Preparation of protein and polypeptide through low-temperature extrusion enzymolysis method

A protein and low-temperature technology, applied in fermentation and other directions, can solve the problems of low protein extraction rate, long time, low conversion rate of peptides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of corn polypeptide

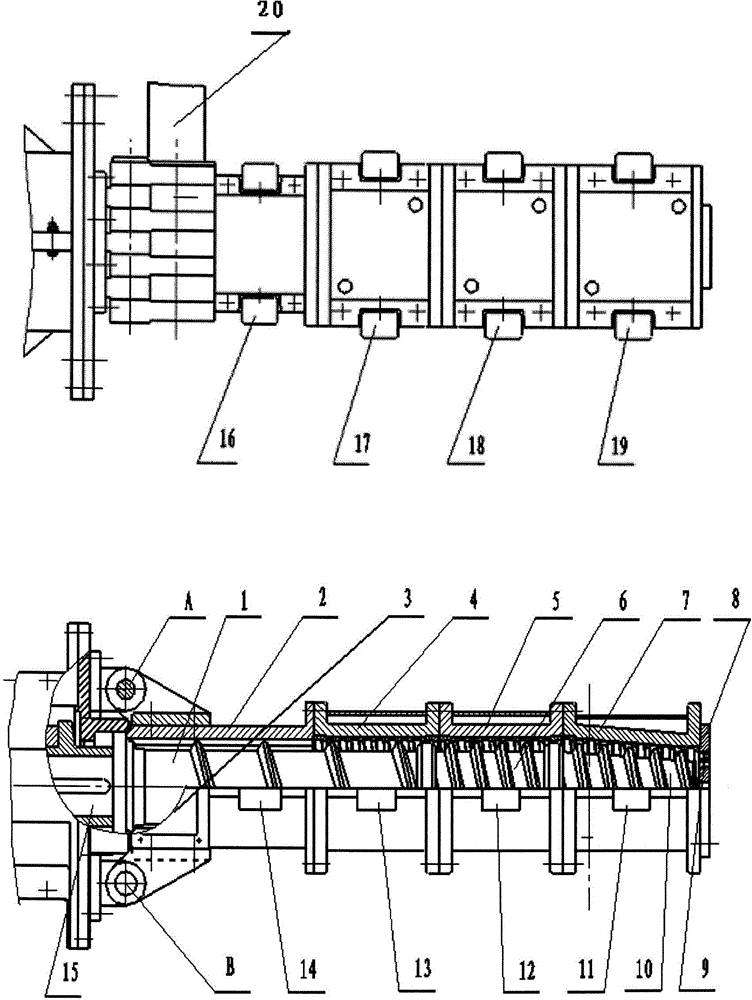

[0018] A low-temperature extrusion enzymolysis method for raw materials with added enzyme preparations for preparing corn polypeptides, wherein the moisture content of corn gluten powder before extrusion is less than 14%, its particle size should pass through an 80-mesh sieve, and then an appropriate amount of water is added to make the moisture content The rate is adjusted to 40%, and an appropriate amount of neutral protease is added at the same time. The amount of addition is 5L or 5kg of neutral protease per ton of raw materials for preparing corn polypeptides before extrusion, and the pH value of the added water is adjusted to 6.8-8.0. The extrusion device of the single-screw extruder extrudes and processes the above-mentioned corn gluten powder with the moisture content adjusted to 40% for the preparation of corn polypeptides with enzyme preparations, wherein the extrusion system parameter range is: connecting the templat...

Embodiment 2

[0020] Example 2 Preparation of soybean protein isolate powder

[0021] A low-temperature extrusion enzymolysis method of defatted soybean meal added with an enzyme preparation for preparing soybean protein isolate powder, wherein the moisture content of the defatted soybean meal soaked in oil before extrusion is less than 14%, and its particle size should pass through an 80-mesh sieve , then add an appropriate amount of water to adjust the water content to 40%, and at the same time add an appropriate amount of alkaline protease, the amount added is 5L or 5kg of alkaline protease per ton of defatted soybean meal, adjust the pH value of the added water to 8-12, use The extrusion device of a commercially available single-screw extruder extrudes and processes the above-mentioned defatted soybean meal with the moisture content adjusted to 40% to prepare the soybean protein isolate and add an enzyme preparation, wherein the extrusion system parameter range is: connecting the templat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com