An intelligent and quick evaluation method for the insulation reliability of xlpe cable terminals

A cable termination and reliability technology, applied in the field of intelligent and quick evaluation of XLPE cable termination insulation reliability. The effect of explosion and improved operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

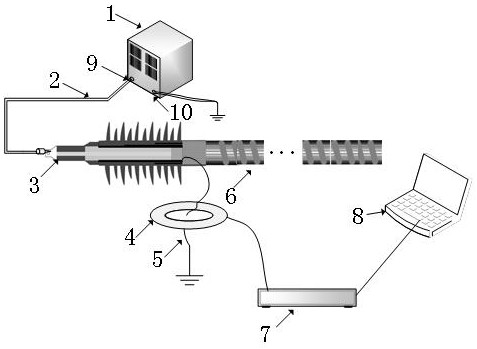

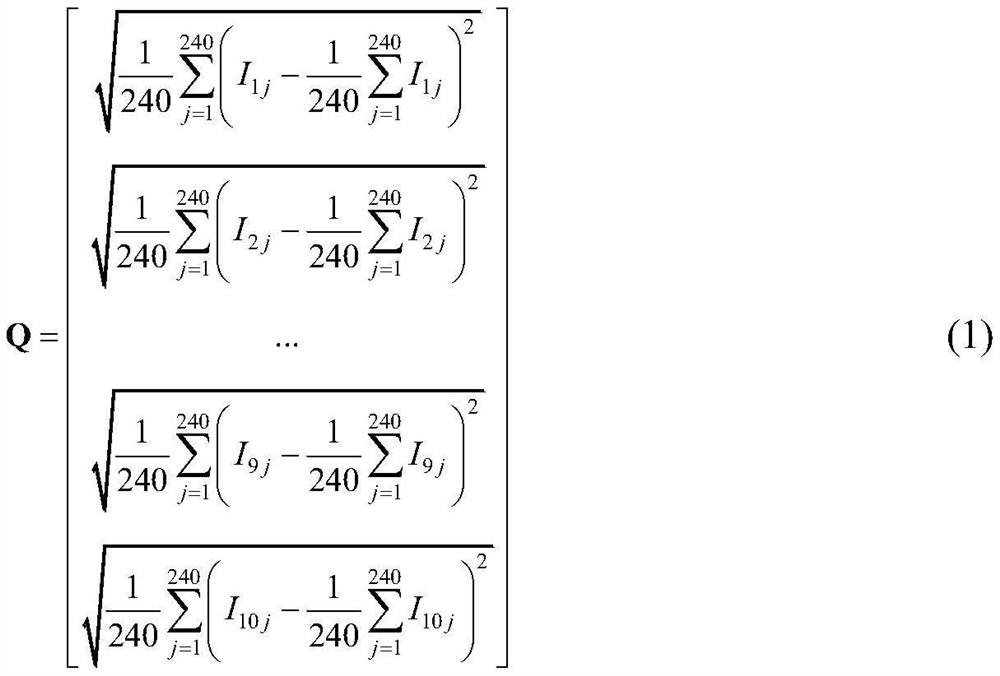

[0027] according to figure 1 Cable leakage current test platform wiring diagram, the specific calculation steps of the present invention are as follows:

[0028] Step 1: Build a cable leakage current test platform

[0029] Connect the No. 1 port 9 of the high-frequency voltage source 1 to the copper terminal 3 of the XLPE cable terminal 6 through the high-voltage test line 2, the No. 2 port 10 is grounded, and the ground wire 5 of the XLPE cable terminal 6 passes through the high-frequency current transformer 4, The high-frequency current transformer 4 is connected to the data collector 7, and the data collector 7 is connected to the host computer 8, and the rated voltage U is applied to the XLPE cable terminal 6, and the leakage current value I is recorded by the host computer 8 n ;

[0030] Step 2: Set the collection cycle

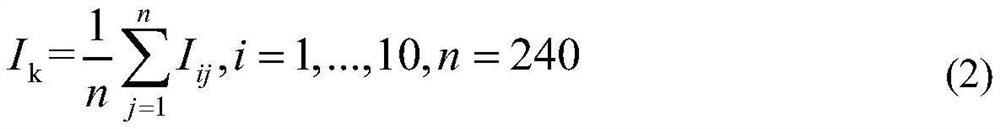

[0031] Data collector 7 collects current data every 5s, and each round of collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com