One-way pressure dynamic loading device

A dynamic loading and one-way pressure technology, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of unrealistic loading force, unstable loading force, and excessive pressure, etc., and achieve the overall goal of the device. The effect of compact structure, smooth movement and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

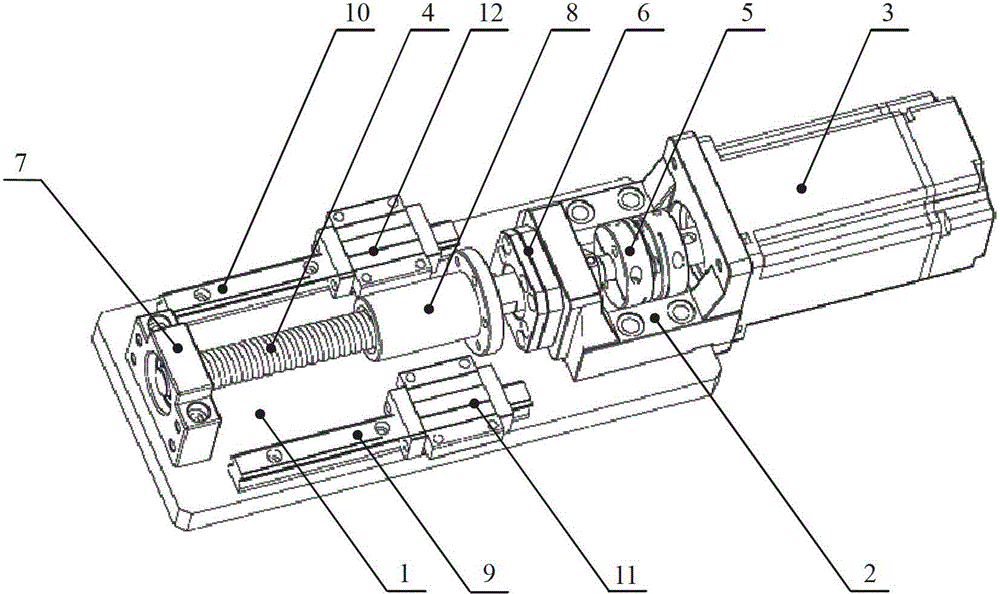

[0020] Such as figure 2 As shown, the structure of the servo transmission mechanism is: a motor support base 2 is fixed at one end of the base plate 1, and the servo motor 3 is fixed on the motor support base 2; the ball screw 4 is connected to the rotating shaft of the servo motor 3 through a coupling 5; The end of the ball screw 4 close to the coupling 5 is supported by the fixed end 6 of the ball screw fixed on the motor support base 2, and the other end is supported by the support end 7 of the ball screw fixed on the bottom plate 1. Support rotation; the ball screw 4 is sleeved with a flange-type screw nut 8; on both sides of the ball screw 4, there are first sliding guide rails 9 and second sliding guide rails 10 arranged in parallel and at equal intervals. A first slider 11 is arranged on a sliding guide rail 9, and a second slider 12 is arranged on a second sliding guide rail 10; the lead screw nut 8, the first slider 11 and the second slider 12 are positioned perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com