A reliability test method of multi-working condition simulated loading servo-powered tool holder

A dynamic tool holder and loading test technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problem of single loading method, poor load condition simulation, and simulation of load condition applied by the dynamic tool head Single and other problems, to achieve the effect of saving equipment costs, reducing operating costs, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

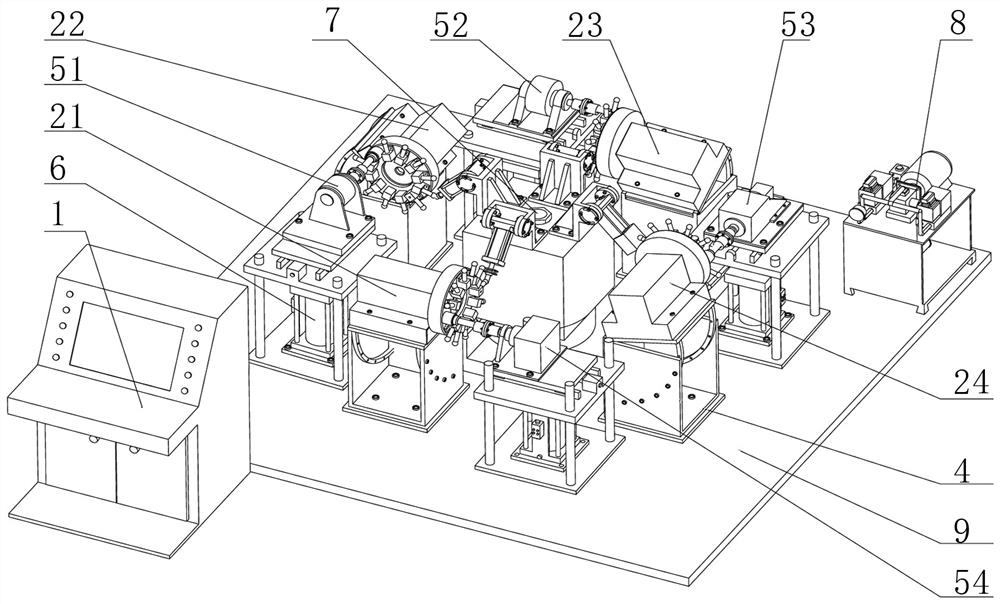

[0072] Embodiment 1 A reliability test platform for multi-working condition simulation loading servo power tool holder

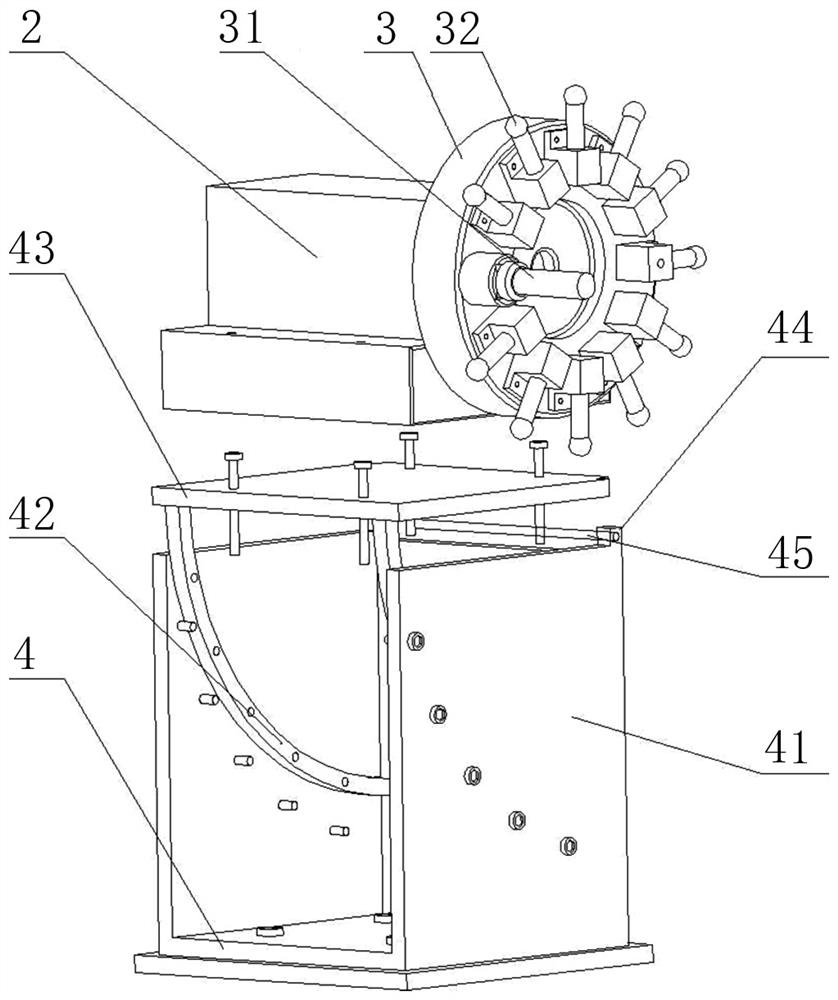

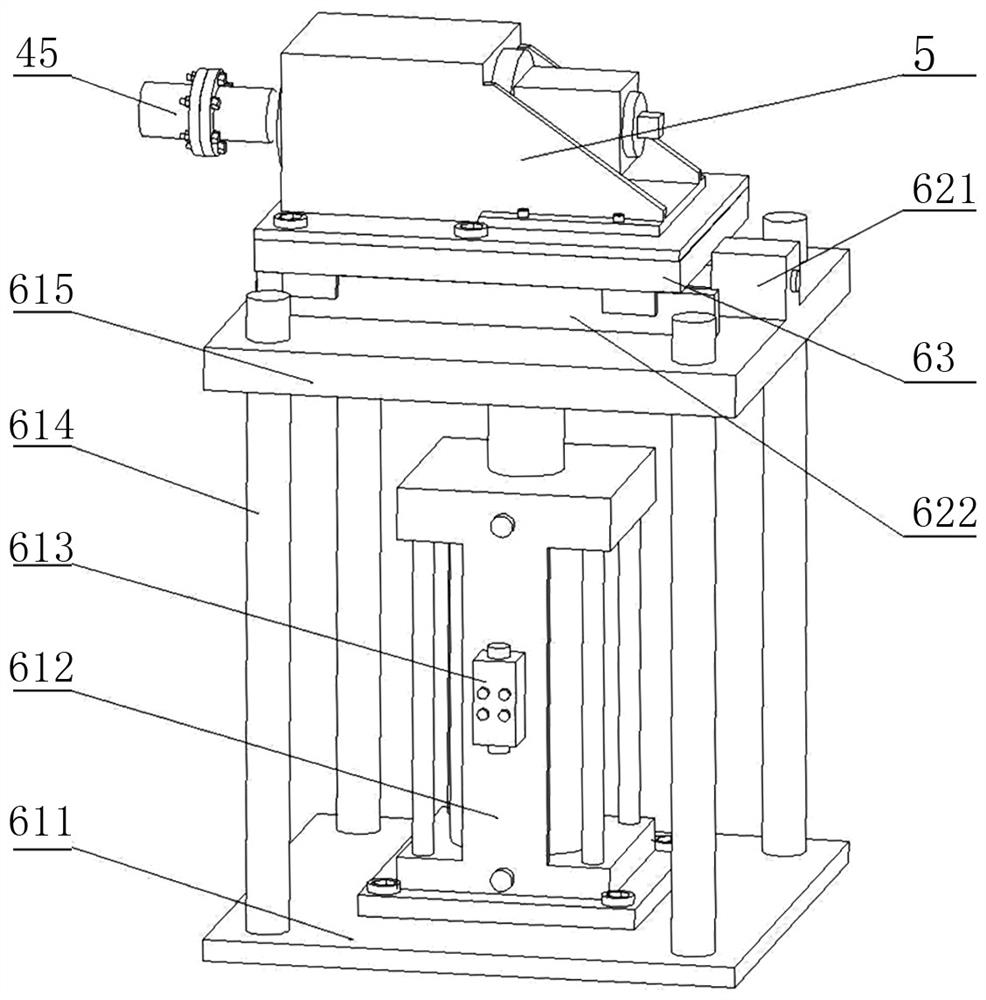

[0073] refer to Figure 1 to Figure 7 As shown, a reliability test platform for multi-working conditions simulated loading servo power tool rest, including: console 1, tool holder, tool holder seat 4, dynamometer, dynamometer device seat 6, loading device frame, hydraulic system 8;

[0074] Described knife rest and dynamometer are all provided with four, and every knife rest, dynamometer are respectively installed on the horizontal iron 9 by knife rest seat 4, dynamometer device seat 6;

[0075] The loading device frame includes: the lower base 71 of the loading device, the rotary drive unit, the upper rotating seat 73 of the loading device, the upper rotating seat 73 of the loading device is connected to the lower base 71 of the loading device through the rotating drive unit; the upper rotating seat 73 of the loading device is connected to Four groups of ...

Embodiment 2

[0099] Embodiment 2 A reliability testing method for multi-working-condition simulated loading servo-powered tool holders

[0100] A method for testing the reliability of a multi-working-condition simulated loading servo-powered tool holder according to the present invention is to use the multi-working-condition simulated-loaded servo-powered tool holder reliability test platform described in Embodiment 1, aiming at four tested servo-powered knives The reliability test method provided by the frame;

[0101] participate Figure 1 to Figure 10 , the multi-working condition simulation loading servo power tool holder reliability test platform and method of the present invention The specific steps are as follows:

[0102] 1. Servo powered tool post indexing test

[0103] 1) Keep the test temperature constant at 23°C, and place the test bench in the test environment for more than 8 hours;

[0104] 2) Ensure that the eddy current dynamometer 51, the hydraulic dynamometer 52, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com