Patents

Literature

37results about How to "Simple and scientific structure design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

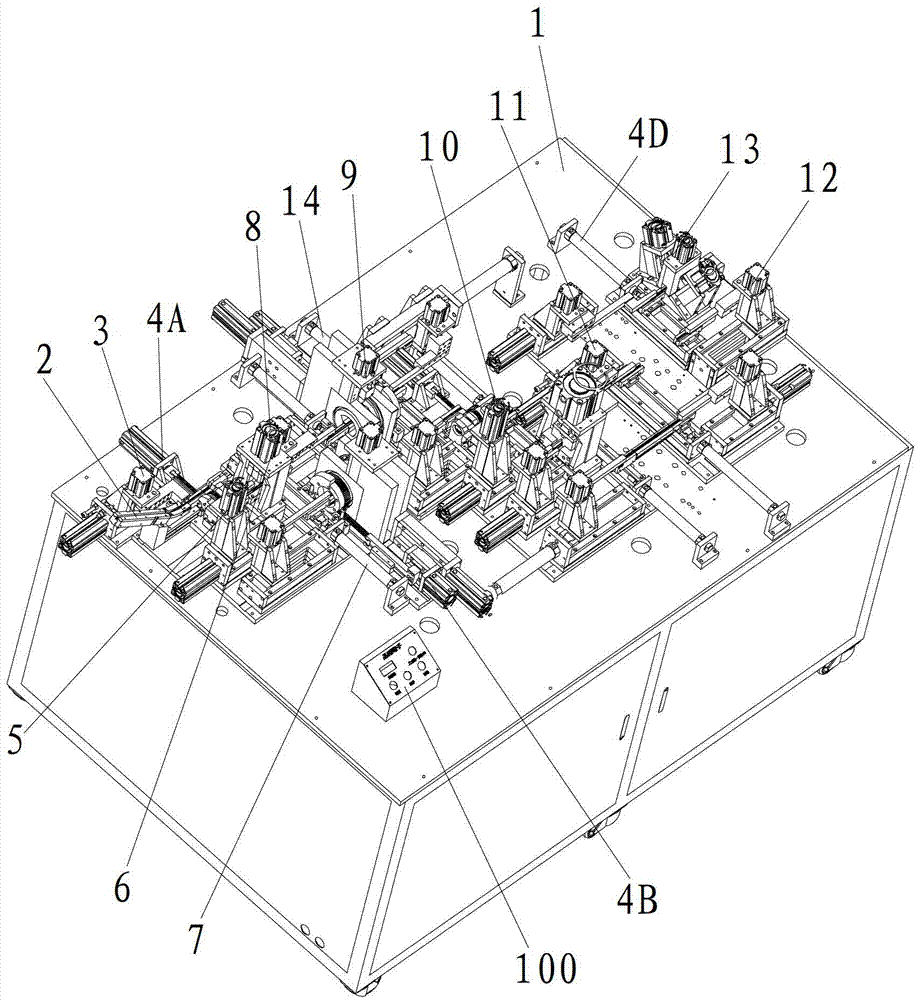

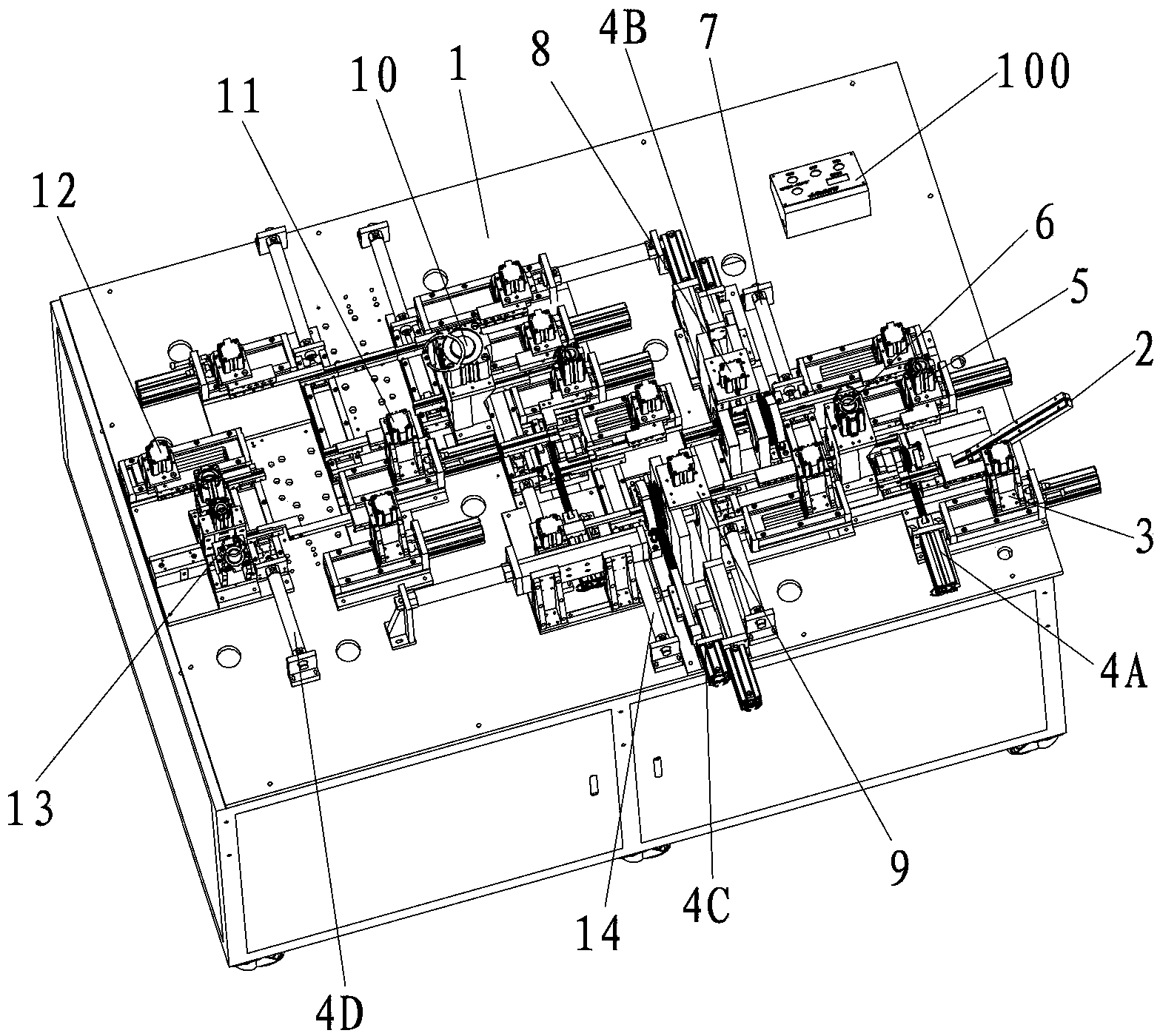

Full-automatic production equipment for electronic element

InactiveCN102904147ASimple and scientific structure designIncrease productivityContact member manufacturingContact member assembly/disassemblyEngineeringElectronic component

The invention relates to the technical field of detecting equipment for an electronic element, and particularly relates to full-automatic production equipment for an electronic element. The full-automatic production equipment for the electronic element comprises a rack body, a material plate, a striping device, a terminal feeding device, a terminal cutting device, a terminal inserting device, a primary pre-bending and shaping device, a 180-degree turnover device, and a secondary pre-bending, shaping and pin-cutting device; the material plate and the striping device are arranged at one side of the rack body; the terminal feeding device, the terminal cutting device, the terminal inserting device, the primary pre-bending and shaping device, the 180-degree turnover device, and the secondary pre-bending, shaping and pin-cutting device are sequentially arranged on the upper end surface of the rack body; and a controller and a body material feeding opening are further arranged on the rack body. The full-automatic production equipment provided by the invention has the advantages of simple and scientific structural design, full-automatic production, high production efficiency and good product quality.

Owner:品翔电子塑胶制品(东莞)有限公司

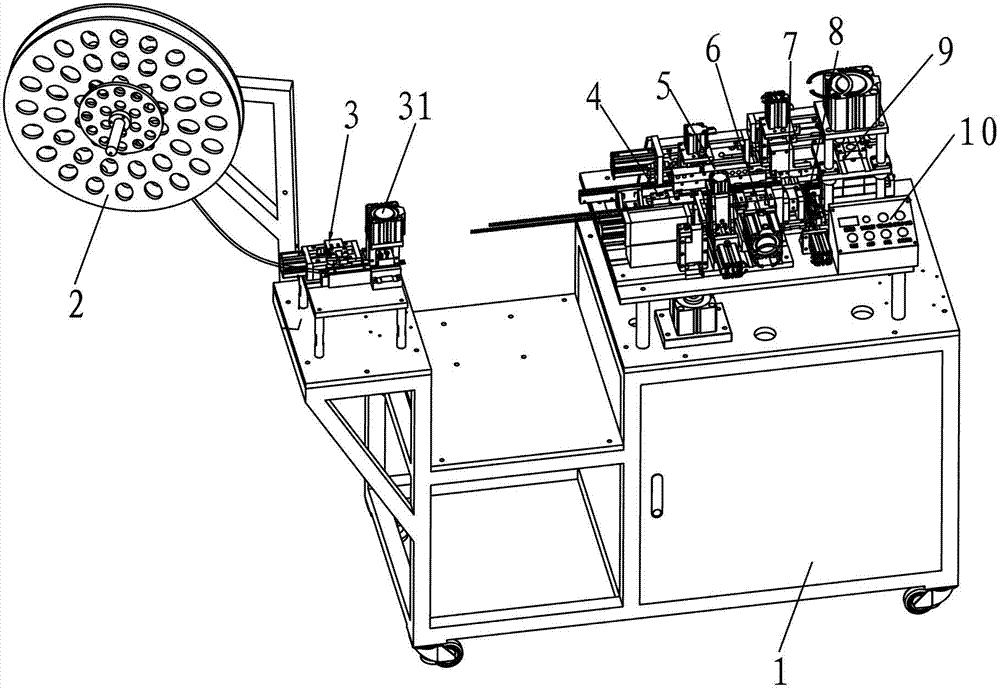

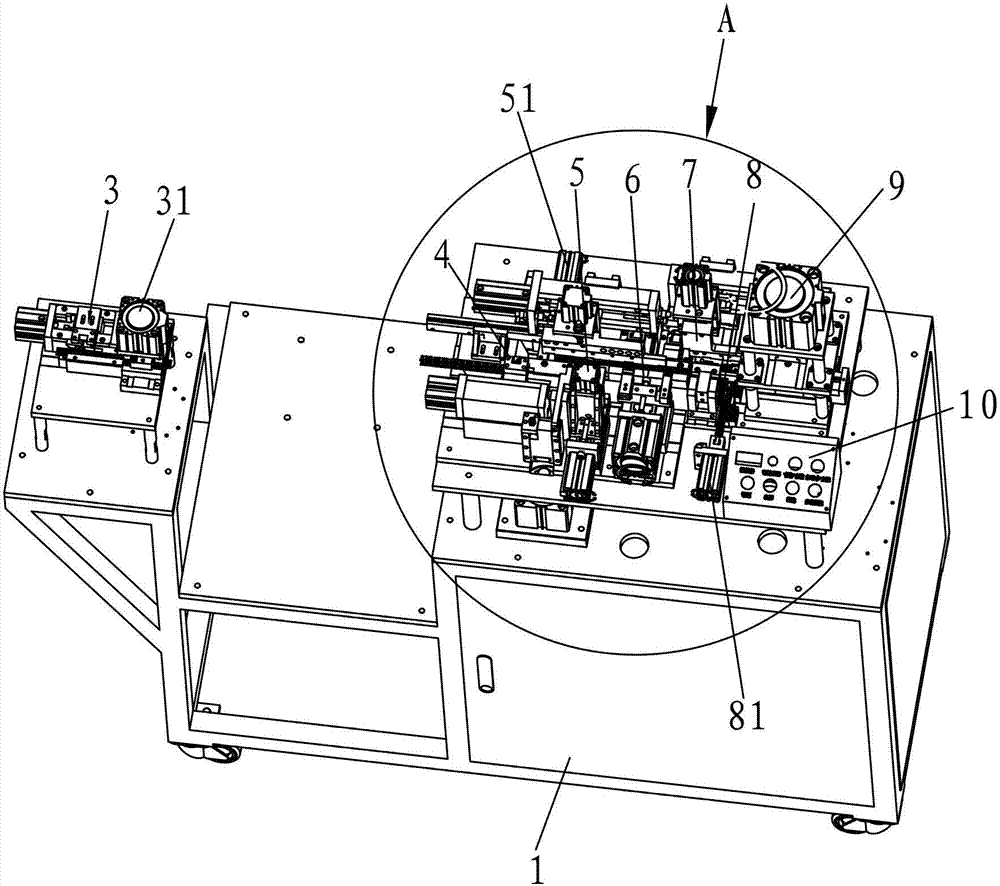

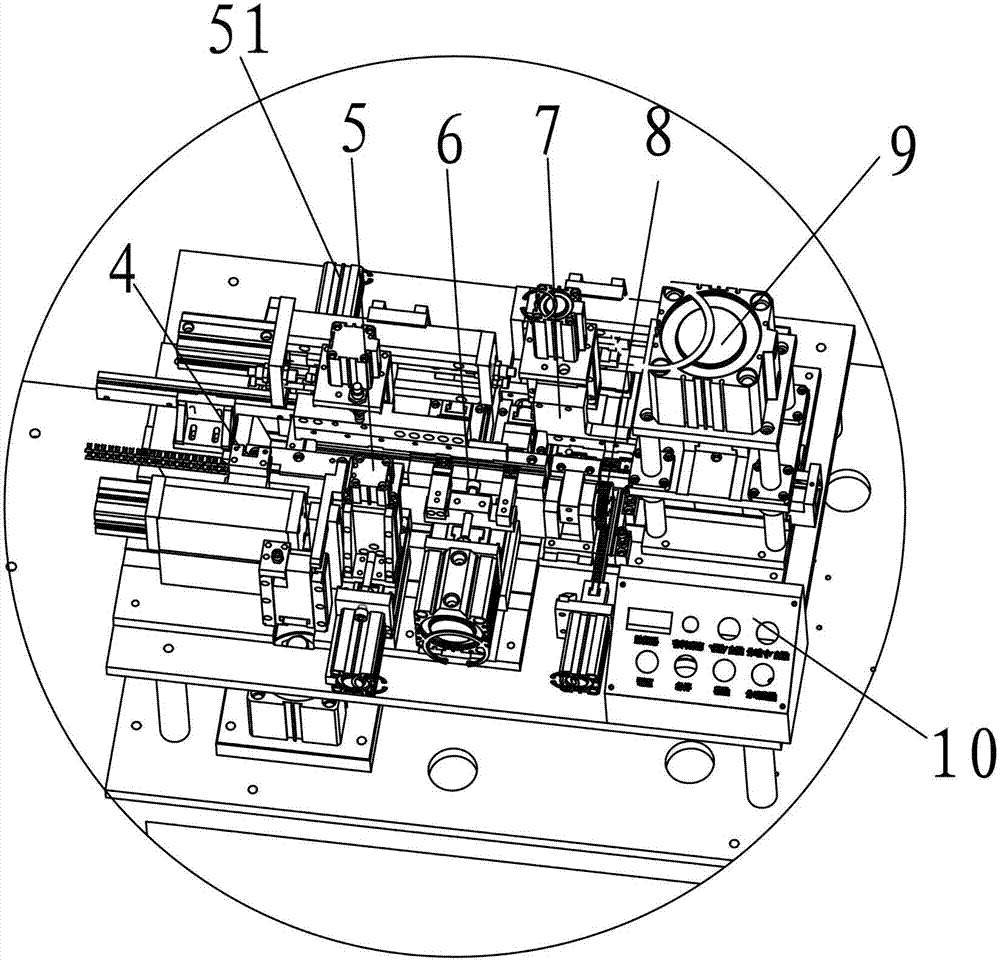

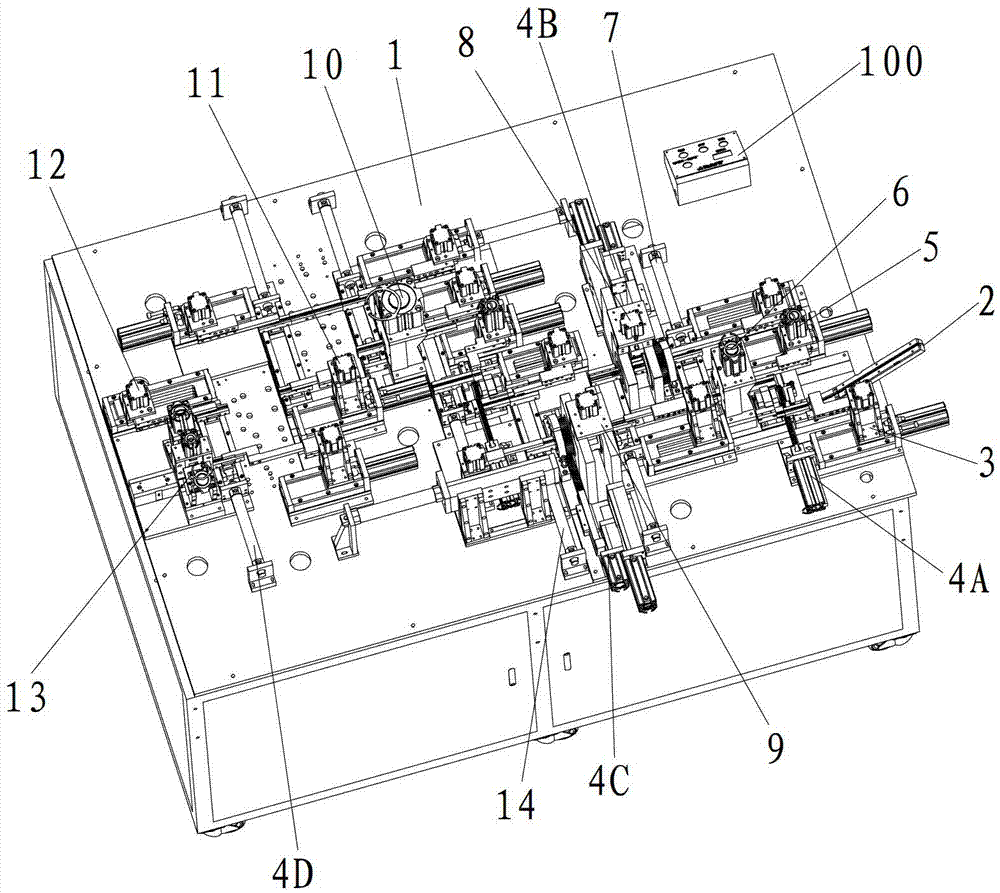

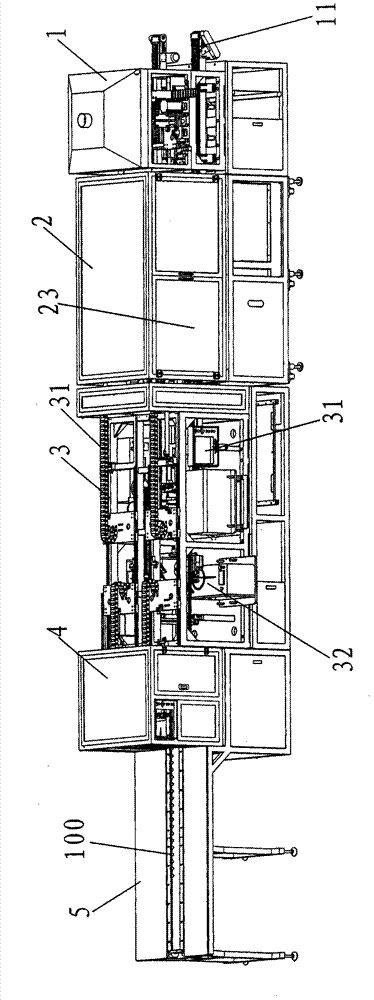

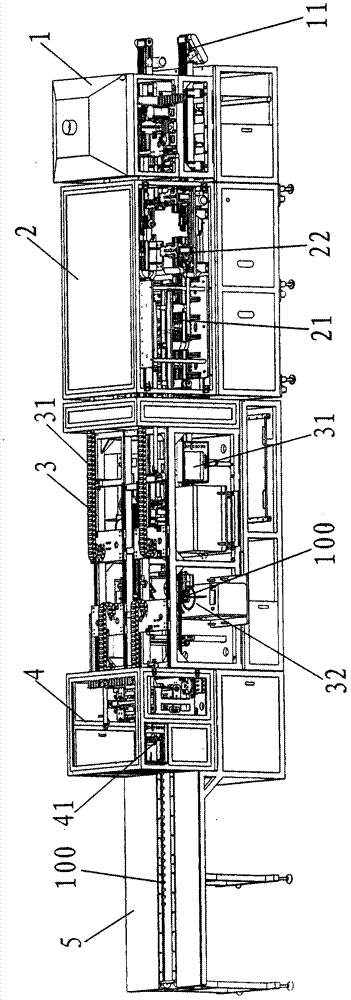

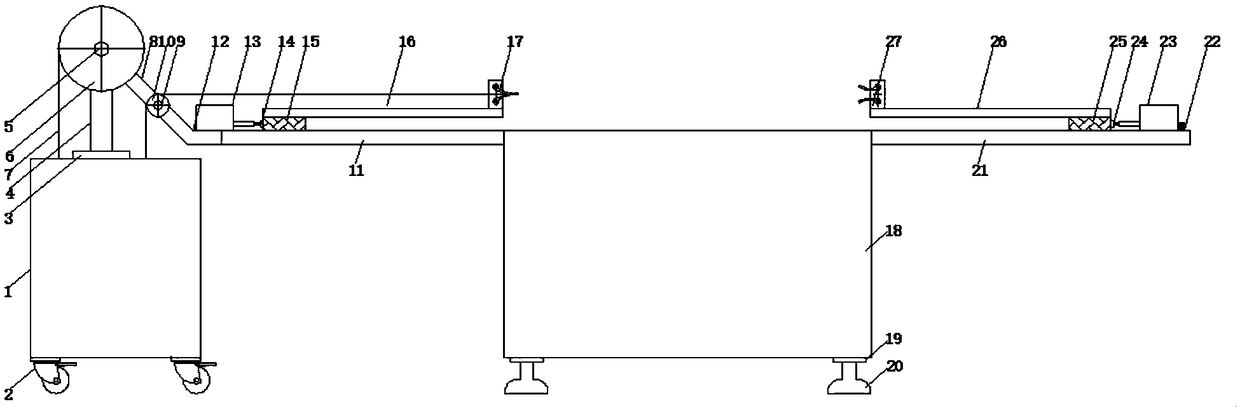

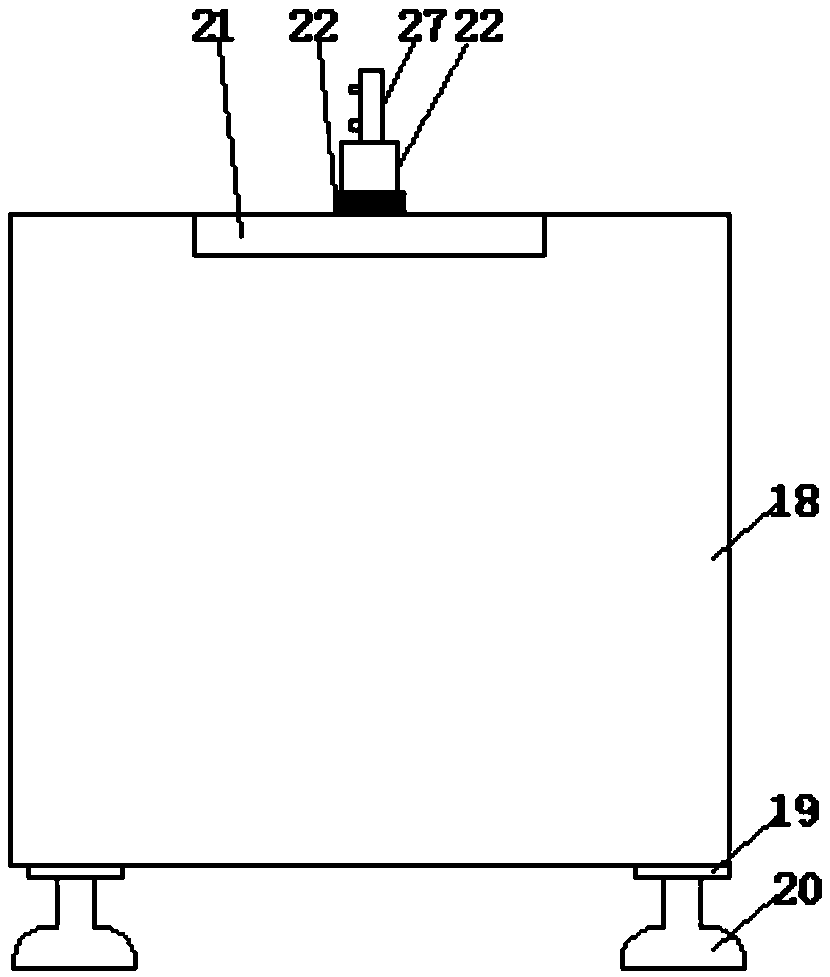

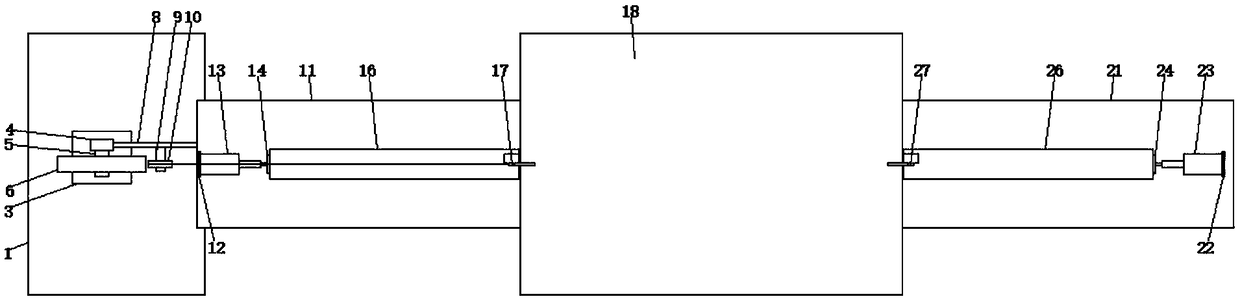

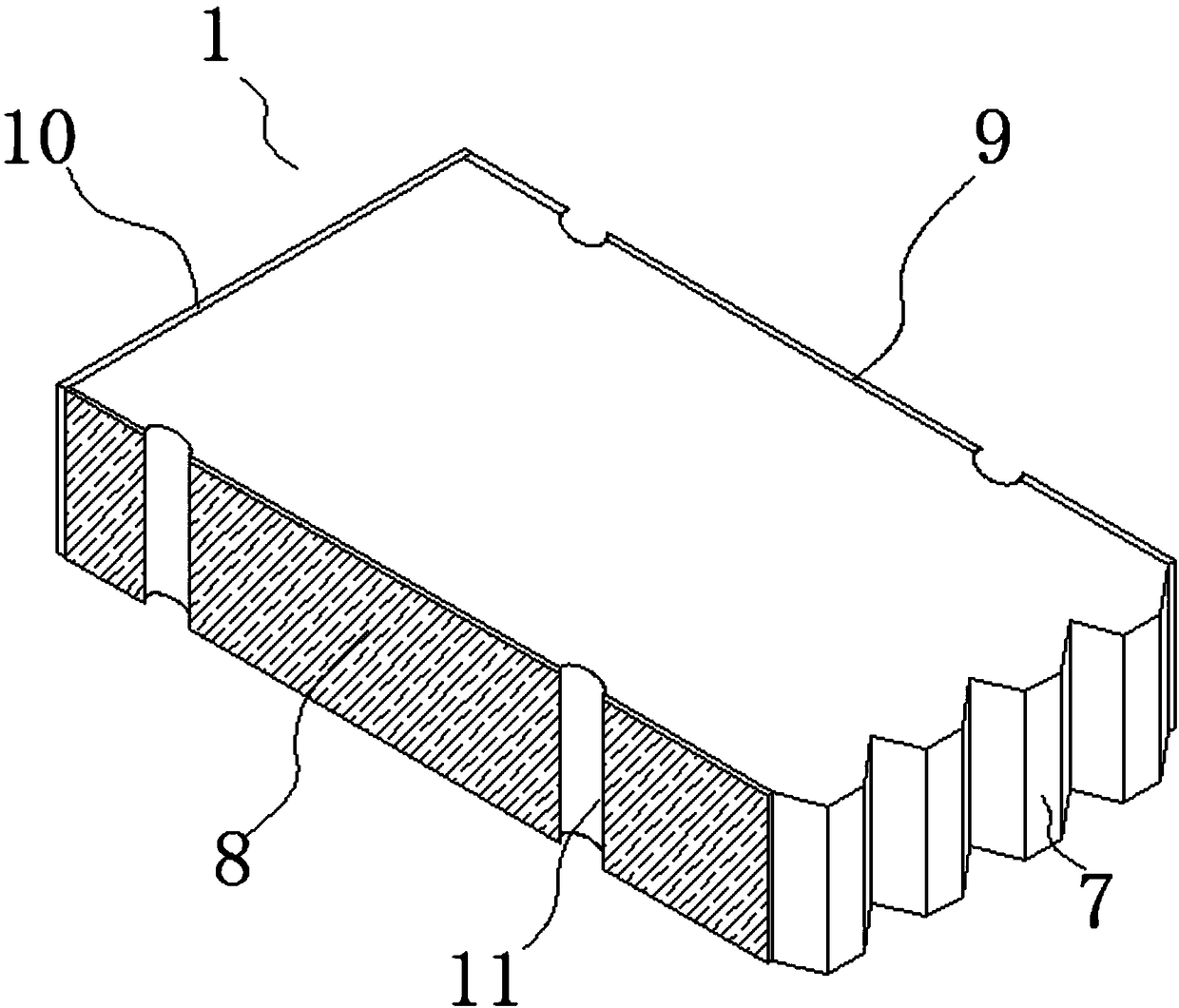

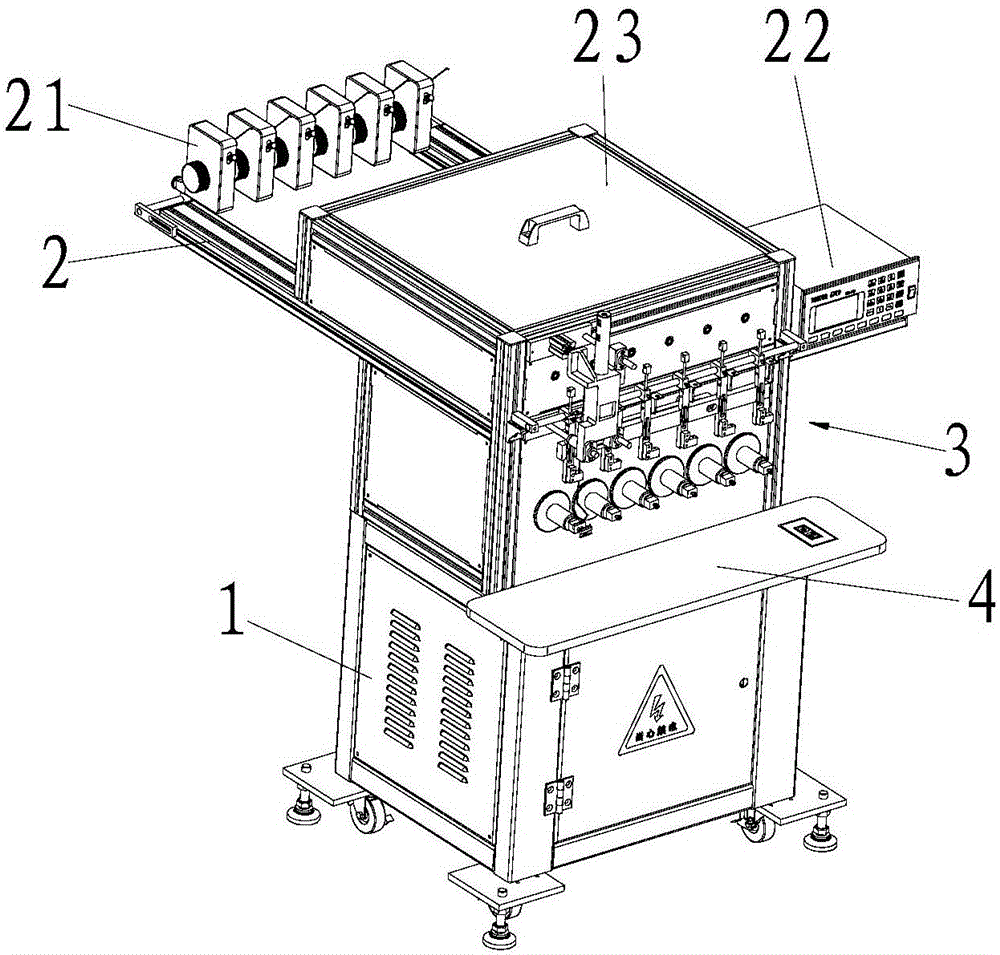

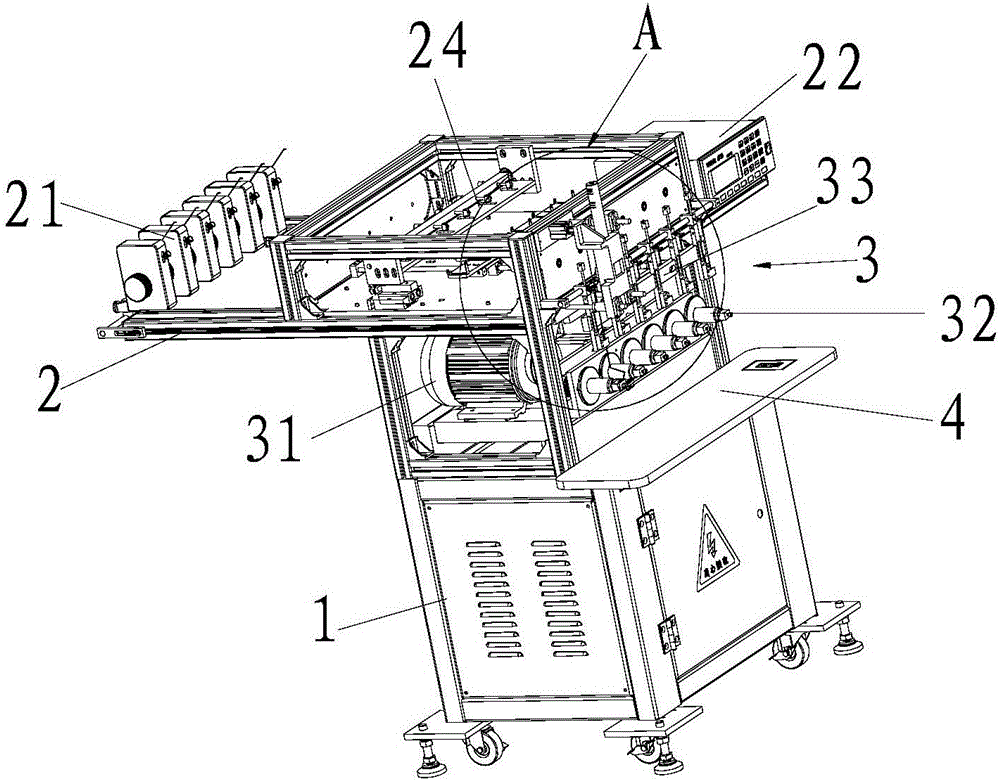

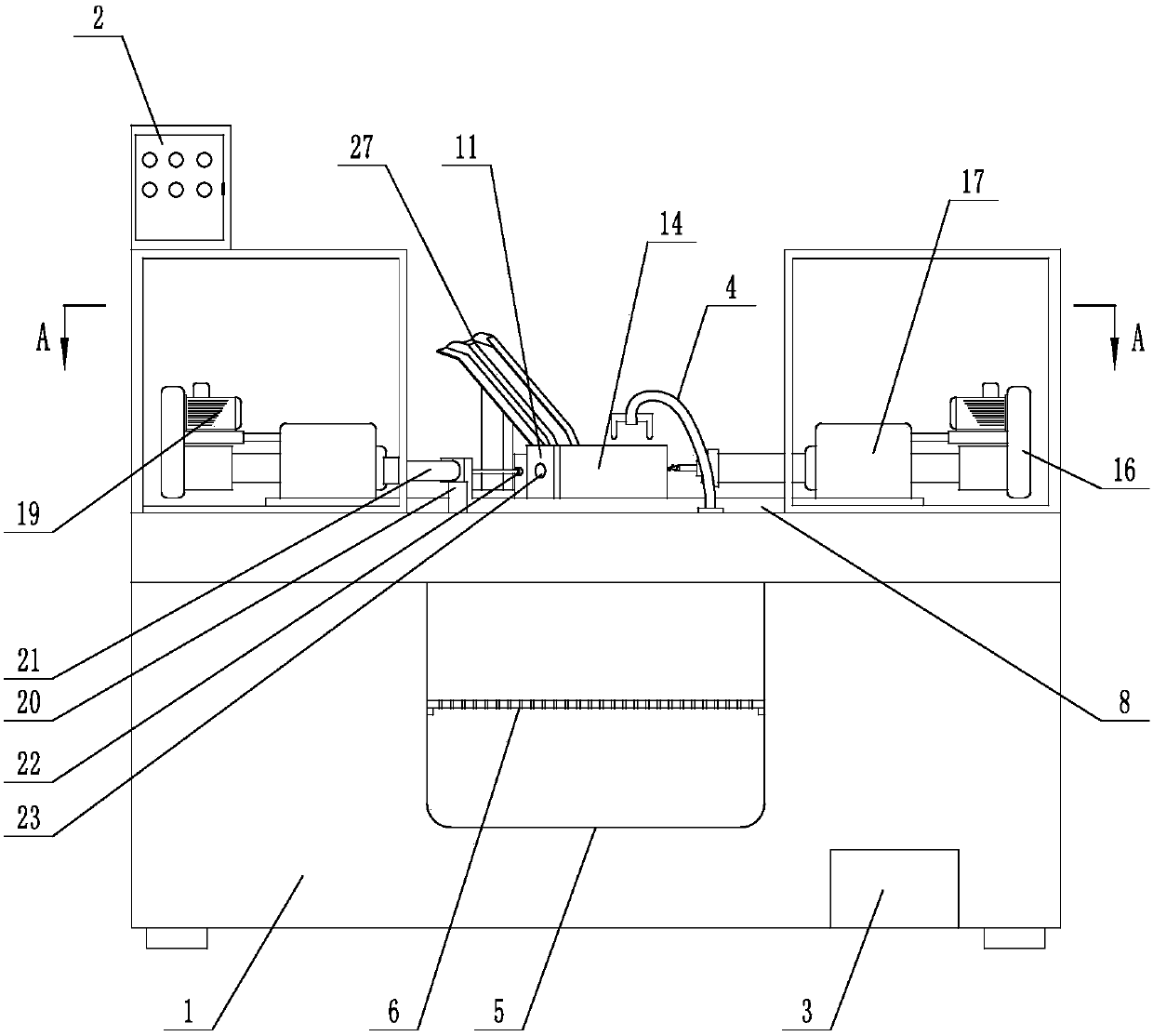

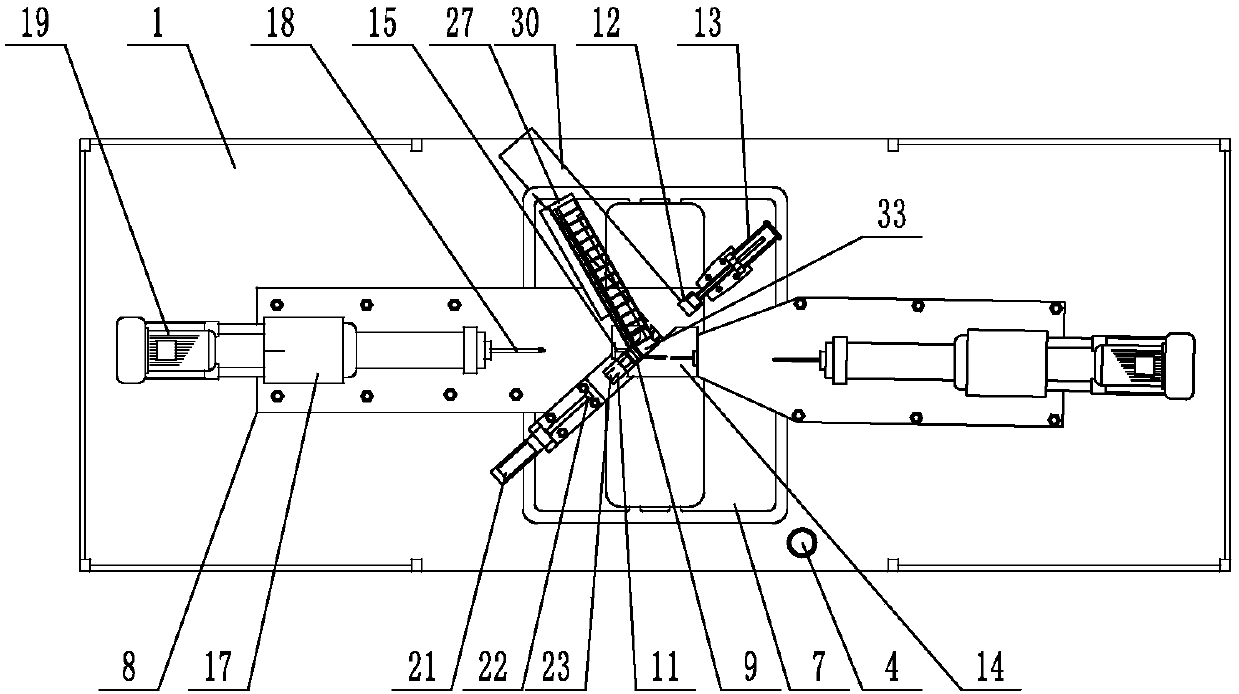

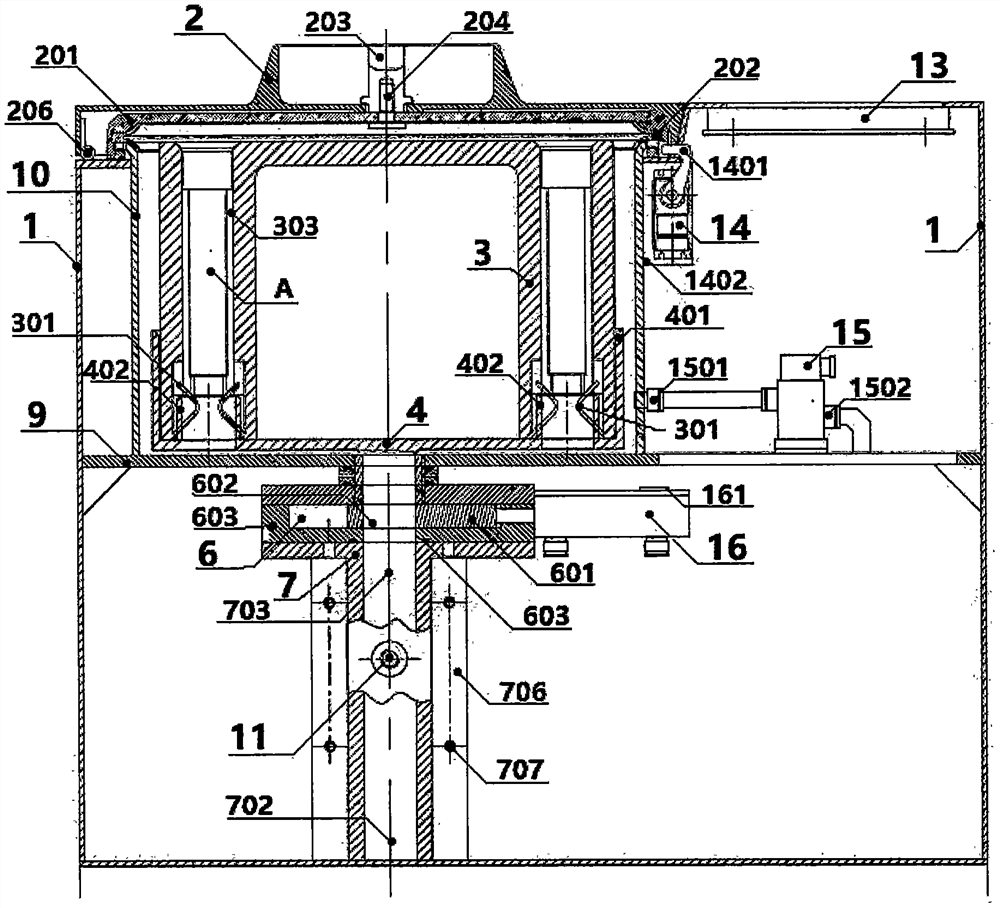

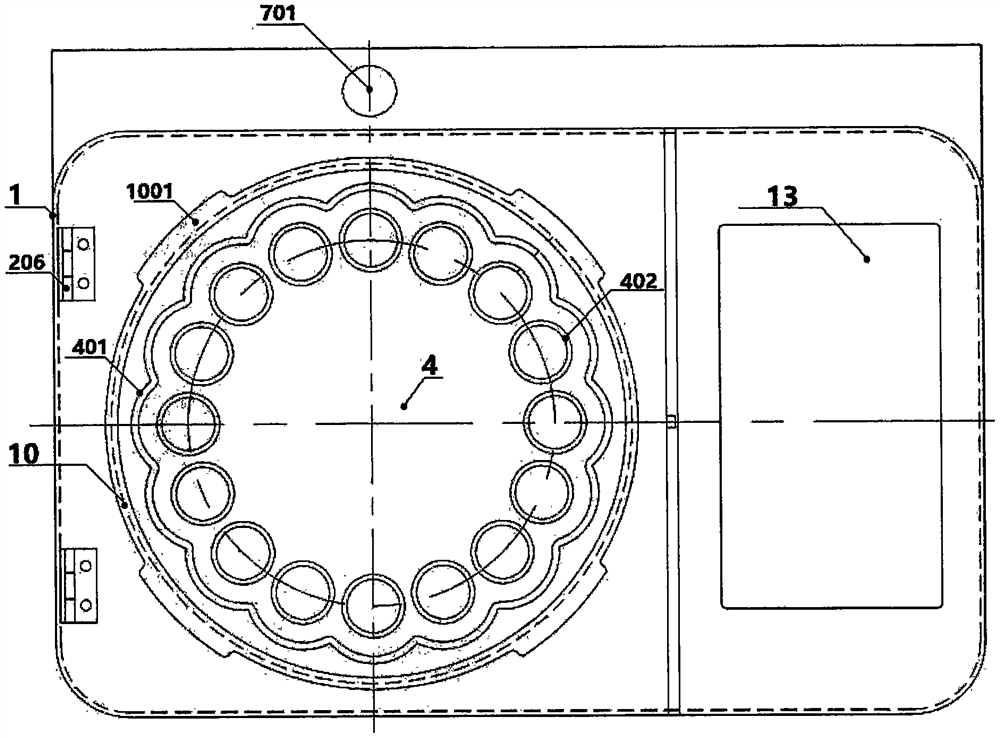

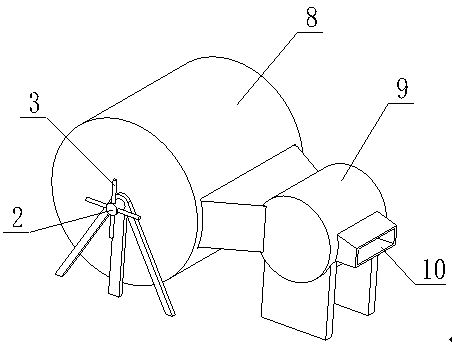

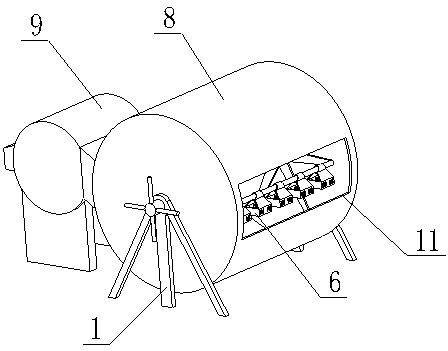

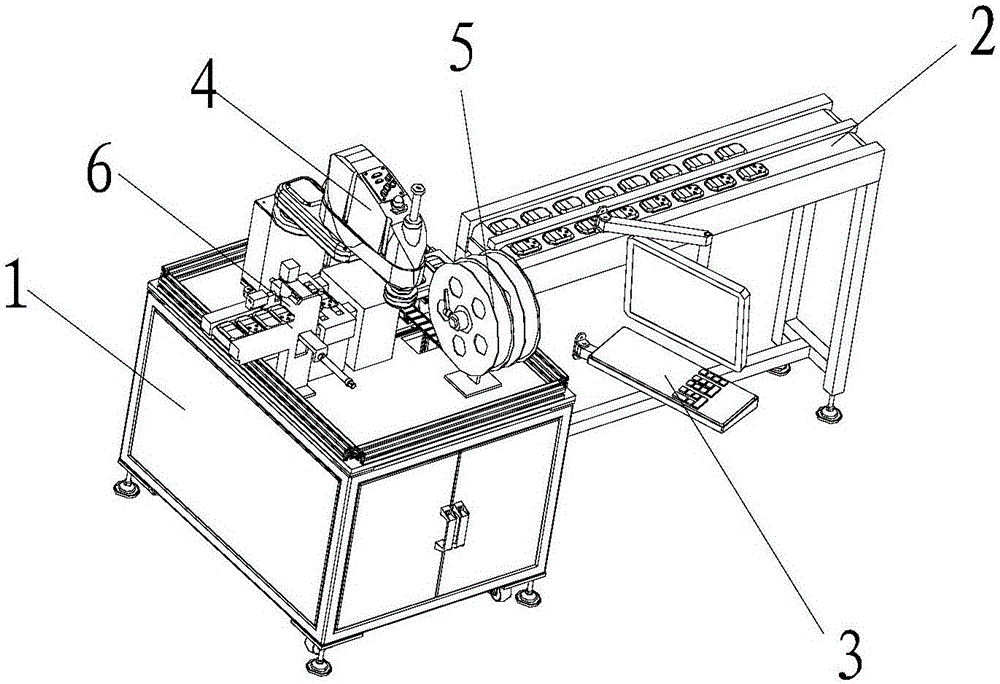

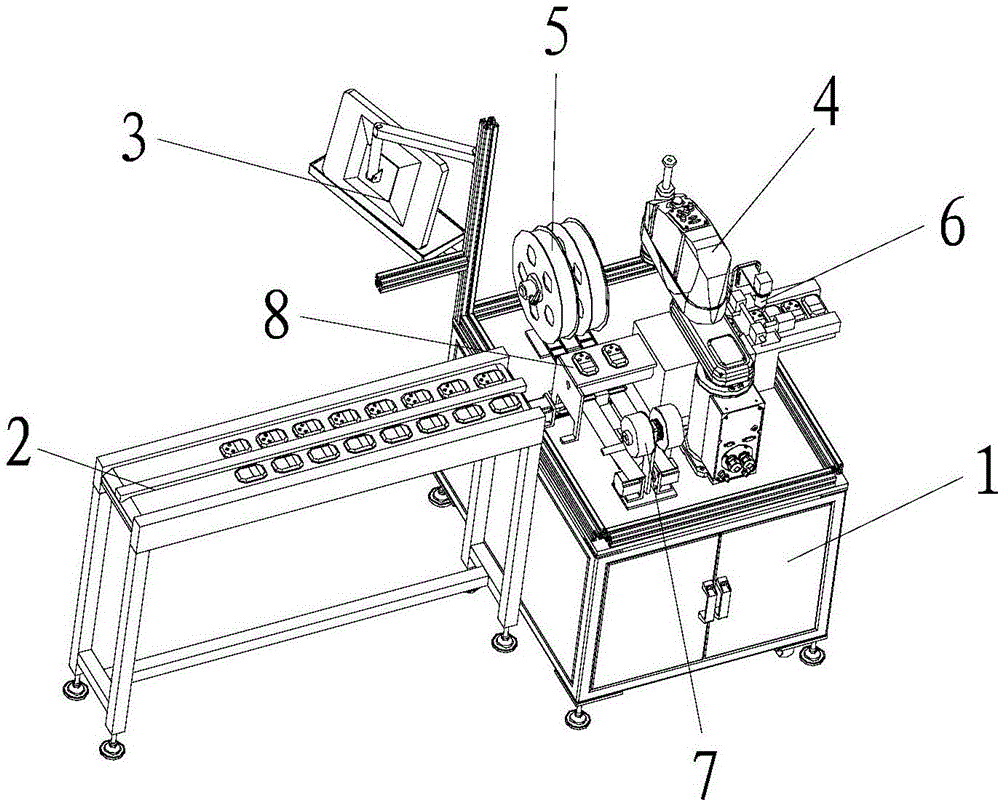

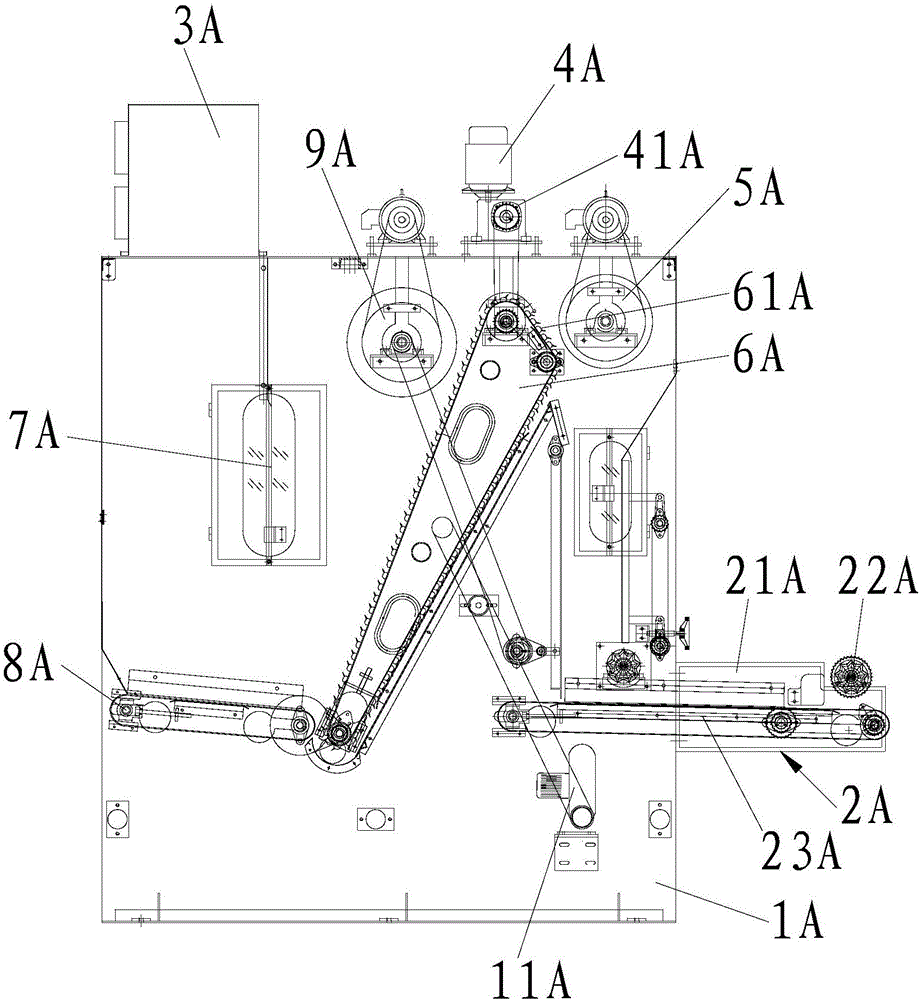

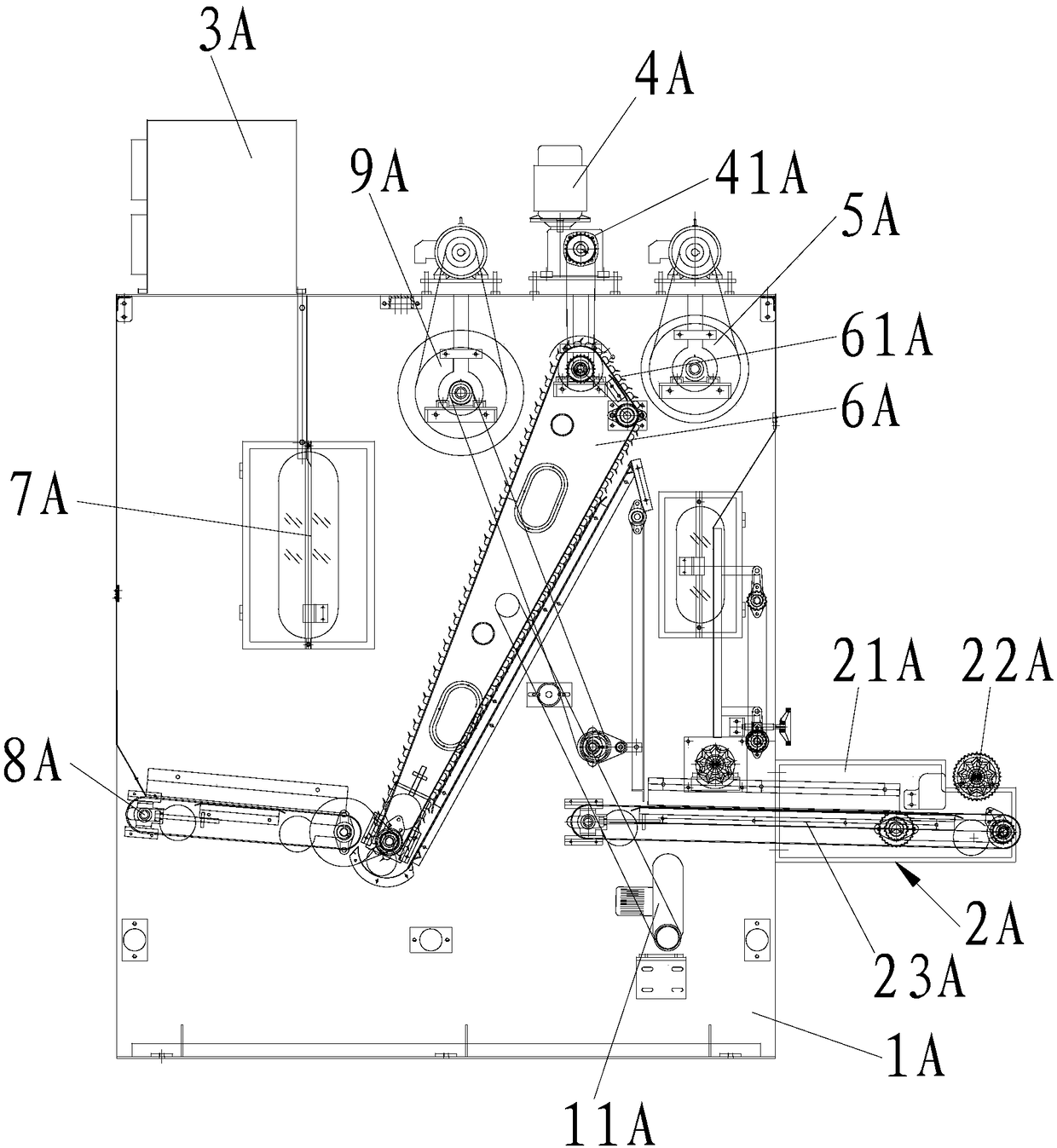

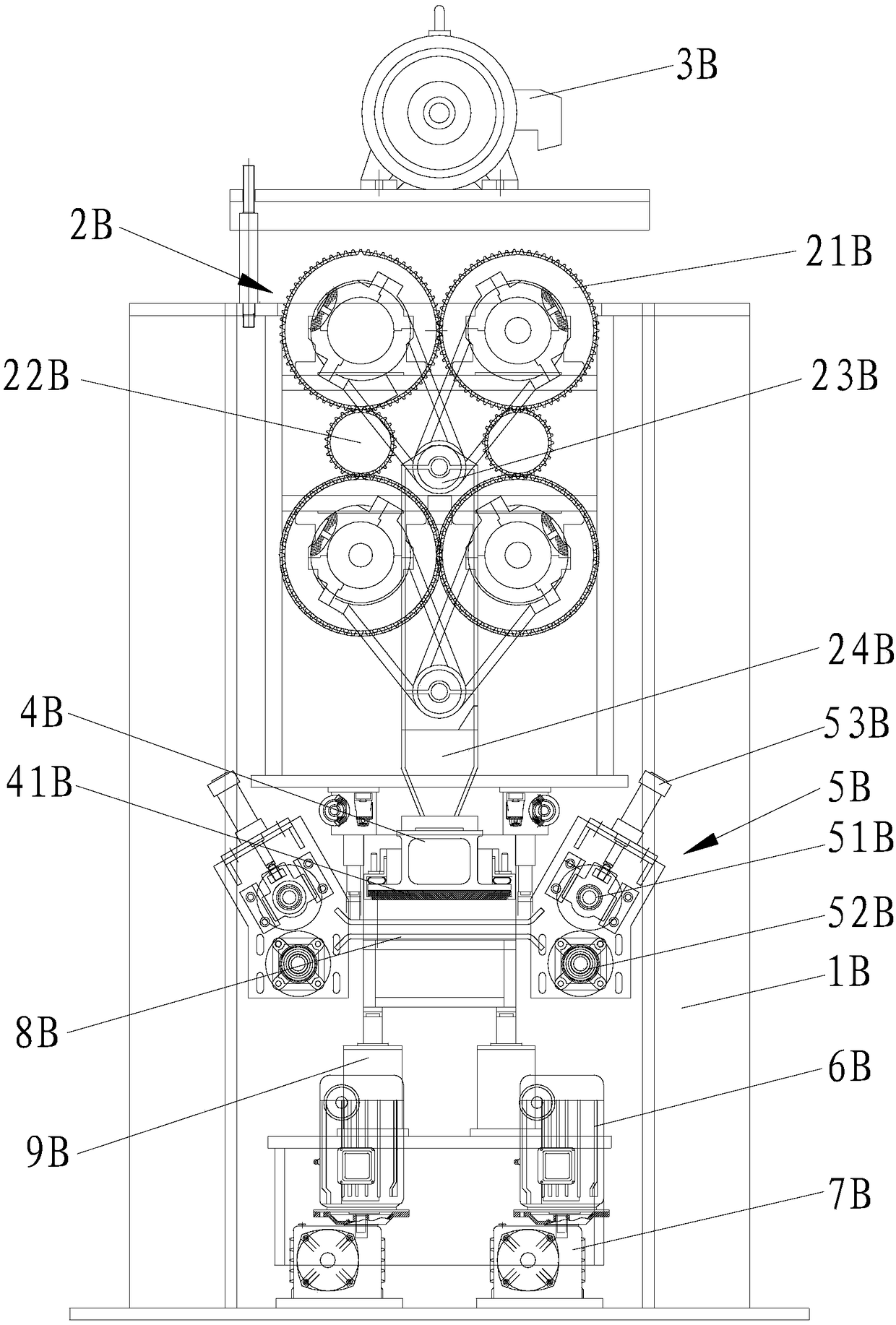

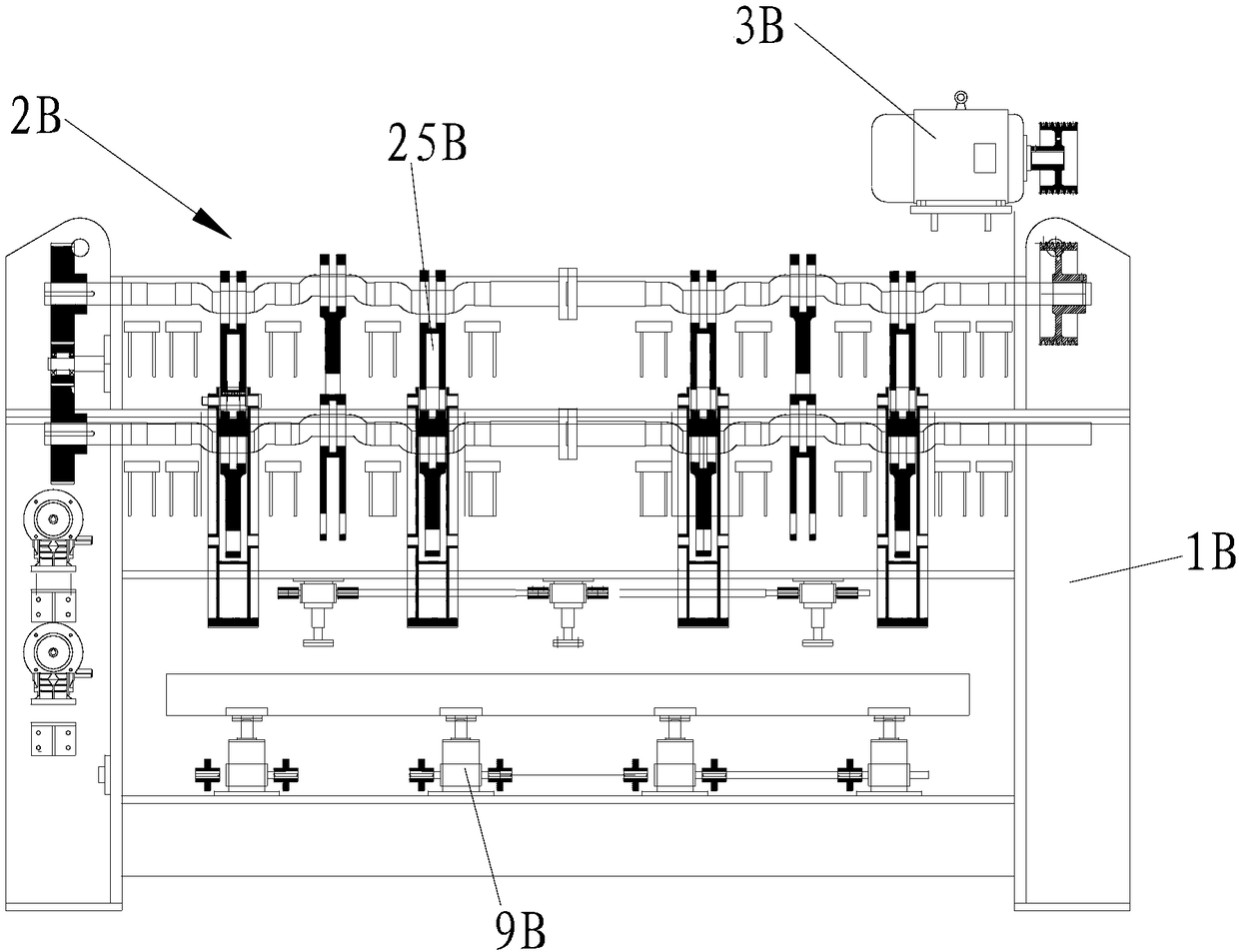

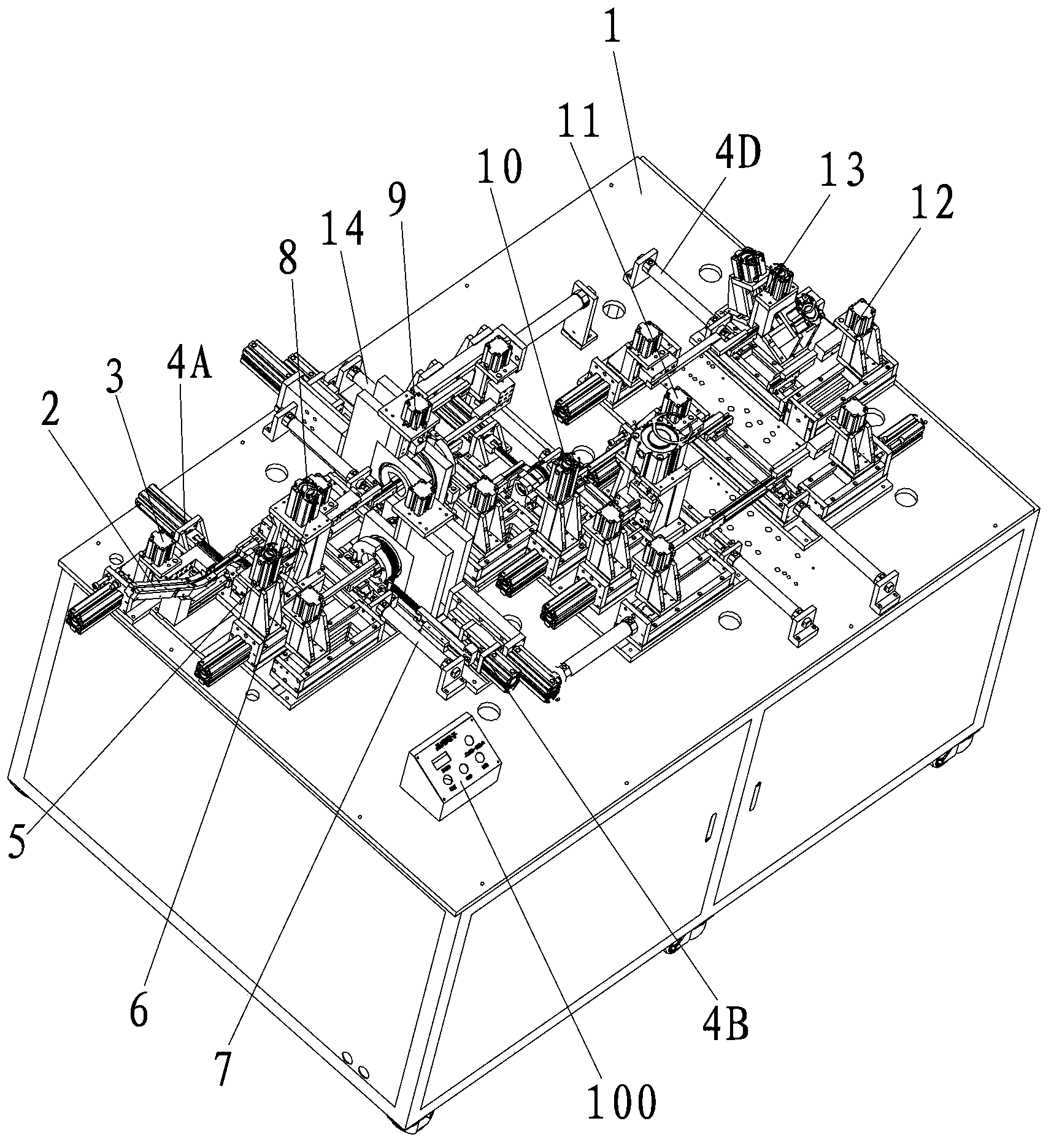

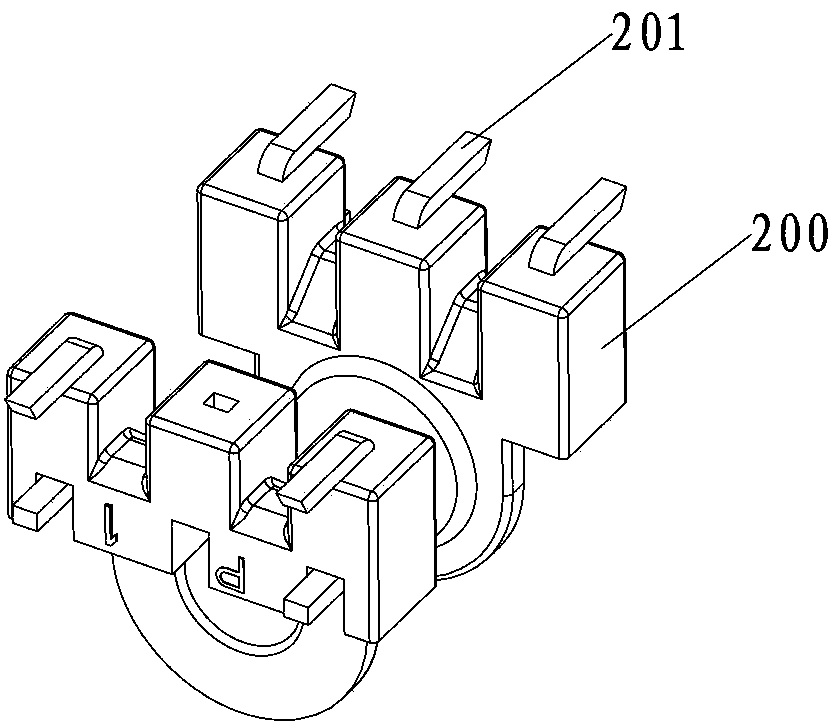

Full-automatic production equipment for radar element for full-automatic automobile

ActiveCN102896496ASimple and scientific structure designIncrease productivityOther manufacturing equipments/toolsMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of production equipment for electronic elements, in particular to full-automatic production equipment for a radar element for a full-automatic automobile. A feeding device, a pin inserting device, a material pushing device, a pre-bending device, a material grabbing device, a bending device, a deep-angle bending device, a pin cutting device, a No.1 90-degree bending device, a No.2 90-degree bending device and a bevel cutting mechanism are arranged on a frame body in sequence; a No.1 reversing device is arranged between the pin inserting device and the material pushing device; a No.2 reversing device is arranged between the material grabbing device and the bending device; a No.3 reversing device is arranged on the deep-angle bending device; a material pushing mechanism is arranged between the deep-angle bending device and the pin cutting device; a No.4 reversing device is arranged on the bevel cutting mechanism; and a controller is arranged on the frame body. The equipment is simple and scientific in structural design, full-automatic production is realized, and production efficiency and product quality are high.

Owner:DONGXIANG ELECTRONICS DONGGUAN CO LTD

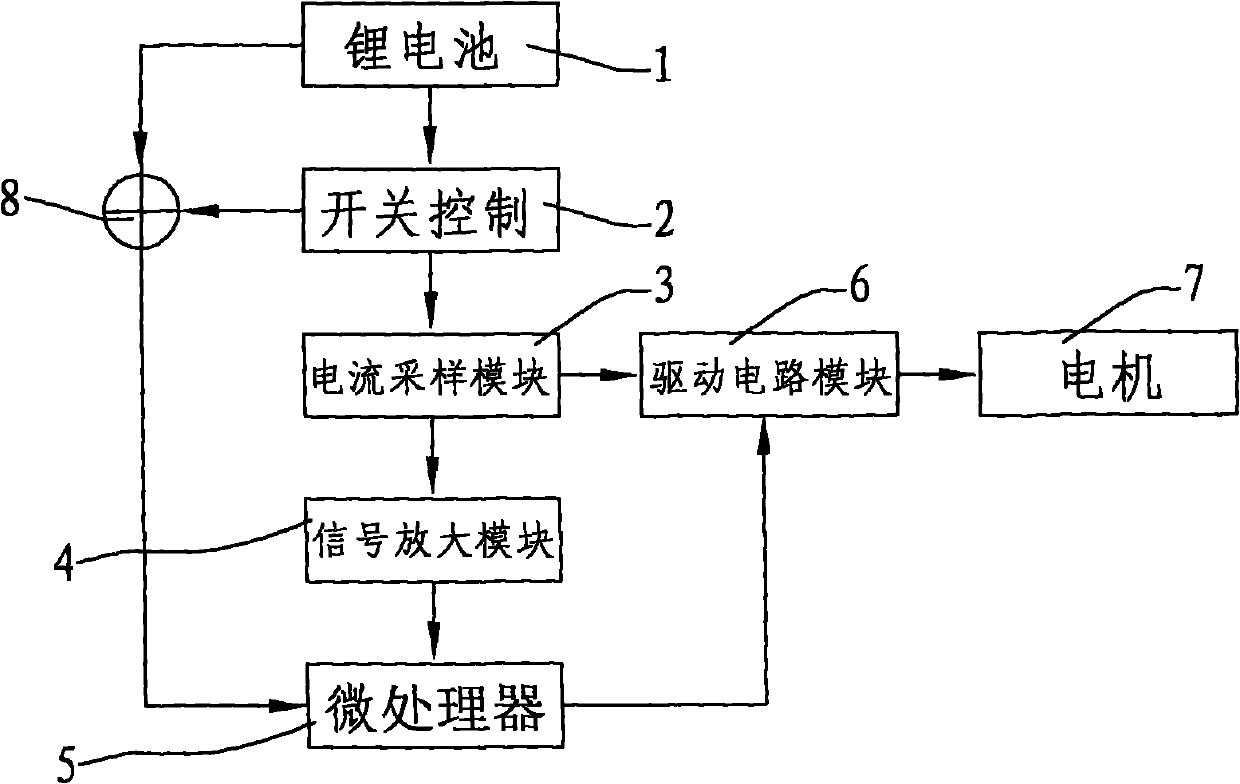

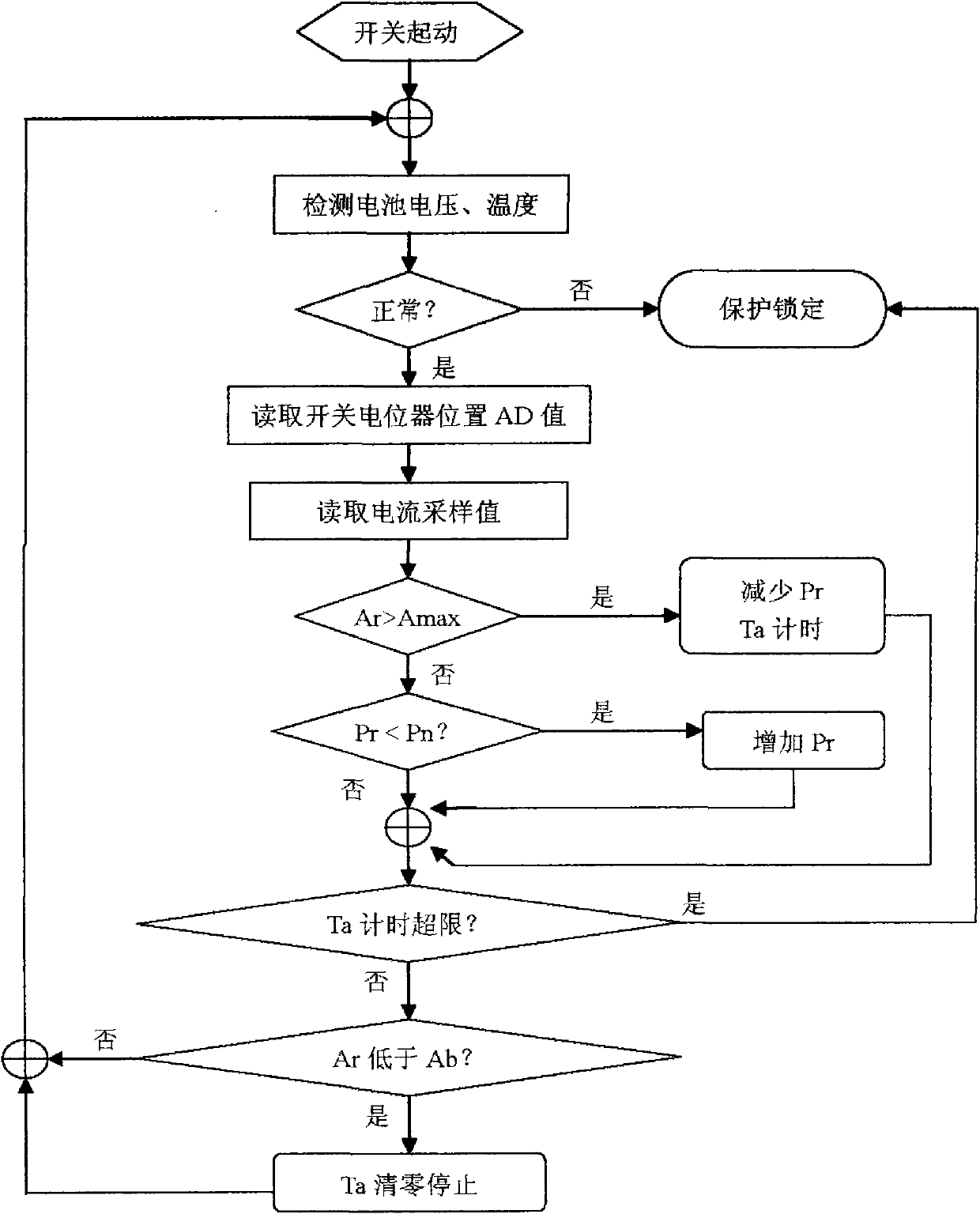

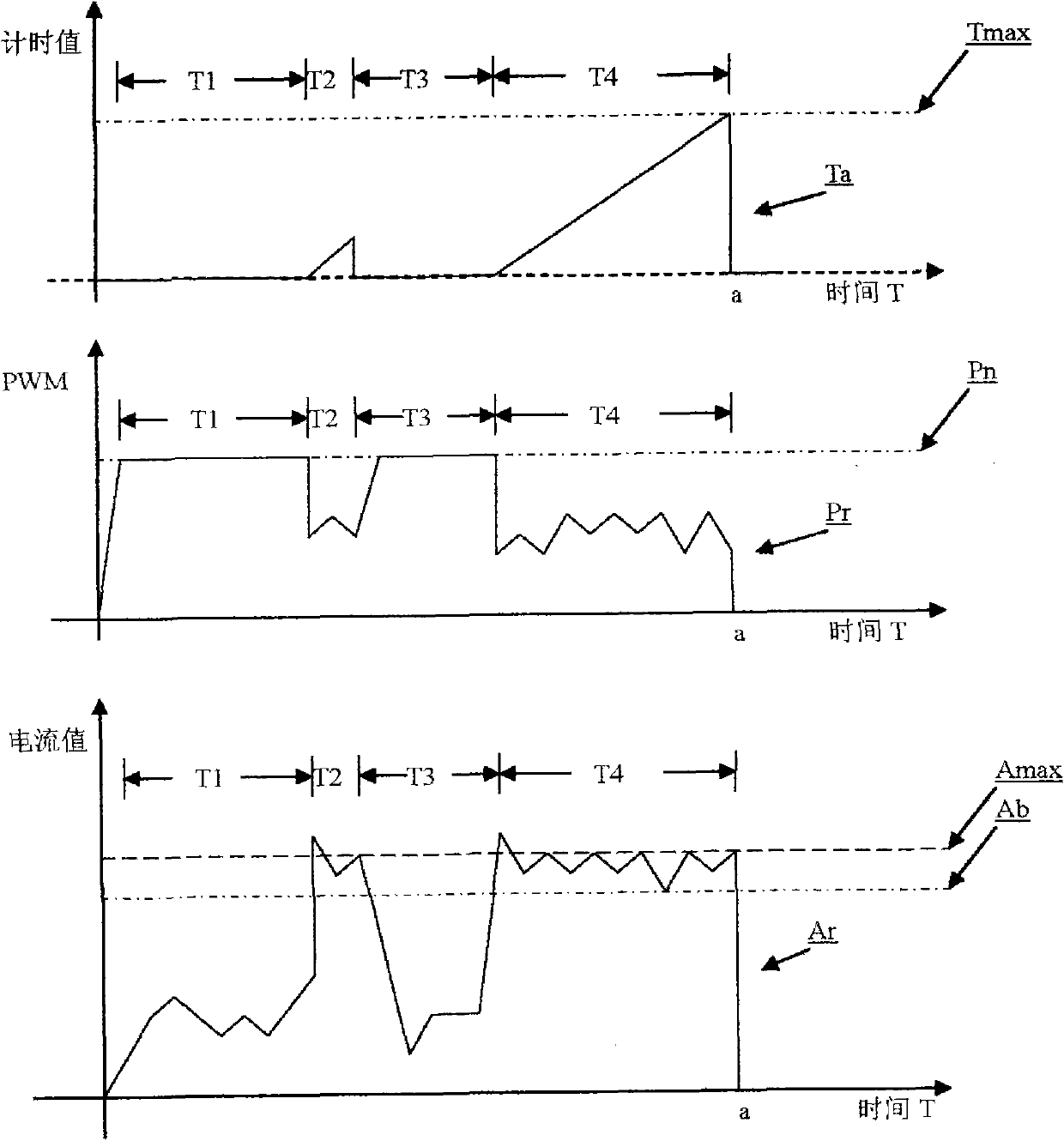

Current-limiting delay protection circuit of lithium battery charge drill

InactiveCN102570398ASimple and scientific structure designDon't feel powerlessEmergency protective circuit arrangementsElectricityDriver circuit

The invention relates to the technical field of supply circuits, in particular relates to a current-limiting delay protection circuit of a lithium battery charge drill, which comprises a lithium battery, a switch control, a current sampling module, a signal amplifying module and a microprocessor which are sequentially connected in series, wherein the current sampling module and the microprocessor are electronically connected with a driving circuit module, the output end of the driving circuit module is electronically connected with a motor, and the lithium battery and the switch control are electronically connected with the microprocessor after passing through a temperature / voltage and control signal generator. The current-limiting delay protection circuit has a simple and scientific structure design; the current is fed back in the circuit, a driving circuit is controlled through the microprocessor, so as to realize limiting of maximum current of the motor, and the current-limiting delay protection circuit is turned on or off within a certain time after reaching the maximum current, so that the effect of protecting the motor and the battery is achieved, meanwhile, the drill is powerful, and the current-limiting delay protection circuit has long service life.

Owner:东莞市妙达电动工具制造有限公司

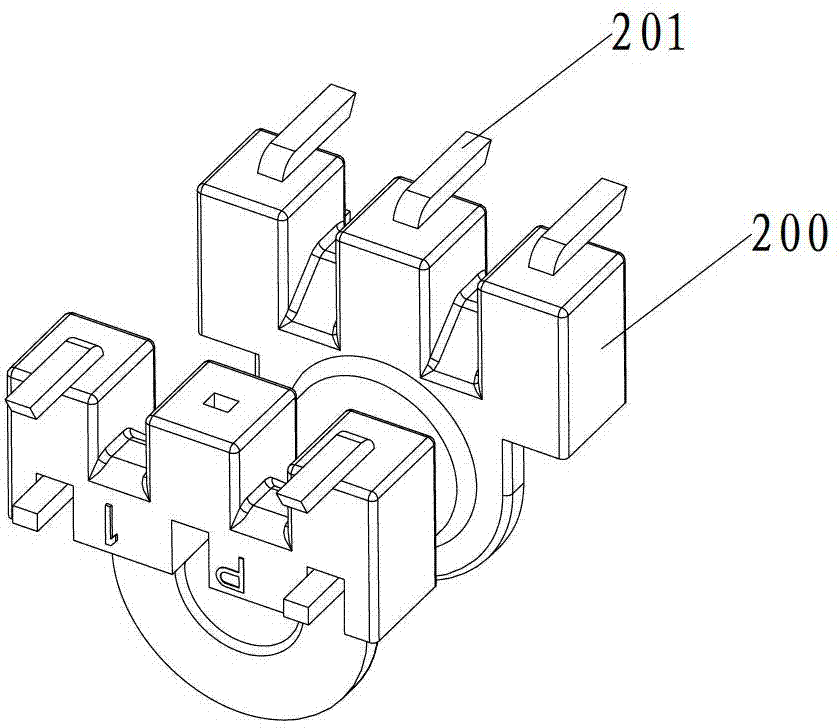

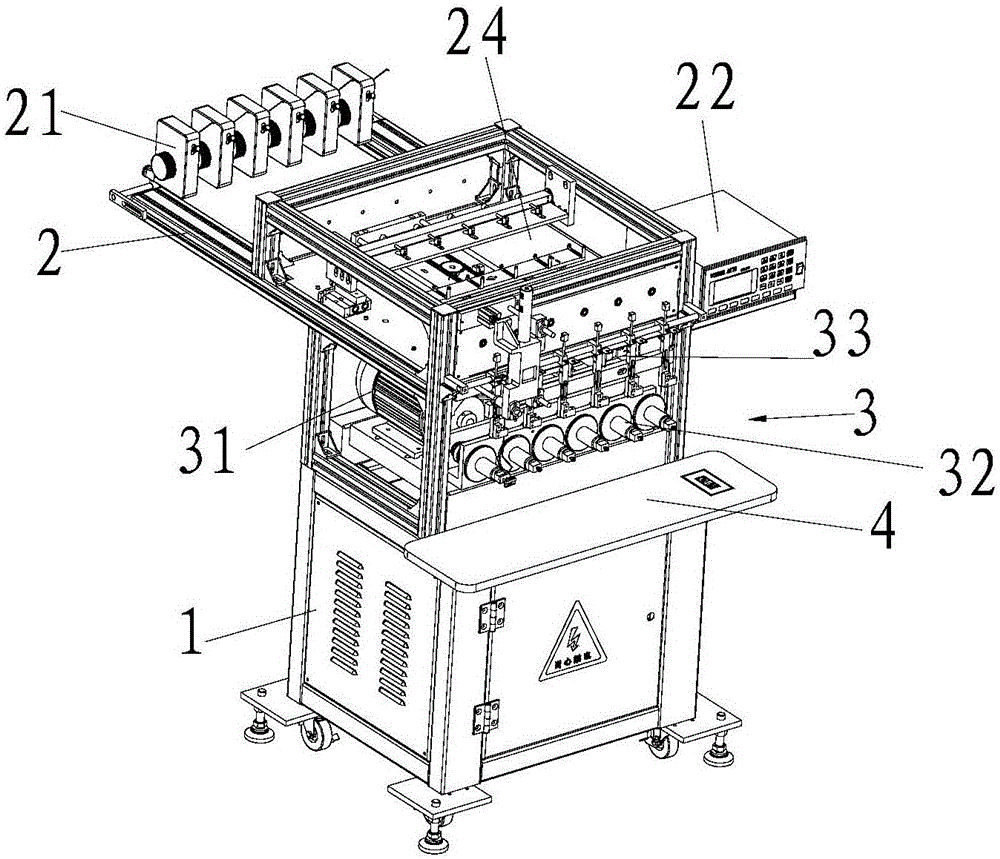

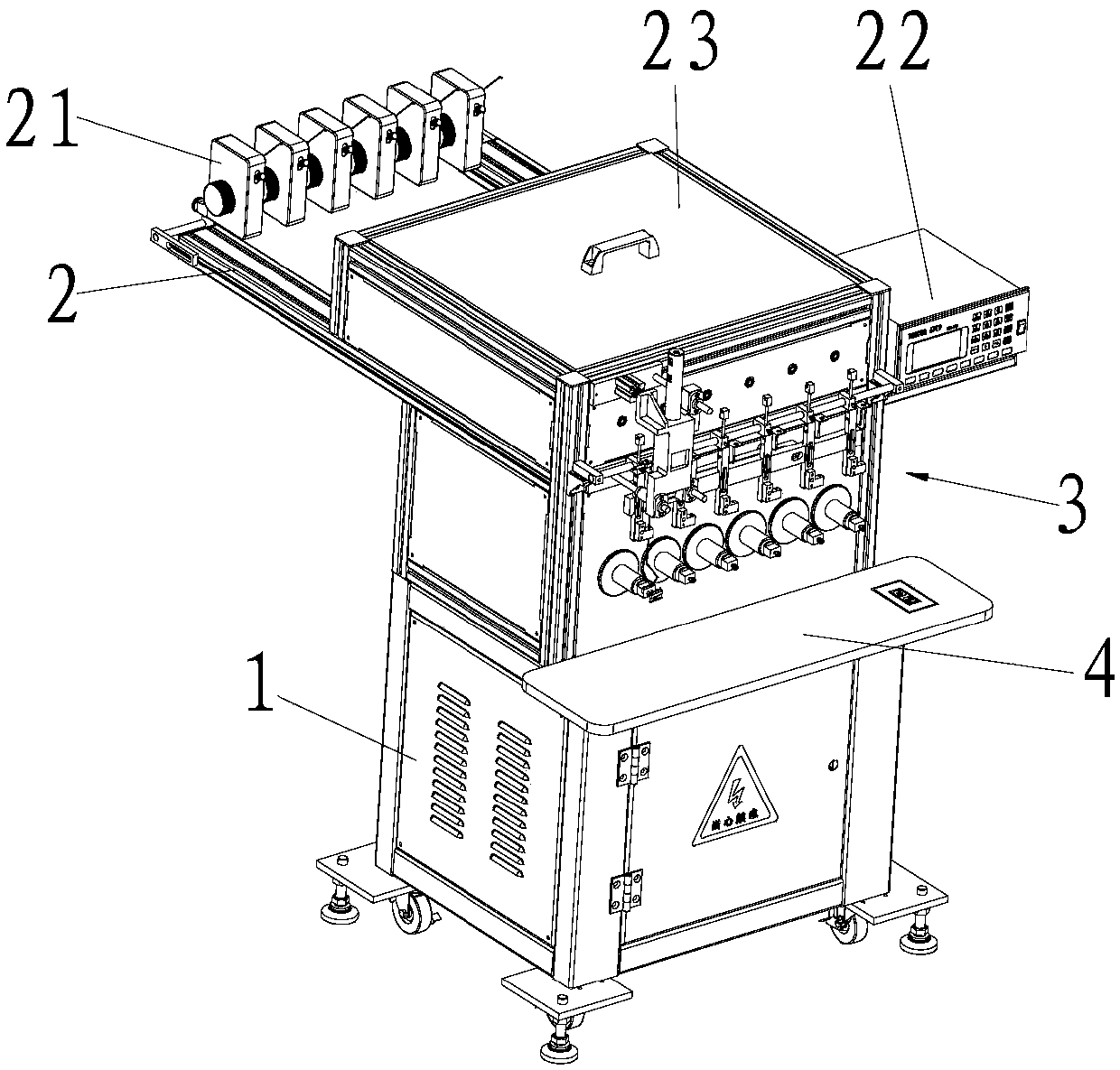

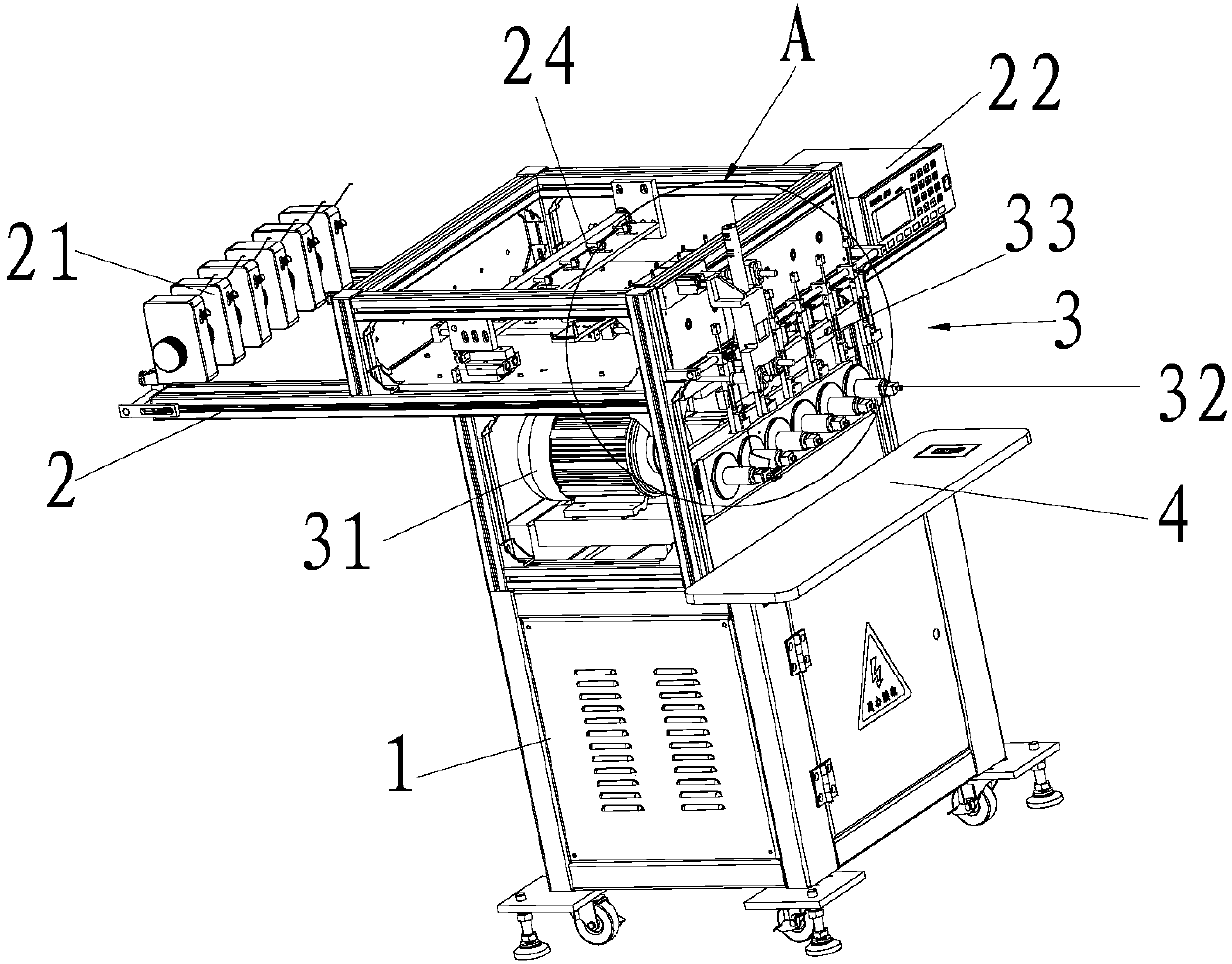

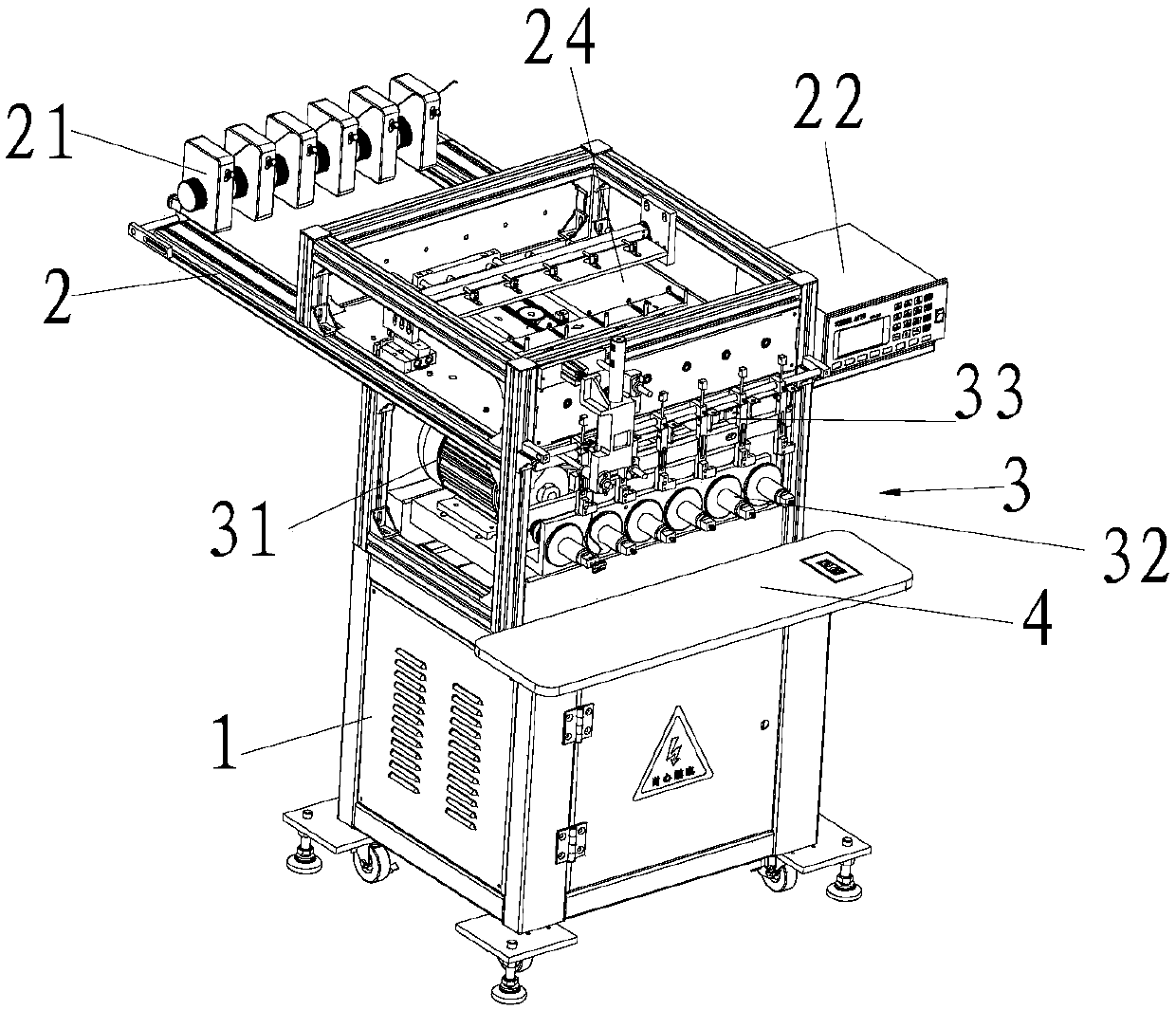

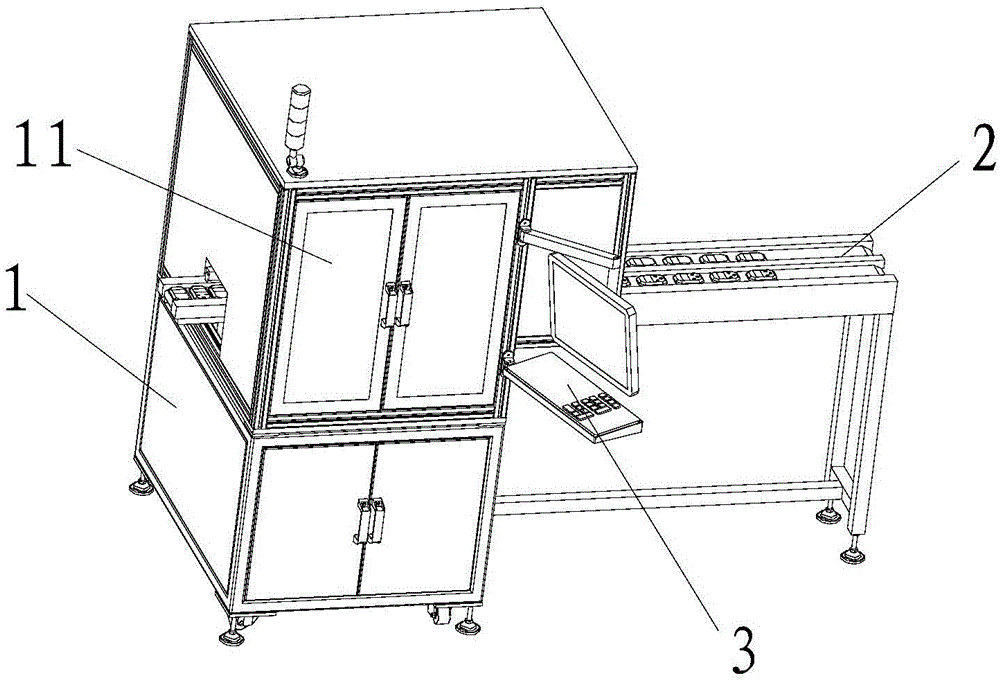

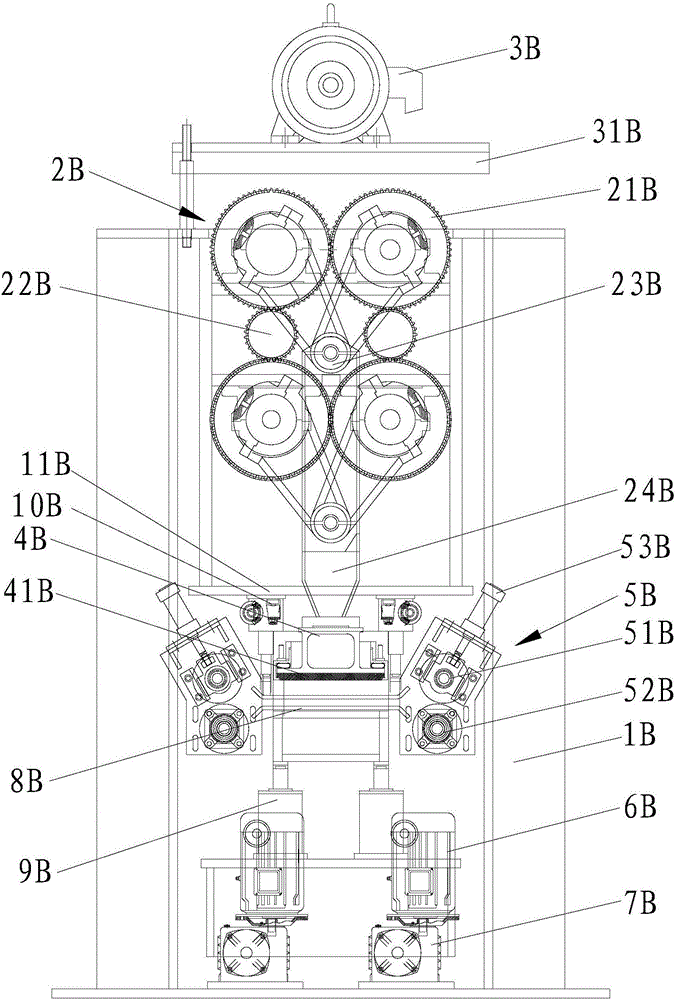

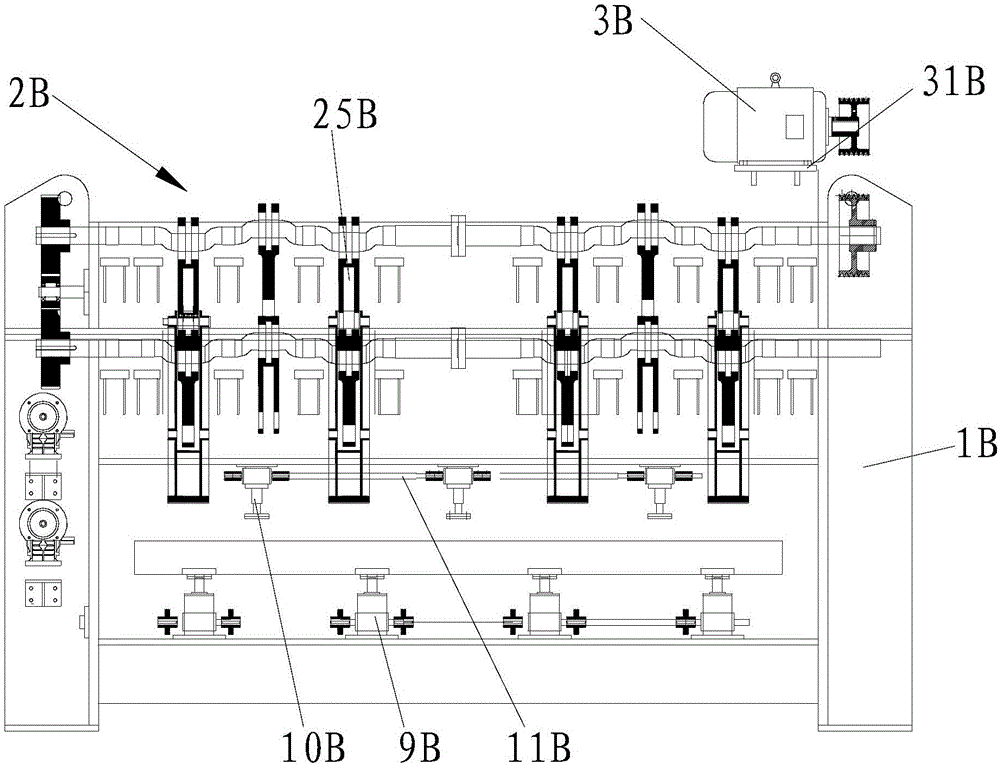

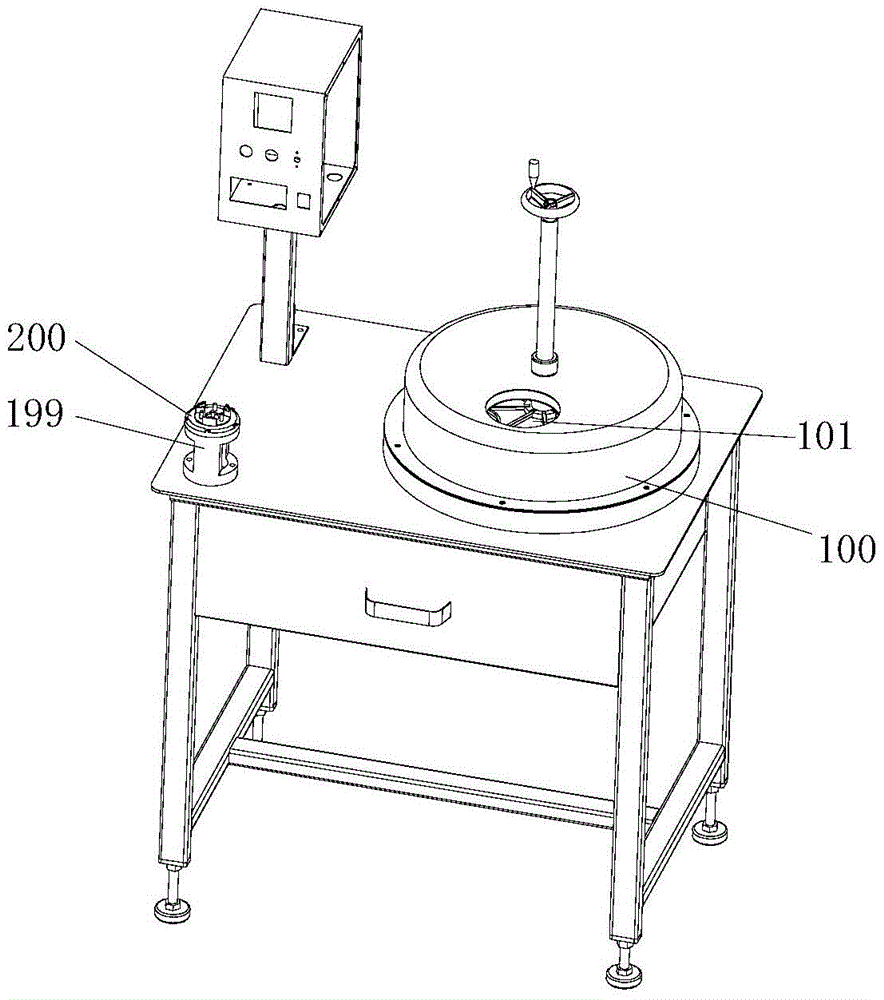

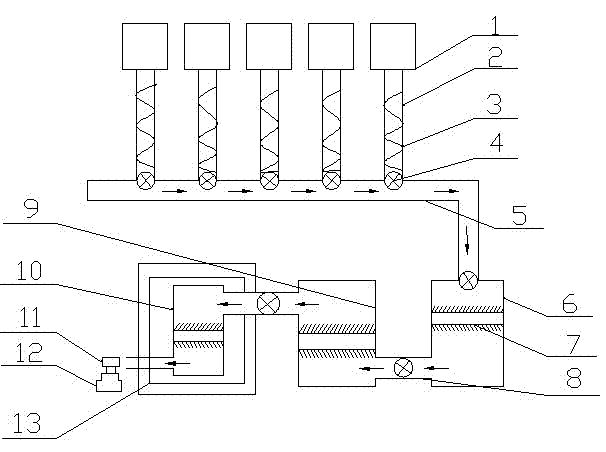

Fully-automatic production line of transformer

InactiveCN102779638ASimple and scientific structure designIncrease productivityInductances/transformers/magnets manufactureProduction lineTransformer

The invention relates to the technical field of electronic product machining equipment, in particular to a fully-automatic production line of a transformer. The fully-automatic production line comprises a feeding mechanism, a coil assembling mechanism, an assembling mechanism, a tin soldering mechanism and a product conveying table, which are sequentially connected to form a machine body, wherein a conveying belt is arranged in the feeding mechanism; a jig positioning table and a coil assembling table are arranged in the coil assembling mechanism; an operation panel is arranged on the assembling mechanism; and a soldering table for soldering a pin is arranged in the tin soldering mechanism. The fully-automatic production line is simple and scientific in structural design, fully automatic in production assembly, high in production efficiency and high in precision of a produced product.

Owner:东莞市立敏达电子科技有限公司 +1

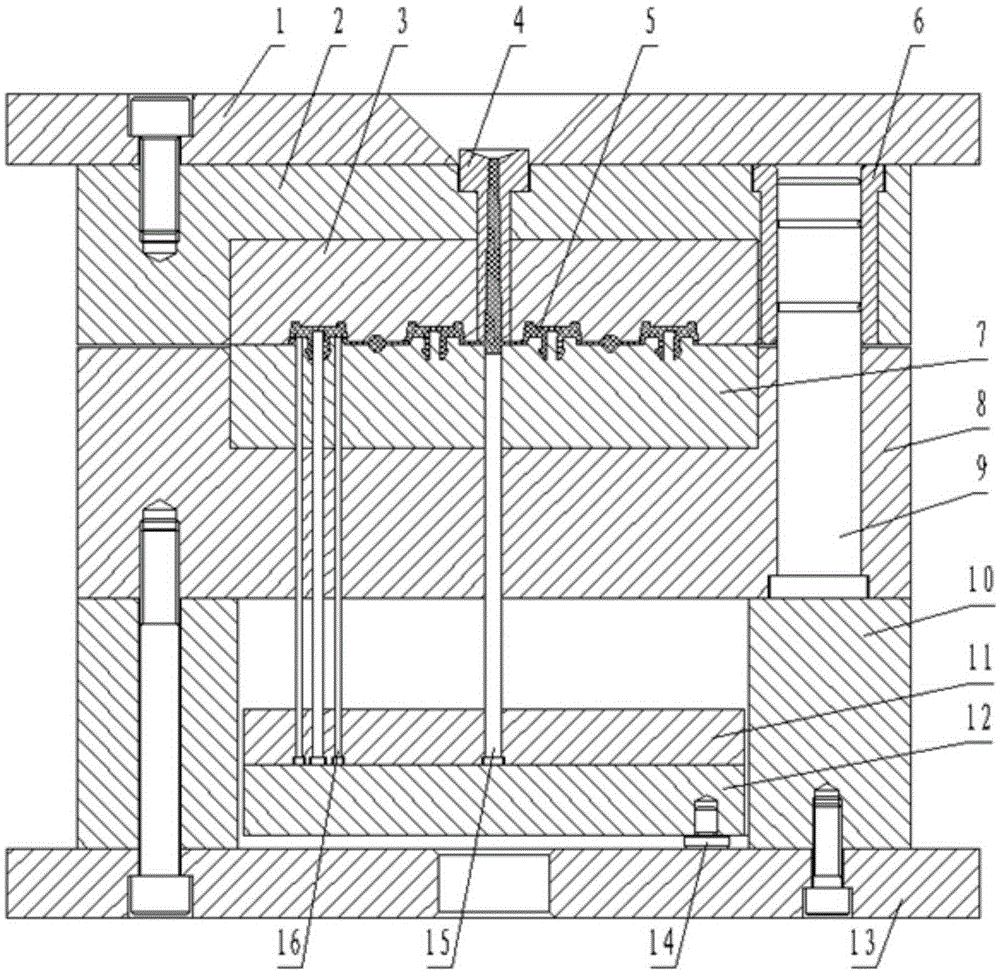

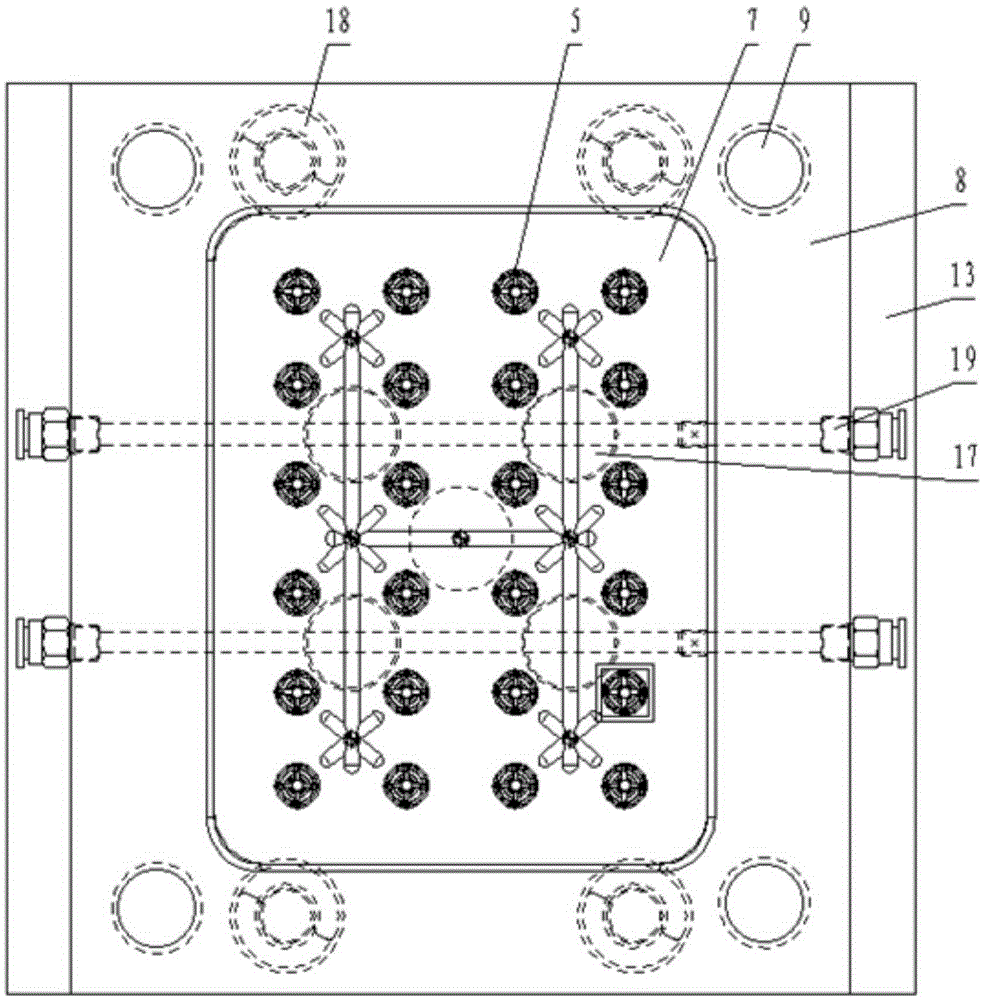

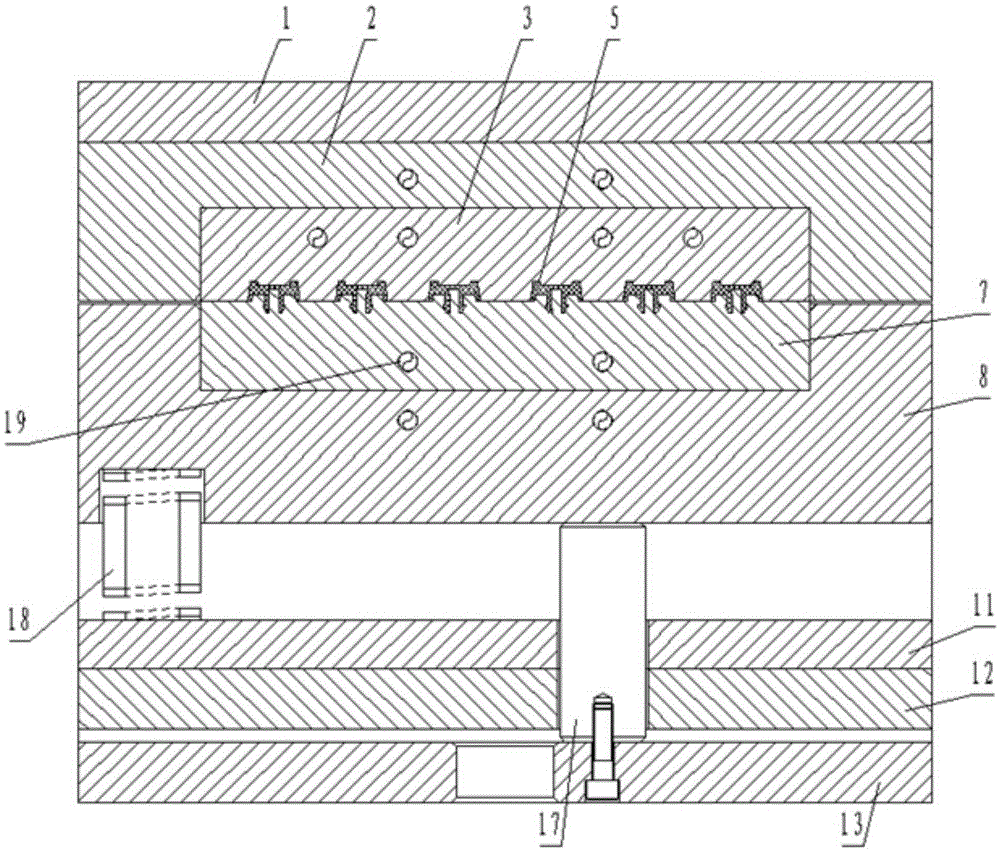

Injection mold for foot pad of computer case

The invention discloses an injection mold for a foot pad of a computer case. The injection mold comprises a fixed mold body and a movable mold body. The fixed mold body comprises an upper mold plate, a concave mold fixing plate, a concave mold insert, a sprue bush, mold cavities, a guide sleeve and cooling water channels. The movable mold body comprises a convex mold insert, a convex mold fixing plate, guide columns, supporting plates, an ejector pin fixing plate, an ejector pin cushion plate, a lower mold plate, a stop pin, a sprue puller, double-joint round ejector pins, supporting columns, return pins and cooling water channels. The fixed mold body and the movable mold body are matched and connected through the guide column and the guide sleeve. The 10 cooling water channels are arranged in the injection mold for the foot pad of the computer case, so that cooling time is short, and production efficiency is high; the four supporting columns are arranged, so that the materials of the supporting plates can be reduced, and the mold cost is low; the 24 mold cavities are adopted for injection molding at the same time, so that production efficiency is high; and a convex mold and a concave mold are both made to be of an insert structure, so that replacement is convenient, and the mold cost is low.

Owner:广州市花都区花山精宏塑胶模具厂

Weft storage type double rapier sheet ribbon-shaped tow carbon fiber braiding machine

The invention relates to the technical field of braiding machines, in particular to a weft storage type double rapier sheet ribbon-shaped tow carbon fiber knitting machine, which comprises a weft storage mechanism, wherein four corners of the bottom of the weft storage mechanism are fixedly connected with rollers; the top of the weft storage mechanism is fixedly connected with a base; the top of the base is fixedly connected with a bracket; one side of the bracket is rotatably connected with a first connecting shaft; the middle part of one end of the first connecting shaft far away from the bracket is fixedly connected with a weft disc; the weft disc is wound and connected with weft yarns; one side of the bracket is fixedly connected with a connecting frame; the outer wall of one side of the connecting frame close to the weft disc is rotatably connected with a second connecting shaft; the middle part of one end of the second connecting shaft far away from the connecting frame is fixedly connected with a yarn guide wheel; one end of the connecting frame far away from the bracket is fixedly connected with a weft feeding guide rail seat; the top of one side of the weft feeding guide rail seat close to the connecting frame is fixedly provided with a first positioning block. The whole structure is scientific and reasonable, the design and the installation are convenient and fast, the practicability is high, and the application range is wide.

Owner:航宸石家庄新材料科技有限公司

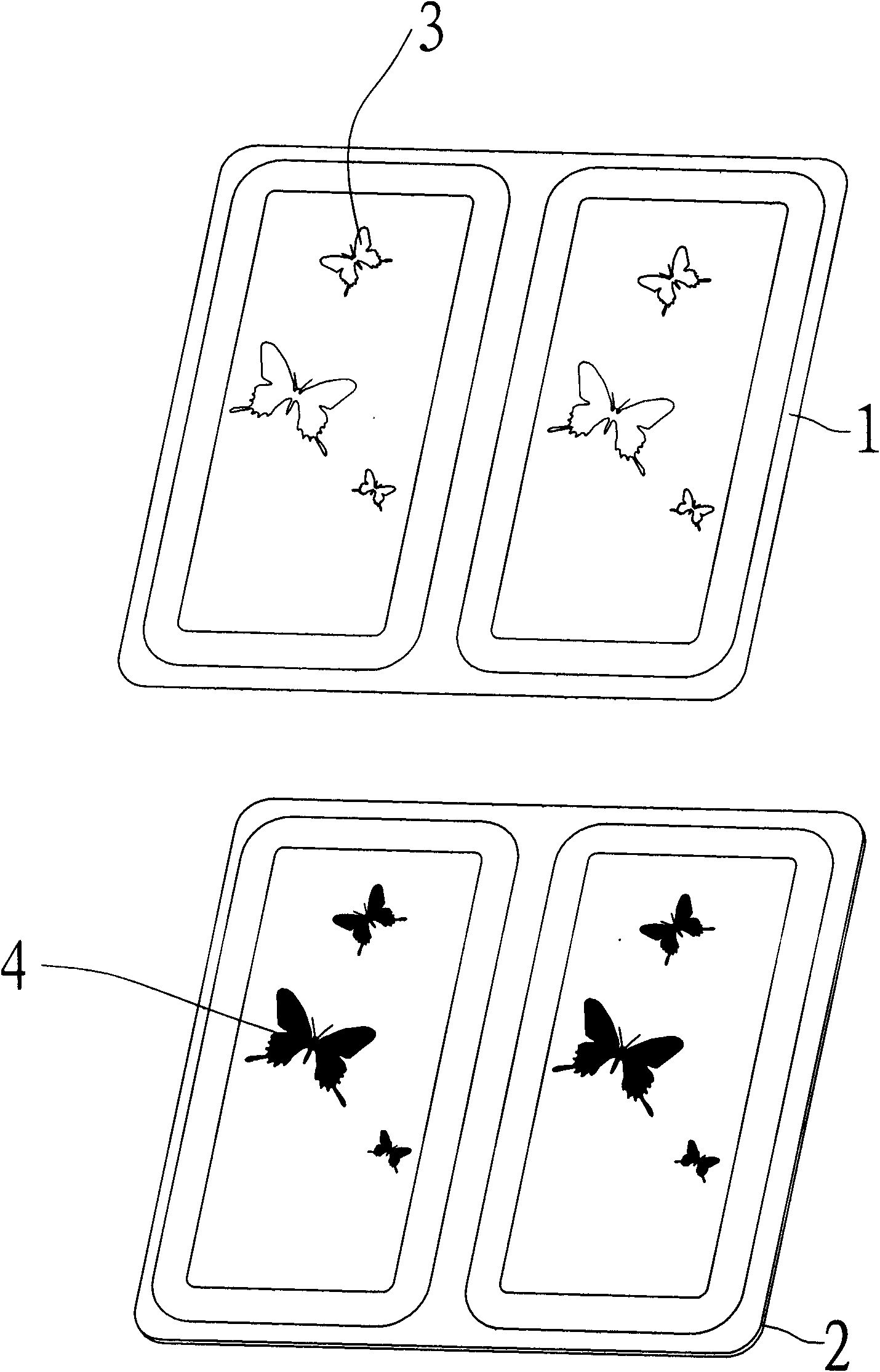

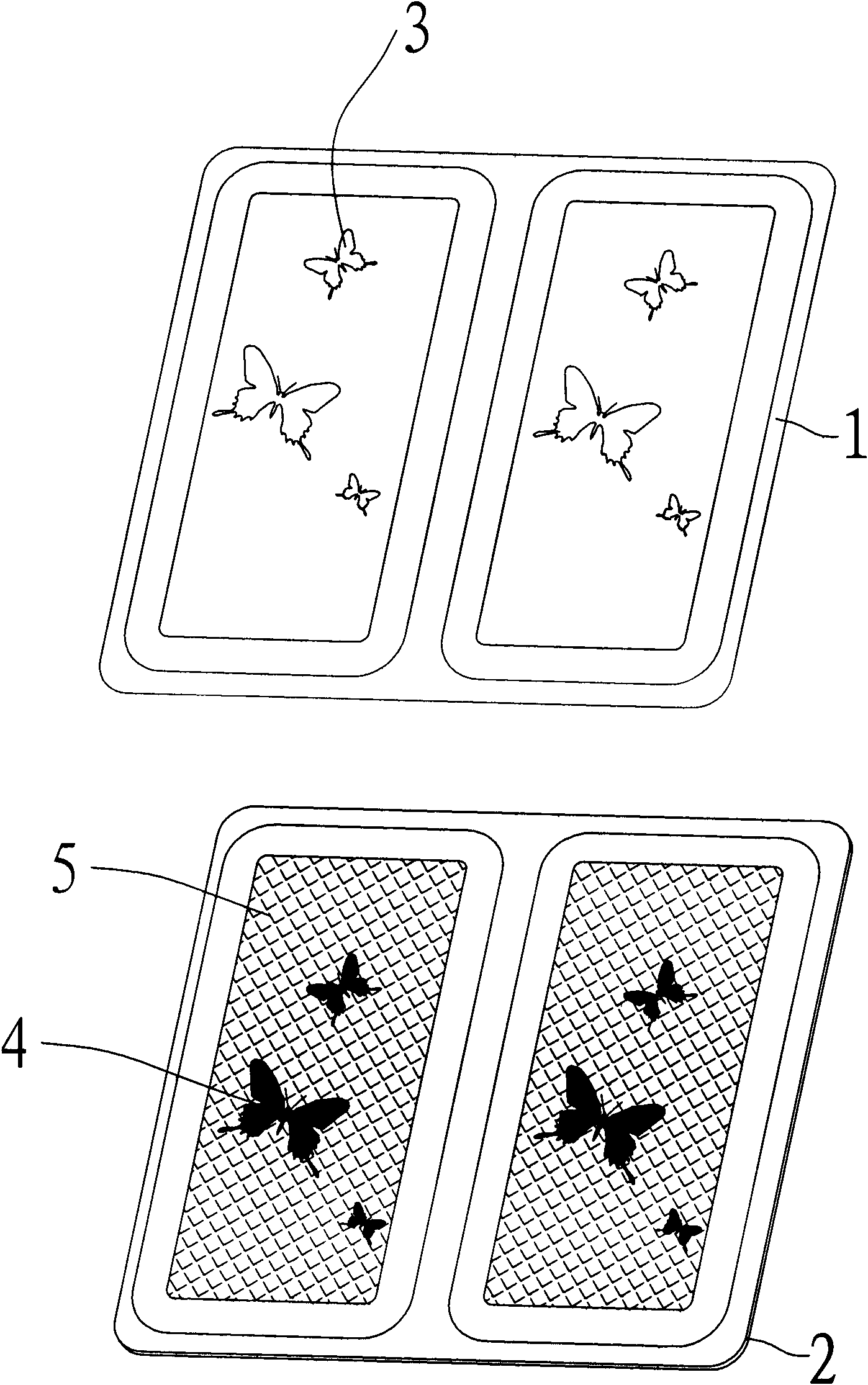

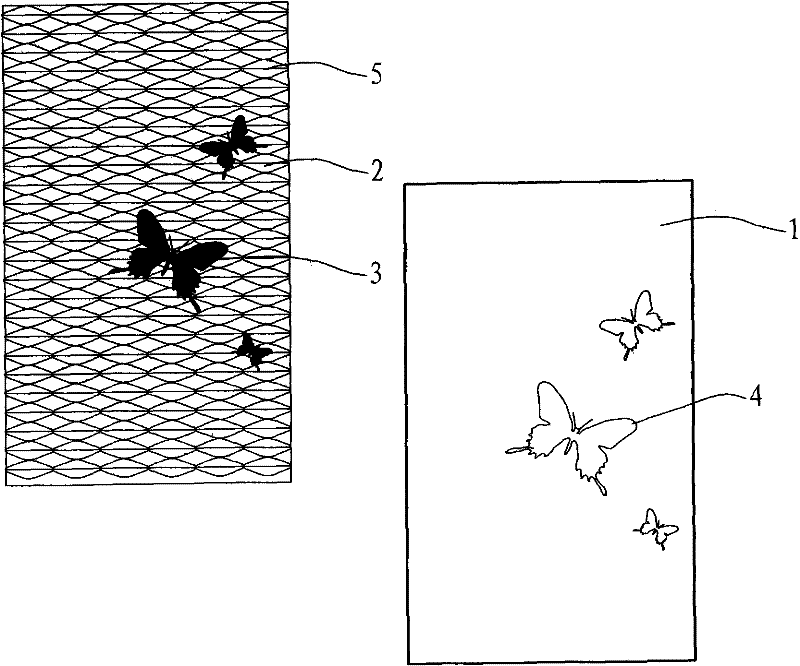

A surface-mount sheet injection-molded part and its fabrication process

InactiveCN102848663ASimple and scientific structure designEasy to produceLamination ancillary operationsSynthetic resin layered productsSurface finishingEngineering

The invention relates to the technical field of the surface treatment of an electronic product and household apparatus injection-molded part, specifically to a surface-mount sheet injection-molded part and its fabrication process. The surface-mount sheet injection-molded part comprises a sheet and an injection-molded part. A first printed pattern is arranged on the upper surface of the injection-molded part, a second printed pattern is arranged on the lower surface of the sheet and corresponding to the first printed pattern, and the lower surface of the sheet and the upper surface of the injection-molded part are bonded together through a bonding mode. The invention has simple and scientific structure design, convenient normal-temperature fabrication, and multilayer pattern effect, each layer of the patterns can be treated by various surface fabrication processes, the surface has the advantages of high hardness and high resistance to scratching and wear, and the product appearance has diverse expressiveness.

Owner:东莞市汇诚塑胶金属制品有限公司

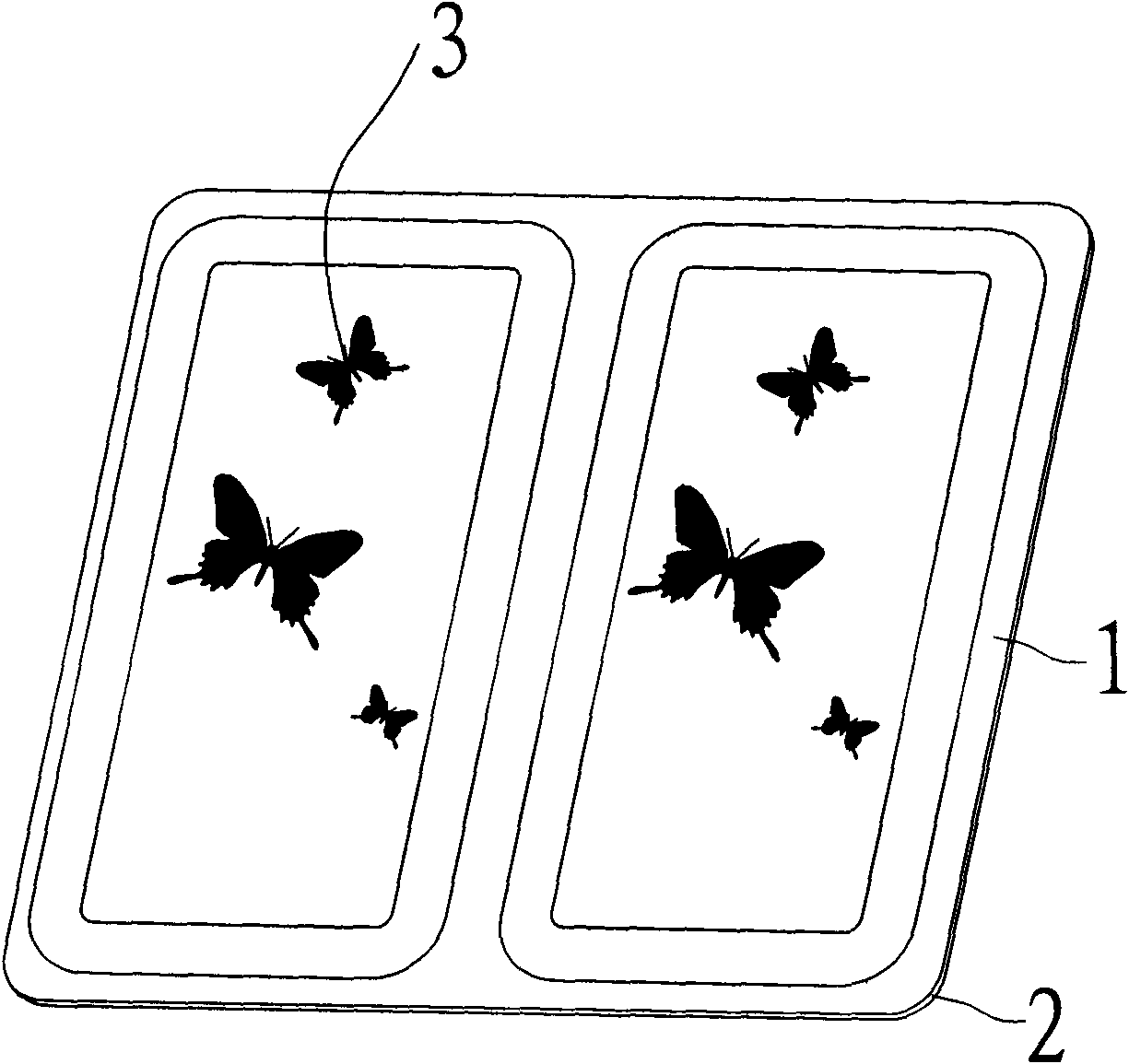

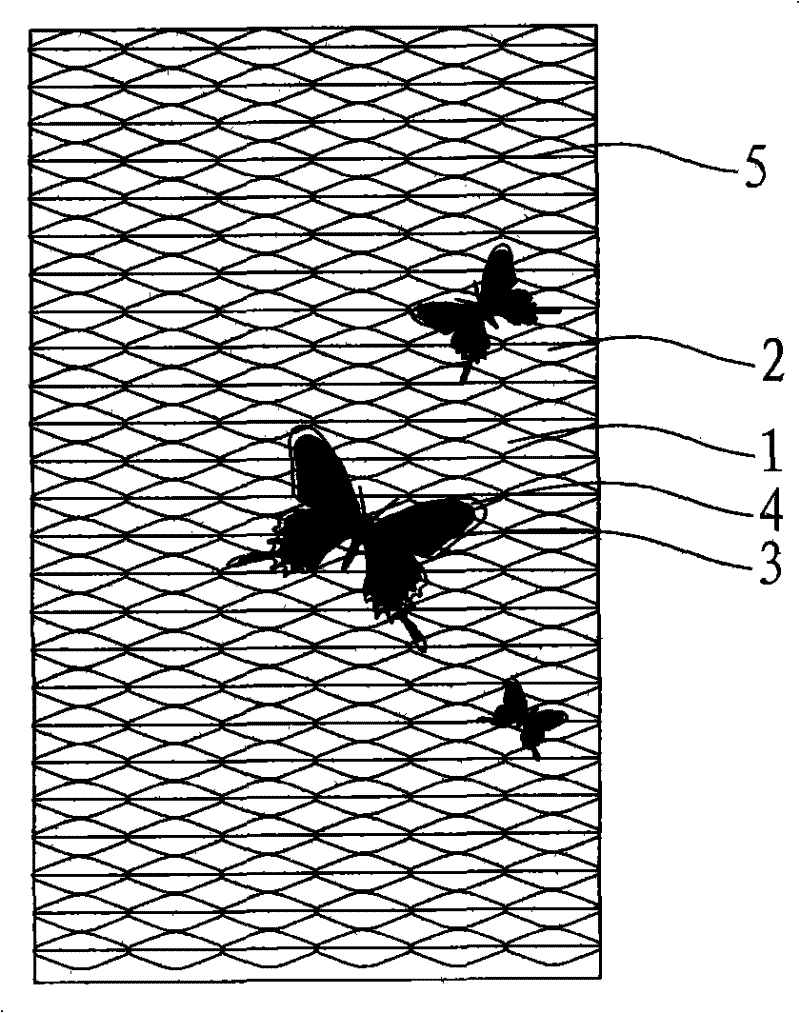

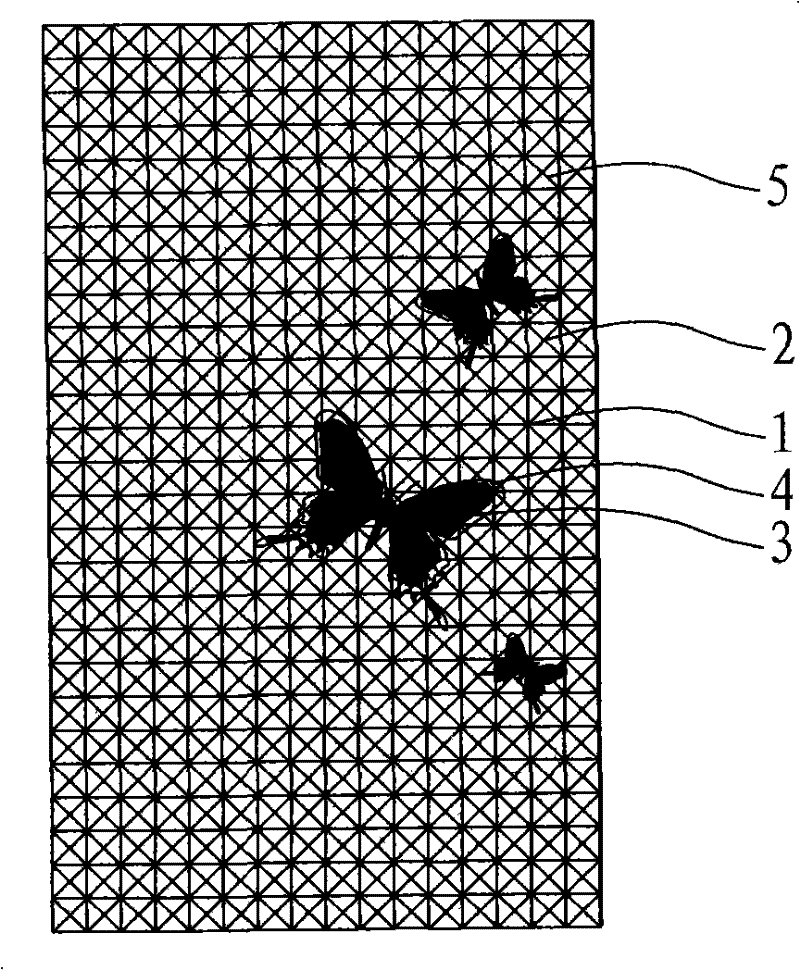

Decorating plate with multilayer three-dimensional effect and machining process of decorating plate

InactiveCN102529547ASimple and scientific structure designEasy to process and produceDecorative surface effectsThree-dimensional effectsEngineeringHardness

The invention relates to the technical field of household appliance housing plates, in particular to a decorating plate with a multilayer three-dimensional effect and a machining process of the decorating plate. A printed pattern is arranged on the upper surface of a plate, a pattern layer with a three-dimensional image-text effect is formed on the lower surface of the plate by adopting a surface treatment process, and a printed pattern is correspondingly arranged on the lower surface of a sheet. The machining process comprises the steps of: 1, carrying out silk-screening, spraying, transferring, electroplating and graving surface treatment on the sheet and the plate; 2, after fixing the plate through a location plate, coating transparent liquid or solid glue on the surface of the plate, fixing the plate through the location hole and jointing the plate with the sheet; and 3, carrying out silk-screening, spraying, transferring, electroplating and graving surface treatment processes on the other surface of the plate, forming the pattern layer with the three-dimensional image-text effect, and then cutting and forming. The decorating plate has a simple and scientific structure design, can obtain a multilayer three-dimensional image-text effect from the surface, and has the advantages of high hardness, scratching resistance and abrasion resistance of the surface.

Owner:东莞市汇诚塑胶金属制品有限公司

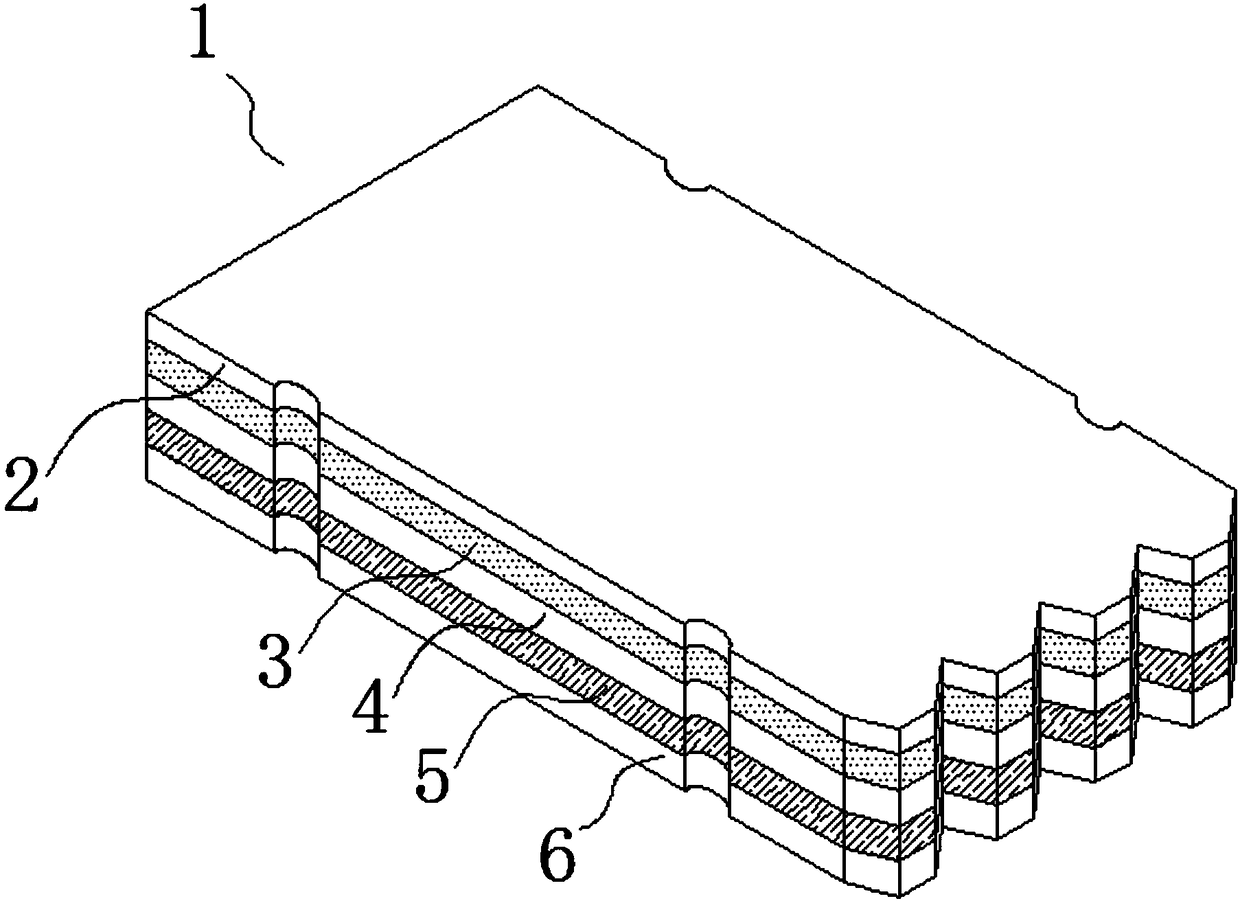

Light guide plate for mobile phone and manufacturing method thereof

InactiveCN108205169AImprove light uniformitySimple and scientific structure designPlanar/plate-like light guidesLight guideOptics

The invention discloses a light guide plate for a mobile phone. The light guide plate comprises a light guide plate body, the light guide plate body includes an upper diffusion film, a brightness enhancement film, a lower diffusion film, a light guide plate main body and a reflective film. The upper diffusion film, the brightness enhancement film, the lower diffusion film, the light guide plate main body and the reflective film are sequentially bonded from top to bottom, and the two sides of the light guide plate body are provided with semi-arc-shaped clamping grooves, and the light inlet endof the light guide plate body is provided with isosceles trapezoids which are sequentially adjacent. The light guide plate is of an isosceles trapezoid sawtooth structure, incident light of the lightguide plate body can be emitted more favorably, and thus the light emitting evenness is improved. The light guide plate is scientific and simple in structure design, the ultra-thin structure design and the arrangement of the upper diffusion film, the brightness enhancement film, the lower diffusion film, the light guide plate body and the reflective film make the light guide plate body have good light conductivity and reduce light loss; and the arrangement of first light-shielding paper, second light-shielding paper and third light-shielding paper reduces interference of light on the side of the light guide plate body.

Owner:滁州佳宏光电有限公司

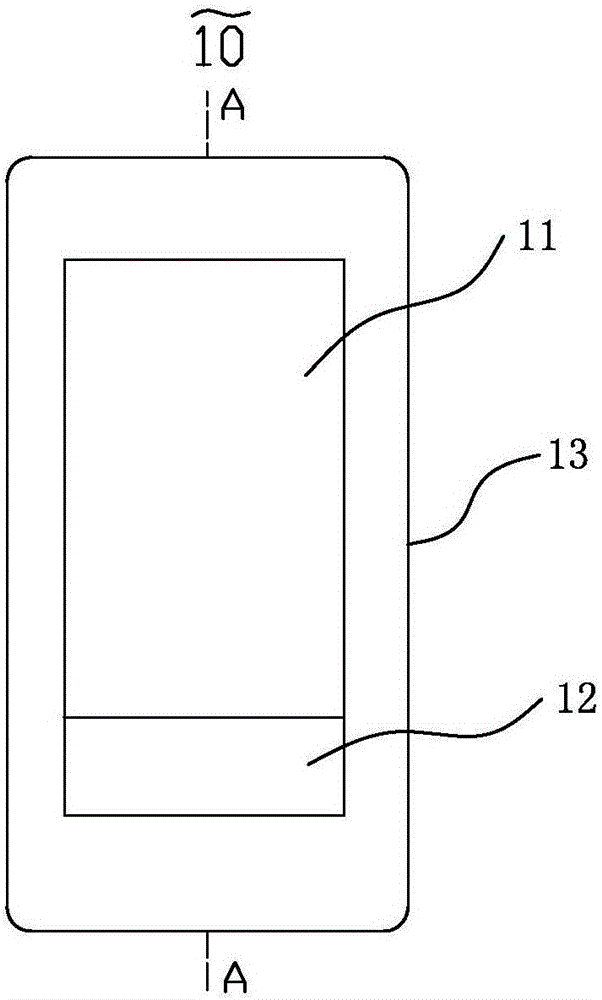

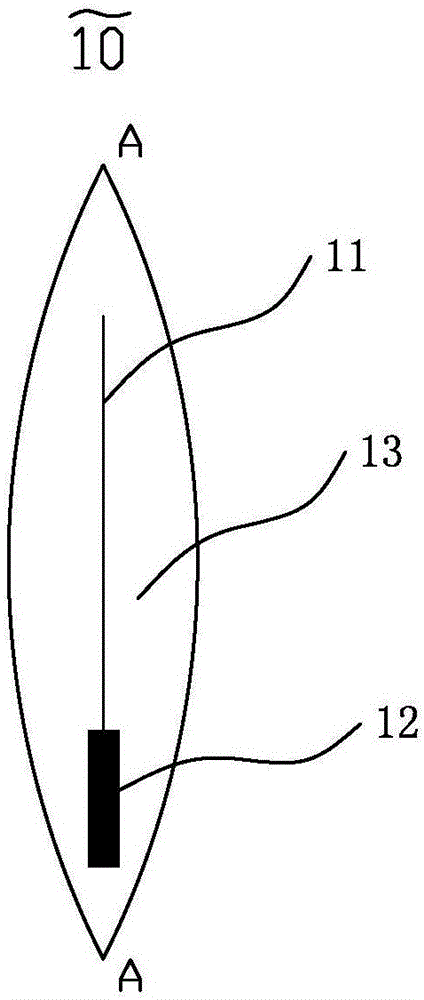

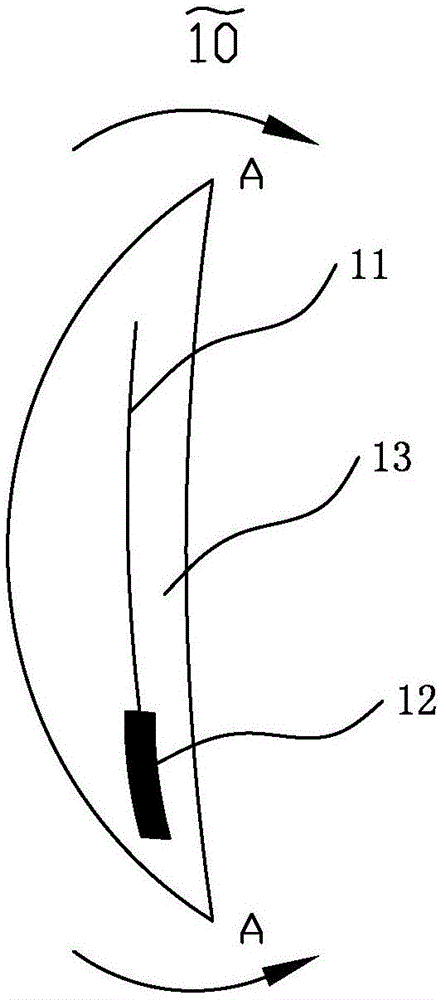

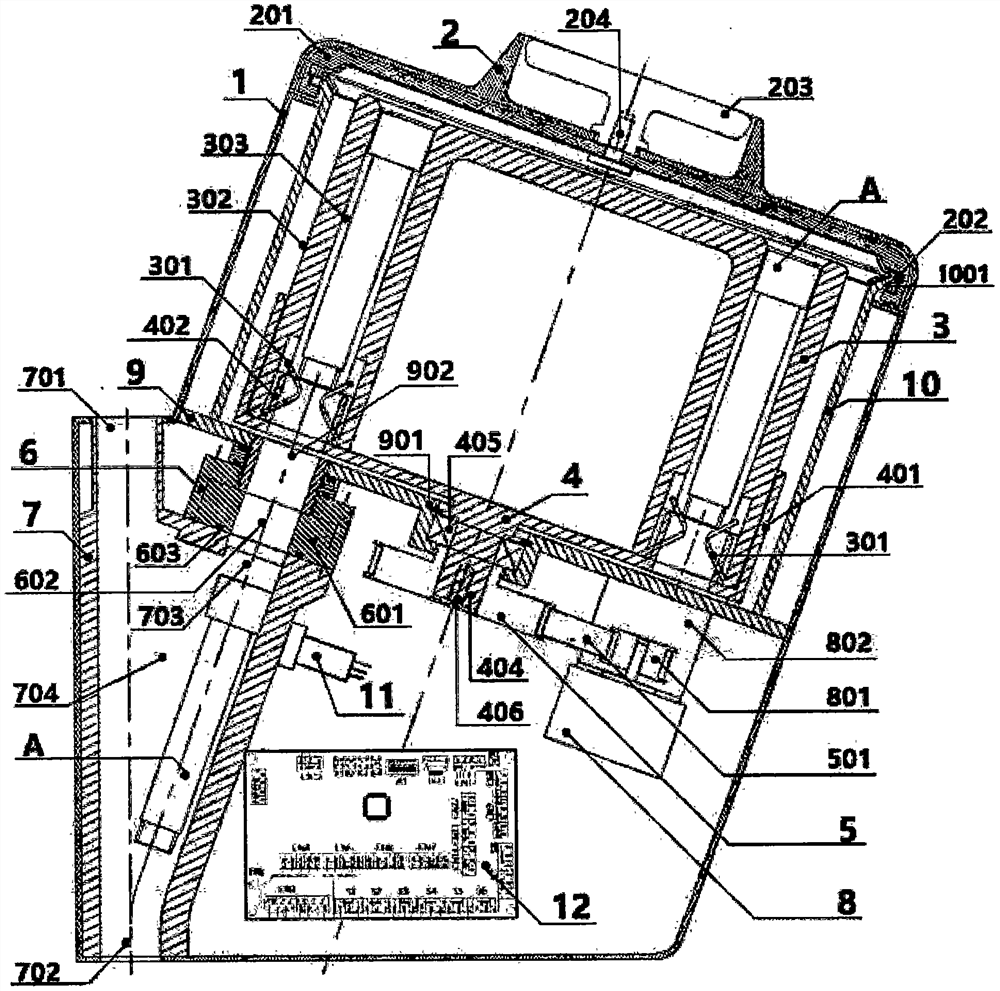

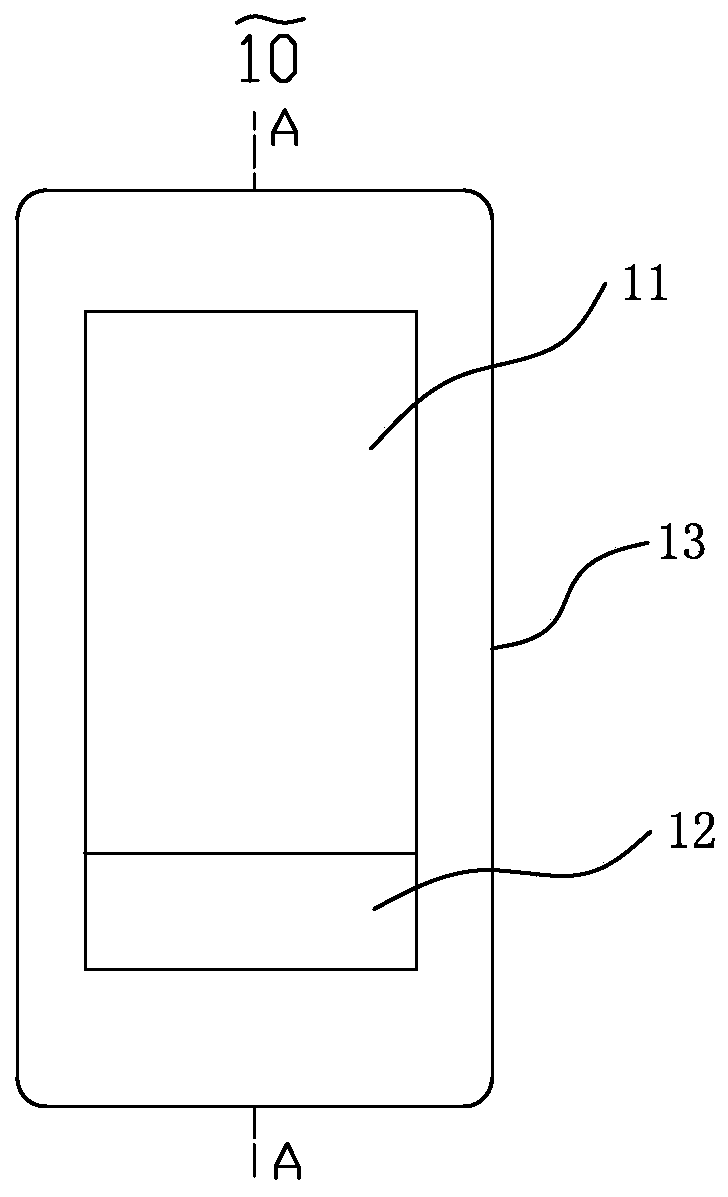

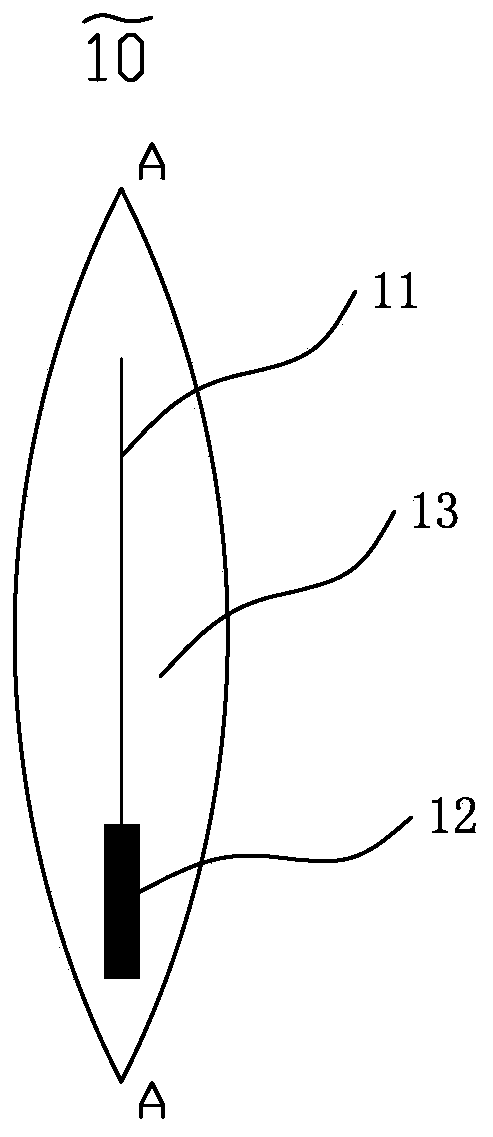

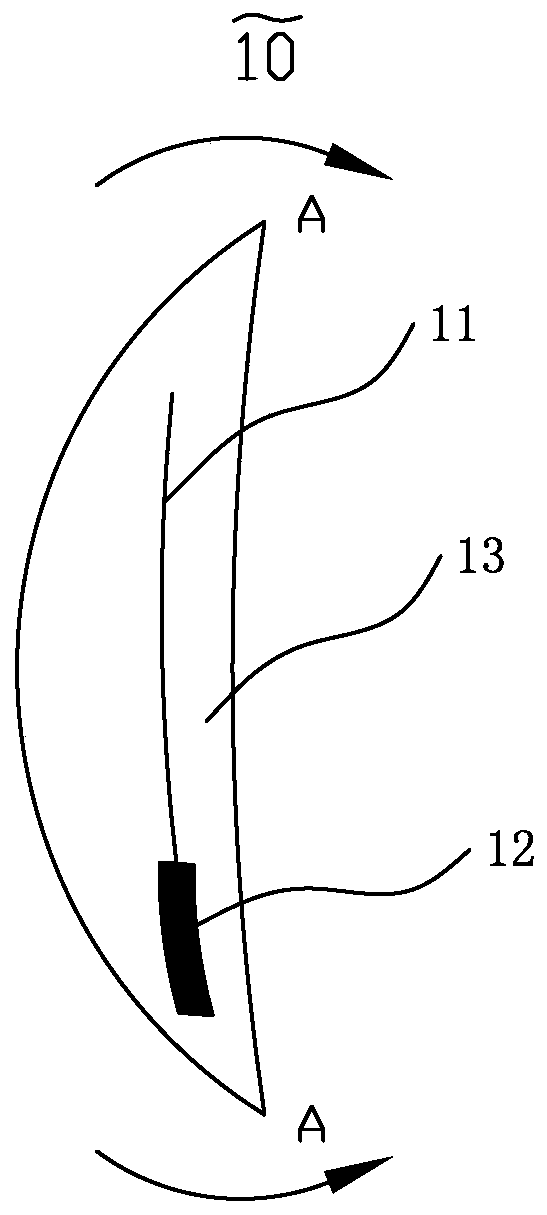

Flexible display device and manufacturing method thereof

ActiveCN106486019ASo as not to damageSimple and scientific structure designIdentification meansEngineeringFlexible display

The invention provides a flexible display device and a manufacturing method thereof, relates to the technical field of displaying, and can enable an encapsulation structure of a flexible display to meet a requirement on flexibility. The flexible display device comprises a flexible display screen, hardware and the encapsulation structure, wherein the encapsulation structure comprises an encapsulation piece; the encapsulation piece comprises a close body; the close body comprises an accommodating space; the flexible display screen and the hardware are arranged in the accommodating space. The flexible display device can be well protected from being damaged by outside destroy; with the adoption of an olive-shaped structure, the flexible display device has a thick middle part and two thin ends when bent, so that damage to a screen body due to excessive bending is effectively prevented, moreover, the flexible display device is simple and scientific in structural design and low in production cost.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Automatic sleeve feeding device for multi-axial winding machine

The invention relates to the technical field of winding devices of high-frequency transformation, in particular to an automatic sleeve feeding device for a multi-axial winding machine. A line passing mechanism and a driving mechanism are arranged on a frame, a spool is arranged on the line passing mechanism, the driving mechanism comprises a motor, a multi-axial winding machine axle center, a winding machine head, an automatic hot-melting sleeve stringing device and a transmission device, a supporting plate is arranged on one side of the frame, and a movable device cylinder, an air pressure eddy current cooling pipe, a fixing frame, a heating device and a fitting clamp head are arranged on the automatic hot-melting sleeve stringing device. The automatic sleeve feeding device is simple and scientific in structural design and mounted on the multi-axial automatic winding machine, and sleeves are automatically strung on a copper line.

Owner:湖南立敏达电子科技有限公司

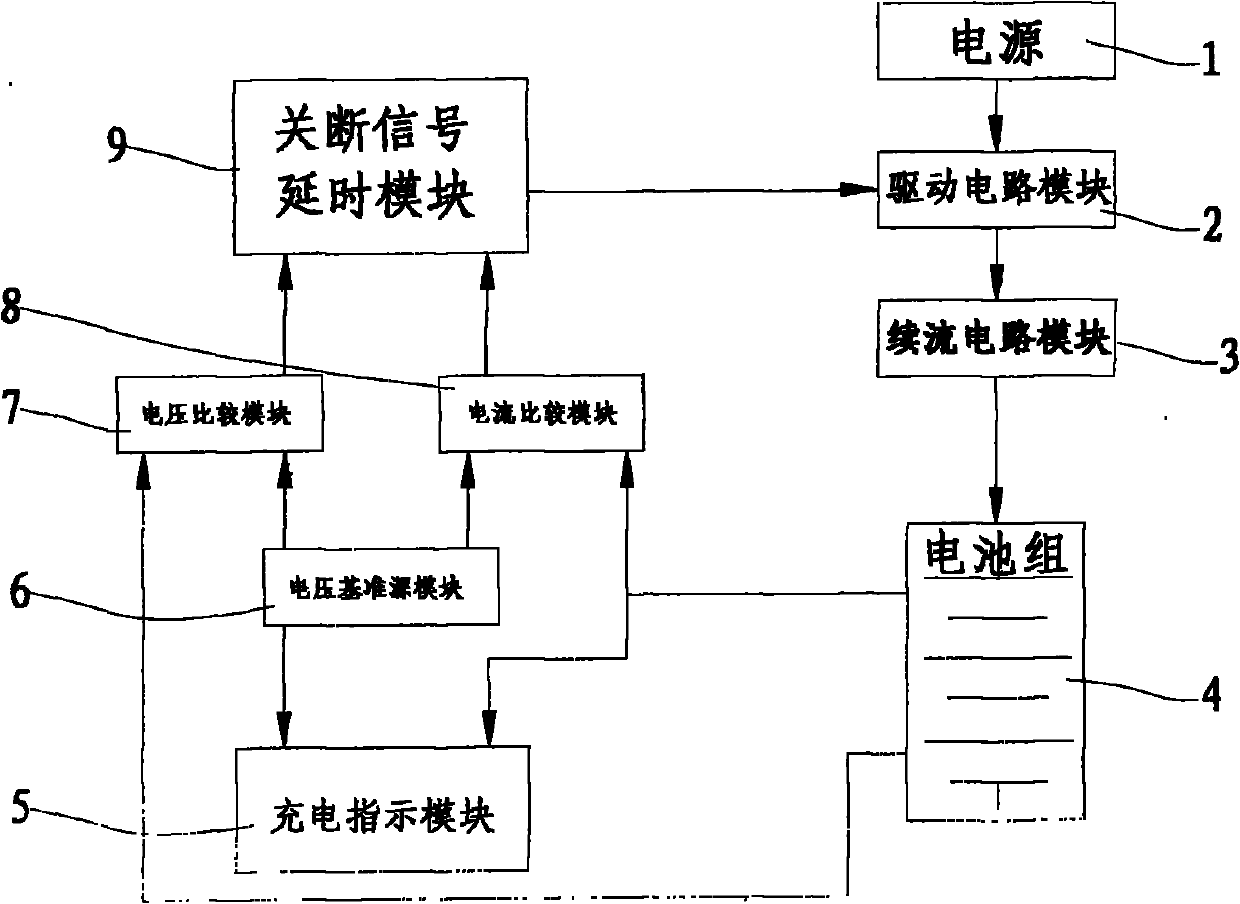

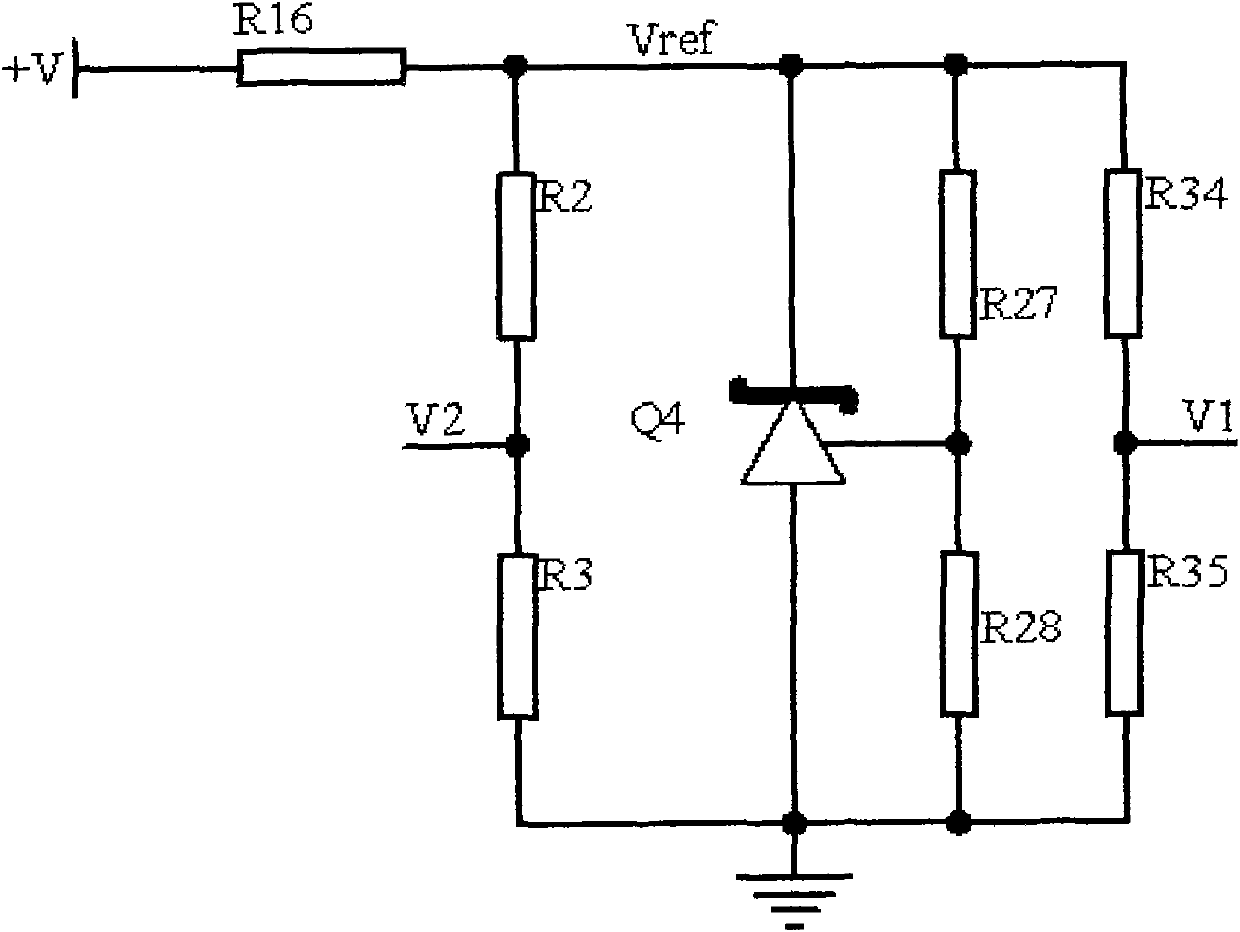

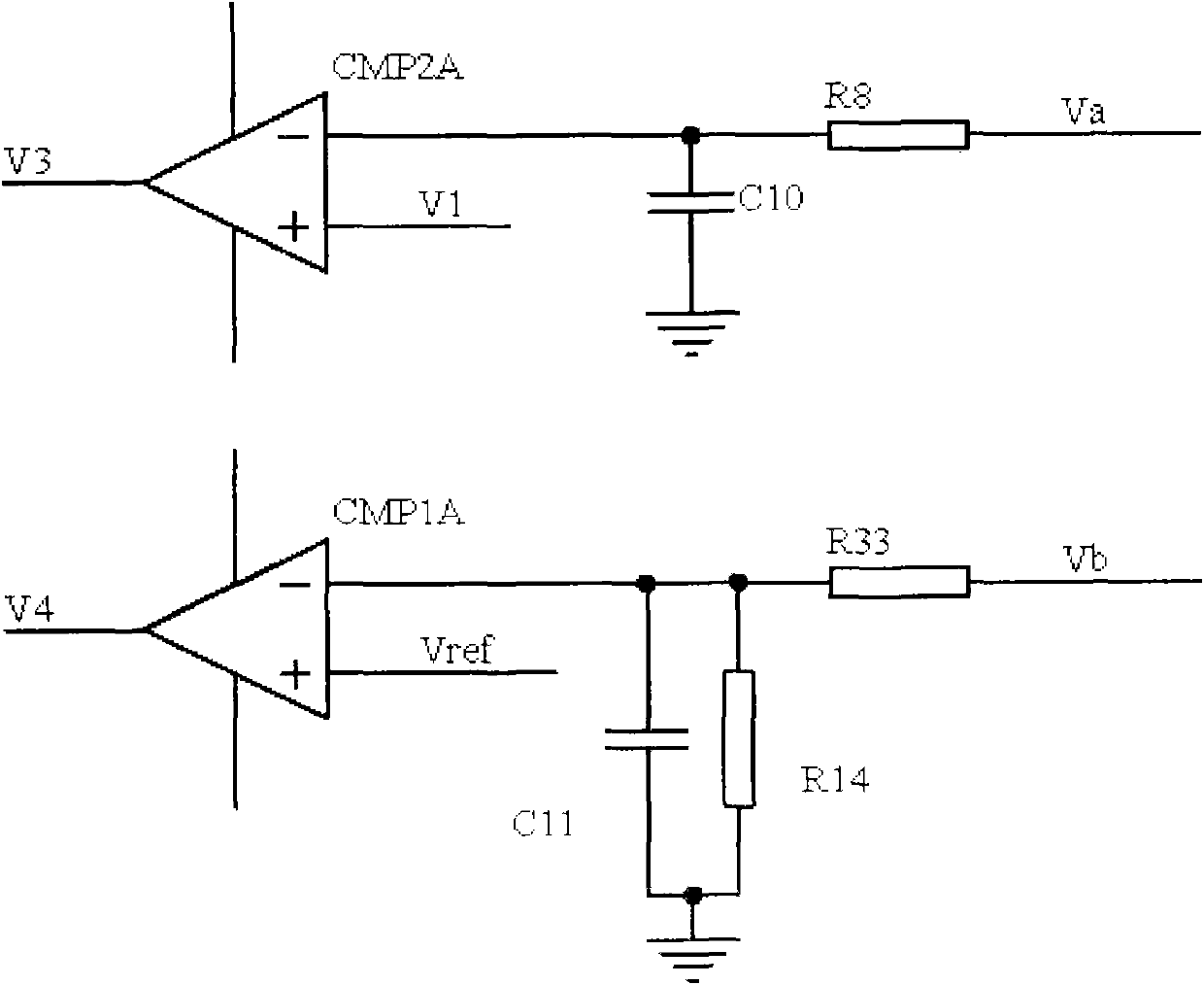

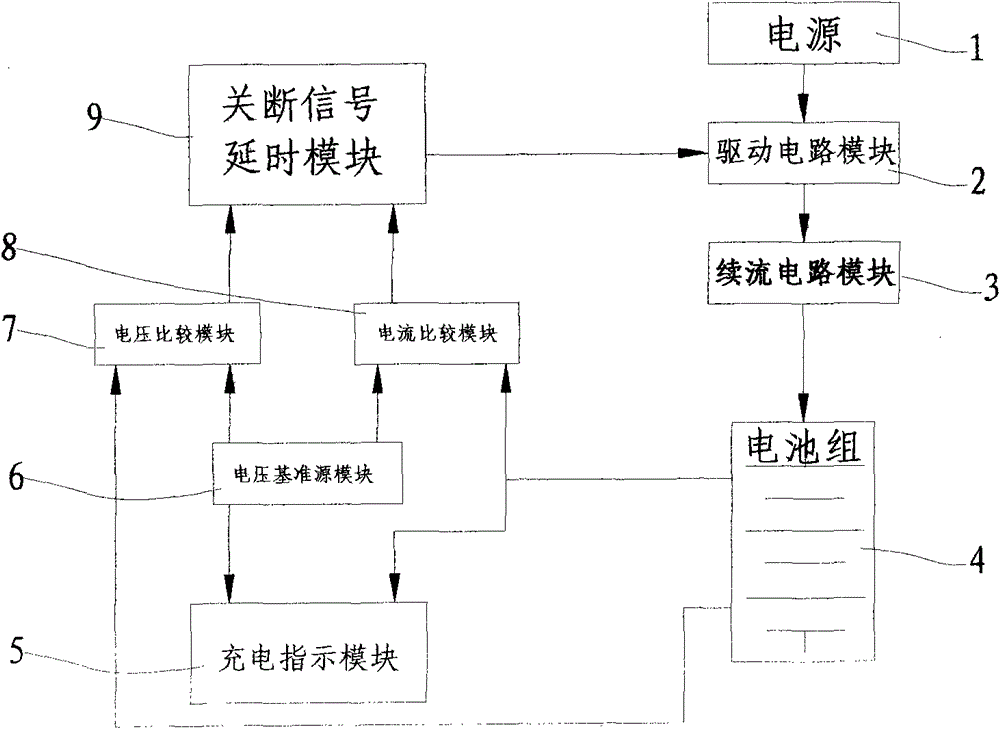

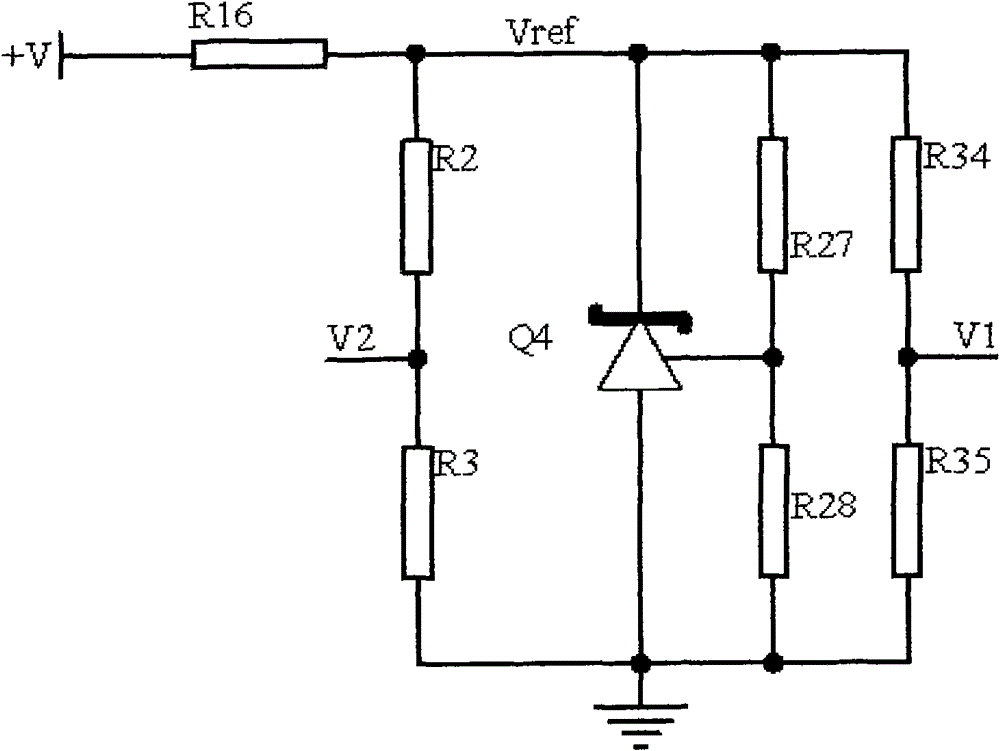

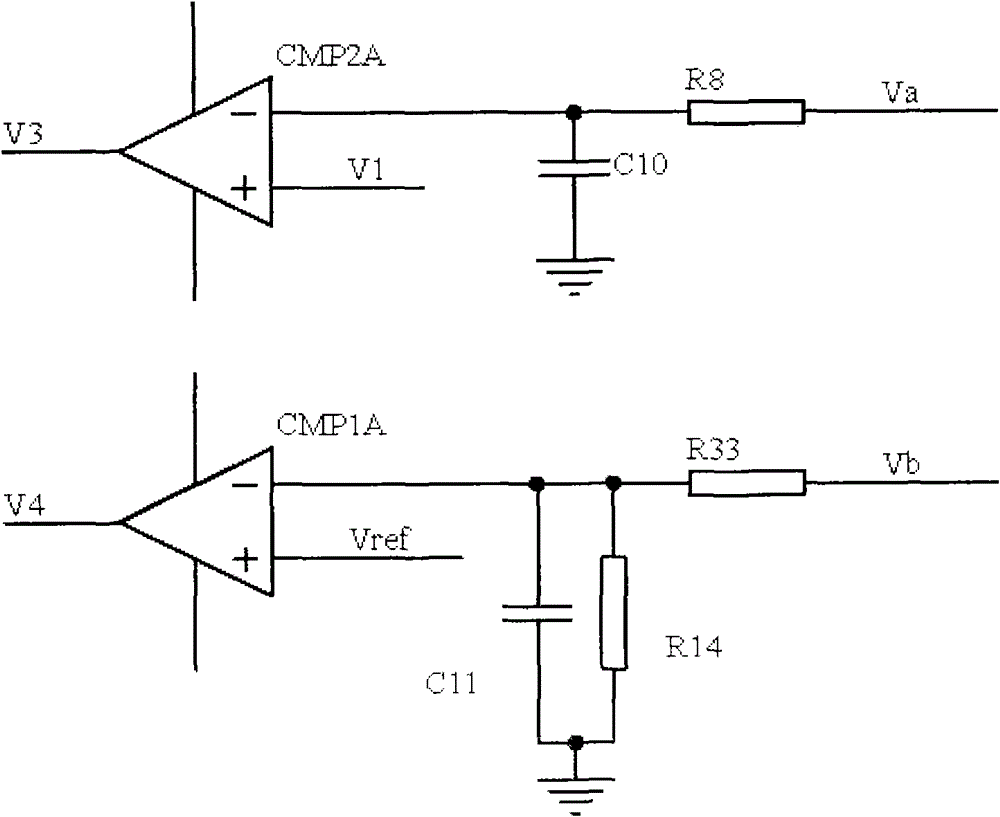

Current-limiting and voltage-limiting lithium battery charge circuit based on comparer

InactiveCN102570528ASimple and scientific structure designLow costBatteries circuit arrangementsElectric powerCurrent limitingVoltage reference

The invention relates to the technical field of power supply circuits, in particular relates to a current-limiting and voltage-limiting lithium battery charge circuit based on a comparer. A power supply, a driving circuit module, a follow current circuit module and a battery pack are connected in series; the battery pack is electrically connected with a charging indicating module, a voltage comparing module and a current comparing module respectively; a voltage reference source module is electrically connected with the charging indicating module, the voltage comparing module and the current comparing module respectively; and the voltage comparing module and the current comparing module are electrically connected with the input end of a turning-off signal delay module respectively, and the input end of the turning-off signal delay module is electrically connected with the driving circuit module. The current-limiting and voltage-limiting lithium battery charge circuit has a simple and scientific structure design, completes functions of current limiting, voltage limiting, charge indicating and the like of switching mode control, and has the advantages of low cost, high efficiency and high reliability.

Owner:东莞市妙达电动工具制造有限公司

Special CNC (computer numerical control) machine tool for tappet drilling

ActiveCN107695379APrecise positioningAdjust in timePositioning apparatusMaintainance and safety accessoriesNumerical controlMachine tool

The invention discloses a special CNC (computer numerical control) machine tool for tappet drilling. The machine tool comprises a tool body and a control box, and is characterized in that a base is fixedly connected with the upper end of the tool body, a workpiece groove is formed in the middle of the base, a plurality of transverse supporting columns for supporting a workpiece are arranged at thelower end of the workpiece groove, and both sides and the middle of each supporting column are hollowed out; a stop block is fixed at one end of the workpiece groove, and a workpiece clamping block is arranged at the other end of the workpiece groove and is fixed at a telescopic end of a clamping oil cylinder; fixing blocks are arranged on two sides of the workpiece groove, and drilling holes inclined to the workpiece are formed in the fixing blocks; drilling devices are arranged two ends of each drilling hole respectively, and each drilling device comprises a two-way oil cylinder fixed at the upper end of the base; a drilling knife matched with the corresponding drilling hole is fixedly connected with one end of a piston rod of each two-way oil cylinder, and a motor for driving the piston rod to rotate is arranged at the other end of the corresponding two-way oil cylinder. The machine tool has the beneficial effects that two-way simultaneous drilling of the workpiece is realized, accurate positioning of the workpiece is ensured, and machining precision of the workpiece is ensured.

Owner:SHANDONG GAOQIANG FASTENER

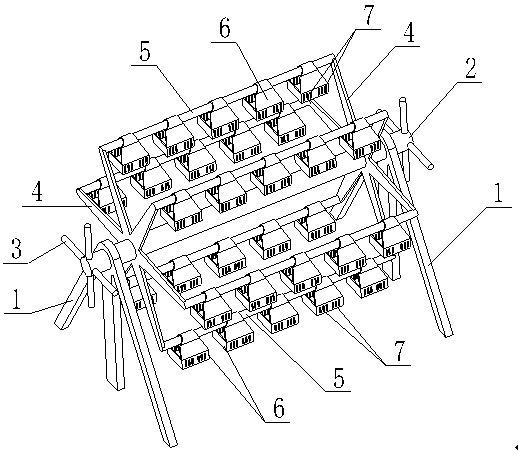

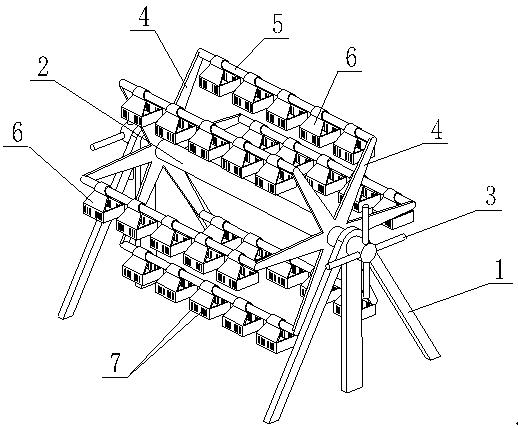

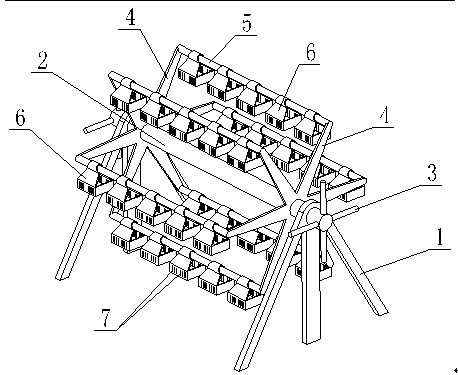

Food airing frame

InactiveCN108464341AIncrease storage spaceSave drying spaceMeat/fish preservation by dryingImpellerNacelle

The invention relates to the field of food equipment, in particular to a food airing frame. The food airing frame comprises a bracket, a rotating shaft and handles, wherein the rotating shaft is arranged on the bracket. According to the food airing frame provided by the invention, the handles are respectively arranged at two ends of the rotating shaft of the food airing frame; a plurality of crossbeams are fixed between vane wheels; a plurality of hanging baskets are arranged on each crossbeam; the hanging baskets can be driven to rotate at the same time through rotation of the handles; storing space of foods is increased through design of the nacelles, and the airing space of the foods is saved; a plurality of ventilation holes are formed in two sides of each hanging basket, so that the air-drying effect of the foods is improved; and the food airing frame is simple and scientific in structural design, the airing space of the foods is saved, the airing efficiency of the foods is improved, and the food airing frame is suitable for popularization and application.

Owner:SUZHOU XINWEN FOOD

Nurse station specimen sending device and operation control

PendingCN112141712AMeet needsTroubleshoot interconnect issuesConveyorsStructural engineeringMechanical engineering

The invention discloses a nurse station specimen sending device and operation control. The sending device is composed of a specimen box, a pipeline valve, a pipe feeding device and a control mechanism. A specimen insertion hole is designed on the specimen box , the specimen box is specimen box connected to a driving platform in an inserted manner, and the driving platform is fixed on a mounting partition plate in a device shell. The lower portion of the pipeline valve is connected with the pipe feeding device of a system pipeline, an outlet of the pipeline valve is connected with a branch pipeopening above the pipe feeding device, the specimen box, the pipeline valve and drivers are all installed in the same device shell, a machine box cover plate is designed above the device shell, and alocking device is designed between the machine box cover plate and the device shell. The corresponding driver is designed on each of the specimen box and the pipeline valve. The device is multi-pointto one-point specimen conveying equipment designed according to the requirements of a hospital nurse station, the structural design is simple and scientific, operation is simple and convenient, and high intelligence, high efficiency and high safety of operation are achieved.

Owner:九江恒创源科技有限公司 +1

Food drying device

InactiveCN108645167AIncrease storage spaceImprove drying effectDrying gas arrangementsFood preservationImpellerDrying

The invention relates to the field of food equipment, in particular to a food drying device. The food drying device comprises a bracket, a rotating shaft, handles and a drying barrel; and the rotatingshaft is arranged on the bracket. The handles are arranged at the two ends of the rotating shaft of the food drying device; multiple cross beams are fixed between impellers; the cross beams are provided with multiple lifting baskets; the handles can be rotated to drive synchronous rotation of the multiple lifting baskets; through design of the multiple lifting baskets, the food storage space is enlarged, and the food drying space is saved; multiple ventilation holes are formed in the two sides of the lifting baskets to improve the food drying effect; a fan blows air into the drying barrel toaccelerate the drying effect; and foods are taken and placed in the lifting baskets by exhaust ports during exhausting. The food drying device is simple and scientific in structural design, saves thefood airing space, improves the food airing efficiency, and is suitable for popularization and application.

Owner:SUZHOU XINWEN FOOD

Flexible display device and manufacturing method thereof

ActiveCN106486019BSo as not to damageSimple and scientific structure designIdentification meansEngineeringFlexible display

The invention provides a flexible display device and a manufacturing method thereof, relates to the technical field of displaying, and can enable an encapsulation structure of a flexible display to meet a requirement on flexibility. The flexible display device comprises a flexible display screen, hardware and the encapsulation structure, wherein the encapsulation structure comprises an encapsulation piece; the encapsulation piece comprises a close body; the close body comprises an accommodating space; the flexible display screen and the hardware are arranged in the accommodating space. The flexible display device can be well protected from being damaged by outside destroy; with the adoption of an olive-shaped structure, the flexible display device has a thick middle part and two thin ends when bent, so that damage to a screen body due to excessive bending is effectively prevented, moreover, the flexible display device is simple and scientific in structural design and low in production cost.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Automatic sleeve adding device for multi-axis winding machine

The invention relates to the technical field of winding devices of high-frequency transformation, in particular to an automatic sleeve feeding device for a multi-axial winding machine. A line passing mechanism and a driving mechanism are arranged on a frame, a spool is arranged on the line passing mechanism, the driving mechanism comprises a motor, a multi-axial winding machine axle center, a winding machine head, an automatic hot-melting sleeve stringing device and a transmission device, a supporting plate is arranged on one side of the frame, and a movable device cylinder, an air pressure eddy current cooling pipe, a fixing frame, a heating device and a fitting clamp head are arranged on the automatic hot-melting sleeve stringing device. The automatic sleeve feeding device is simple and scientific in structural design and mounted on the multi-axial automatic winding machine, and sleeves are automatically strung on a copper line.

Owner:湖南立敏达电子科技有限公司

Intelligent electronic product anti-vibration pad assembling equipment

InactiveCN106704325ASimple and scientific structure designReasonable structureMaterial gluingManipulatorWaste material

The invention relates to the technical field of electronic product automatic production equipment, in particular to intelligent electronic product anti-vibration pad assembling equipment. A shell feeding table is arranged on one side of a frame body; a control screen is arranged on the frame body; a manipulator is arranged at the upper end surface of the frame body; a feeding disc and a waste material colleting disc are arranged on one side of the manipulator; a material distributing mechanism is arranged between the feeding disc and the waste material collecting disc; the material distributing mechanism comprises a material sucking table and material distributing lines; the material distributing lines are arranged at the lower end of the material sucking table; the material distributing lines are metal wires; the material distributing lines are adhered and mounted on the upper end surface of material belts of the feeding disc and the waste material collecting disc; a detecting device is arranged on the other side of the manipulator; the angle of the material sucking table is controlled by a servo motor; a rotating angle is any one of 30 degrees, 60 degrees and 90 degrees; the intelligent electronic product anti-vibration pad assembling equipment is simple and scientific in structural design; a material is taken by adopting the manipulator; the material distributing lines are reasonable in structures; an anti-vibration pad is directly and thoroughly separated from a material disc, so that the anti-vibration pad is assembled conveniently and precisely.

Owner:天一新能源(东莞)有限公司

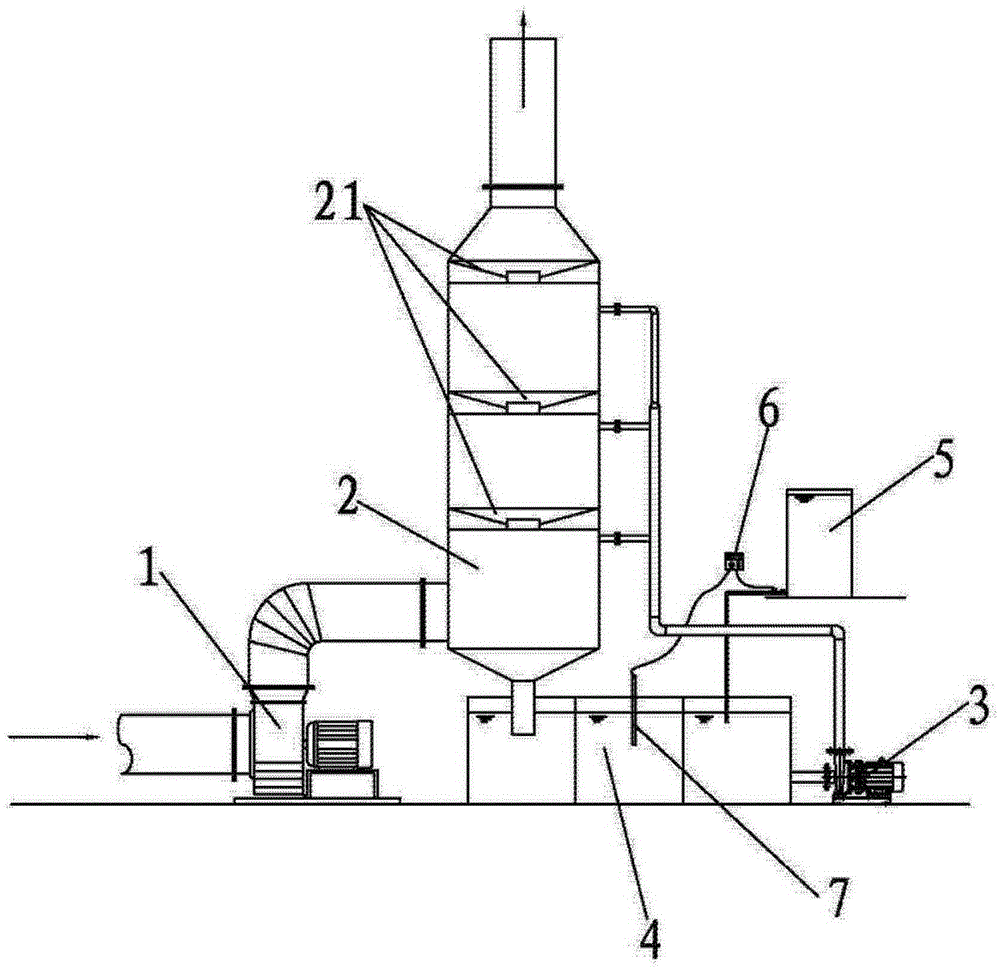

Energy-saving waste gas treatment facility

InactiveCN106669397ASimple and scientific structure designGas treatmentUsing liquid separation agentCycloneTower

The invention relates to the technical field of environment-friendly purifying facilities, particularly an energy-saving waste gas treatment facility which comprises a boiler induced fan, a cyclone plate tower, a circulating water pump and a circulating water tank, wherein one end of the boiler induced fan is connected with the cyclone plate tower; the circulating water tank is arranged below the cyclone plate tower; one side of the circulating water tank is provided with the circulating water pump; the input end of the circulating water pump is connected with the circulating water tank, and the output end of the circulating water pump is connected with the tower body of the cyclone plate tower through a water pipe; two or more cyclone plates are arranged in the cyclone plate tower; and a dosing barrel and a tester are arranged in the circulating water tank. The energy-saving waste gas treatment facility has the advantages of simple and scientific structural design, energy saving and environment friendliness, and can purify waste gas thoroughly.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

Current-limiting and voltage-limiting lithium battery charge circuit based on comparer

InactiveCN102570528BSimple and scientific structure designLow costBatteries circuit arrangementsElectric powerElectricityCurrent limiting

The invention relates to the technical field of power supply circuits, in particular relates to a current-limiting and voltage-limiting lithium battery charge circuit based on a comparer. A power supply, a driving circuit module, a follow current circuit module and a battery pack are connected in series; the battery pack is electrically connected with a charging indicating module, a voltage comparing module and a current comparing module respectively; a voltage reference source module is electrically connected with the charging indicating module, the voltage comparing module and the current comparing module respectively; and the voltage comparing module and the current comparing module are electrically connected with the input end of a turning-off signal delay module respectively, and the input end of the turning-off signal delay module is electrically connected with the driving circuit module. The current-limiting and voltage-limiting lithium battery charge circuit has a simple and scientific structure design, completes functions of current limiting, voltage limiting, charge indicating and the like of switching mode control, and has the advantages of low cost, high efficiency and high reliability.

Owner:东莞市妙达电动工具制造有限公司

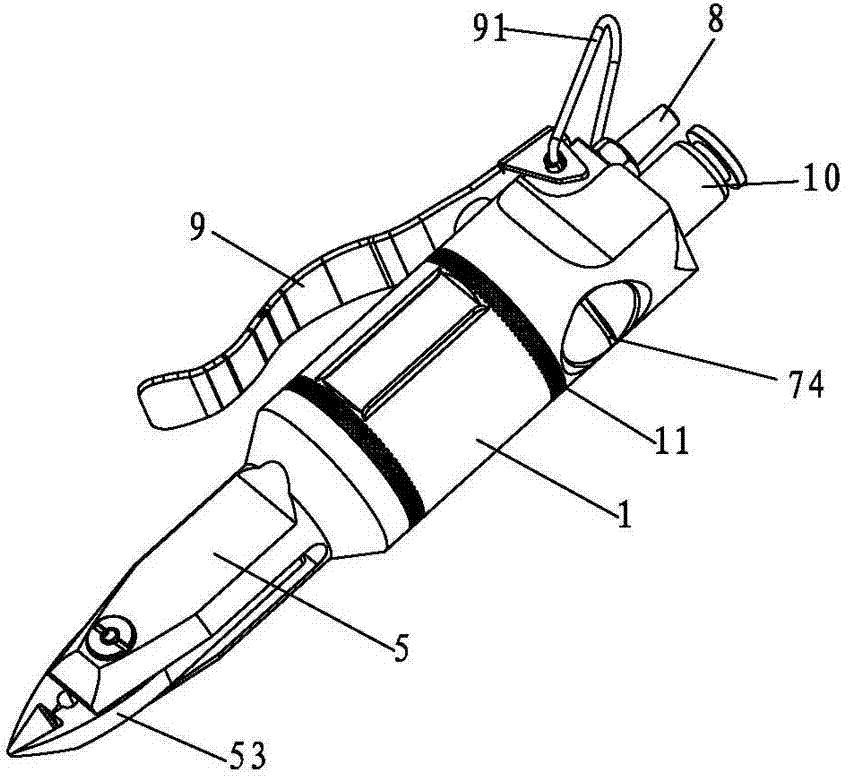

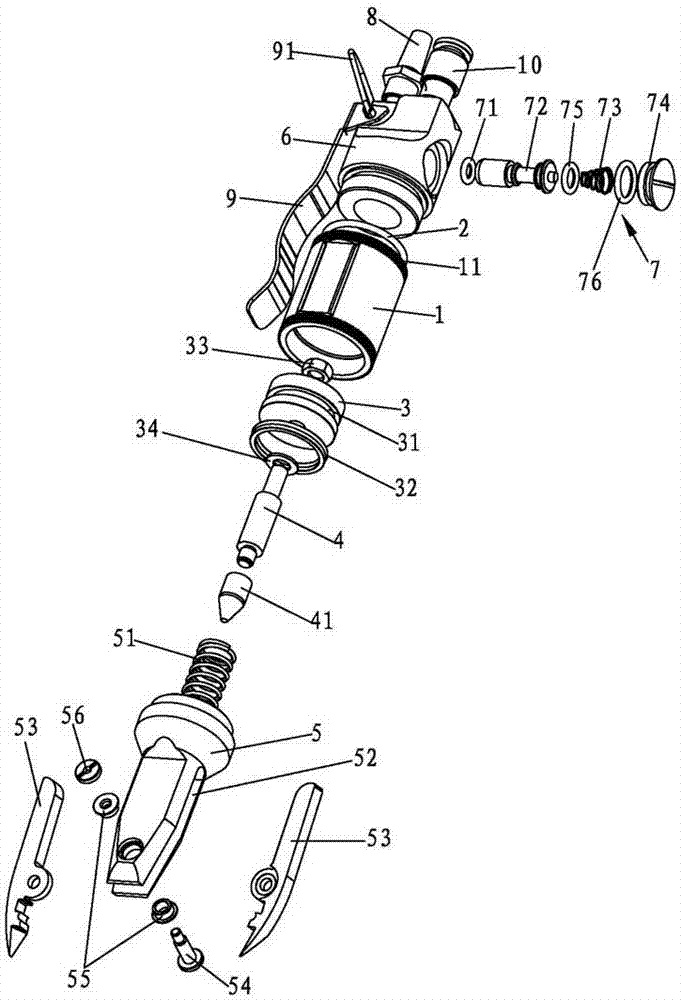

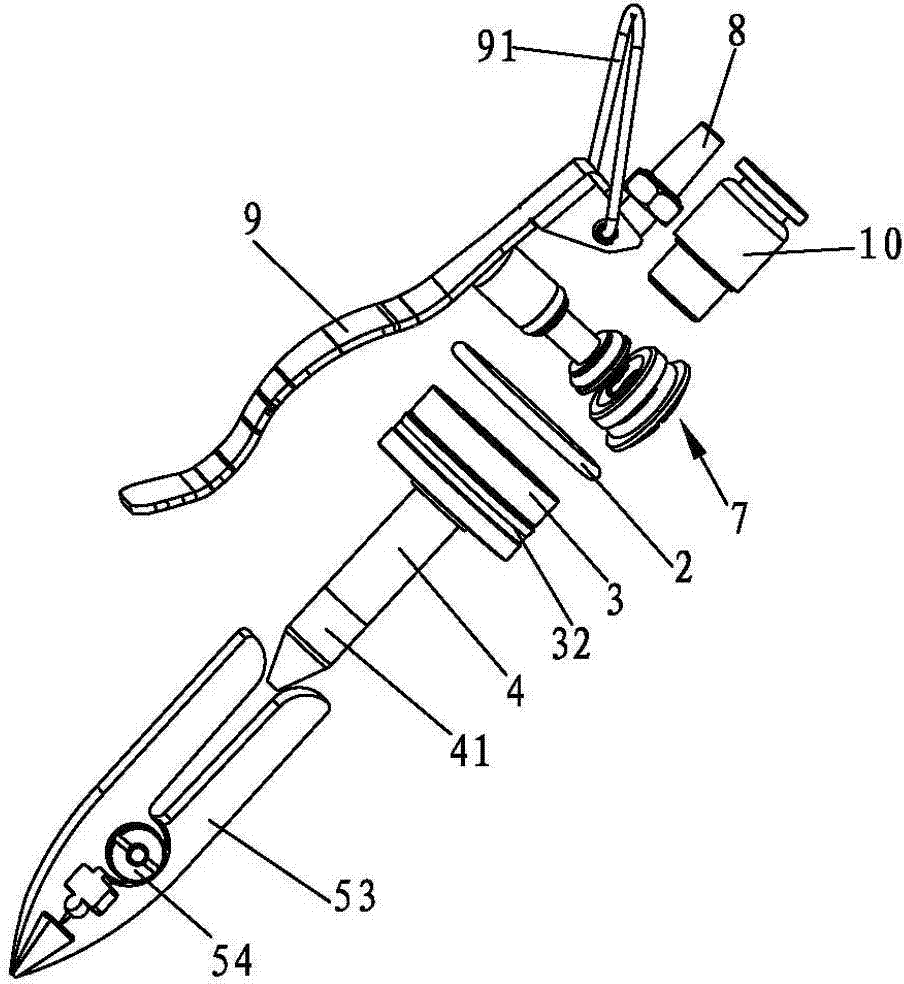

Pneumatic cutting pliers

ActiveCN103252530BSimple and scientific structure designReduce noiseNibbling shearing machinesEngineeringPneumatic tool

The invention relates to the technical field of pneumatic tools, in particular to a pair of pneumatic cutting pliers. The pair of pneumatic cutting pliers comprises a cylinder barrel, an end cover sealing ring, a piston, a piston rod, a scissor head top piece, a scissor head mounting support, a scissor head and an end cover body, wherein the cylinder barrel is of a barrel-shaped structure, one end of the cylinder barrel is connected with the end cover body, an air valve, an exhaust silencer, a control handle and an air inlet are arranged on the end cover body, a hanging piece is arranged in the control handle, the piston is arranged in the cylinder barrel, the piston sealing ring is arranged on the piston, the piston rod is installed on the piston, the cone-shaped scissor head top piece is arranged at the top end of the piston rod, a piston spring is connected on the piston rod in a sleeved mode, the other end of the cylinder barrel is connected to the scissor head mounting support, and the scissor head is installed on the scissor head mounting support. The pair of pneumatic cutting pliers is simple and scientific in structural design, free of air leakage in use, small in noise and stable in using performance and working performance.

Owner:圣辰自动化技术(东莞)有限公司

Full-automatic electrostatic cloth processing equipment

InactiveCN106676755AEfficient suctionSimple and scientific structure designCarding machinesNeedling machinesFiberBiochemical engineering

The invention relates to the technical field of electrostatic cloth production equipment, in particular to full-automatic electrostatic cloth processing equipment. A motor of a carding machine is provided with a transmission, one side of the carding machine rack body is provided with a transitional shaft, an output end of the transmission is connected to a chain wheel, a card flat is arranged on the chain wheel, the two sides of the chain wheel are provided with a scutching roller and a cotton leveling roller respectively, an input end of the card flat is provided with a cotton guiding leather plate, the position of the cotton guiding leather plate is provided with a vibration plate, the lower end of the vibration plate is provided with an air blower, an air exhaust duct is arranged on the air blower, one end of the air exhaust duct is arranged at the position of the card flat, a driving bearing is connected to a needle beam connecting piece through a connecting rod, the lower end of the needle beam connecting piece is connected to a needle beam, the lower end of the needle beam is provided with a needle plate, and a stitching plate is arranged below the needle plate. The full-automatic electrostatic cloth processing equipment is simple and scientific in structural design, through the adoption of a high-speed gear case structure, the needling degree of a vertical needle is good, the operation speed is high, the production efficiency is high, and the problem that a fiber product is contaminated due to oil leakage is thoroughly solved; meanwhile, noil, flyings, dust and static electricity are effectively gettered, and the full-automatic electrostatic cloth processing equipment is convenient to operate and use.

Owner:东莞市伊腾自动化科技有限公司

Automatic electrostatic cloth processing equipment

InactiveCN106676755BEfficient suctionSimple and scientific structure designCarding machinesNeedling machinesFiberBiochemical engineering

The invention relates to the technical field of electrostatic cloth production equipment, in particular to full-automatic electrostatic cloth processing equipment. A motor of a carding machine is provided with a transmission, one side of the carding machine rack body is provided with a transitional shaft, an output end of the transmission is connected to a chain wheel, a card flat is arranged on the chain wheel, the two sides of the chain wheel are provided with a scutching roller and a cotton leveling roller respectively, an input end of the card flat is provided with a cotton guiding leather plate, the position of the cotton guiding leather plate is provided with a vibration plate, the lower end of the vibration plate is provided with an air blower, an air exhaust duct is arranged on the air blower, one end of the air exhaust duct is arranged at the position of the card flat, a driving bearing is connected to a needle beam connecting piece through a connecting rod, the lower end of the needle beam connecting piece is connected to a needle beam, the lower end of the needle beam is provided with a needle plate, and a stitching plate is arranged below the needle plate. The full-automatic electrostatic cloth processing equipment is simple and scientific in structural design, through the adoption of a high-speed gear case structure, the needling degree of a vertical needle is good, the operation speed is high, the production efficiency is high, and the problem that a fiber product is contaminated due to oil leakage is thoroughly solved; meanwhile, noil, flyings, dust and static electricity are effectively gettered, and the full-automatic electrostatic cloth processing equipment is convenient to operate and use.

Owner:东莞市伊腾自动化科技有限公司

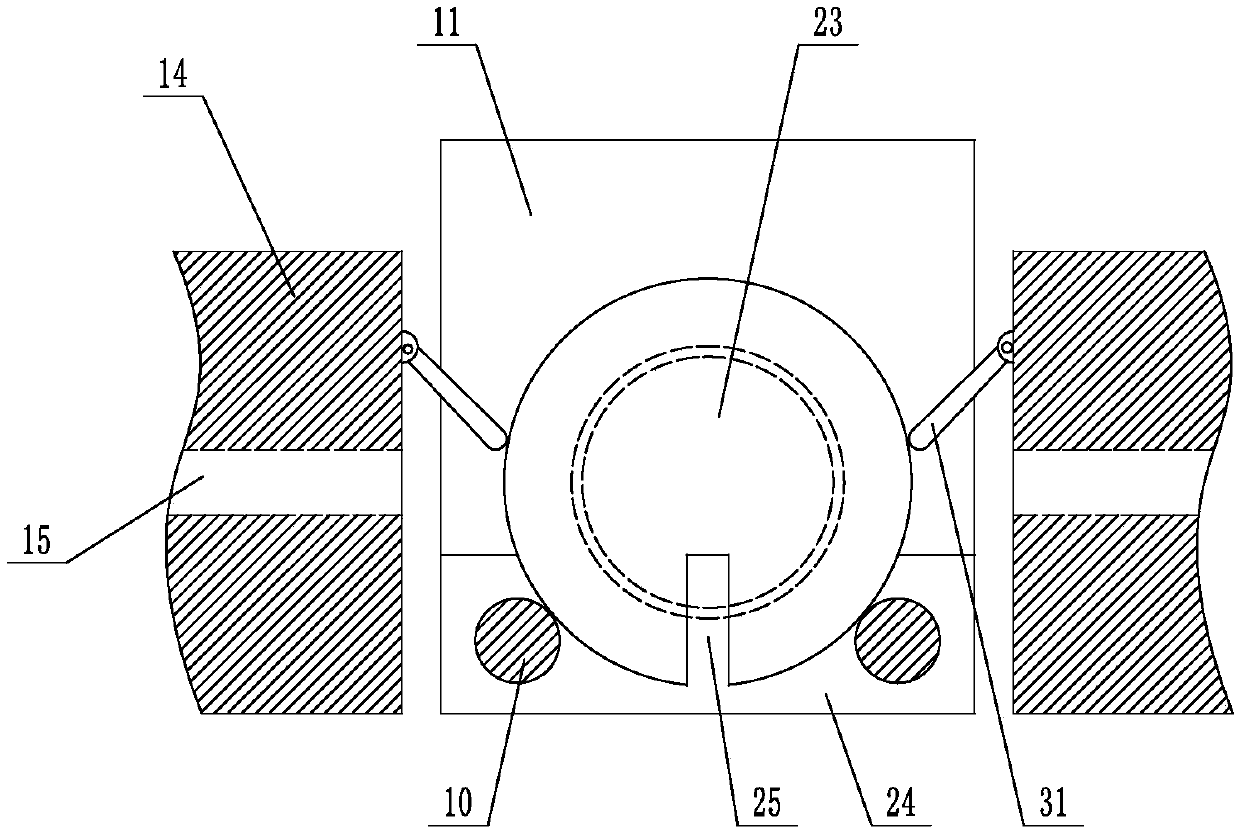

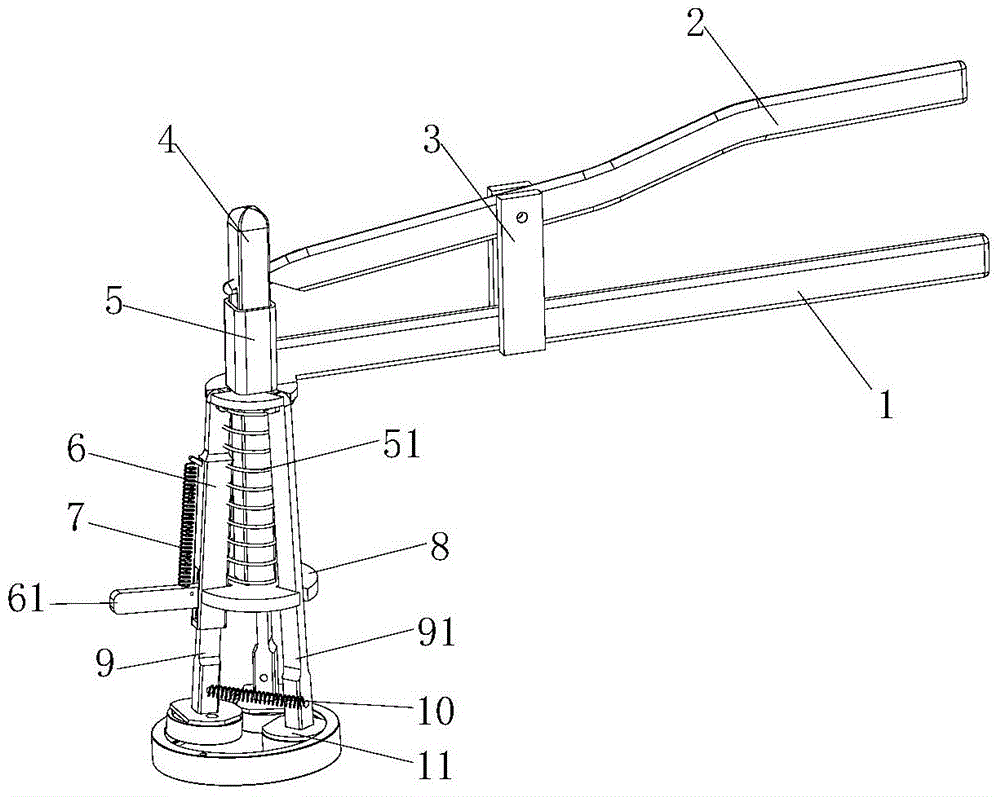

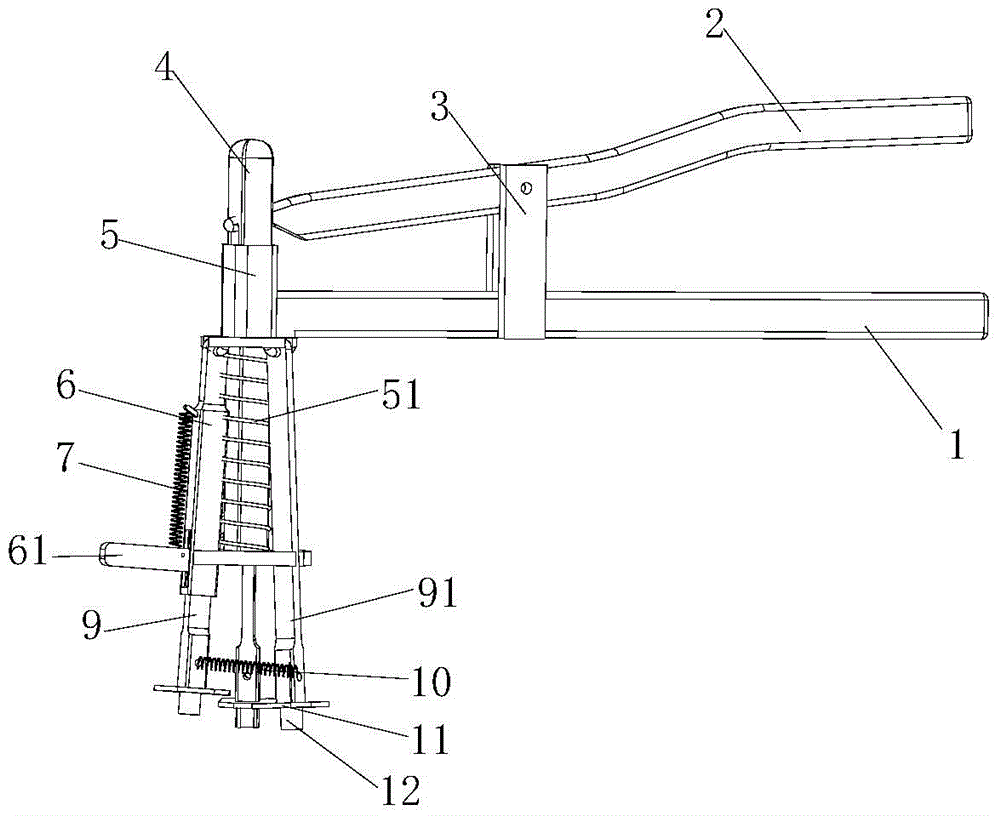

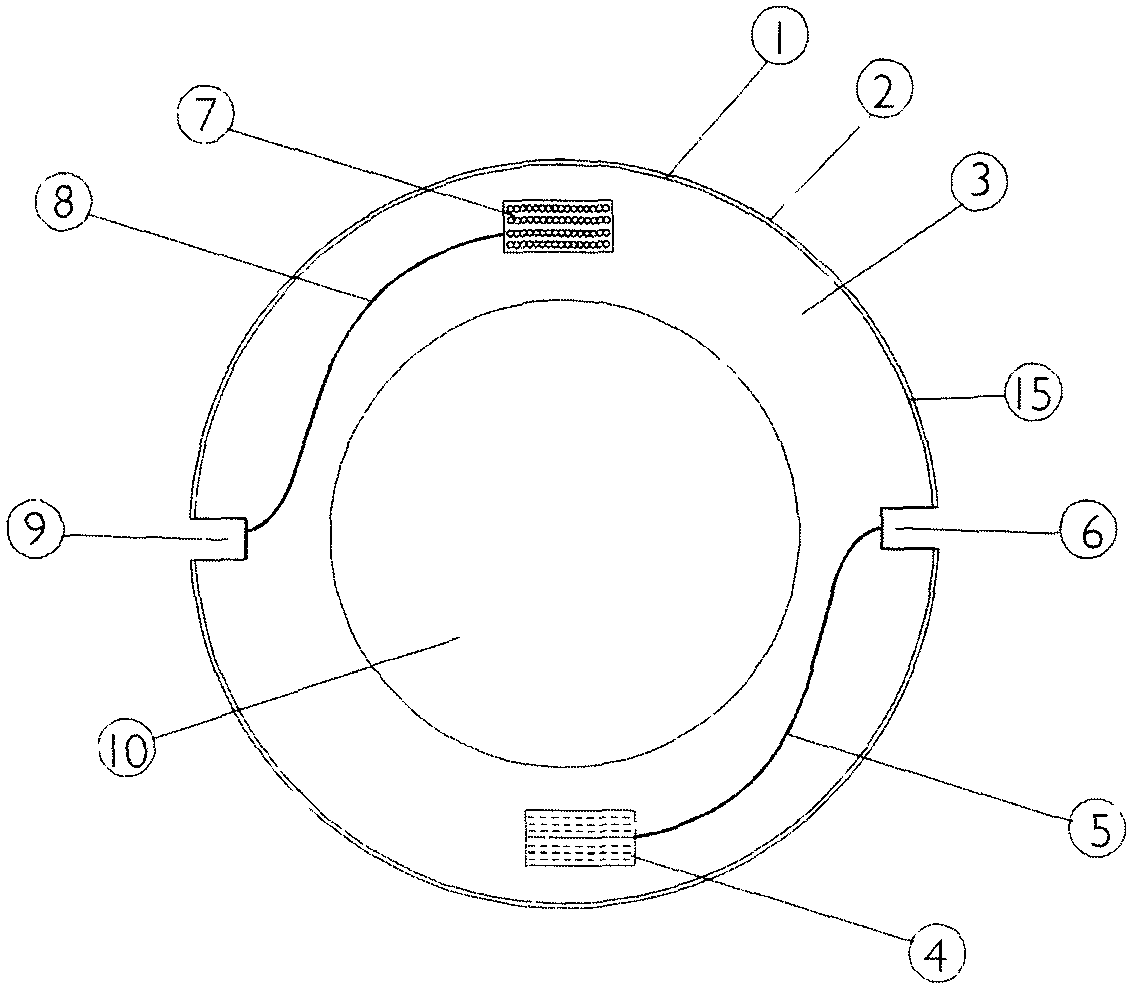

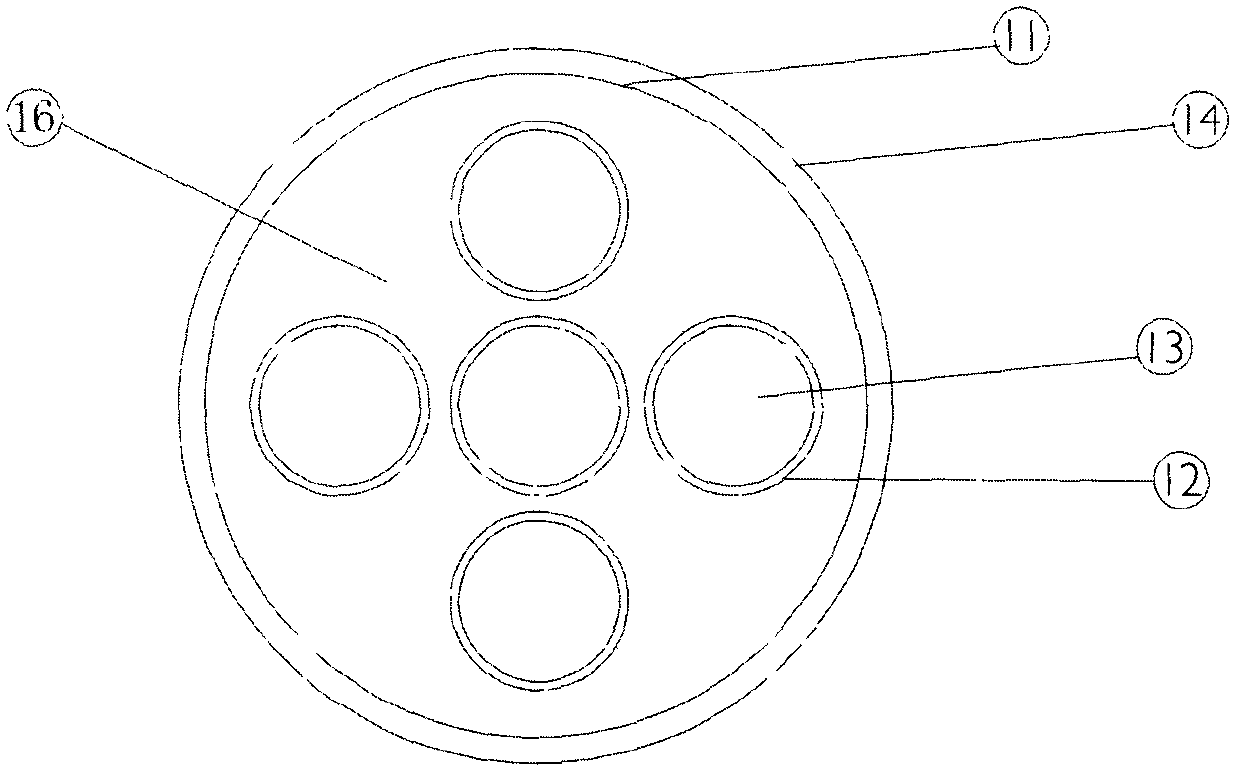

Assembly jig and assembly method for motor transmission ring

ActiveCN104786005BNo damageSimple and scientific structure designMetal working apparatusMotor driveManufacturing technology

The invention relates to the technical field of motor manufacturing, in particular to a motor transmission ring assembling clamp and method. A fixed handle and a movable handle are hinged through a supporting rod. One end of the movable handle is movably connected with a center rod. The center rod is movably inserted in a fixed rod sleeve. The fixed rod sleeve is connected with one end of the fixed handle. A pressing rod and movable supporting rods are movably hinged to the fixed rod sleeve. The pressing rod is provided with a pressing rod sleeve. A movable supporting disc is arranged between the movable supporting rods and the pressing rod. The supporting disc is connected with a center rod. A reset spring is arranged between the supporting disc and the center rod. The pressing rod is provided with a pressing rod handle, a tension spring is arranged between the pressing rod handle and the pressing rod sleeve, trays are arranged at the tail end of the movable supporting rod and the tail end of the pressing rod, and positioning cylinders are arranged in the centers of the trays. The motor transmission assembling clamp is ingenious in structural design and convenient to assemble and install. According to the assembling method, by means of the assembling clamp, related components are fast assembled when a transmission ring is still in a thermal expansion state, and the transmission ring cannot be damaged in the whole process.

Owner:广东磁瑞磁悬浮科技有限公司

A fully automatic production equipment for radar components for automobiles

ActiveCN102896496BSimple and scientific structure designIncrease productivityOther manufacturing equipments/toolsMetal working apparatusMechanical engineeringAutomotive radar

The invention relates to the technical field of production equipment for electronic elements, in particular to full-automatic production equipment for a radar element for a full-automatic automobile. A feeding device, a pin inserting device, a material pushing device, a pre-bending device, a material grabbing device, a bending device, a deep-angle bending device, a pin cutting device, a No.1 90-degree bending device, a No.2 90-degree bending device and a bevel cutting mechanism are arranged on a frame body in sequence; a No.1 reversing device is arranged between the pin inserting device and the material pushing device; a No.2 reversing device is arranged between the material grabbing device and the bending device; a No.3 reversing device is arranged on the deep-angle bending device; a material pushing mechanism is arranged between the deep-angle bending device and the pin cutting device; a No.4 reversing device is arranged on the bevel cutting mechanism; and a controller is arranged on the frame body. The equipment is simple and scientific in structural design, full-automatic production is realized, and production efficiency and product quality are high.

Owner:DONGXIANG ELECTRONICS DONGGUAN CO LTD

Energy conversion generating device

ActiveCN103670940AEasy to controlMeet the requirements of useFluid-pressure convertersMachines/enginesEngineeringHigh pressure

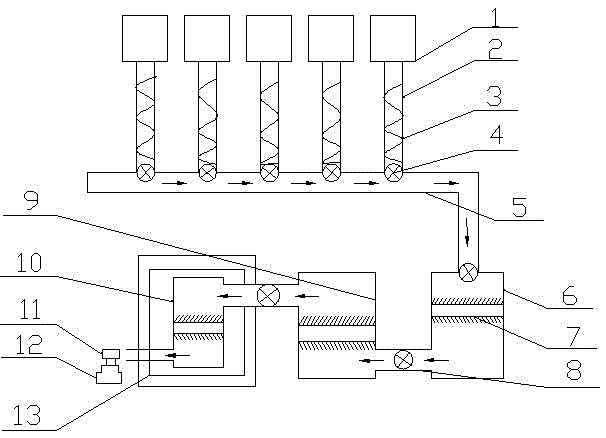

The invention relates to the field of generating devices, in particular to an energy conversion generating device, which is characterized by comprising windmills, small hydraulic cylinders, helical augers, valves, a hydraulic pipeline, a large hydraulic cylinder chamber, a pneumatic cylinder chamber, a small hydraulic cylinder chamber, a high-pressure tube, pistons, a pressure control chamber, a hinge plate and a generator, wherein the windmills are fixedly arranged on the small hydraulic cylinders; the small hydraulic cylinders are connected with the hydraulic pipeline; one end of the large hydraulic cylinder chamber is connected with the hydraulic pipeline, and the other end of the large hydraulic cylinder chamber is connected with the pneumatic cylinder chamber through the high-pressure tube; the pneumatic cylinder chamber is connected with the small hydraulic cylinder chamber in the pressure control chamber through the high-pressure tube; the hinge plate is fixedly arranged on the generator; the small hydraulic cylinder chamber is formed in the pressure control chamber; the valves are arranged between the small hydraulic cylinders and the hydraulic pipeline, between the hydraulic pipeline and the large hydraulic cylinder chamber, between the large hydraulic cylinder chamber and the pneumatic cylinder chamber as well as between the pneumatic cylinder chamber and the pressure control chamber; the helical augers are arranged in the small hydraulic cylinders; the pistons are arranged in the small hydraulic cylinders, the large hydraulic cylinder chamber, the pneumatic cylinder chamber and the small hydraulic cylinder chamber.

Owner:来风新能源科技(河南)有限公司

A multifunctional magnetic therapy badge capable of preventing and treating diseases

ActiveCN105664360BMeet the use requirementsReduce wasteElectrotherapyMagnetotherapyHuman bodyDisease

The invention relates to a multifunctional magnetic therapy chest card capable of preventing diseases. The multifunctional magnetic therapy chest card is composed of a chest card display panel and a chest card magnetic therapy disc, and can meet the demand of people for using chest cards. When people wear the chest card, the chest card magnetic therapy disc can perform preventive magnetic field penetration physical therapy on the chest card wearing part to improve the microcirculation of the human body. The multifunctional magnetic therapy chest card plays a very good prevention and auxiliary treatment role in the body health of wearers, is a very ideal modern green health product, and can be widely used in organs, schools, hospitals, meetings, all kinds of celebrations and VIP receptions and other fields.

Owner:洛阳中伟环保科技有限公司

An energy conversion type power generation device

ActiveCN103670940BEasy to controlMeet the requirements of useFluid-pressure convertersWind motor combinationsEngineeringHigh pressure

The invention relates to the field of generating devices, in particular to an energy conversion generating device, which is characterized by comprising windmills, small hydraulic cylinders, helical augers, valves, a hydraulic pipeline, a large hydraulic cylinder chamber, a pneumatic cylinder chamber, a small hydraulic cylinder chamber, a high-pressure tube, pistons, a pressure control chamber, a hinge plate and a generator, wherein the windmills are fixedly arranged on the small hydraulic cylinders; the small hydraulic cylinders are connected with the hydraulic pipeline; one end of the large hydraulic cylinder chamber is connected with the hydraulic pipeline, and the other end of the large hydraulic cylinder chamber is connected with the pneumatic cylinder chamber through the high-pressure tube; the pneumatic cylinder chamber is connected with the small hydraulic cylinder chamber in the pressure control chamber through the high-pressure tube; the hinge plate is fixedly arranged on the generator; the small hydraulic cylinder chamber is formed in the pressure control chamber; the valves are arranged between the small hydraulic cylinders and the hydraulic pipeline, between the hydraulic pipeline and the large hydraulic cylinder chamber, between the large hydraulic cylinder chamber and the pneumatic cylinder chamber as well as between the pneumatic cylinder chamber and the pressure control chamber; the helical augers are arranged in the small hydraulic cylinders; the pistons are arranged in the small hydraulic cylinders, the large hydraulic cylinder chamber, the pneumatic cylinder chamber and the small hydraulic cylinder chamber.

Owner:来风新能源科技(河南)有限公司

Liner structure of bulletproof helmet and manufacturing process thereof

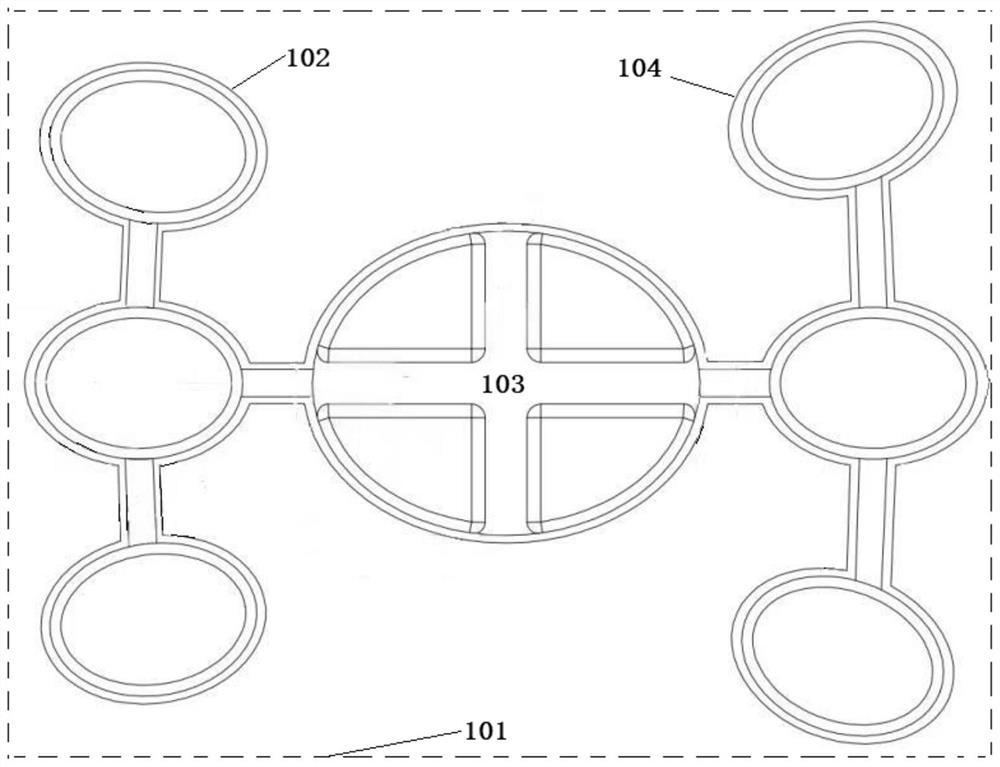

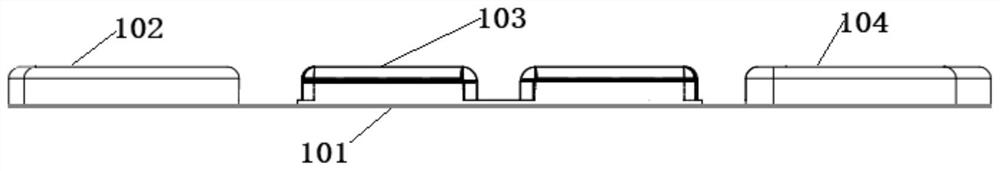

PendingCN112315101ASpeed up circulationImprove portabilityHelmetsHelmet coversStructural engineeringMechanical engineering

The invention discloses a liner structure of a bulletproof helmet and a manufacturing process thereof. The liner structure comprises a buffer layer and a comfortable layer; the buffer layer comprisesa front structure, a top structure and a rear structure, wherein the front structure adopts three elliptical structures with the same size and shape, which are unfolded backwards in a circular arc shape at equal intervals; the rear structure also adopts three elliptical structures with the same size and shape, which are unfolded forwards in a circular arc shape at equal intervals; the top structure is in an elliptical shape with a cross-shaped groove in the center; the buffer layer is connected by hook and loop fasteners to the inside of the helmet; and the comfort layer comprises seven groupsof single liner structures which are connected by hook and loop fasteners to the buffer layer. The liner structure is manufactured by adopting a special process, the structural design is simple and scientific, the impact buffering effect is excellent, the weight is light, the comfort degree of helmet fitting by a wearer is greatly improved, and the discomfort of the wearer is reduced; air flow inthe helmet is improved, and the temperature difference between the inside of the helmet and the outside world after the helmet is worn in different seasons and different environments is improved, sothat discomfort caused after the helmet is taken off is avoided, and the sweating frequency of a wearer is reduced.

Owner:BEIJING PT PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com