Plunger press and method for producing compressed bales

A press and plunger type technology, which is applied in the field of plunger presses, can solve the problems of stress, twisting and material damage of unideal materials, and achieve uniform packing density, high packing density, and high packing density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

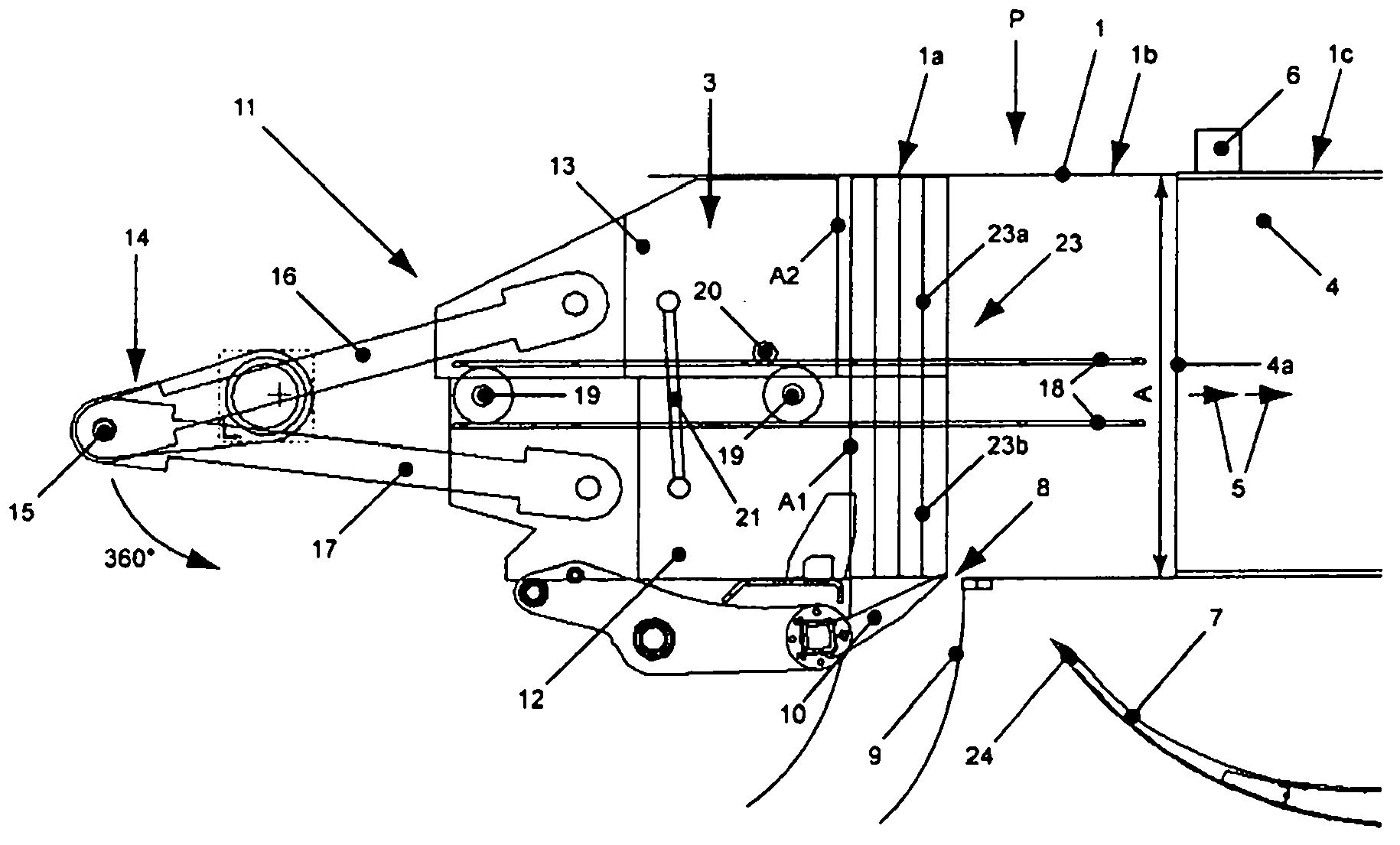

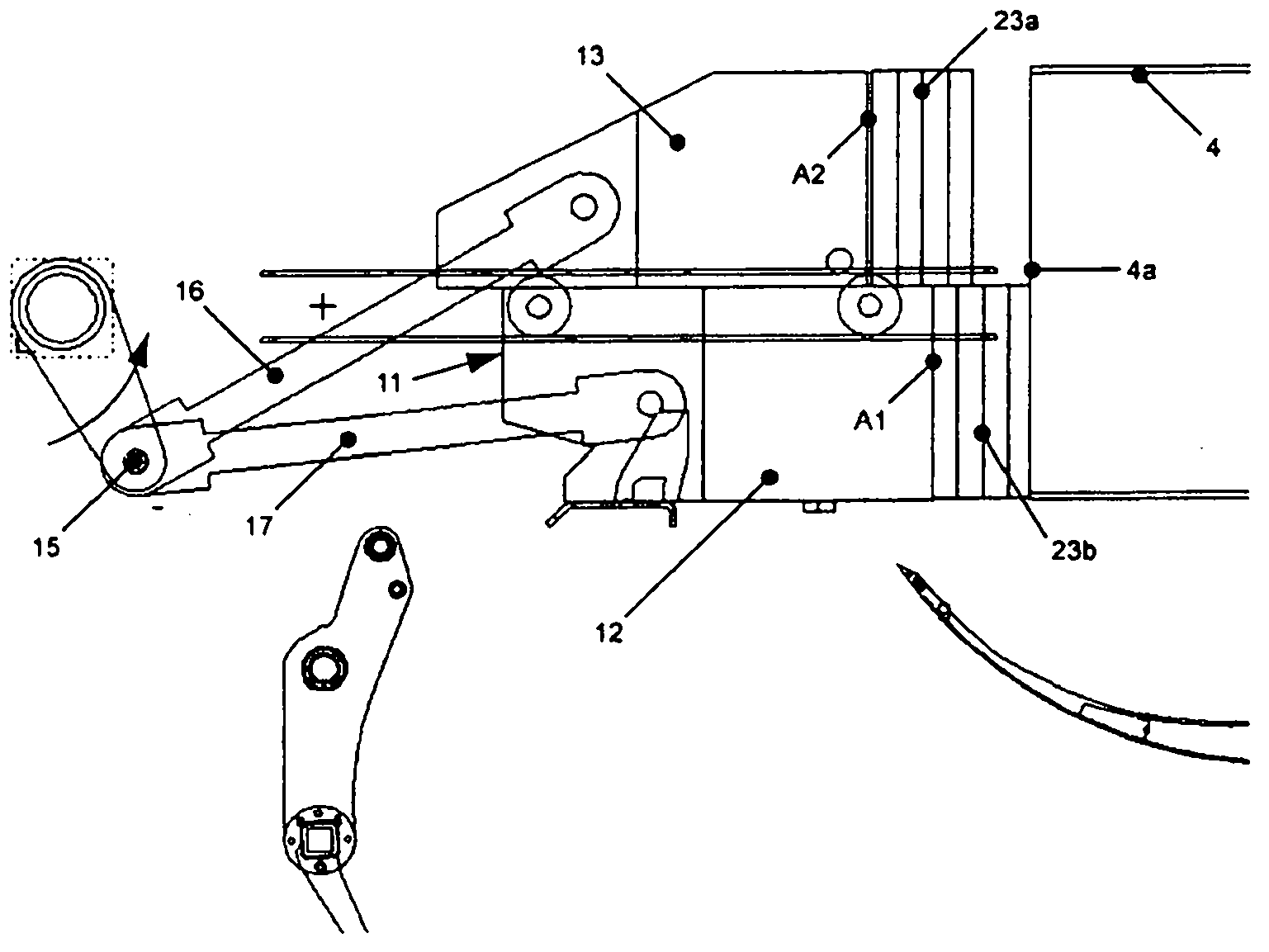

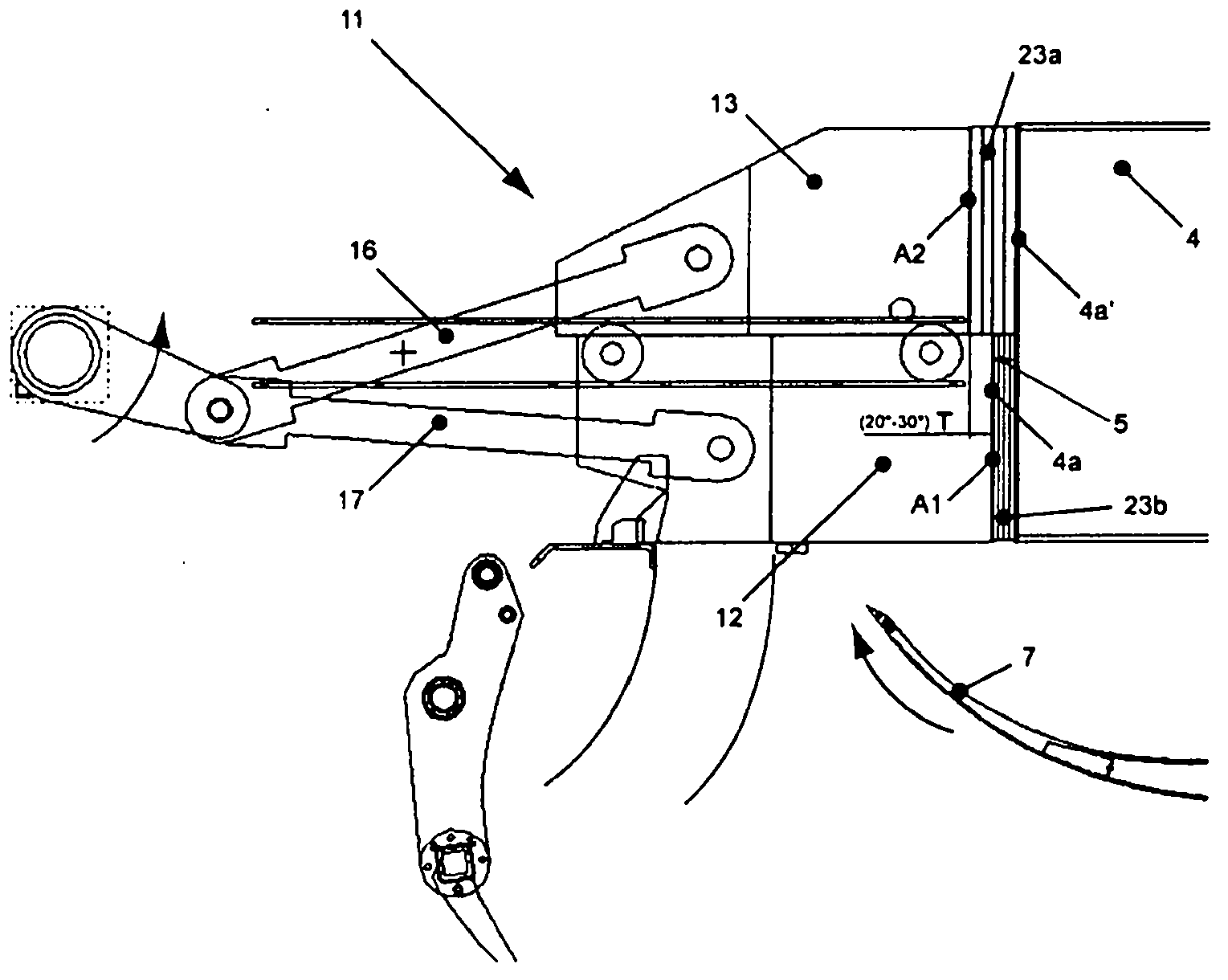

[0039] Figures 1 to 4 Shown is the production of compressed bales for agricultural and / or industrial use (e.g. hay, straw, biomass or fibrous bodies) in a ram press as part of an open channel baler (not shown). different stages of operation. As is conventional, the ram press P has a frame (not shown) enclosing the baler housing 1, which is arranged on a movable undercarriage, which is either self-propelled, or coupled via The tongue part of the coupling device is pulled. The plunger press P is either equipped with its own drive source, such as an internal combustion engine, or is supplied, for example, with hydraulic power from a traction vehicle. Alternatively, the ram press P can be integrated in the box baler.

[0040] The feed duct 9 is connected to the baler housing 1 , in particular to the underside (inlet 8 ) of the feed supply part 1 a , which in the baler housing 1 passes through the compression part 1 b and the strand channel part 1 c and continue until figure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap