Line-contact sliding-friction vibration noise test bench

A sliding friction, vibration and noise technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of no testing device, high sound insulation cost, and difficulty in eliminating noise, and achieve precise characteristics and effects. Factors, convenient disassembly and replacement of specimens, and the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

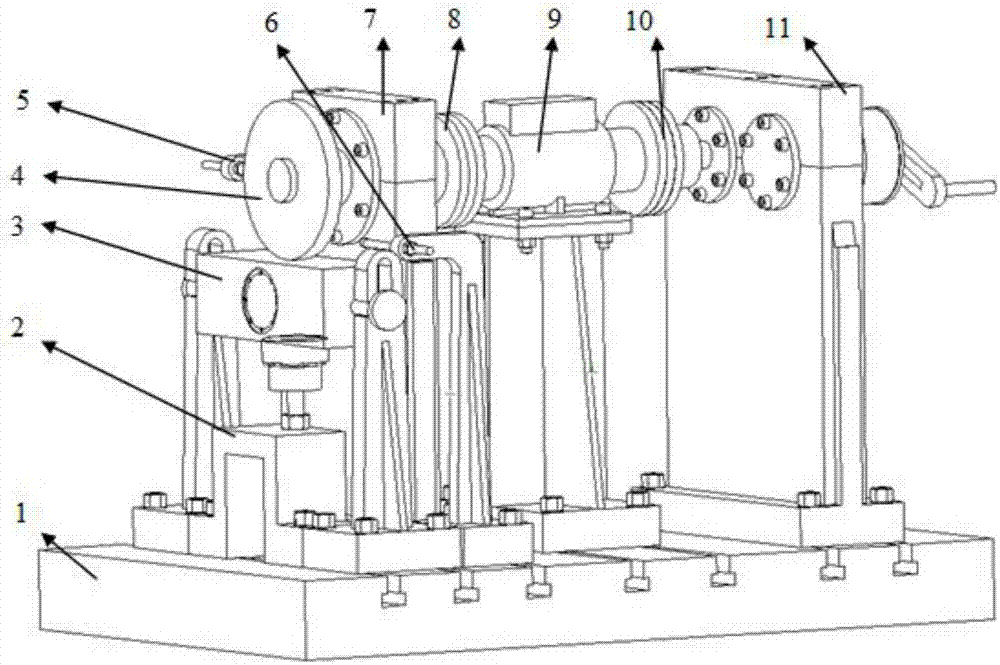

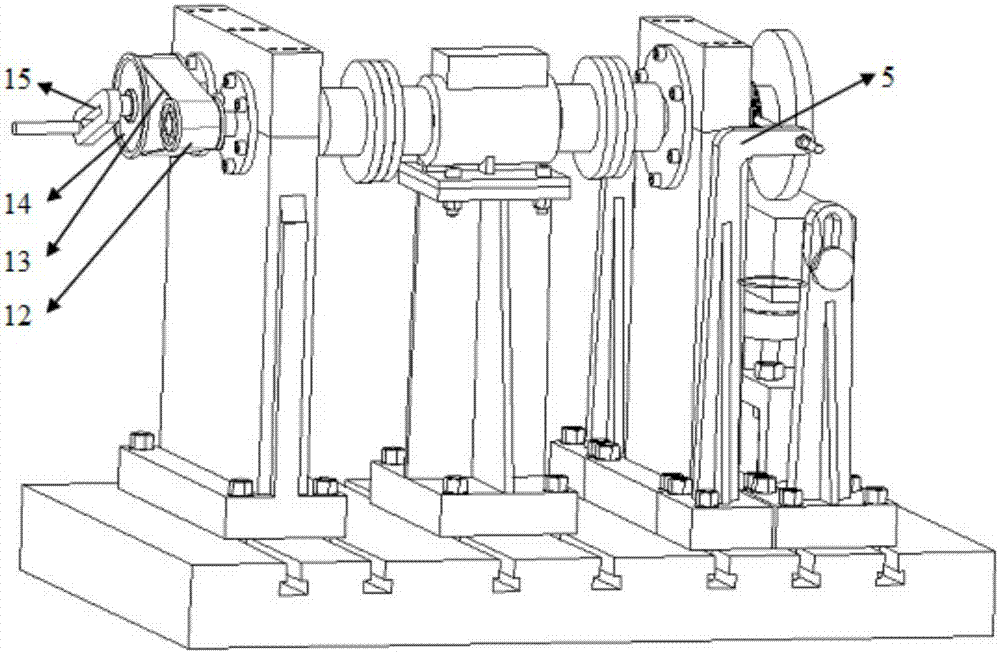

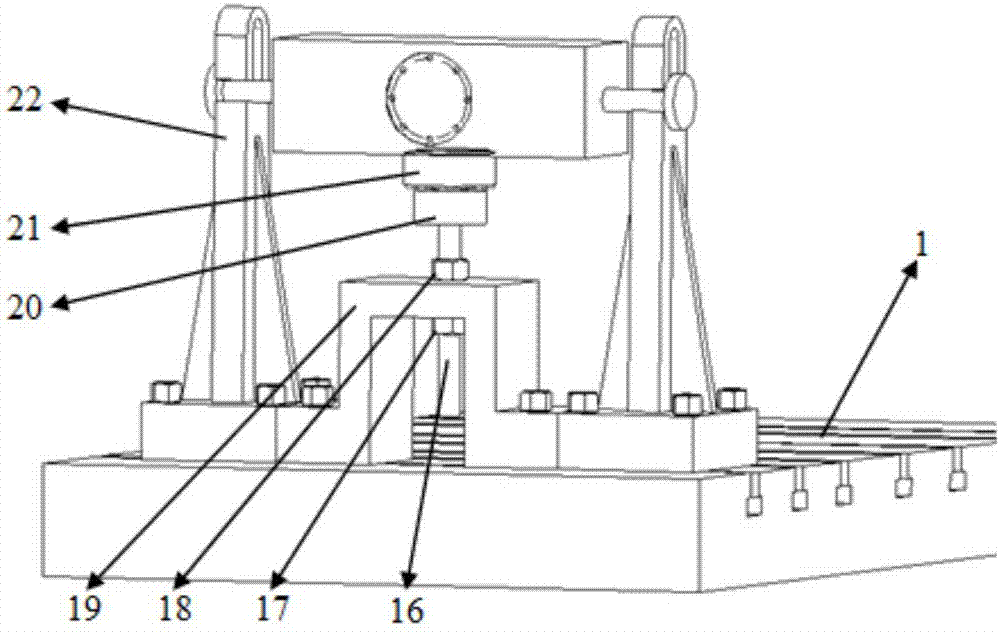

[0022] A line contact sliding friction vibration noise test bench in this embodiment mainly includes a basic platform 1, a loading assembly 2, a plane specimen 3, a cylindrical specimen 4, a velocity sensor 5, an acoustic sensor 6, a support assembly 7, a front coupling Shaft device 8, torque sensor 9, rear coupling 10, timing belt support assembly 11, small pulley 12, timing belt 13, large pulley 14, driving rocker arm 15. Such as figure 1 and figure 2As shown, the loading assembly 2, supporting assembly 7, and synchronous belt supporting assembly 11 are respectively installed on the foundation platform 1 through T-slot bolts; the plane specimen 3 is installed on the loading assembly 2 through the U-shaped groove; the cylindrical specimen 4 is installed through the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com