Three-section type overhead combustion chamber carbon black cracking furnace

A combustion chamber carbon black, three-stage technology, applied in the direction of fibrous filler, etc., can solve the problems of low output of single furnace, large waste of energy consumption and natural gas raw materials, low quality of carbon black products, etc., to achieve stable product quality, conversion The effect of long cycle time and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

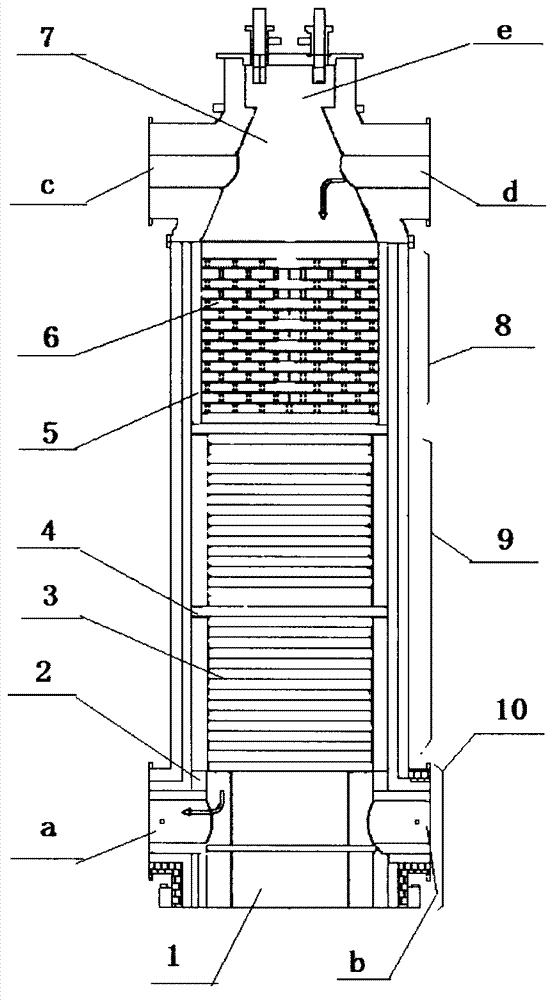

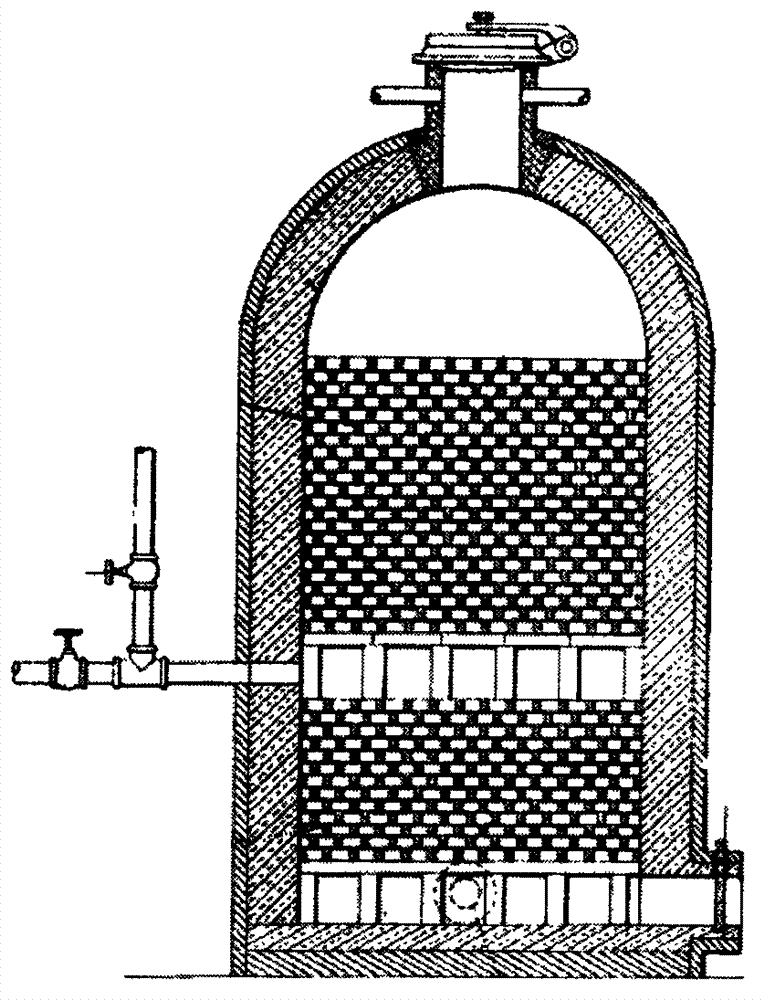

[0021] as attached figure 1 As shown, the vertical furnace body includes a heat exchange heat storage section 8, a heat storage cracking section 9, and a support collection section 10 from top to bottom. There is a top cone cavity 7 in the upper top of the furnace body, and the top cone cavity 7 corresponds to the explosion-proof connection outside the furnace body. Nozzle c, natural gas inlet and flushing nozzle d, burner nozzle e is installed on the top of cone cavity 7, lining wall 5 and upper wall 6 are installed in heat exchange and heat storage section 8, and lower wall is installed in heat storage and cracking section 9 3 and the lower interlayer 4, the tower base 1 and the bottom neck 2 are installed in the support collection section 10, and at the same time, the support collection section 10 is connected to the carbon black flue gas outlet a and the heat storage flue gas outlet b.

[0022] Square heat-resistant bricks are built on the inner wall of tower base 1, ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com