Injection mold for foot pad of computer case

A computer case and injection mold technology, applied in the field of injection molds, can solve the problems of low production efficiency, unreasonable design, cumbersome processes, etc., and achieve the effects of high production efficiency, simple and scientific structure design, and low mold cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

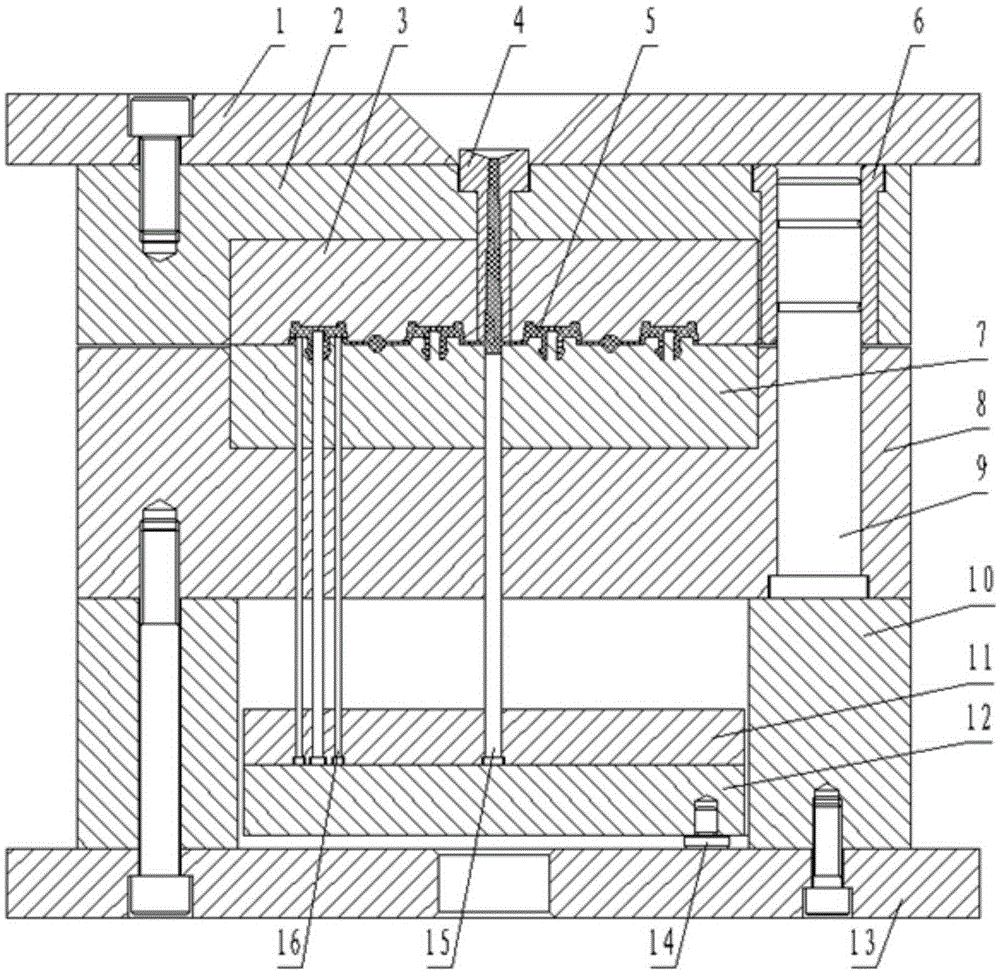

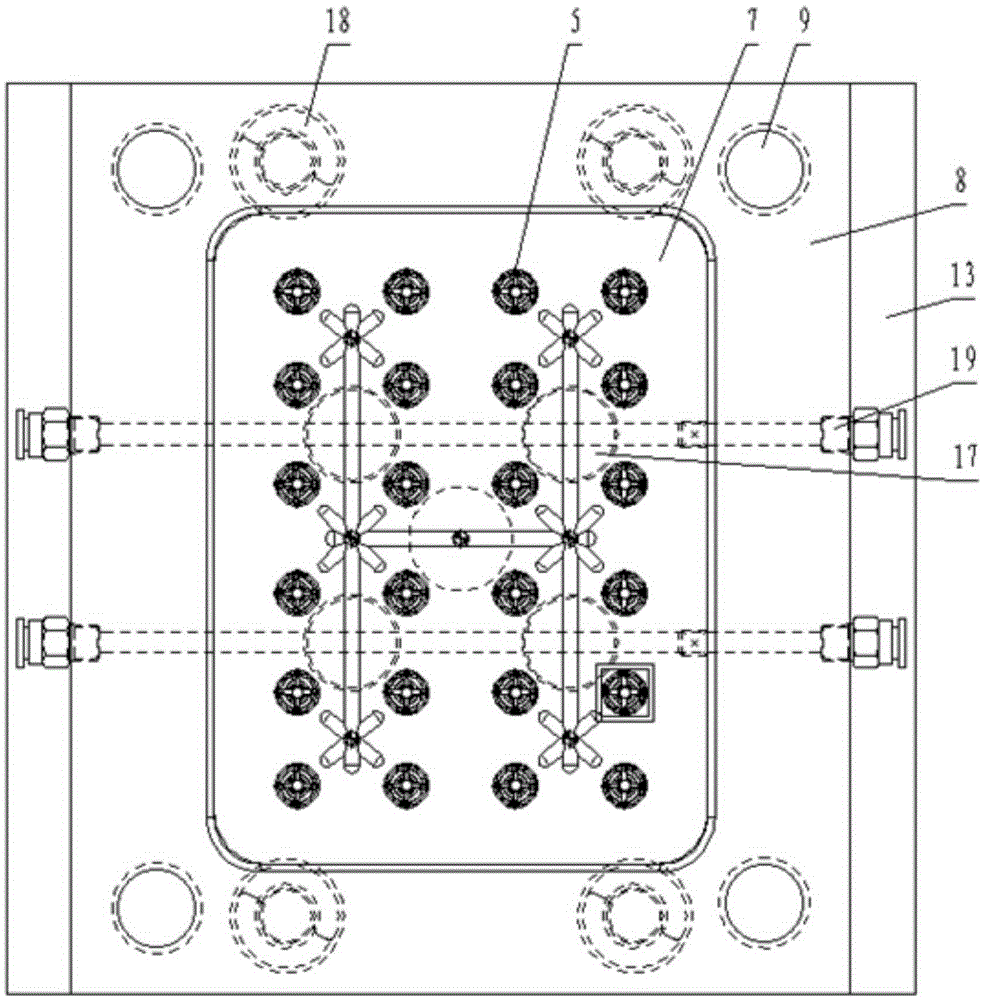

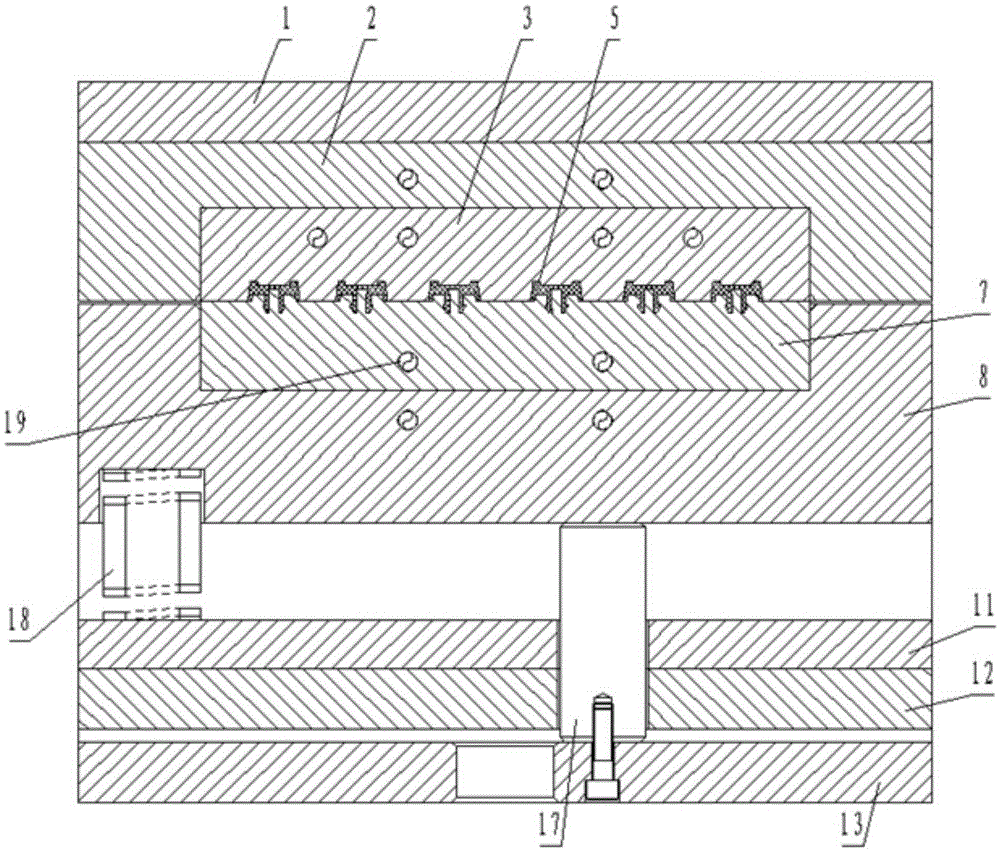

[0028] Such as figure 1 As shown, the computer case foot pad injection mold described in the embodiment of the present invention includes a fixed mold and a movable mold. and a cooling water channel, the upper end surface of the die fixing plate is provided with the upper template, the die fixing plate is provided with a step hole matching the sprue sleeve, and the sprue sleeve is arranged on the step In the hole, the die fixing plate is provided with a square groove matching the die insert, the die insert is arranged in the square groove, the die fixing plate and the die insert The blocks are provided with cooling water channels, the die insert is provided with a cavity matching the chassis foot pad, the die fixing plate is provided with a guide sleeve hole matching the guide sleeve, and the guide sleeve Set in the hole of the guide sleeve; the movable mold includes a punch insert, a punch fixing plate, a guide column, a support plate, a thimble fixing plate, a thimble backi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com