Intelligent electronic product anti-vibration pad assembling equipment

A technology for intelligent electronic products and assembly equipment, applied in mechanical equipment, connecting components, material gluing, etc., can solve problems such as low efficiency, inaccurate positioning and separation, and inability to meet product assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

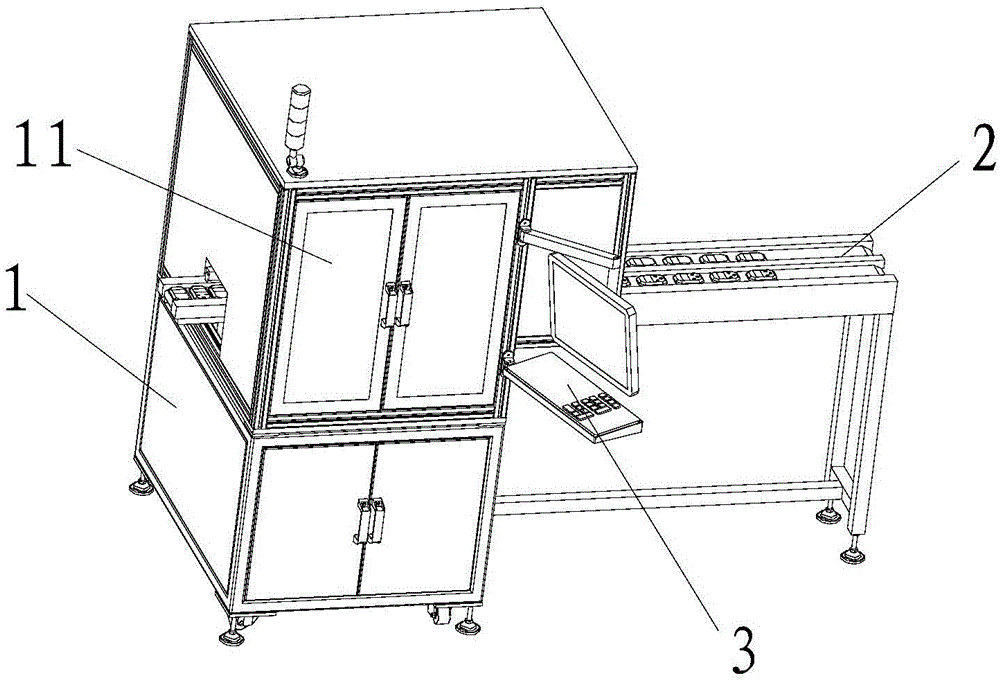

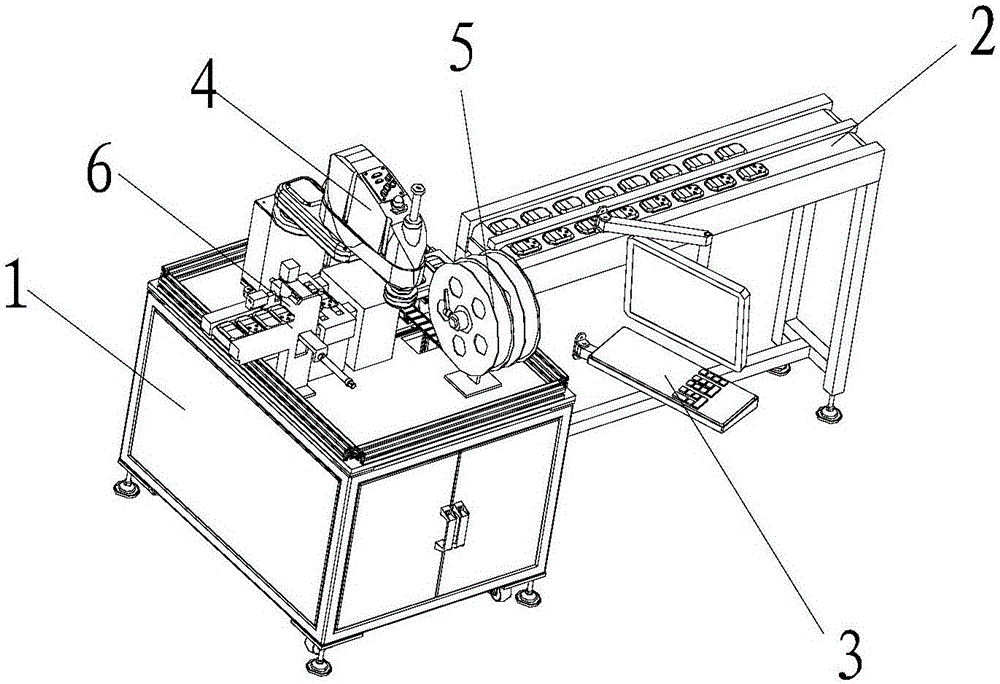

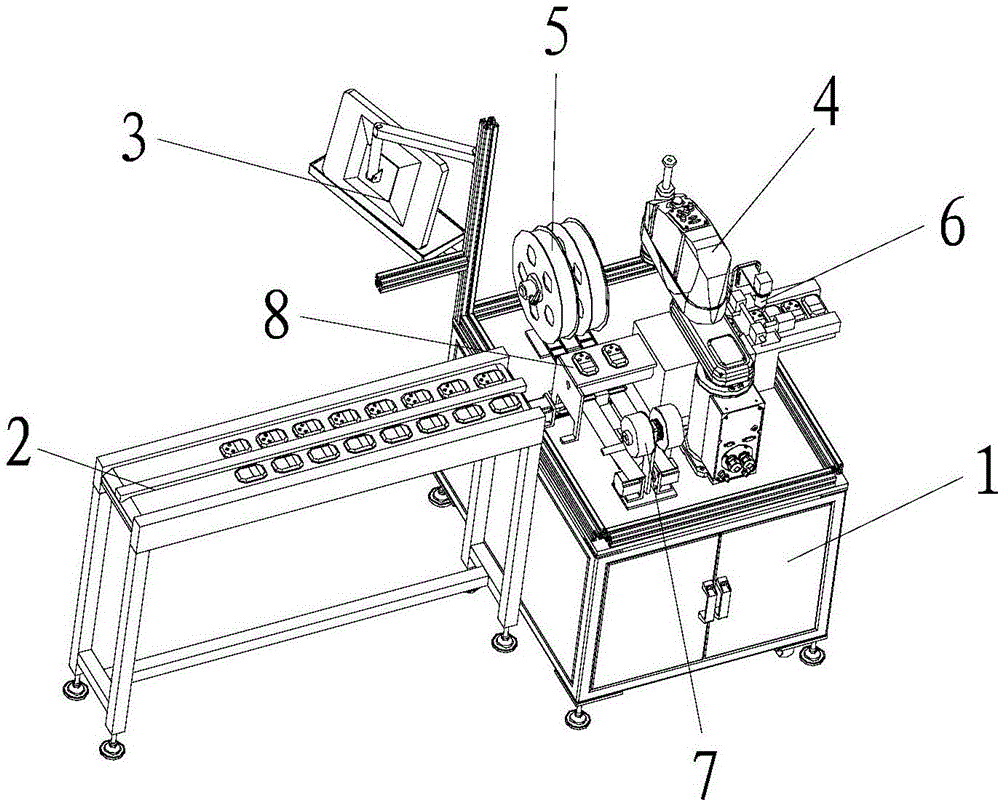

[0022] See Figure 1 to Figure 8 Shown: Embodiment 1 and Embodiment 2 are two kinds of schemes of the present invention, two kinds of similar models, the present invention comprises frame body 1, shell feeding platform 2, manipulator 4, and one side of frame body 1 is provided with shell Body feeding table 2, a control panel 3 is provided on the frame body 1, a manipulator 4 is provided on the upper end surface of the frame body 1, and a feeding tray 5 and a waste material receiving tray 7 are arranged on one side of the manipulator 4, and the feeding tray 5 and the waste material receiving tray 7 is provided with material distribution mechanism 8, and material distribution mechanism 8 comprises suction table 81, material distribution line 82, and material distribution line 82 is arranged on the lower end of suction table 81, and material distribution line 82 is a metal wire, and material distribution line 82 Fitted and installed on the upper end surface of the material belt o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com