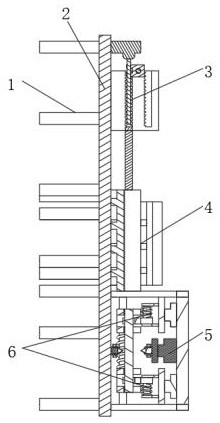

[0042] A fully automatic steel bar fixed-length shearing device, such as figure 1 , 7 As shown, in order to solve the safety problem; this embodiment makes the following improvements on the basis of Embodiment 1: the top outer wall of the workbench 2 is provided with two sets of fixed buffer mechanisms 6 that are symmetrical to the shearing mechanism 5, and the fixed Buffering mechanism 6 comprises fixed claw one 35 and fixed claw two 36, and the inner wall of described fixed claw one 35 and fixed claw two 36 is all provided with V-shaped groove 34, and the opposite side outer walls of two described gantry frames 8 are fixed by bolts Slide bar one 32 is arranged, and described fixed claw one 35 is slidably connected on the outer wall of slide bar one 32, and the opposite side outer wall of two described fixed claw one 35 is welded with spring one 33, and the bottom outer wall of described top plate 9 passes through Cylinder 40 is fixed by bolts, and the piston connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com