Prefabricated light steel concrete laminated slab shear wall

A concrete slab and concrete technology, applied to walls, building components, buildings, etc., can solve the problems of high requirements for stacking and transportation of prefabricated components, increasing the difficulty of stacking and transportation, etc., and achieve simple construction, excellent seismic performance, and simplified construction. The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

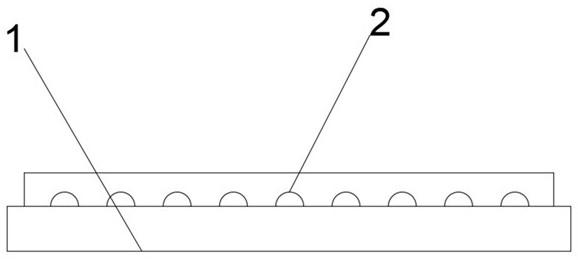

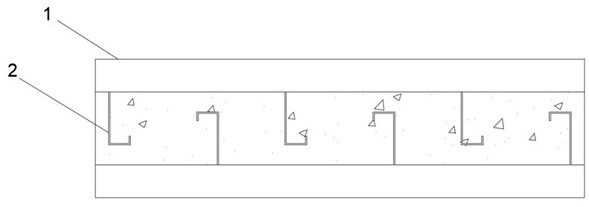

[0021] Such as Figure 1-Figure 2 As shown, the monolithic prefabricated light-steel-concrete laminated slab includes prefabricated slab 1 and light steel 2 with holes, wherein the light steel 2 is placed in the same direction as the C-shaped notch, and according to the laminated slab process, one side of each light steel 2 The side slabs and part of the web are cast in concrete to form prefabricated laminated slabs. The prefabricated light-steel-concrete composite slab shall reserve a section of concrete slab 1 at the end of the slab along the direction of the C-shaped notch of the light-steel-concrete composite slab to ensure that the light-steel 2 in the two prefabricated light-steel-concrete composite slabs does not exceed the height of the concrete slab 1. length range.

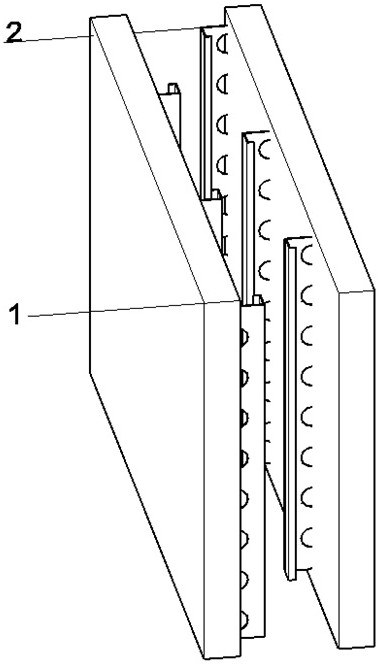

[0022] Such as image 3 As shown, during on-site construction and installation, two pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com