Anti-spill detergent storage device and washing machine

A detergent storage and anti-overflow technology, applied in the field of washing machines, can solve the problems of damage to the automatic feeding system, easy overflow, damage, etc., and achieve better user experience, reasonable and normal internal liquid level, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

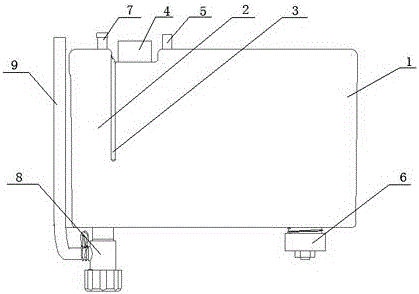

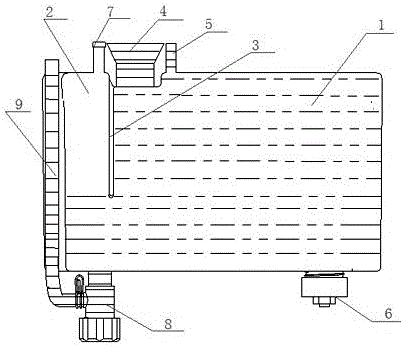

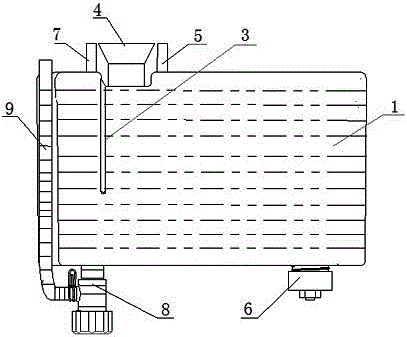

[0015] Such as figure 1 The overall structure diagram of the detergent storage device, which is a detergent storage device used in the automatic feeding system of the washing machine, is mainly used to hold liquid detergent. The present invention has a main chamber 1 on the right side and a buffer chamber 2 on the left side, the upper part is separated by a partition 3, and the bottom is communicated to form a structure of a communicator. A detergent addition port 4 and a ventilation hole 5 are provided on the top of the main chamber 1 for adding detergent and air pressure balance in the main chamber, respectively. A liquid level sensor 6 is provided at the bottom of the main storage chamber 1 (since the bottom of the main storage chamber 1 communicates with the buffer chamber 2 , it is also the bottom of the entire storage device). The preferred liquid level sensor 6 adopts a buoyancy slider type liquid level sensor, which can sensitively sense liquid level changes.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com