Pneumatic brake booster with variable force transmission ratio and improved switching performance

A booster, pneumatic technology, applied in the field of pneumatic brake boosters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

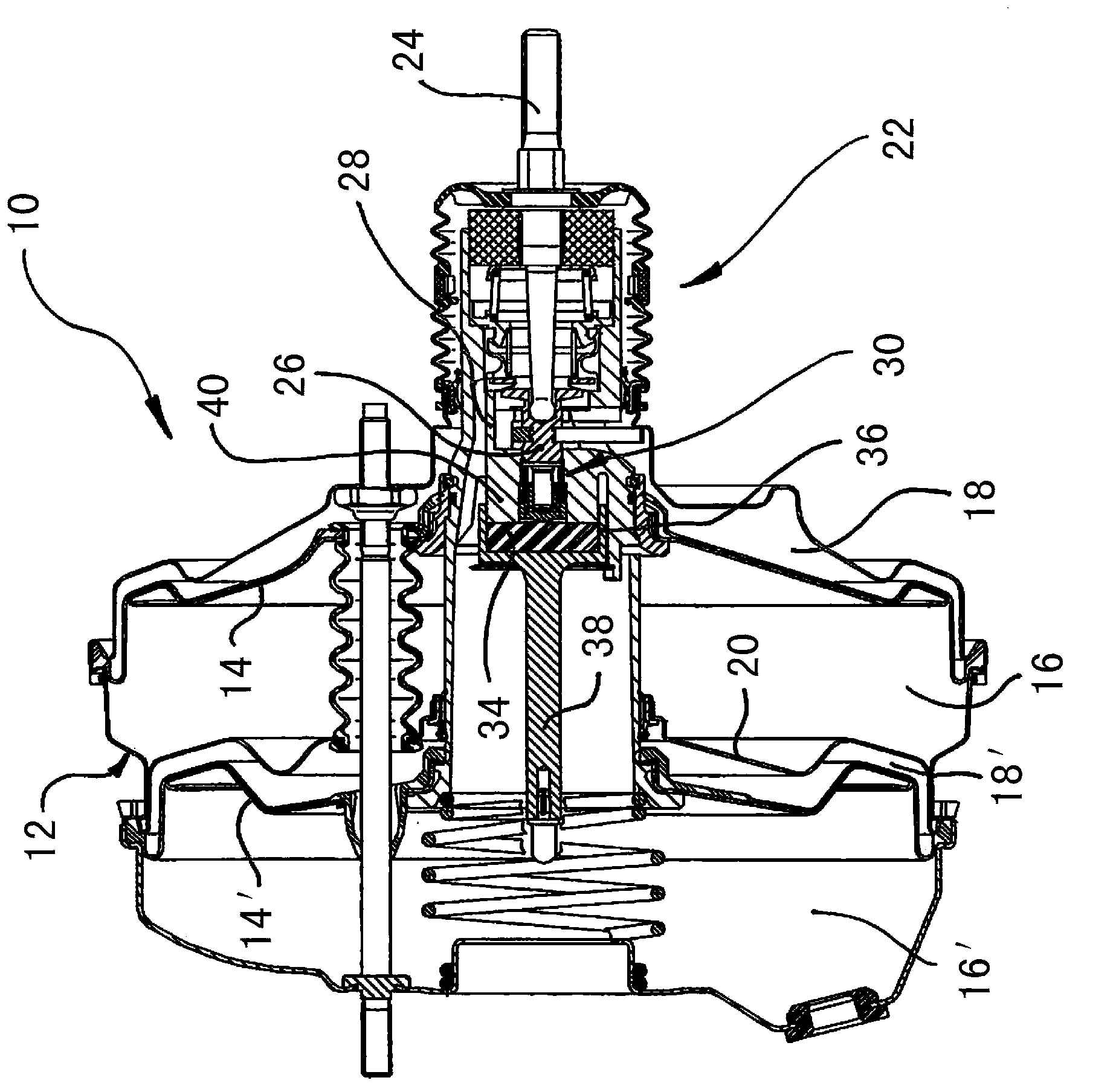

[0026] figure 1 A typical vacuum brake booster 10 is shown in longitudinal section and has a housing 12 which is divided by a movable wall 14 into a vacuum chamber 16 and a working chamber 18 . The brake booster 10 shown here is designed in series, ie it has an additional movable wall 14 ′ which divides the housing 12 part separated by the fixed wall 20 . It is another negative pressure chamber 16' and another working chamber 18'.

[0027] The negative pressure chambers 16 and 16' are always connected with the negative pressure source during the operation of the brake booster 10, while the working chambers 18, 18' can selectively communicate with the negative pressure or the atmospheric pressure. A control valve 22 is used for this, which controls the valve seat in the control valve 22 in accordance with the actuation of a force input mechanism 24, usually connected to a brake pedal (not shown here), in such a way that atmospheric pressure can flow into the working chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com