Automatic sleeve feeding device for multi-axial winding machine

A technology of a winding machine and a transmission device, which is applied in the direction of coil manufacturing, etc., can solve the problems of unscientific design of the high-frequency transformer winding machine and the casing device, and achieve the effect of simple and scientific structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

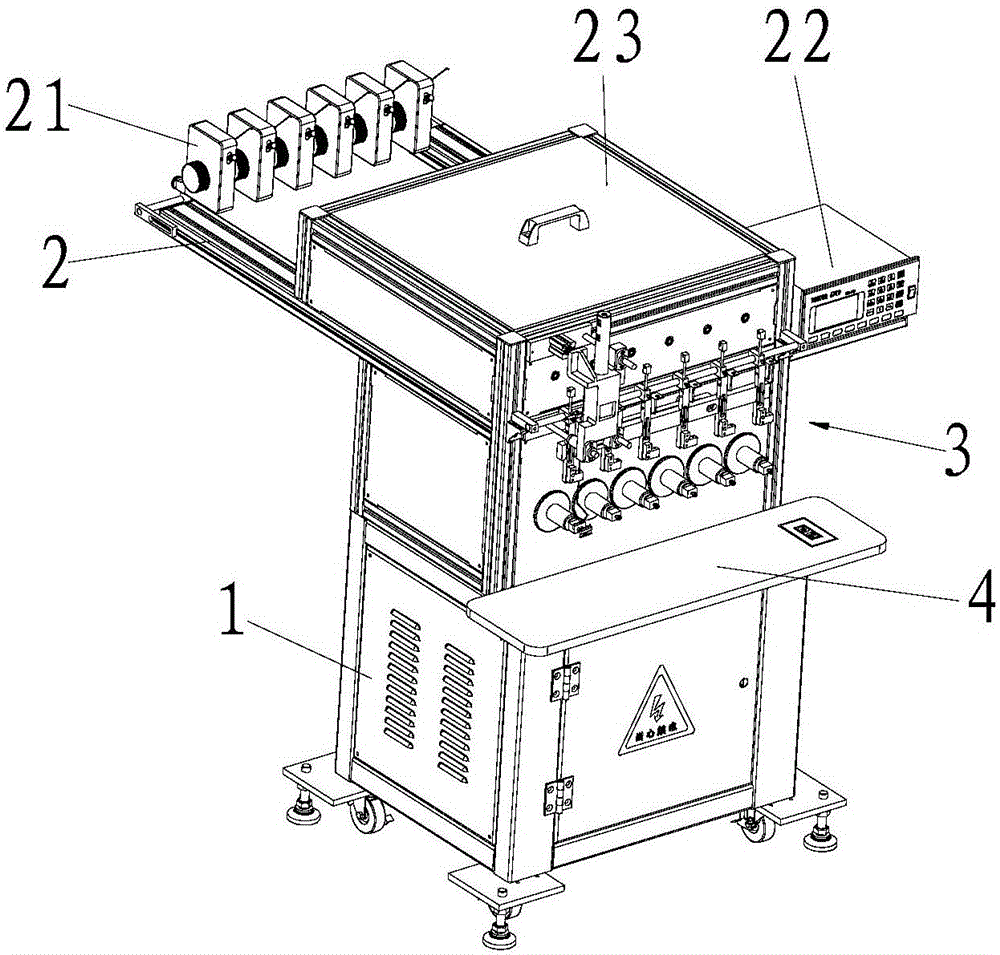

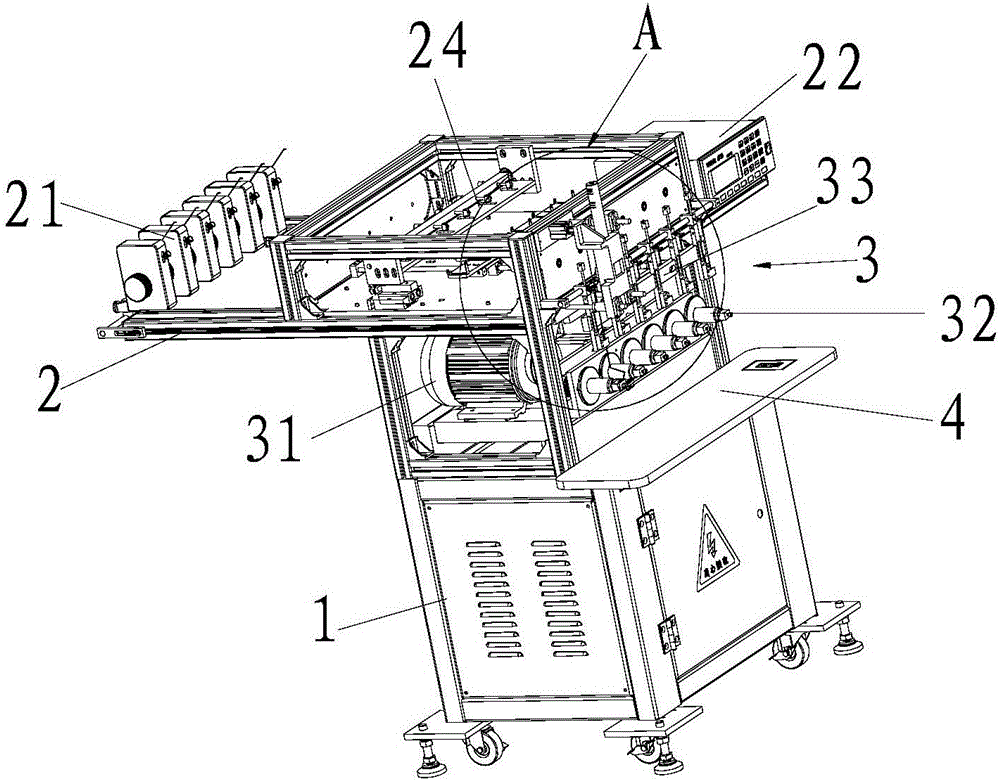

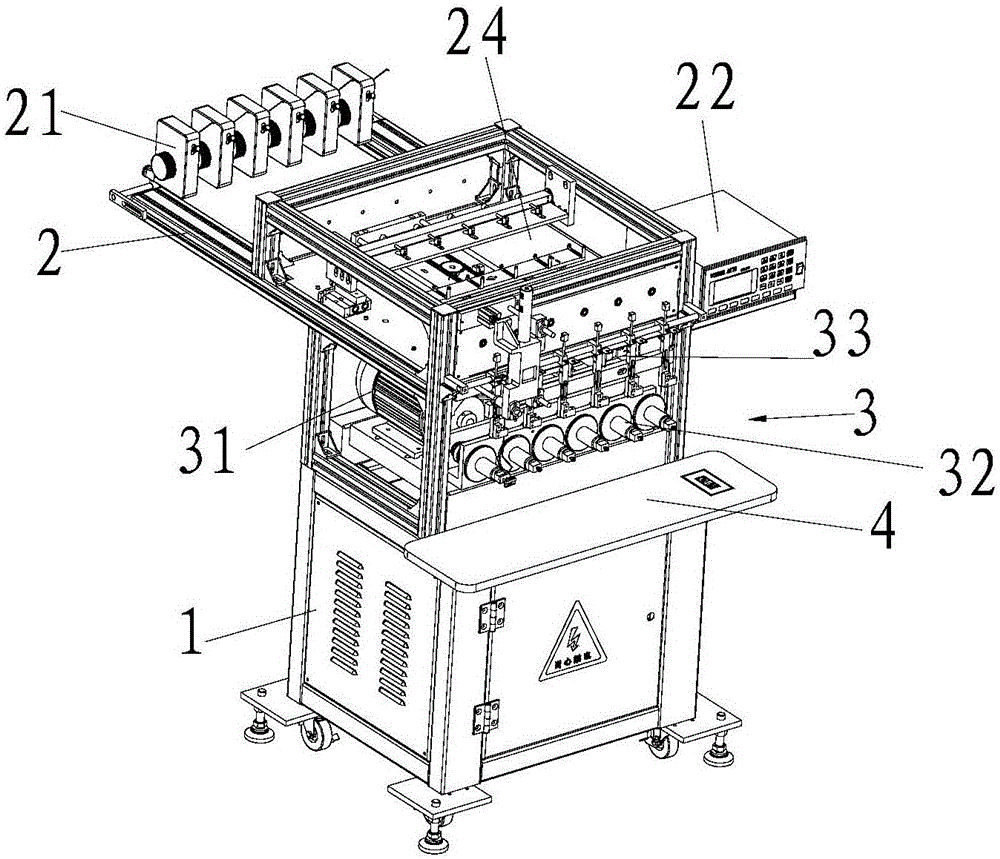

[0020] See Figure 1 to Figure 6 As shown: the present invention includes a frame body 1, a wire passing mechanism 2, and a driving mechanism 3. The frame body 1 is provided with a wire passing mechanism 2 and a driving mechanism 3. The wire passing mechanism 2 is provided with a bobbin 21, and the driving mechanism 3 includes a motor 31. , multi-axis winding machine axis 32, winding machine head 33, hot-melt automatic casing threading device 5, transmission device 24, one side of the frame body 1 is provided with a supporting plate 4, hot-melt automatic casing threading device 5 is provided with movable device cylinder 36, air pressure vortex refrigeration pipe 35, fixed frame 34, and hot-melt mode automatic casing pipe device 5 is also provided with heating device 52, fit chuck 51.

[0021] There are more than two spools 21 , and the thread passing mechanism 2 is provided with a cover plate 23 .

[0022] One side of the frame body 1 is provided with an electronic console 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com