A surface-mount sheet injection-molded part and its fabrication process

A technology of injection molding and bonding, applied in the direction of synthetic resin layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of energy consumption, environmental pollution, and limited expressiveness, and achieve simple and scientific structural design , convenient production, various effects of appearance and expressiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

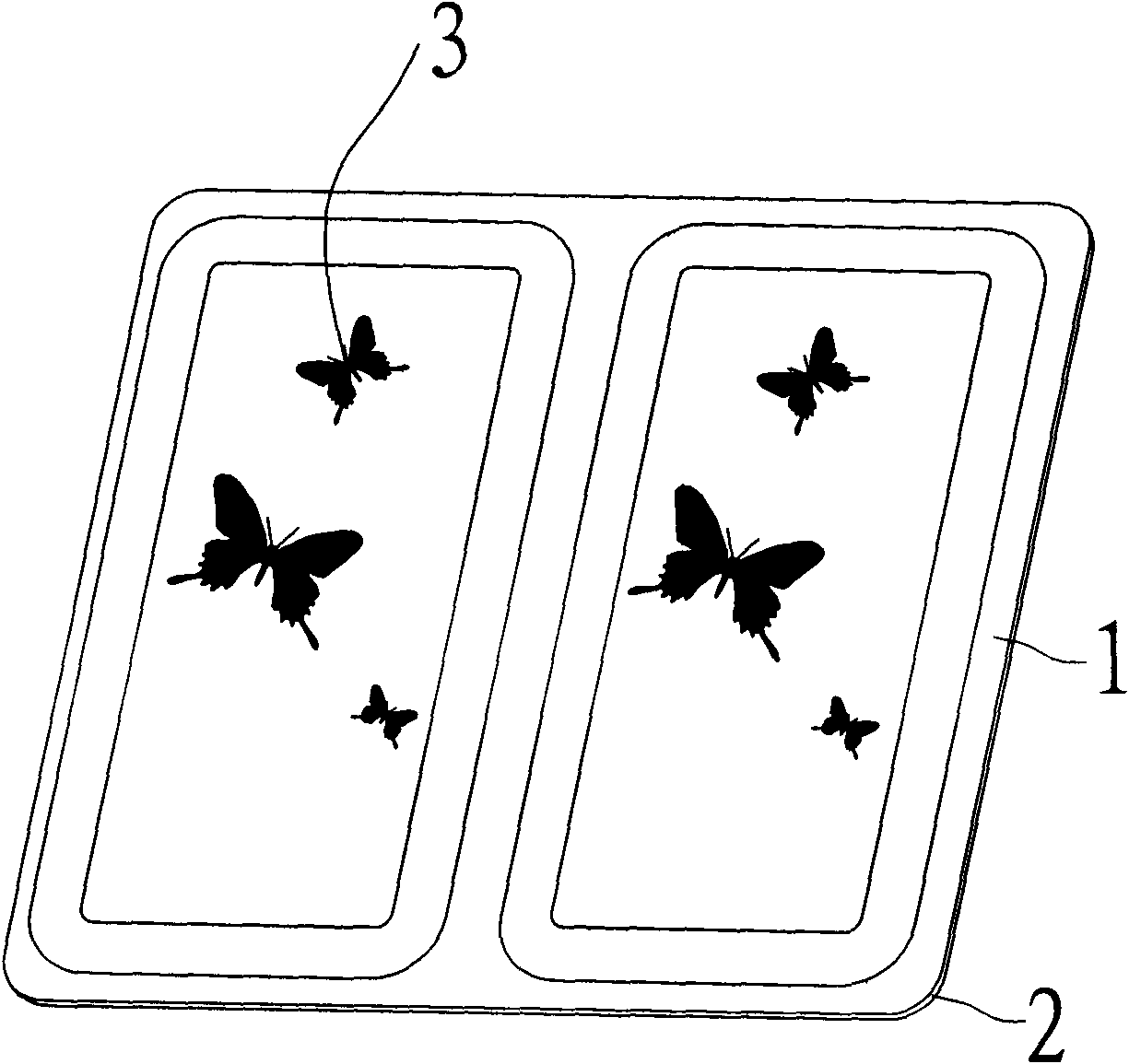

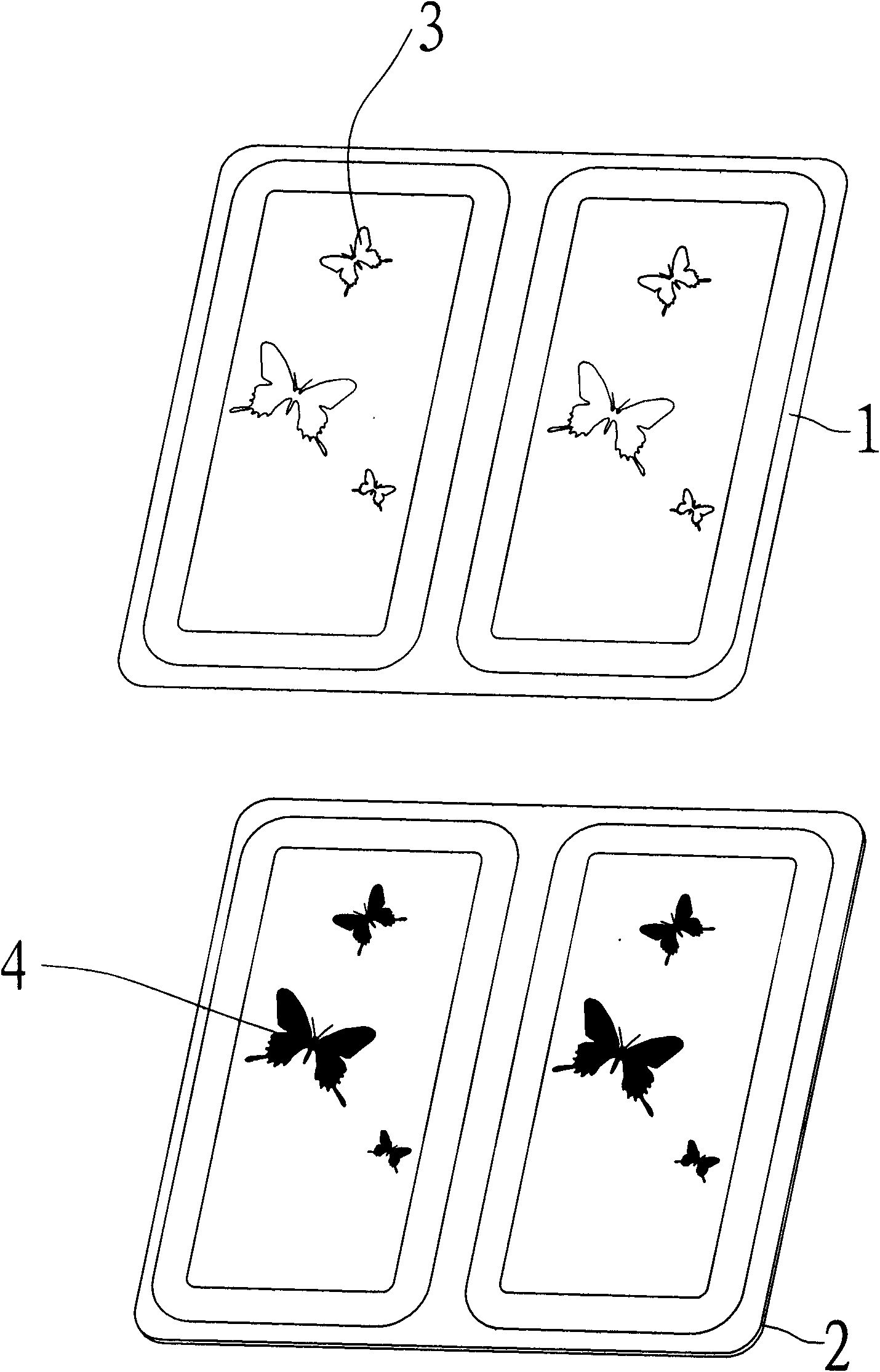

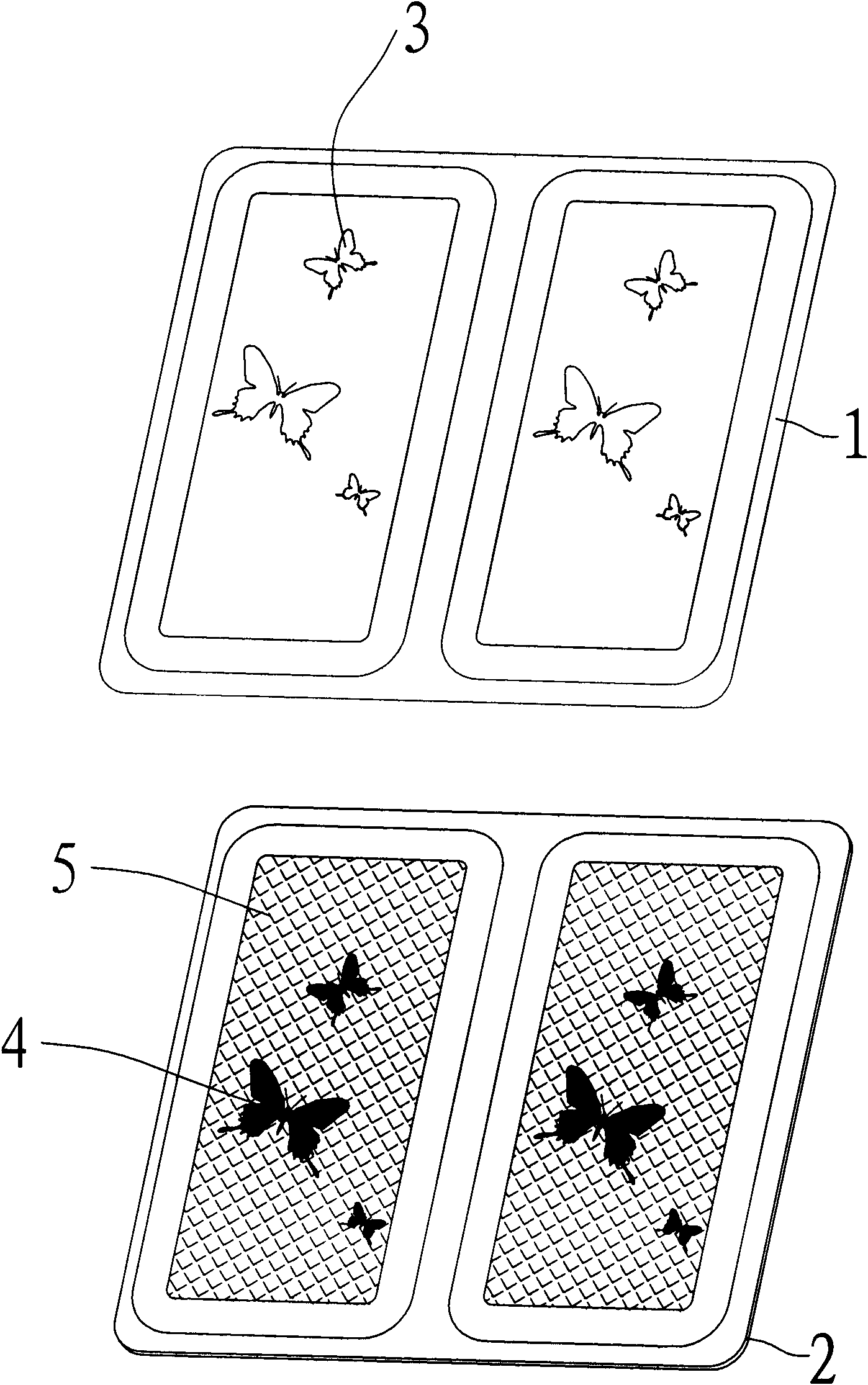

[0024] See Figure 1 to Figure 4 Shown: the present invention comprises a sheet 1, an injection molded part 2, the upper surface of the injection molded part 2 is provided with a No. 1 printed pattern 3, and the lower surface of the sheet 1 is provided with a No. The lower surface and the upper surface of the injection molded part 2 are glued together.

[0025] The lower surface of the injection molded part 2 is formed with a layer 5 with a graphic effect through a surface treatment process.

[0026] The sheet 1 and the injection molded part 2 are transparent plastic plates,

[0027] The sheet 1 is an opaque material, and the injection molded part 2 is a transparent plastic plate.

[0028] The sheet 1 is a transparent material, and the injection molded part 2 is an opaque plastic plate.

[0029] The injection molded part 2 is any one of one side being flat and the other being a three-dimensional curved surface, and both sides being three-dimensional curved surfaces.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com