Machining method of thin-wall heterogenic titanium alloy part

A processing method, a technology of titanium alloy, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of easy deformation, poor rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

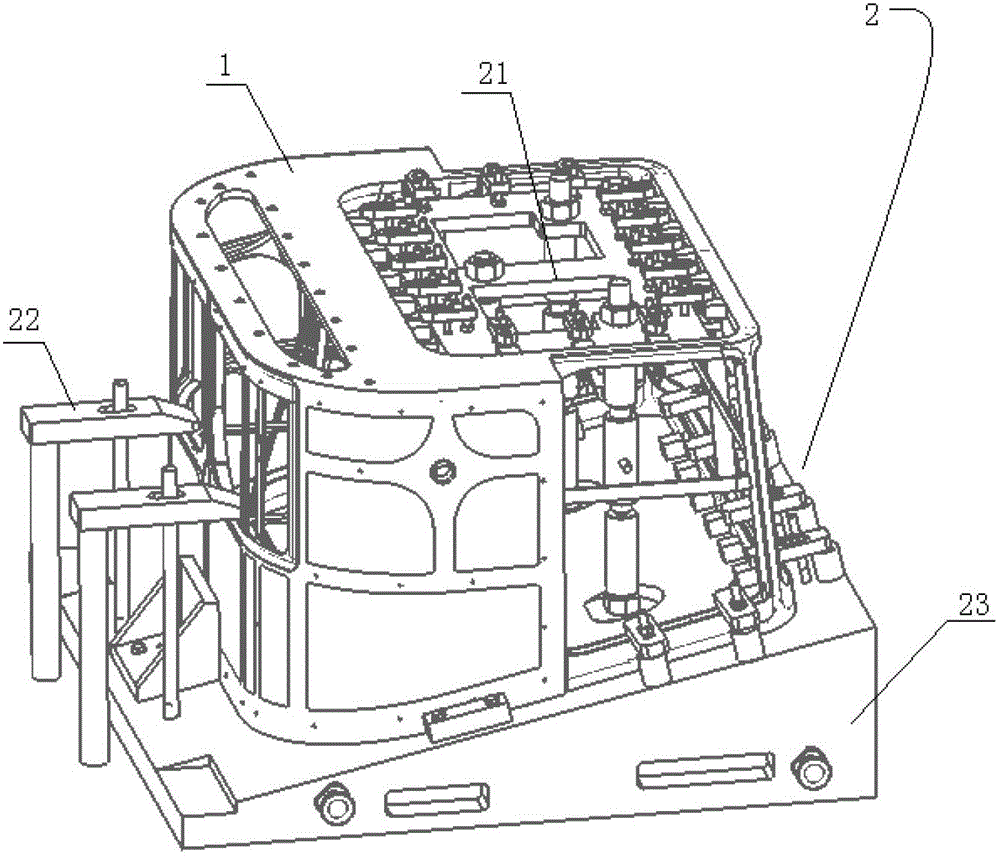

[0031] The parts processed in the test are aerospace titanium alloy thin-walled parts. The OPTICUT software of Beijing University of Aeronautics and Astronautics is used to select the cutting parameters, and the UG software is used to design the CAM program and process equipment. The KPU4000 produced in Spain is used as the processing equipment, and the tool size is 20mm. The cutting depth is 1mm, the cutting width is 12mm, the speed is 900r / min, and the feed is 400mm / min. The structure of part 1 is a casting cabin.

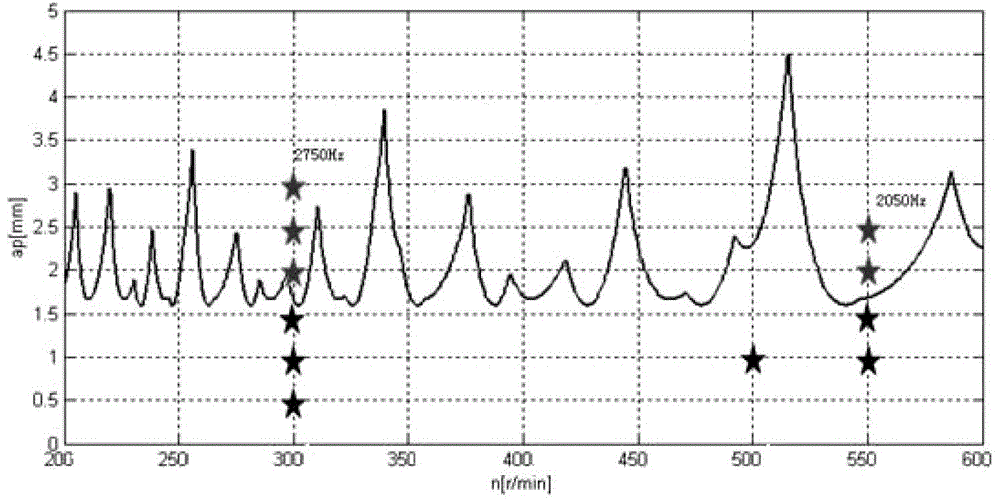

[0032] The main process design process is as follows: design rigidity strengthening tooling such as figure 1 As shown, adjust the clamping position according to the size of part 1. Use the CAM software to generate the profiling processing program for the bottom surface of the flat-bottomed knife, and use the chatter analysis software to analyze the chatter syndrome. figure 2 As shown in the figure, a circular insert tool is selected, and the circular blade of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com