Automatic injection pump

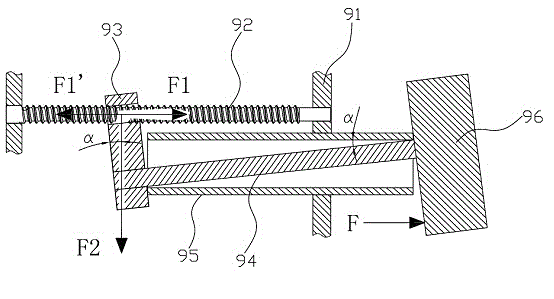

An automatic injection and syringe technology, which is applied in the field of medical devices, can solve the problems of bending deformation of the lead screw 92, twisting and deformation of the thread, poor tooth meshing, etc., and achieves the effect of ensuring the injection accuracy and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

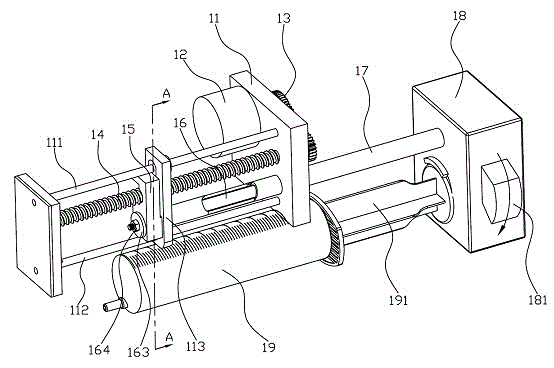

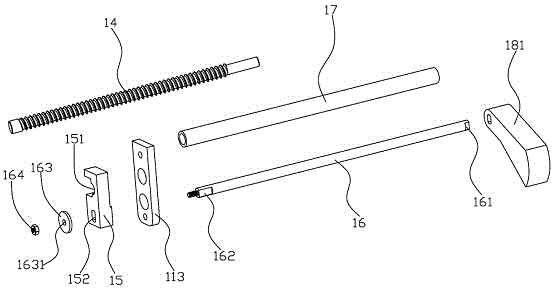

[0024] Such as Figure 2~Figure 4 As shown, an automatic injection pump provided by the embodiment of the present invention includes a frame 11, a driving device 12, a reduction device 13, a screw rod 14, a split nut 15, a solid shaft 16, a hollow tube 17, a push block 18 and a syringe 19 , the two ends of the screw rod 14 are rotatably connected with the frame 11 through bearings (not shown), the split nut 15 has a gap 151, the gap 151 of the split nut 15 is threadedly connected with the screw rod 14, and the split nut 15 passes through the gap 151 The cotter nut 15 can be engaged or separated from the screw rod 14. The solid shaft 16 is arranged in the hollow tube 17. One end of the hollow tube 17 is in contact with the cotter nut 15, and the other end of the hollow tube 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com