Flexible contact sealing device applicable to air preheater

An air preheater and contact sealing technology, which is applied in heat exchanger sealing devices, engine sealing, heat exchange equipment, etc., can solve problems such as failure, spring loss of elasticity, breakage, etc., achieve good sealing effect, and less maintenance probability , to ensure the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

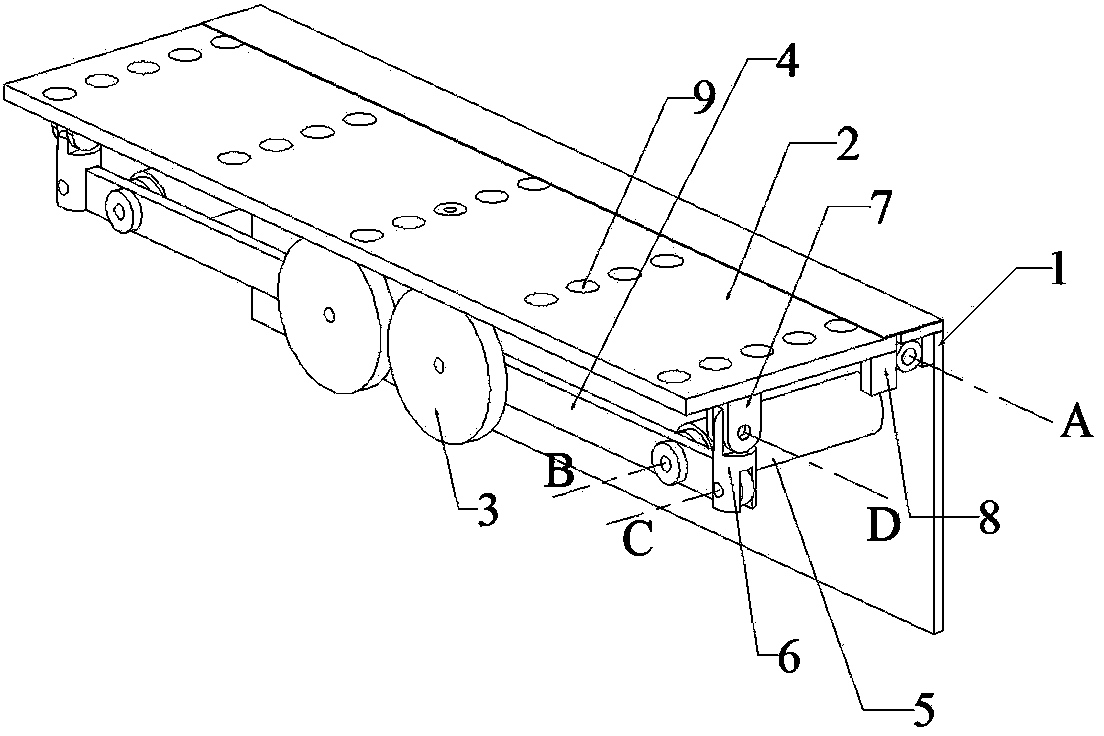

[0021] refer to figure 1 As shown, the flexible contact sealing device applicable to the air preheater of the present invention includes: a fixed plate, a movable plate and a counterweight assembly.

[0022] Among them, the fixed plate is used for installation and fixing, and the movable plate is used as a contact surface to form a seal. The movable plate and the fixed plate form a rotational connection. The counterweight realizes the adjustment of the position of the movable plate, so that it can realize contact sealing at different angles.

[0023] The counterweight assembly includes: counterweights, connecting rods, support columns, and movable joints. Wherein, the counterweight is used for counterweight, and the weight of the counterweight can be appropriately set according to different needs. As a preferred solution, the counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com