Quartic eddy current type vegetable cleaning and disinfecting machine

A cleaning and disinfection, vortex-type technology, applied in the fields of application, food processing, food science, etc., can solve problems such as incomplete cleaning and disinfection, unprepared cleaning and disinfection time, damage to fresh vegetables, etc. Precise and consistent mechanical damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

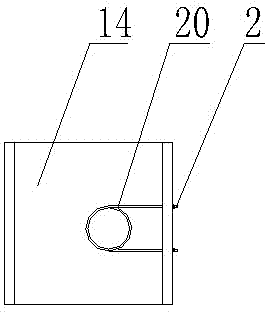

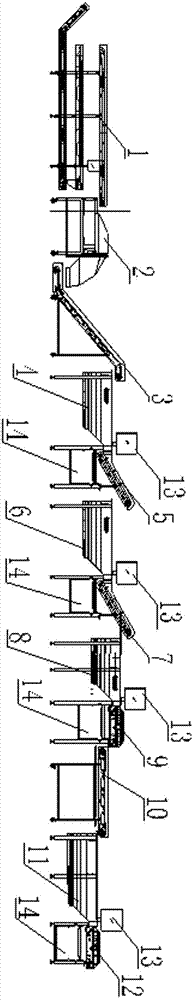

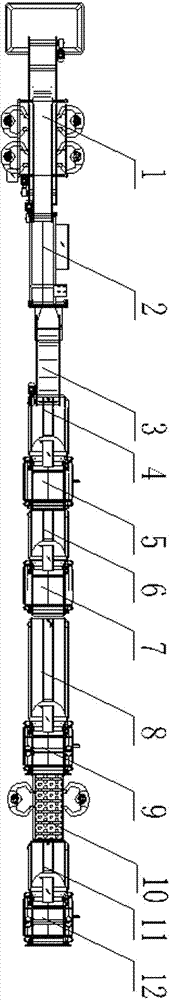

[0017] Such as Figure 1 to Figure 5 As shown, a four-time eddy current type vegetable cleaning and disinfection machine of the present invention includes a manual picking and conveying track 1, a vegetable cutting machine 2 is connected to the end of the manual picking and transporting track 1, and a material lifting track 3 is connected to the rear end of the vegetable cutting machine 2 , the material lifting track 3 is connected to the cleaning pool A4, the cleaning pool A4 is connected to the mesh conveyor belt A5, the mesh conveyor belt A5 is connected to the cleaning pool B6, the cleaning pool B6 is connected to the mesh conveyor belt B7, and the mesh conveyor belt is B7 Connect to the cleaning pool C8, the cleaning pool C8 is connected to the vibrating discharge screen A9, the vibrating discharge screen A9 is connected to the sorting conveyor 10, the sorting conveyor 10 is connected to the cleaning pool D11, and the cleaning pool D11 is connected to the vibrating dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com