A syringe pump and its transmission device

A technology of transmission device and syringe pump, which is applied in the direction of subcutaneous injection equipment, pressure infusion, and equipment introduced into the body, etc., which can solve the problem of the reduction of injection accuracy and service life of the syringe pump, and the aggravation of abnormal wear and tear of the nut and the threaded mandrel. Scratching with the screw rod, etc., to achieve the effect of convenient operation, labor saving, reduced process, and avoiding screw tooth wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

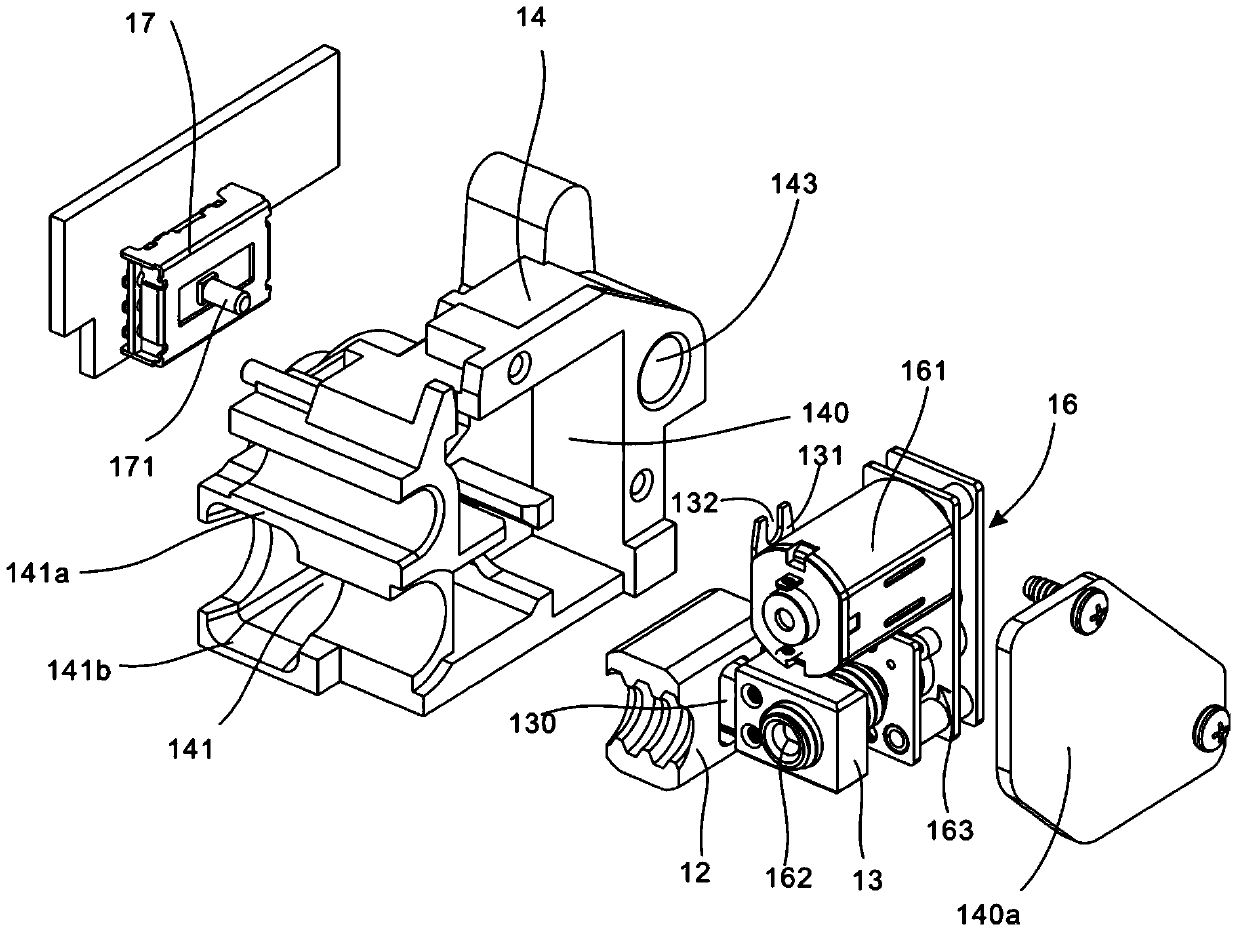

[0045] Here, in other embodiments, it is also possible that the electric drive assembly includes a drive motor and a cam, the drive motor is fixed on the sliding seat, and the cam is connected to the drive motor and rotates under the drive of the drive motor. The cam is connected to the moving part 13 to drive the moving part 13 to reciprocate in a straight line; or, the electric drive assembly includes a driving motor, a gear and a rack, the driving motor is fixed on the sliding seat 14, the gear is connected to the driving motor, and the gear and the rack are meshed , the drive motor drives the gear to rotate to drive the rack to move linearly, and the rack is connected to the moving part to drive the moving part to move; as another embodiment, the electric drive assembly includes a cylinder, which is fixed on the sliding seat 14, and the cylinder The piston rod is connected with the moving part 13 to drive the moving part 13 to move linearly.

[0046] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com