Full-automatic production equipment for radar element for full-automatic automobile

A kind of production equipment and fully automatic technology, applied in metal processing equipment, other manufacturing equipment/tools, metal processing, etc., can solve the problems of unguaranteed product quality and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

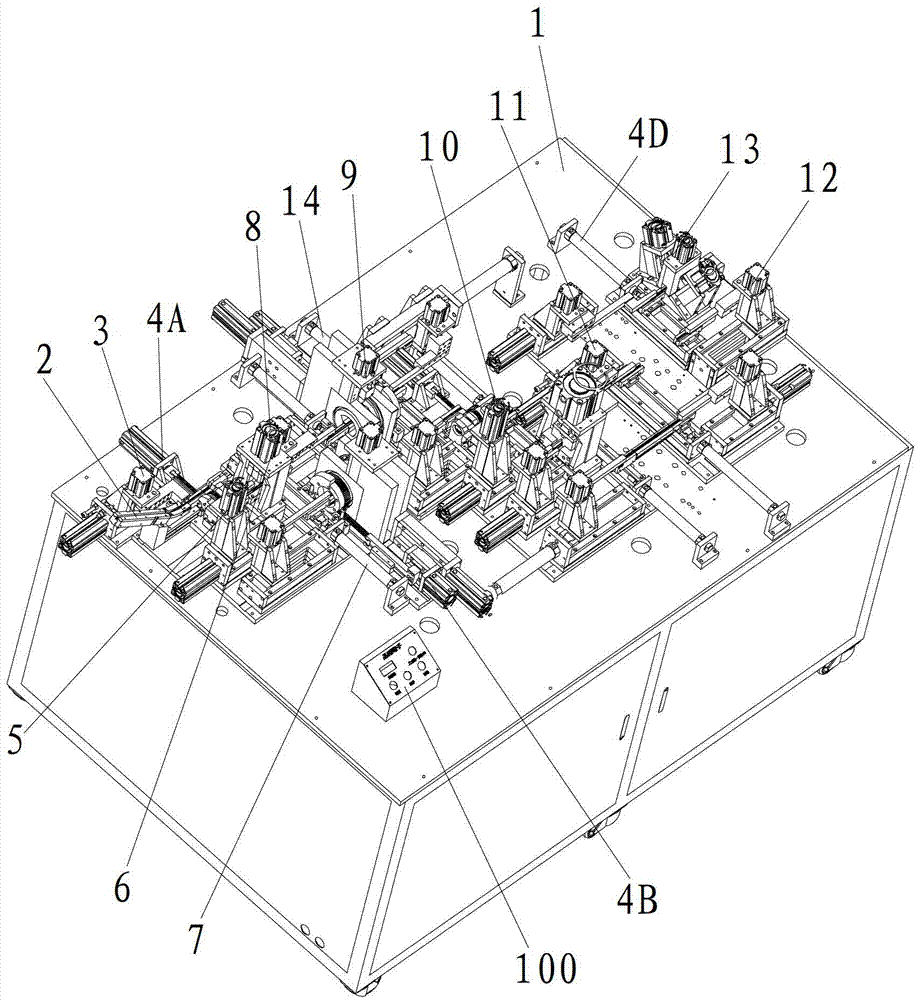

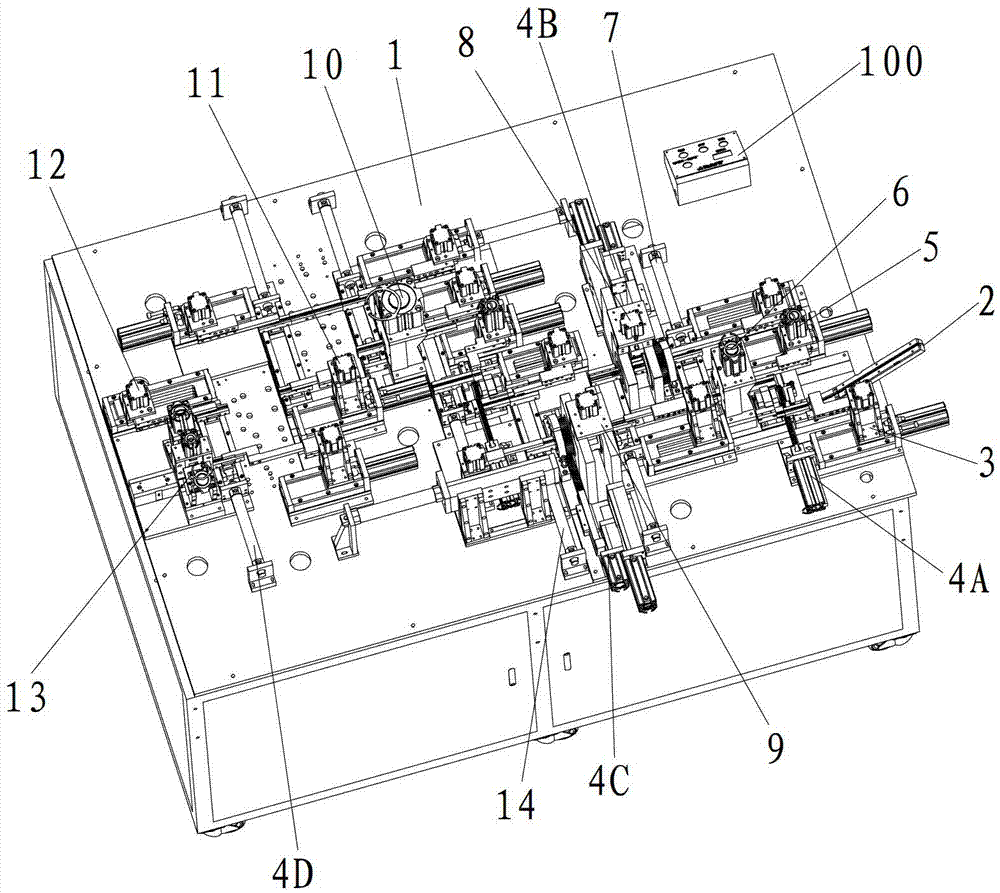

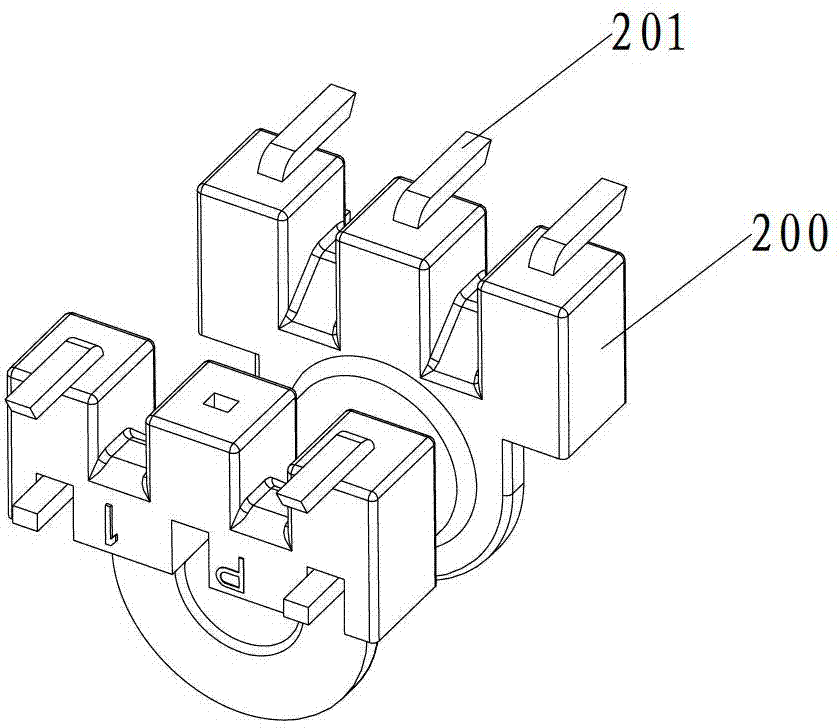

[0019] see Figure 1 to Figure 4 Shown: The present invention includes a frame body 1, a feeding device 2, a needle device 3, a material pushing device 5, a pre-bending device 6, a material grabbing device 7, a bending device 8, a deep angle bending device 9, and a foot cutting device 10. No. 1 bending 90 degree device 11, No. 2 bending 90 degree device 12, bevel angle cutting mechanism 13, the frame body 1 is sequentially provided with a feeding device 2, a pin device 3, a material pushing device 5, and a Bending device 6, gripping device 7, bending device 8, deep angle bending device 9, cutting foot device 10, No. 1 bending 90 degree device 11, No. 2 bending 90 degree device 12, angle cutting mechanism 13, No. 1 reversing device 4A is provided between the pin device 3 and the pushing device 5, the No. 2 reversing device 4B is provided between the grabbing device and the bending device 8, and the No. 3 reversing device is provided on the deep angle bending device 9 In the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com