A Combined Loading Double Tool Holder Reliability Test Device

A technology of combined loading and testing equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc. Head loading cost is high and other problems, to achieve the effect of compact structure, high degree of automation and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

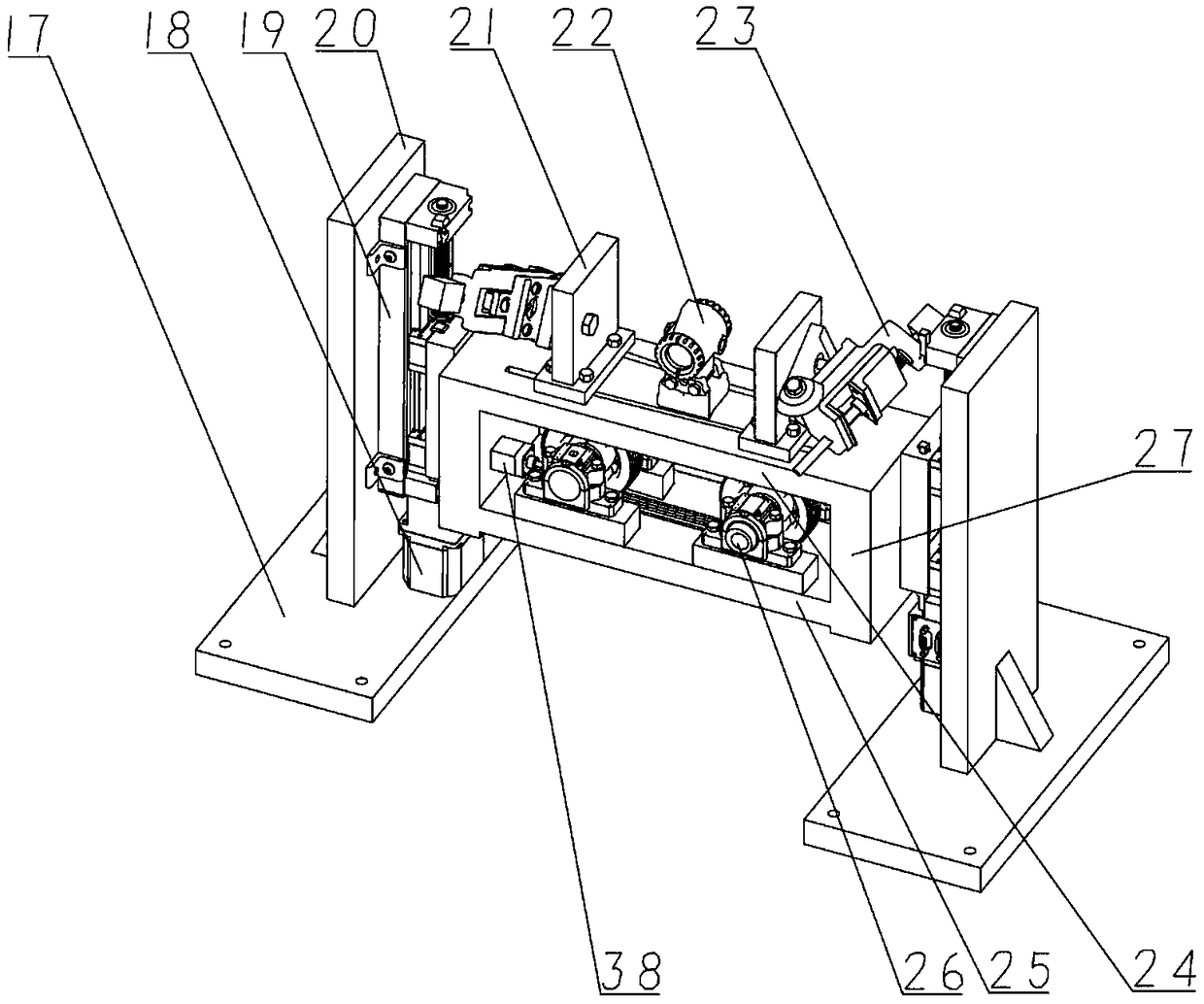

[0050] In conjunction with the accompanying drawings, the description is as follows:

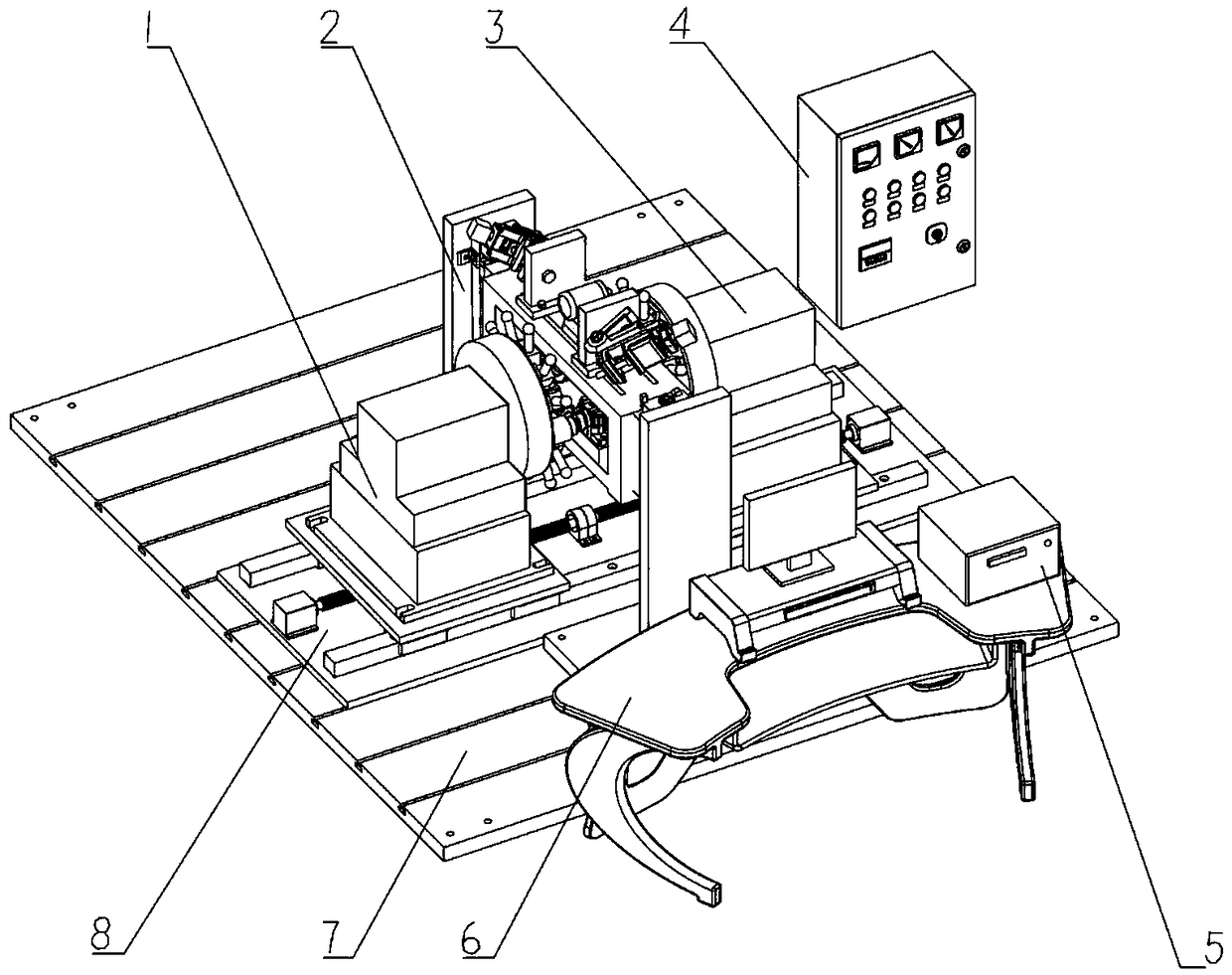

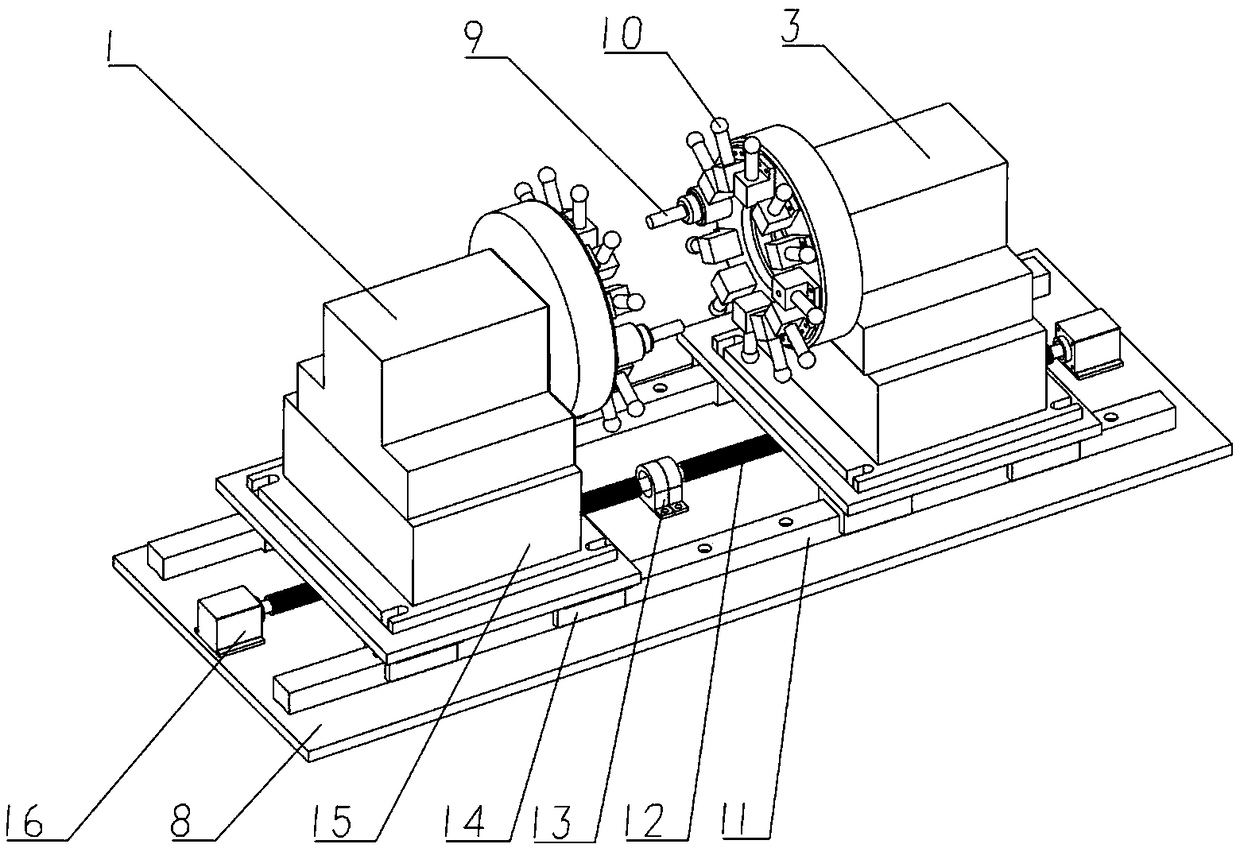

[0051] refer to figure 1 , a device for performing reliability tests on two power servo tool holders at the same time, consisting of two tool holders (knife holder A1, tool holder B3), a double tool holder installation device 8, a joint loading device 2, a control cabinet 4, The data acquisition box 5, the console 6 and the horizontal iron 7 are composed.

[0052] The two knife rests are installed on the double knife rest mounting table device 8, and can move along the guide rails on the double knife rest mounting table device 8 driven by the servo motor 16. The joint loading device 2 is located above the double tool rest mounting table device 8 in terms of spatial arrangement, and is arranged between the two tool rests. Simultaneously simulate the loads of two tool holders during cutting, and test the performance of the tool holders.

[0053] The data collection box 5 is placed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com