An energy conversion type power generation device

A power generation device and energy conversion technology, which is applied in wind power generation, fluid pressure converters, engines, etc., can solve the problems of scattered distribution of fans, inability to control the utilization efficiency of electric energy stably, and inability to meet the energy utilization of the people, etc. requirements, simple and scientific effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

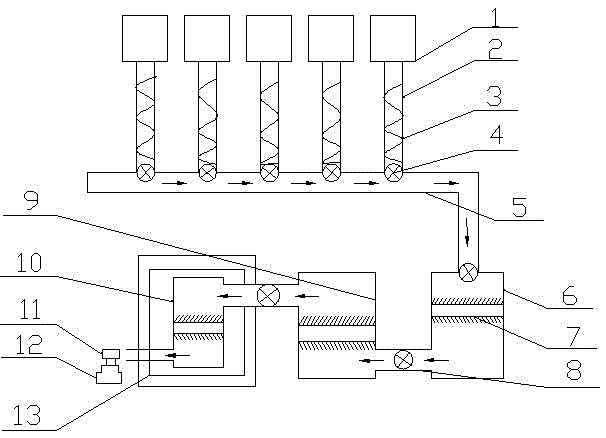

[0012] Specific embodiment 1: as figure 1 The energy conversion type power generation device shown is characterized in that it includes: a windmill 1, a small hydraulic cylinder 2, a screw auger 3, a valve 4, a hydraulic pipeline 5, a large hydraulic cylinder chamber 6, a pneumatic cylinder chamber 9, and a small hydraulic cylinder chamber 10 , a high-pressure pipe 8, a piston 7, a pressure control chamber 13, a page plate 11, and a generator 12, wherein the windmill 1 is fixedly installed on the small hydraulic cylinder 2, the small hydraulic cylinder 2 is connected with the hydraulic pipeline 5, and one end of the large hydraulic cylinder chamber 9 The other end connected with the hydraulic pipeline 5 is connected with the pneumatic cylinder chamber 9 through the high-pressure pipe 8, and the pneumatic cylinder chamber 9 is connected with the small hydraulic cylinder chamber 10 in the pressure control chamber 13 through the high-pressure pipe 8, and the leaf plate 11 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com