Oil conservator structure of transformer

An oil conservator and transformer technology, applied in the field of transformer parts, can solve the problems of inconvenient wiring, long distance of the oil tank cover, etc., and achieve the effect of facilitating on-site wiring and reducing wiring height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

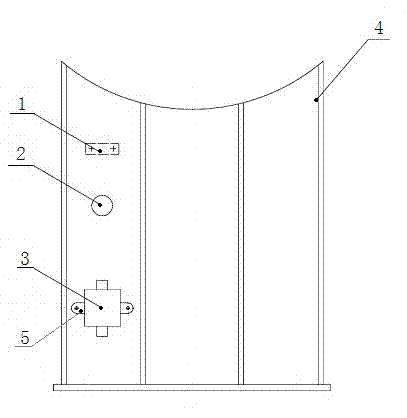

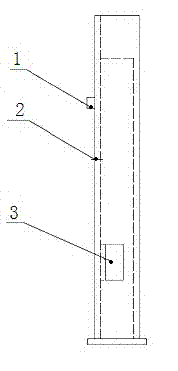

[0011] The present invention includes an oil conservator 4, the foot of the oil conservator 4 is provided with a cable transfer junction box 3, and the cable transfer junction box 3 is fixed on the base of the oil conservator 4 through a connector 5.

[0012] In order to prevent rainwater, the cable transfer junction box 3 is arranged inside the foot of the oil conservator 4, generally 100-200mm away from the ground.

[0013] A plurality of wire clips 1 are welded at appropriate positions on the oil conservator 4 cabinets for fixing the cables of the oil level gauge. An opening 2 is provided in the vicinity of the wire clamp 1 to facilitate the entry of cables from the outside to the inside.

[0014] In the present invention, a cable transfer junction box 3 is added to the cabinet foot of the oil storage cabinet 4, and the oil level gauge is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com