Full-automatic production equipment for electronic element

A technology for production equipment and electronic components, applied in the field of automatic production equipment for electronic components, can solve the problems of inconvenient production, low production efficiency, and low product quality, and achieve high production efficiency, good product quality, and simple and scientific structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

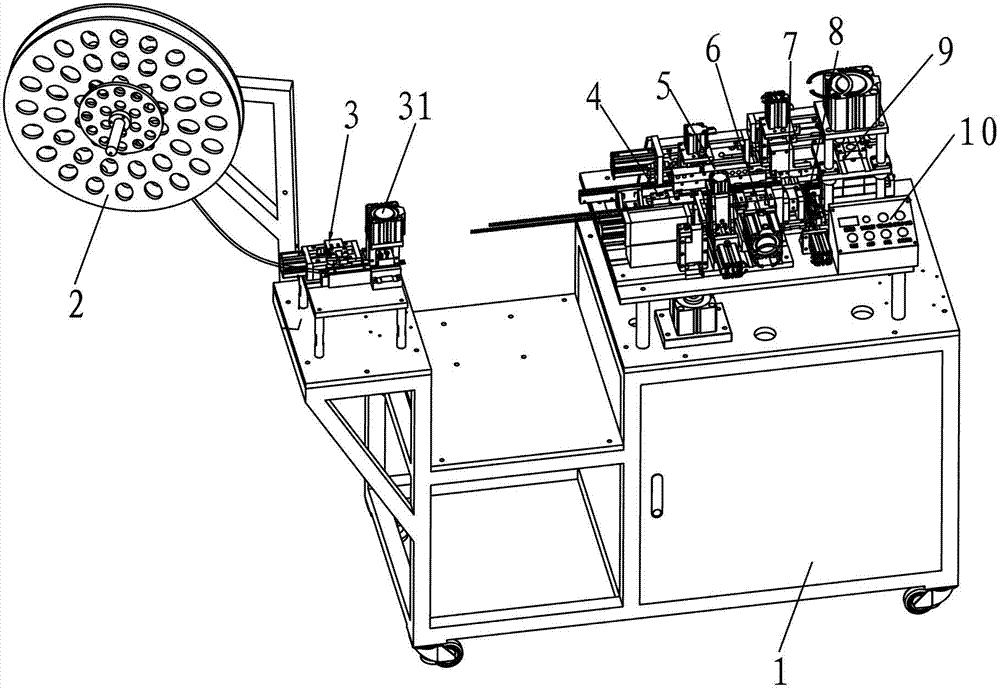

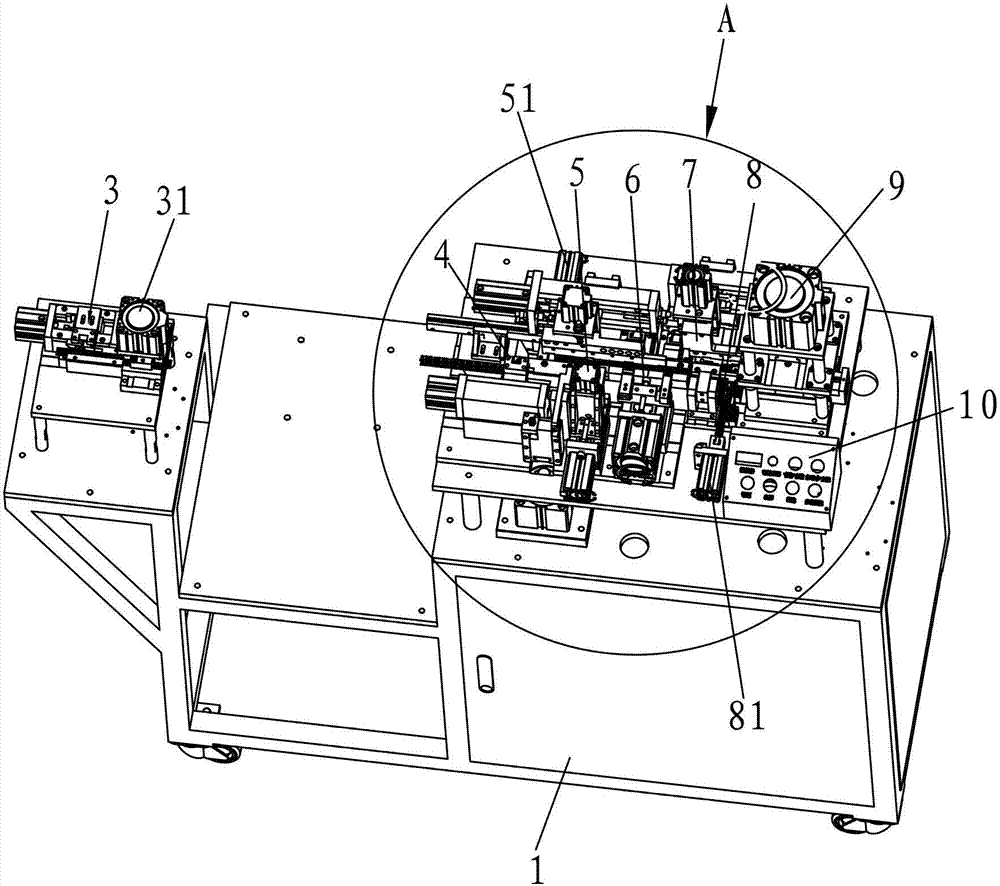

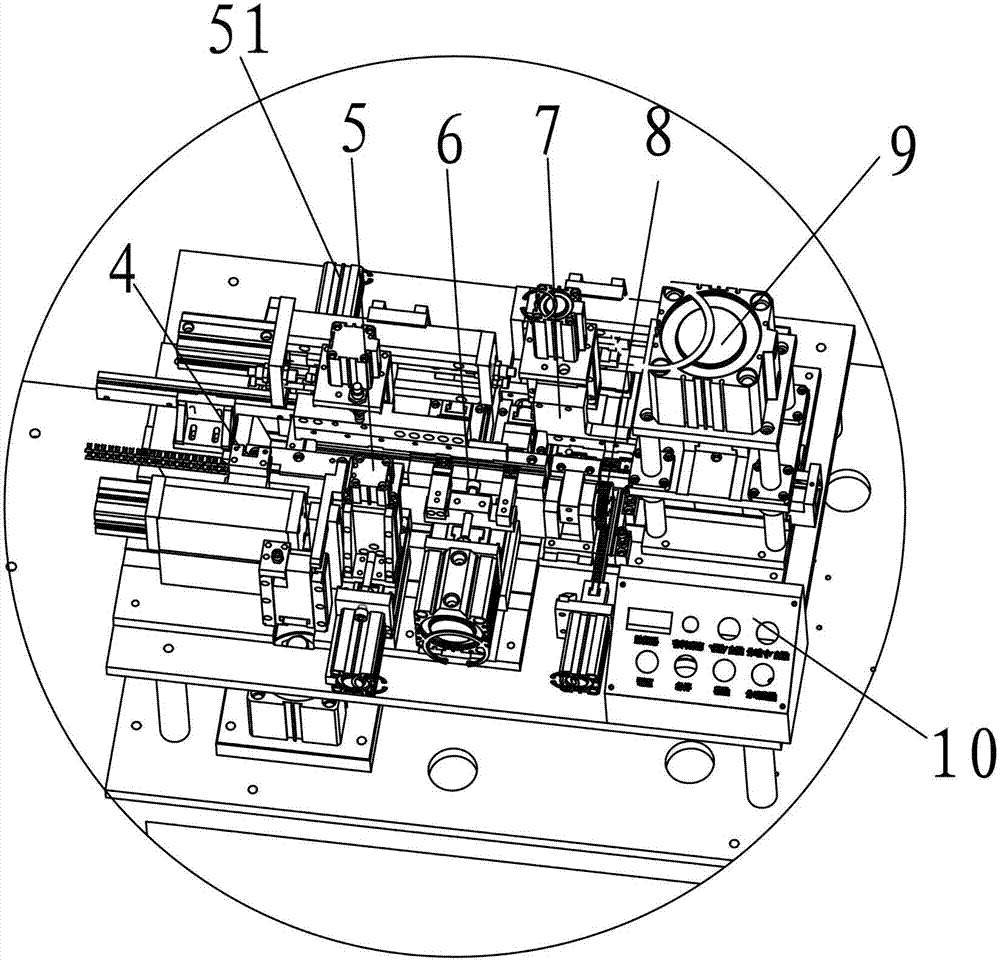

[0015] See Figure 1 to Figure 5 As shown: the present invention includes a frame body 1, a material tray 2, a slitting device 3, a terminal feeding device 4, a terminal cutting device 5, a terminal insertion device 6, a primary pre-bending shaping device 7, a 180° turning device 8, and a secondary Pre-bending, shaping and cutting device 9, one side of the frame body 1 is provided with a material tray 2, a slitting device 3, and the upper end surface of the frame body 1 is sequentially provided with a terminal sending device 4, a terminal cutting device 5, a terminal insertion device 6, The first-level pre-bending and shaping device 7, the 180° turning device 8, the second-level pre-bending, shaping, and cutting device 9, the upper end of the frame body 1 is also equipped with a controller 10 and a main body feeding port 51, and the controller 10 controls the whole machine Work.

[0016] The slitting device 3 is driven by a slitting cylinder 31 .

[0017] The 180° overturnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com