Reliability test method of dual-servo dynamic tool post with high frequency simulated loading

A technology of dynamic tool holder and high-frequency simulation, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., and can solve the problems of inability to automate the reliability test of the servo powered tool holder, high loading cost of the powered tool head, Problems such as working conditions cannot be well simulated to achieve the effect of increasing general testing, compact structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Reliability Test Device of High Frequency Simulation Loaded Double Servo Power Tool Hand

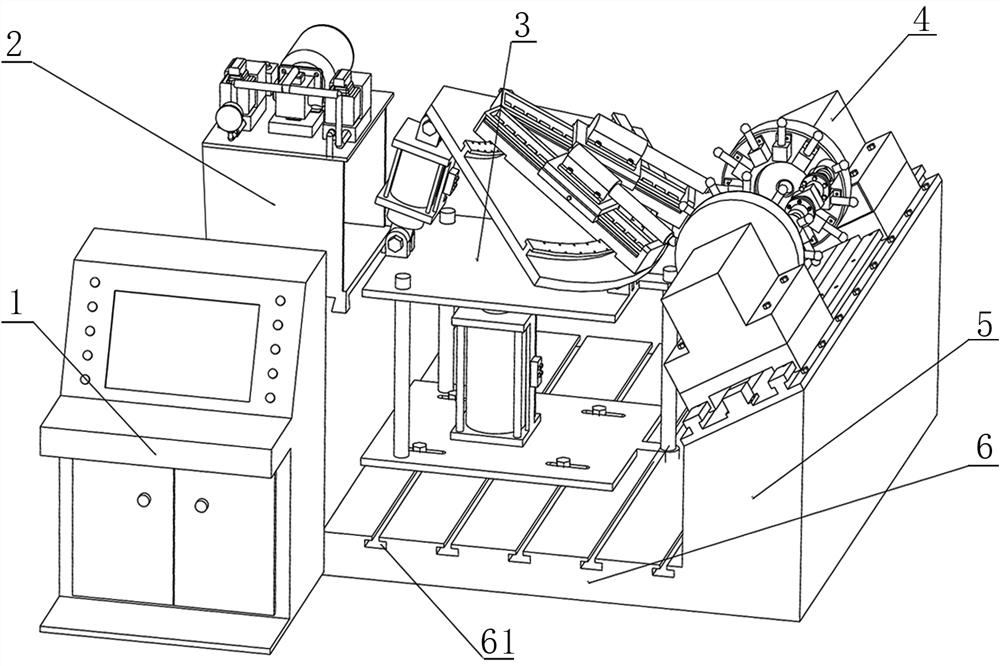

[0071] See Figure 1 to 4 As shown, a high-frequency simulation loaded dual servo power tool holder reliability test device, including: console 1, hydraulic system 2, loading system 3, double tool holder system 4, diagonal bed body 5;

[0072] The double-tooling system is fixed to the plane of the ground wire, the loading system and the slanted bed;

[0073] Hydraulic system 2 provides the required hydraulic pressure throughout the system;

[0074] The console 1 contains a computer, a display, and the components required to control the entire system, data display, parameter recording, and the like; the console 1 is provided with an output, and the output terminal of the console 1 is Hydraulic system 2, loading system 3, double tool holder system 4 and diagonal bed body 5 electrical connection;

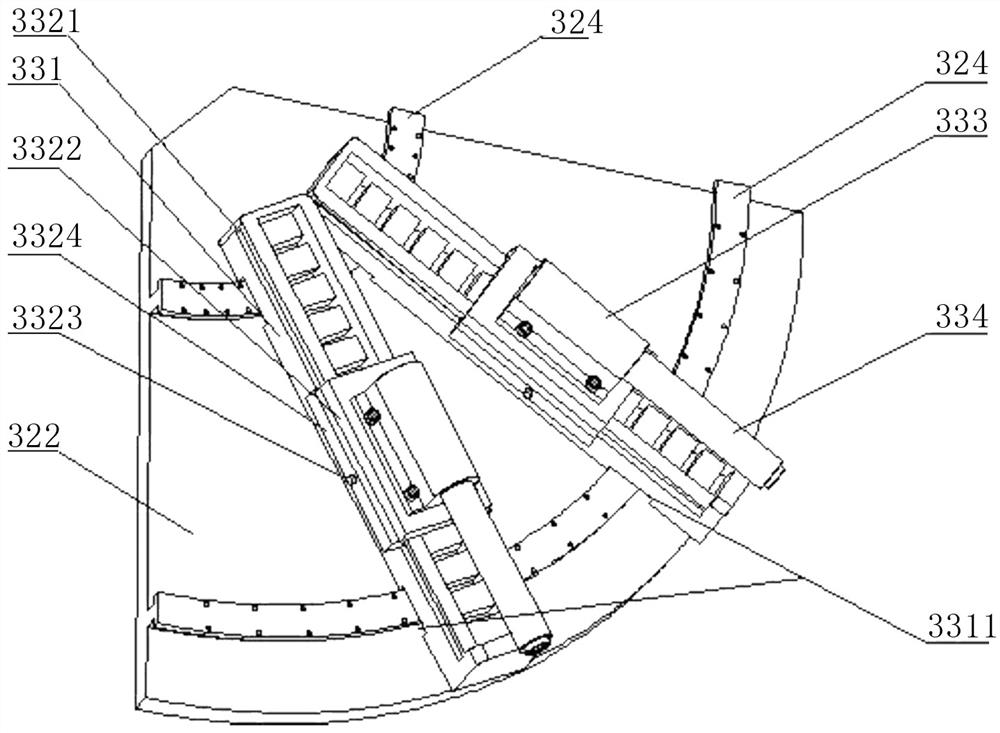

[0075] The loading system 3 includes: a lifting portion, an angular adjustment po...

Embodiment 2

[0099] Example 2 Reliability Test Method of Dual Servo Power Tutter Rack Loaded by High Frequency Simulation

[0100] See Figures 1 to 7 , High frequency simulation loaded double servo power tool holder reliability test method, steps are as follows:

[0101] The first step: the servo power tool holder normal cutter head reliability test and servo power tool holder dynamic head reliability test is carried out separately;

[0102] 1) The maintenance test temperature is constant at 23 ° C, and the test bench is placed in the test environment for more than 8 hours;

[0103] 2) Install the servo power tool holder and check whether the loading device and the hydraulic system are normal;

[0104] 3) Console 1 Select the servo power tool holder regular head reliability test and servo power tool holder power head reliability test;

[0105] A. Select the servo power tool holder ordinary head loading test;

[0106] a. Ensure that the ordinary head load system and power head loading system ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com