Reverse IGBT (insulated gate bipolar transistor) device structure and manufacturing method therefor

A device structure and manufacturing method technology, applied in the field of IGBT, can solve the problems of reducing the tape-out yield, debris and scratches, etc., to reduce the probability of debris and scratches, improve the yield, and avoid the effect of flipping the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings.

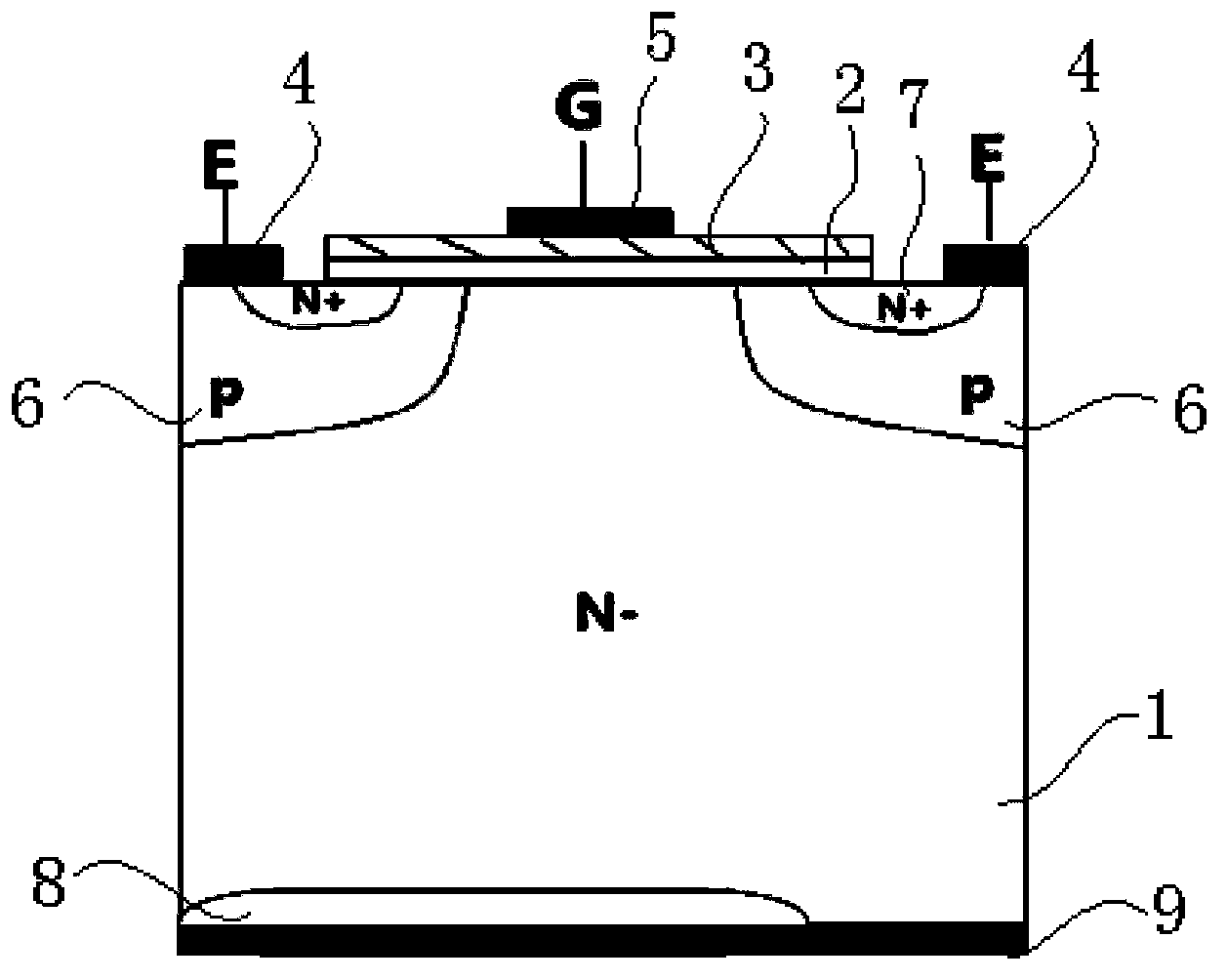

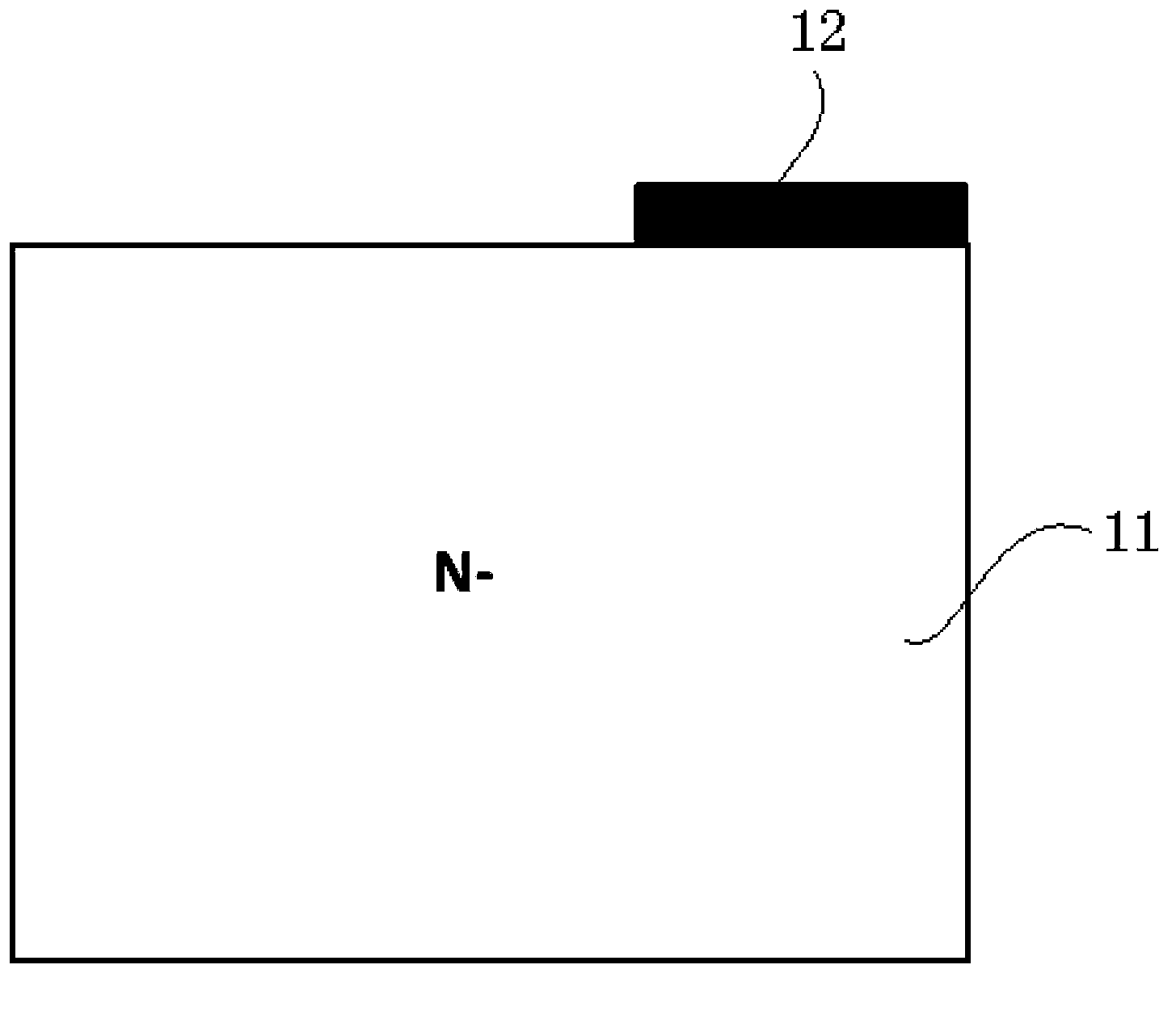

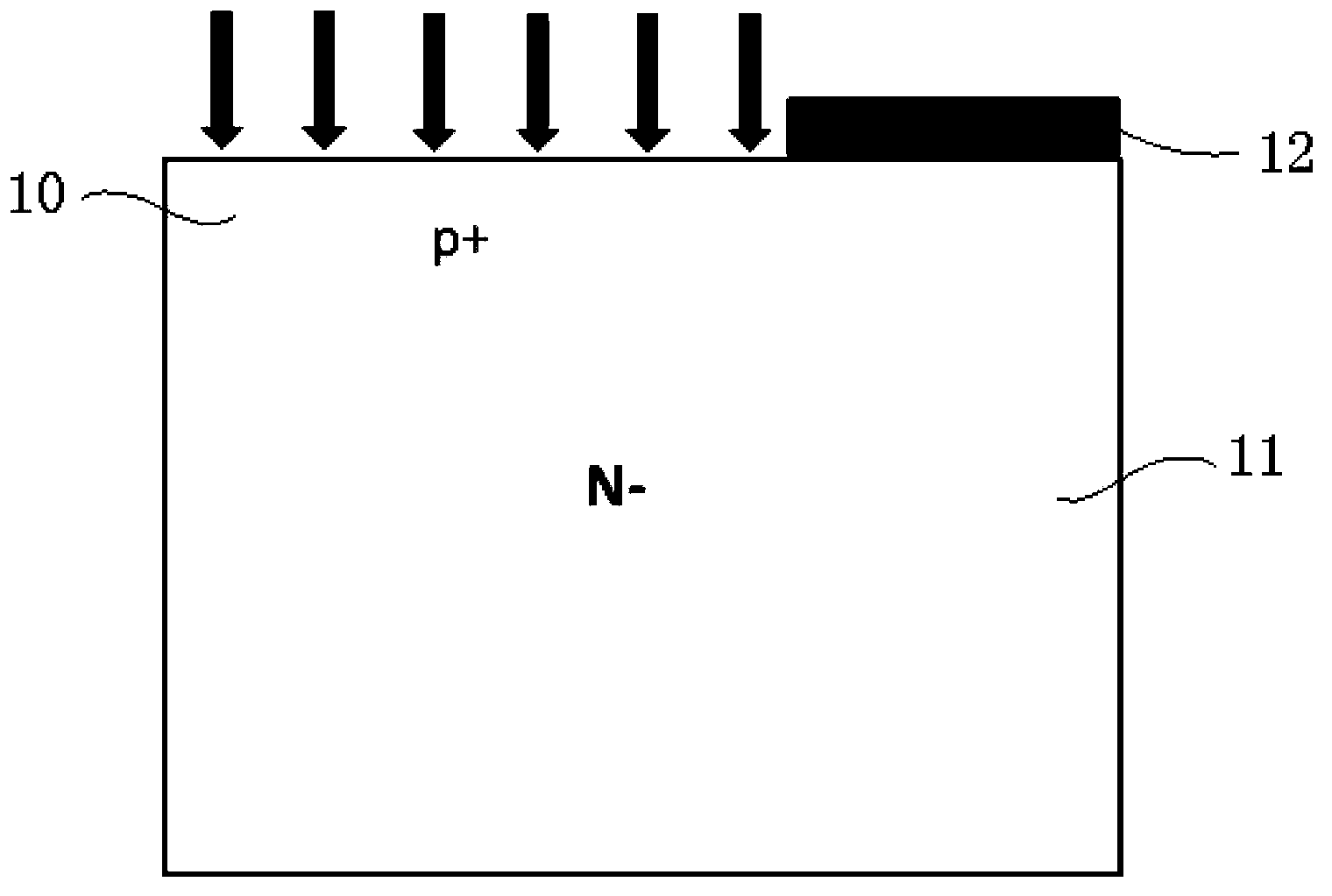

[0036] Such as Figure 1 to Figure 10 Shown: Taking an N-type IGBT device as an example, the present invention includes an N-drift region 1, a gate oxide layer 2, a polycrystalline gate 3, an emitter 4, a gate electrode 5, a P-type base region 6, an N+ emitter region 7, a P+ Collector region 8 , P+ collector metal region 9 , P doped region 10 .

[0037] Such as figure 1 , Figure 10As shown, on the cross-section of the reverse conducting IGBT device, the semiconductor substrate includes an N-drift region 1, and the N-drift region 1 has a front and a back side parallel to each other; a P-type base region is provided in the N-drift region 1 6. The P-type base region 6 extends from the front to the back of the N-drift region 1, and the extension distance of the P-type base region 6 is less than the thickness of the N-drift region 1; the P-type base region 6 is provided with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com