Novel test sample polishing machine

A polishing machine, a new type of technology, applied in the preparation of test samples, etc., can solve the problems of low work efficiency and poor safety, and achieve the effect of low labor intensity and standardized work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

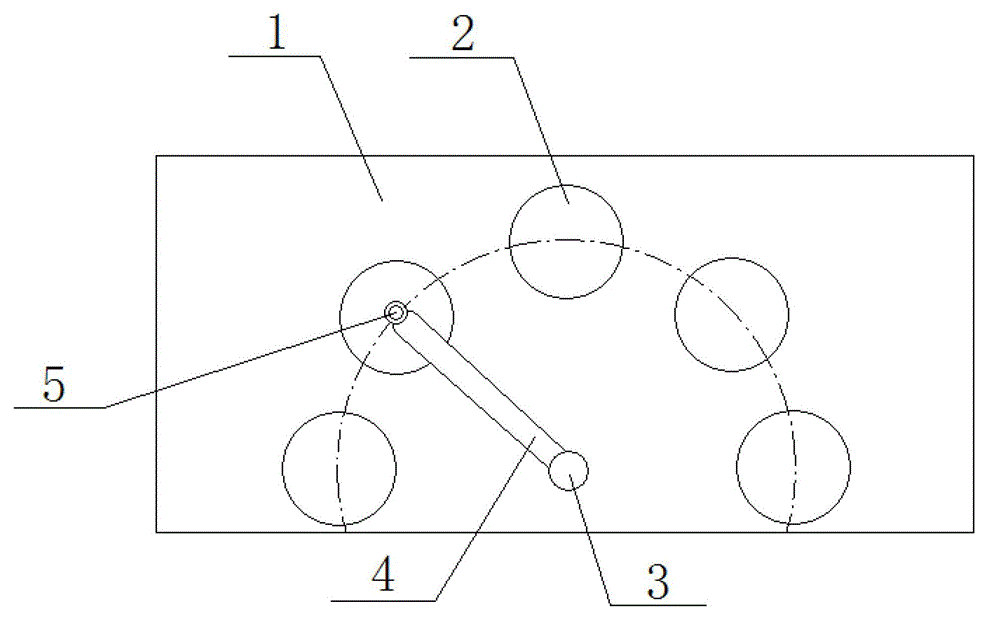

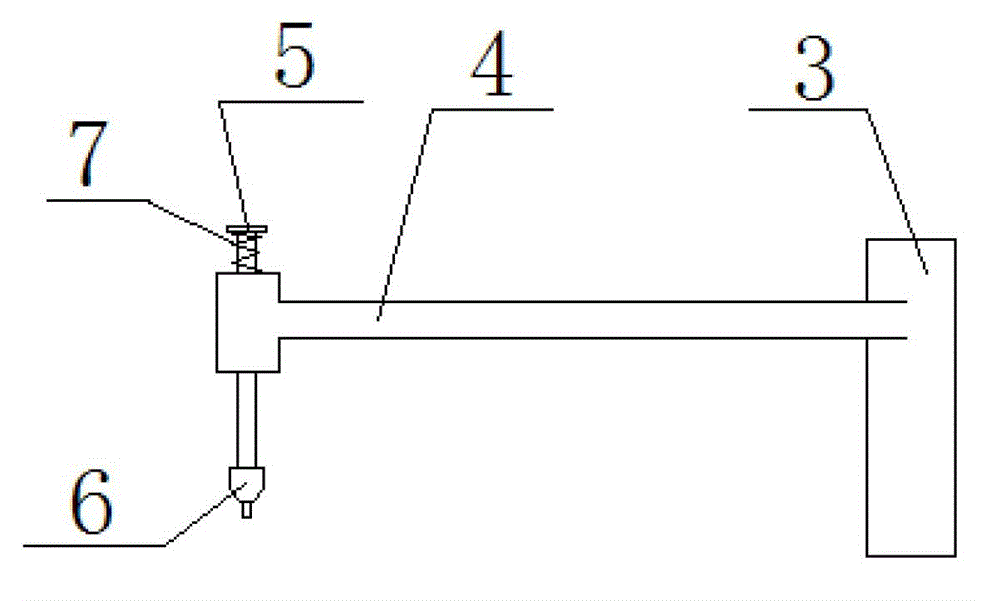

[0011] Such as figure 1 with figure 2 As shown, the new sample polishing machine includes a multi-station polishing disc 2, which is characterized in that: it also includes a rotary bracket and a clamping device; the multi-station polishing disc 2 is composed of a plurality of polishing discs driven by a power mechanism; The slewing bracket is composed of a rotating arm 4 and a pillar 3 arranged on the console, wherein: one end of the rotating arm is slidingly connected with the slide bar 5 of the clamping device, and the other end is connected with the pillar 3 through a bearing; the clamping device is composed of Slide bar 5, spring 7 and clamper 6 constitute; The rotating shaft of described multi-station polishing disk is arranged on the circumference that is coaxial with pillar axis and the radius is as long as rotating arm on the operating table, and multi-station polishing disk The disk surfaces are all on the same plane and perpendicular to the slide bar of the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com