Multi-way valve

A technology of multi-way valves and valve sliders, which is applied in the direction of multi-way valves, valve devices, servo meter circuits, etc., to achieve the effect of reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

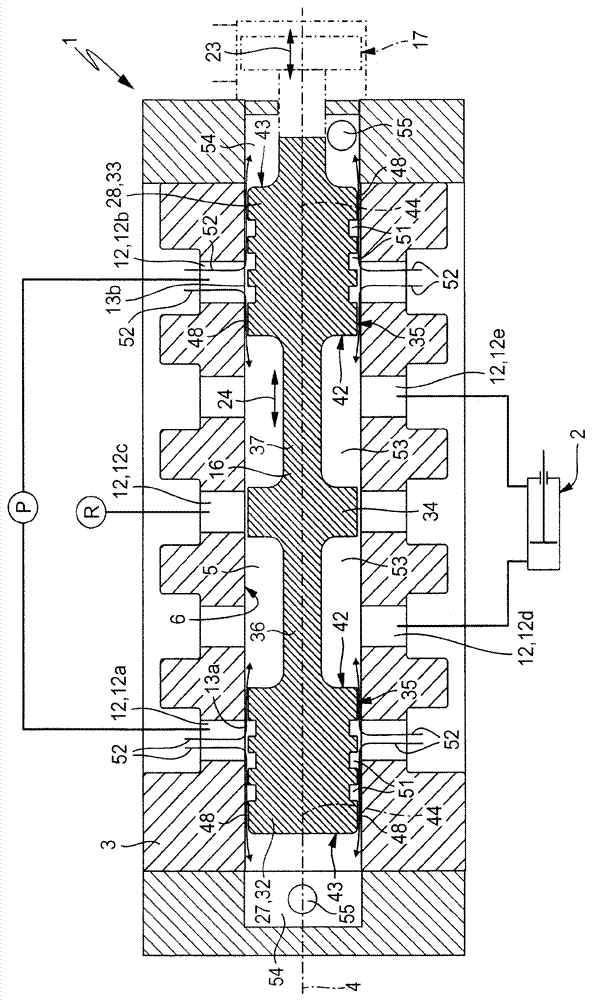

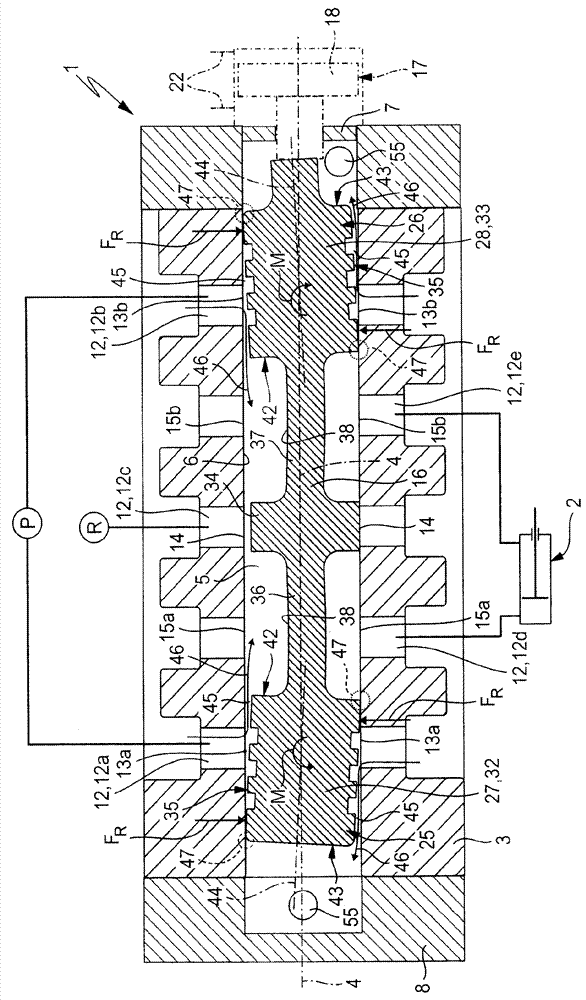

[0026] The multi-way valve 1 as can be seen in the drawings can be used to control any type of fluid flow. A typical application is the control of the flow of pressurized fluid to and from a load 2 indicated schematically in the figure, such as a fluid-operated drive.

[0027] Usually, the controlled pressure fluid is compressed air or pressure oil. However, other fluid media can also be controlled.

[0028]The multi-way valve 1 of this embodiment is designed as a three-position five-way valve. However, the invention can also be implemented in valves with other functionalities.

[0029] The multi-way valve 1 has a valve housing 3 in which is located an elongated control chamber 5 with a longitudinal axis 4 . Expediently, the control chamber 5 has a circular, preferably annular, cross section. On the peripheral side, the control chamber 5 is delimited by a wall referred to as the peripheral wall 6 , which is formed directly by the valve housing 3 in the exemplary embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com