Device for testing explosion characteristic parameters of combustible gas ignited by hot dust under laser irradiation

A technology of laser irradiation and characteristic parameters, applied in the direction of material explosion, can solve the problem of inability to accurately and synchronously test the key parameters of hot dust detonation gas explosion, and achieve the effect of short response time, accurate calculation and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

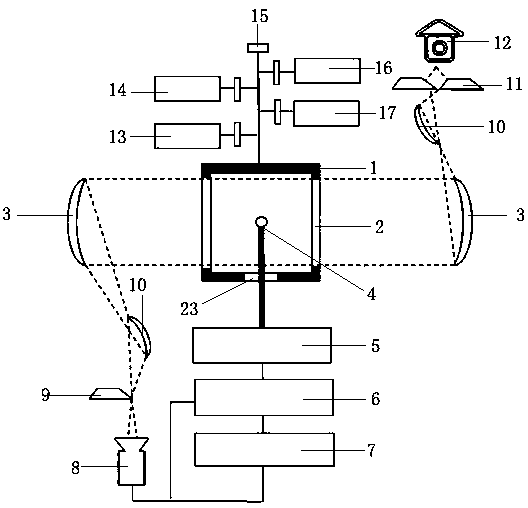

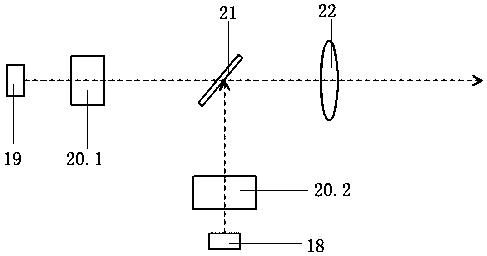

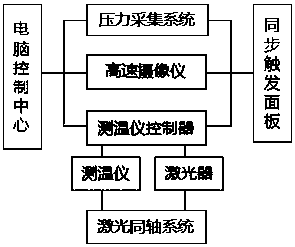

[0022] Such as figure 1 As shown, a test device for the explosion characteristic parameters of hot dust ignited combustible gas under laser irradiation, including a semiconductor continuous wave laser 19, an infrared thermometer 18, a high-speed schlieren camera system, a synchronous trigger system 6 and an explosion container 1, the explosion There are windows 2 sealed with quartz glass on the two side walls of the container 1. A dust support 4 is arranged in the explosion container 1. There is a groove for placing dust on the dust support 4. The explosion container 1 is provided with a reserved hole. A pressure sensor 15, a vacuum gauge 16, a vacuum pump 13, an inflation valve 17 and a pressure reducing valve 14 are installed in the hole, and sealing means are used to seal, and the explosion vessel 1 is also provided with a glass window 23, a semiconductor continuous wave laser 19 and an infrared thermometer 18 The laser is irradiated on the center of the dust through the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com