Process for detecting self-discharge of lithium batteries

A screening method and lithium battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as low reliability and decreased test accuracy, and achieve the effect of prolonging battery life and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Pick out the batteries with abnormal self-discharge rate from the 3.2V10Ah batteries that are ready to be assembled as 48V10Ah electric bicycle battery packs.

[0023] A screening method for lithium battery self-discharge, specifically comprising the following steps:

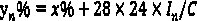

[0024] First the standard lithium battery 3 of the same model and the lithium battery 4 to be tested are fully charged, connected in parallel, and left standing in the workshop for 40 hours; the monthly self-discharge rate of the known selected standard lithium battery 3 is 3%, and the self-discharge current It is 0.45mA; select milliampere meter 1 (range 2mA, accuracy 0.001mA) to connect with wire 2 and measure the current flowing from the standard lithium battery to the lithium battery to be tested, and calculate the inflow current of each lithium battery to be tested.

[0025] The lithium battery to be tested with an inflow current of 0.3mA is calculated to have a monthly self-discharge rate of 5%, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com