Model test device for simulating jacked pile driving process

A model test device and a technology of static pressure piles, which are applied in foundation structure tests, foundation structure engineering, construction, etc., can solve problems such as insufficient consideration and interpretation of influencing factors and pile sinking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

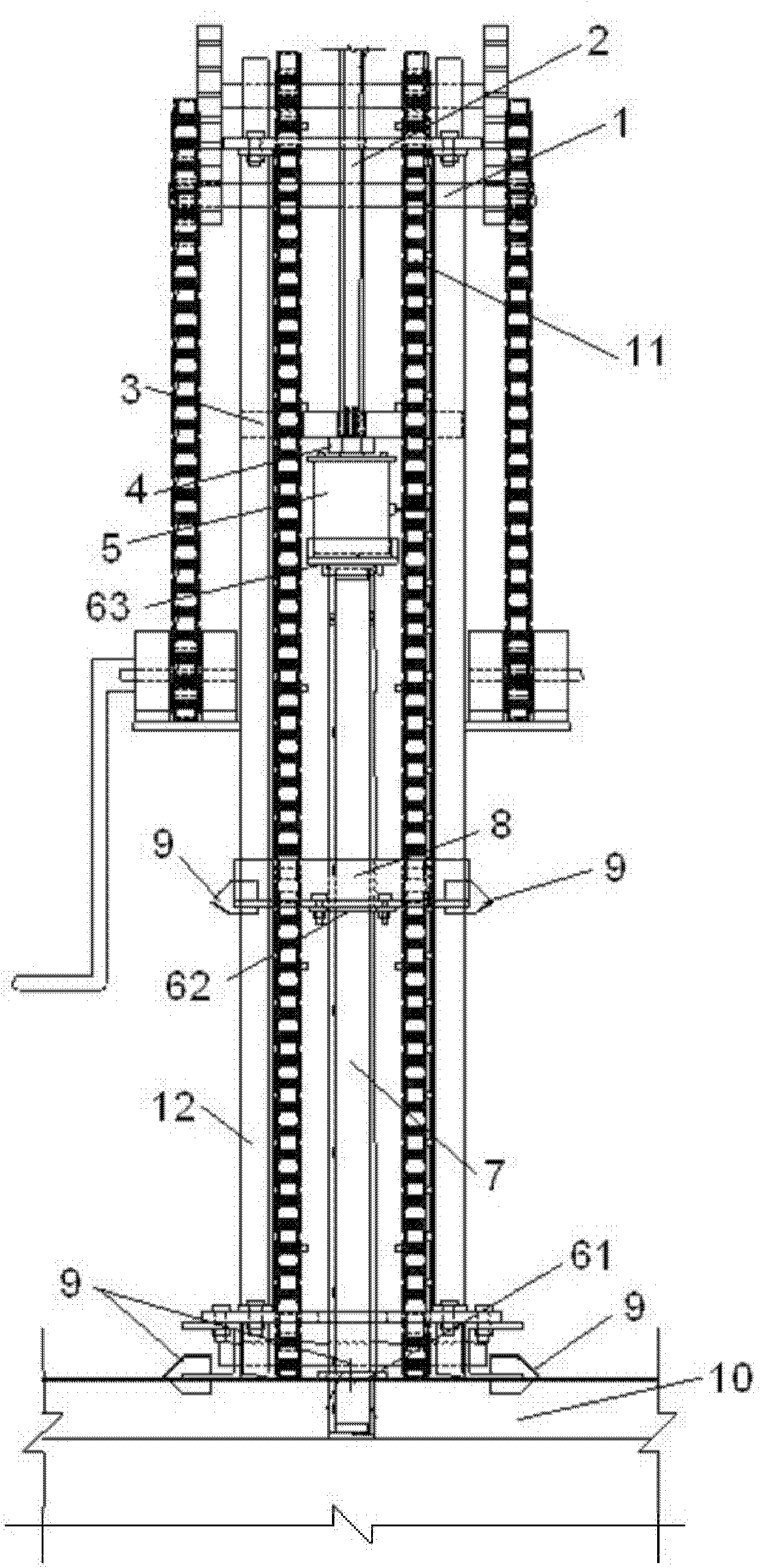

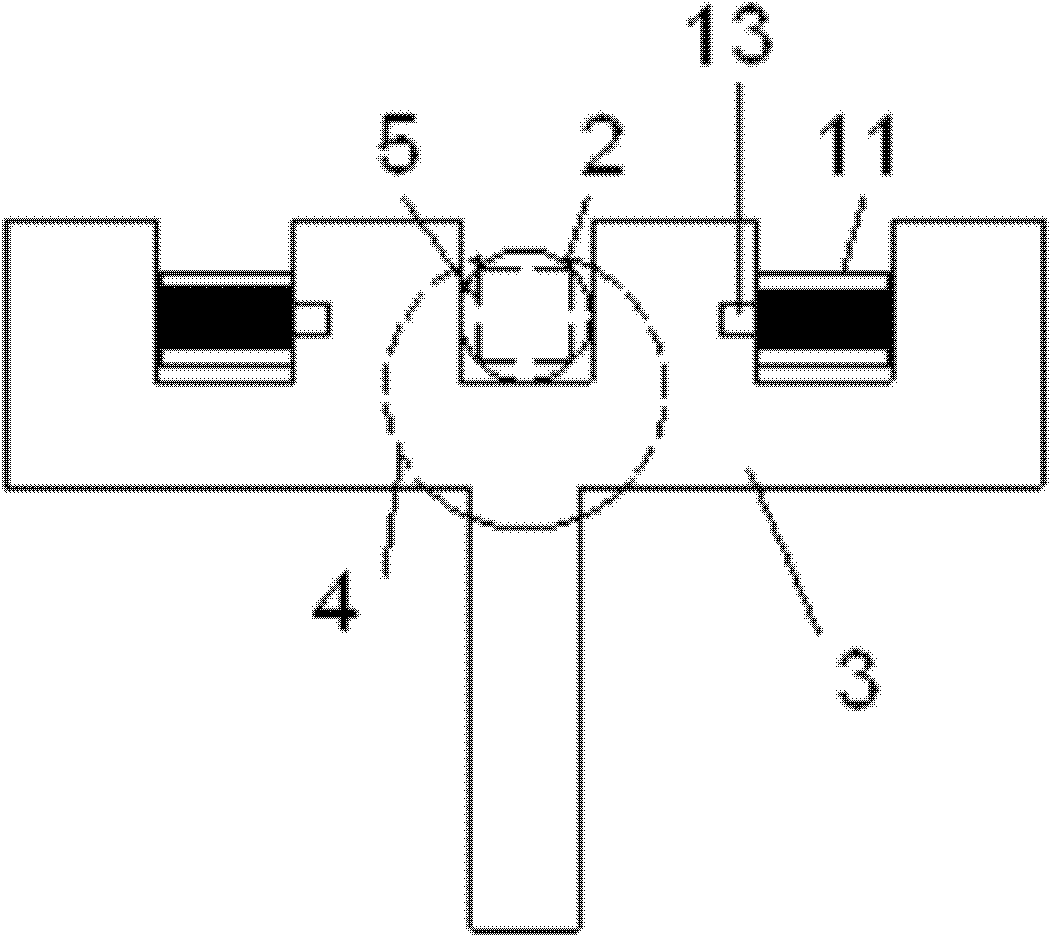

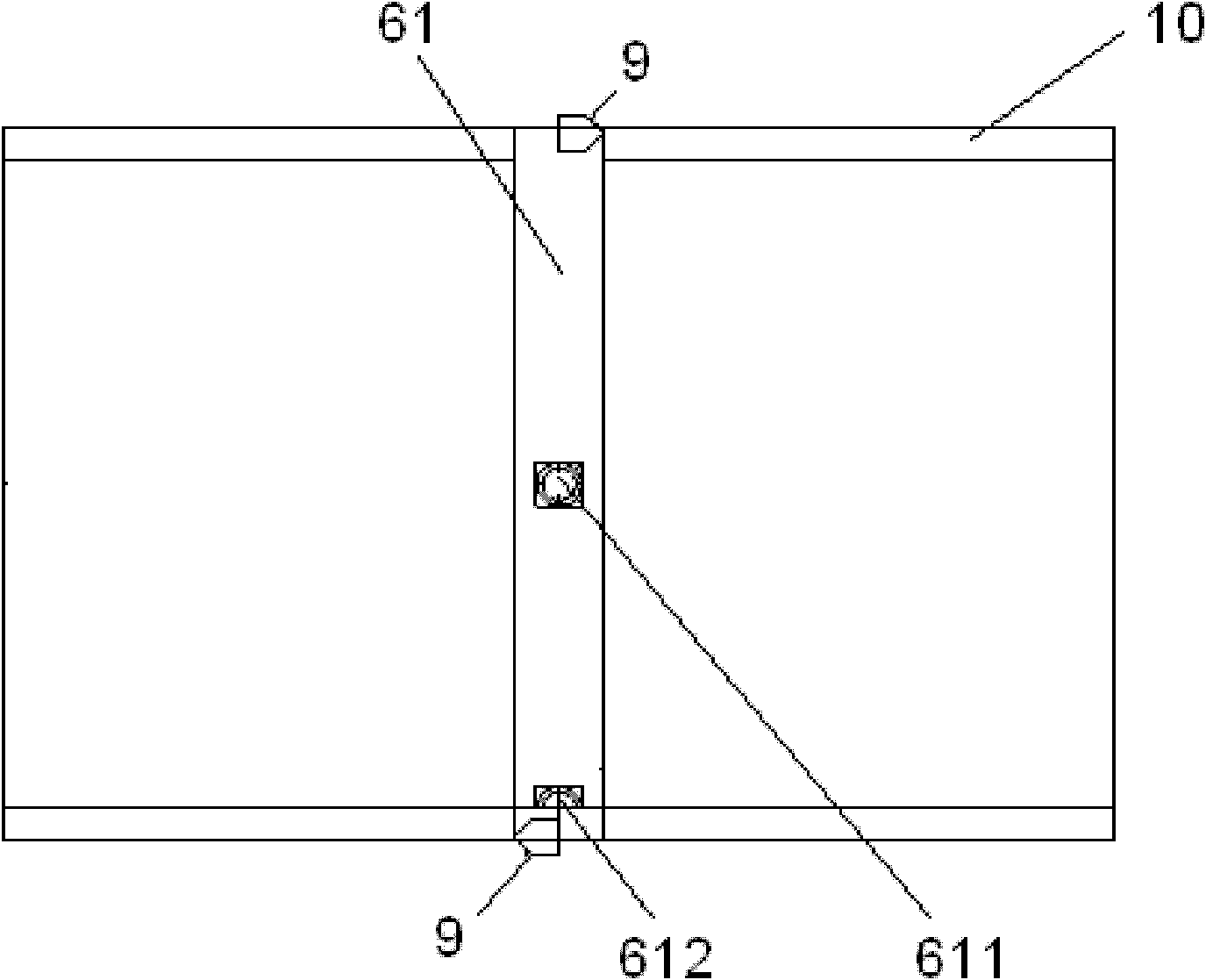

[0021] Such as Figure 1~5 As shown, a model test device for simulating the process of static pressure pile sinking, the manual chain type static penetrating sounder 1 is fixed on the top of the model box by 4 U-shaped clips 9, the chain of the manual chain type static penetrating sounder 1 11 is provided with locking tooth 13, and this locking tooth 13 clamps gable plate 3, and gable plate 3 is fixed on the chain 11. Pad pressing plate 4 pad is arranged on the below of gable plate 3. There is a reserved hole on the top of the manual chain type static penetrometer 1 through which the iron rod 2 can pass. The iron rod 2 extends into the reserved hole sequentially from above and passes through the gable plate 3 and the backing plate 4 in sequence. The lower end is connected with the pressure sensor 5 by bolts. The model pile 7 adopts a circular full model pile, the upper end of which is connected below the pressure sensor 5 through a positioning sleeve 63. The middle part of t...

Embodiment 2

[0025] A model test device for simulating the pile sinking process of static pressure piles. The model pile 7 adopts a semicircular half mold pile, and the positioning hole 621 on the second positioning plate 62 is correspondingly opened as a semicircle, and the steel pipe at the lower part of the positioning sleeve 63 Also cooperate with the shape of the model pile 7 to be a semicircular steel pipe. When using this device, the model stake 7 passes through the semi-membrane positioning hole 612 on the first positioning plate 61 near the side wall of the model box 7, and adjusts the positions of the manual chain type static penetrometer 1 and the positioning guide assembly, so that the model stake 7 It sticks to the side wall of the model box 7 and extends into the soil. The side wall is made of tempered glass, which is convenient for observing the displacement field change of the soil on the side of the pile when the model pile 7 is inserted into the soil. The rest is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com