Wafer level packaging method for image sensor

A wafer-level packaging and image sensor technology, applied in the semiconductor field, can solve the problems of low process yield and increased production cost of image sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

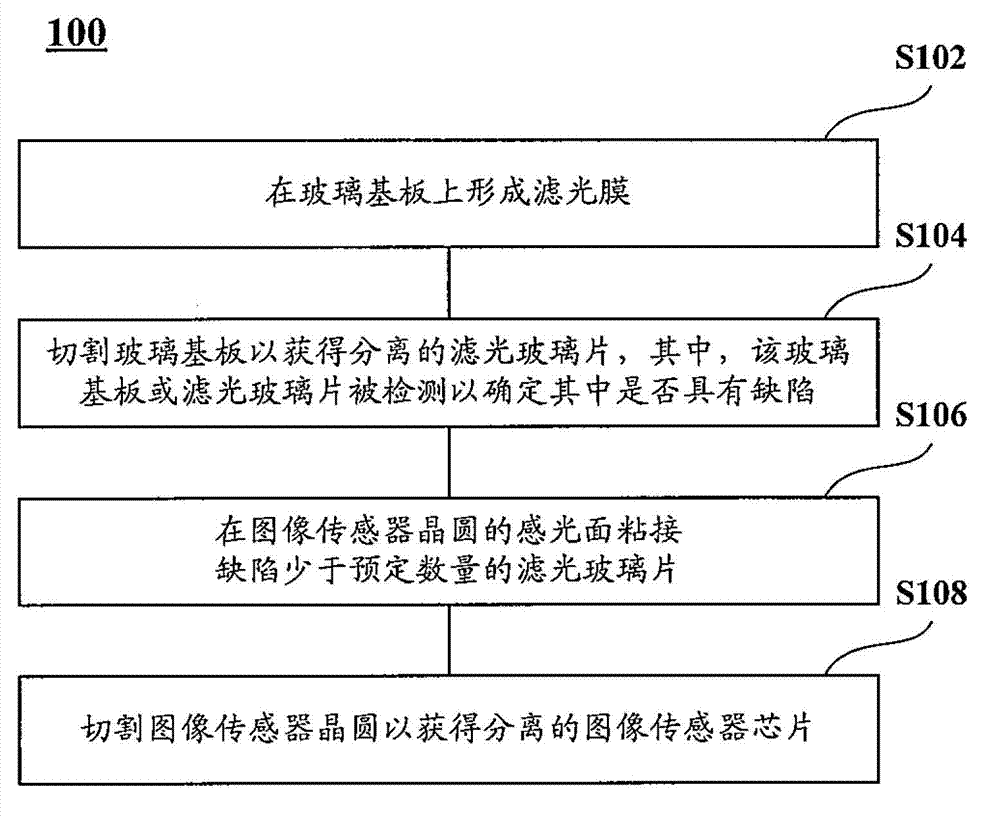

[0026] figure 2 A flow of a wafer-level packaging method 100 for an image sensor according to an embodiment of the present invention is shown.

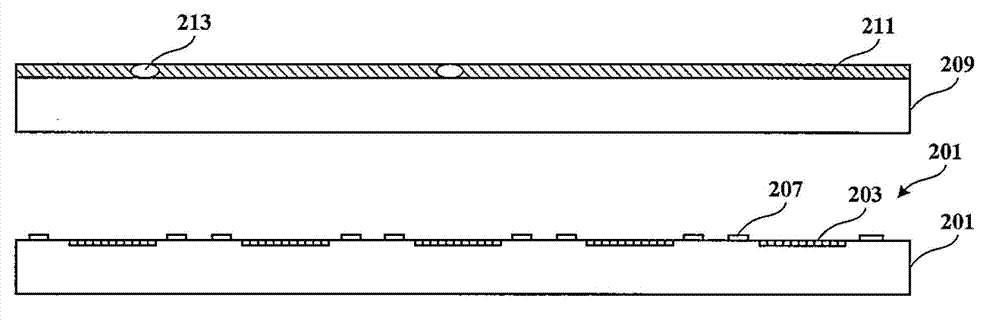

[0027] Such as figure 2 As shown, the packaging method 100 includes: performing step S102, forming a filter film on a glass substrate; performing step S104, cutting the glass substrate to obtain a separate filter glass, wherein the glass substrate or filter glass is detected To determine whether there is a defect; Execute step S106, bond the filter glass with defects less than a predetermined number on the photosensitive surface of the image sensor wafer; Execute step S108, cut the image sensor wafer to obtain separated image sensor chips.

[0028] It can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com