Milk foaming mechanism of coffee maker

A coffee machine and milk technology, applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of inconvenient use, complex structure, and insufficient stability, and achieve adjustable foaming effect, flexible operation, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

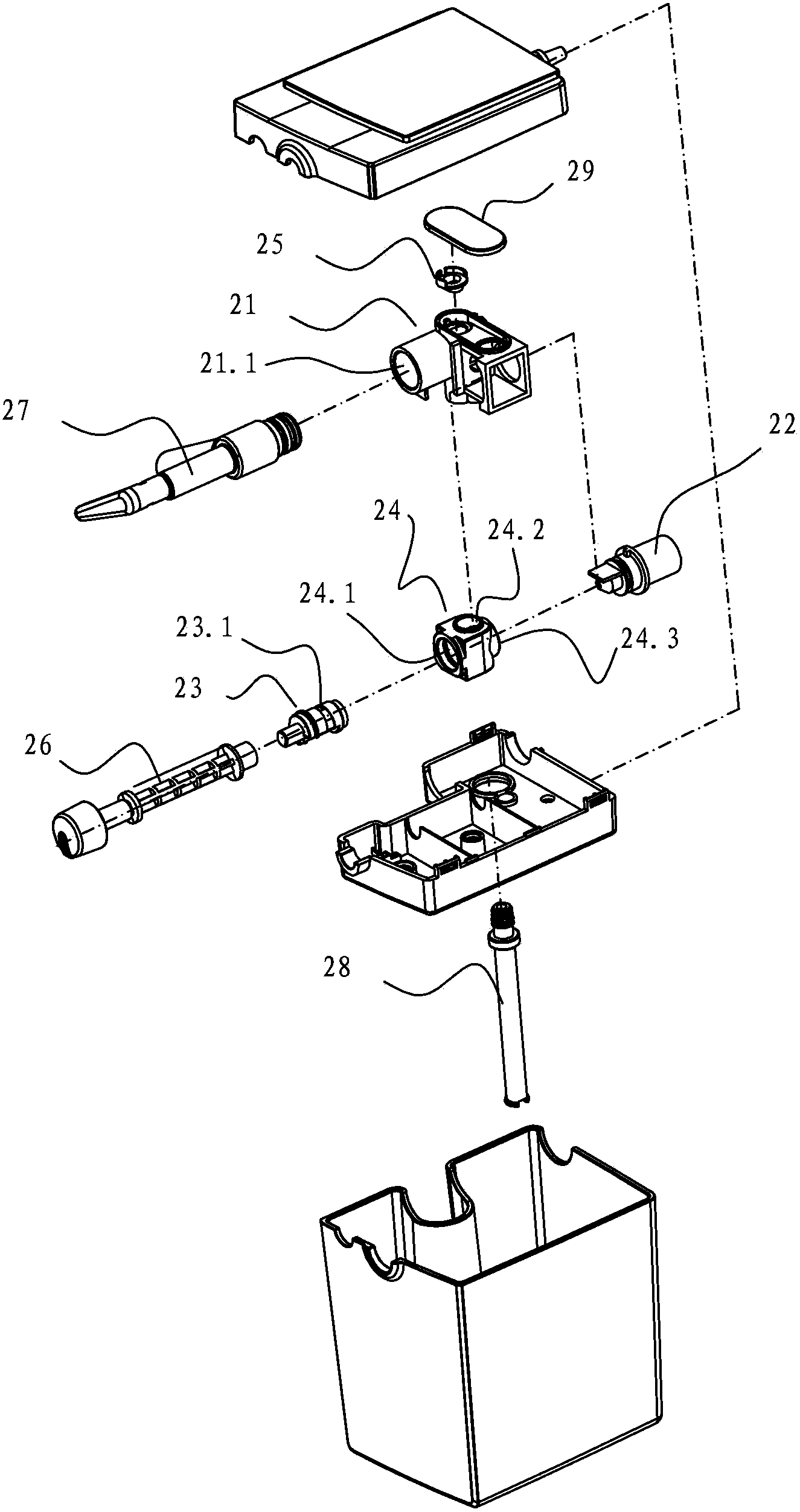

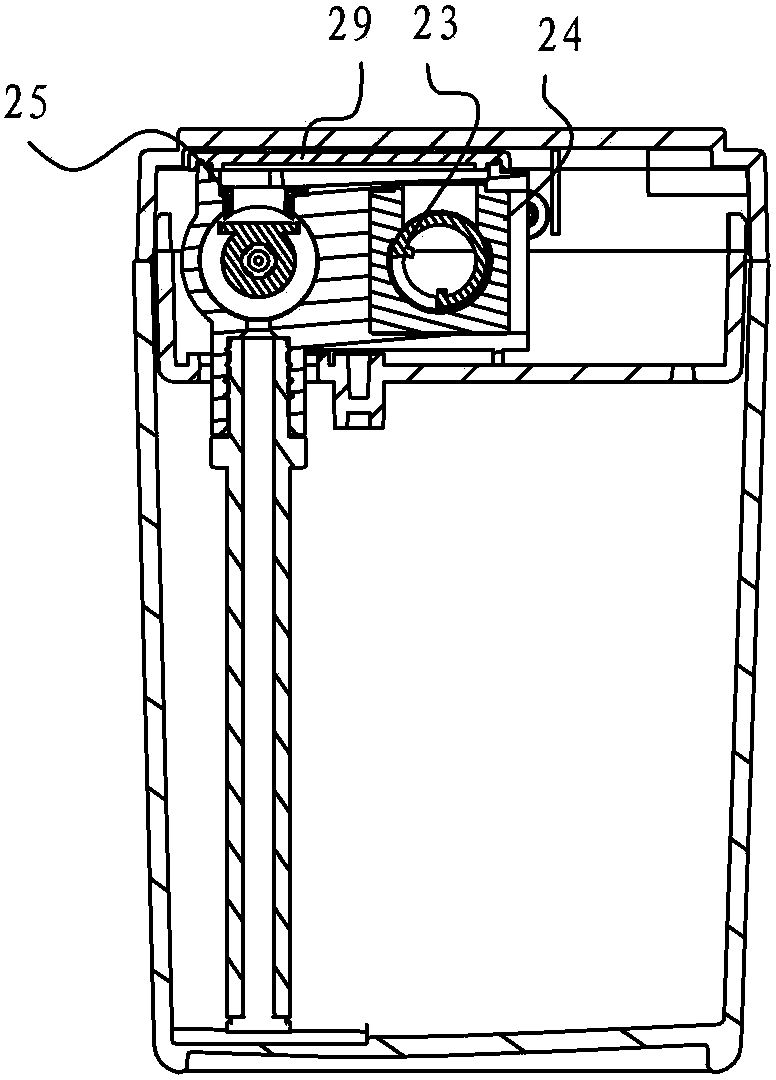

[0029] see Figure 1-Figure 9 The milk frothing mechanism of this coffee machine includes a milk box 10 arranged on the coffee machine, a foamer rubber plug 24 arranged in the foamer main body 21, a cavity is arranged in the foamer rubber plug 24, and foaming The rubber plug 24 of the device is provided with an assembly hole 24.1 communicating with the cavity, a vent hole 24.2, a steam hole 24.3, a liquid outlet and a milk inlet. In communication, the foaming nozzle 27 is connected to the nozzle 21.1, the adjusting rod 23 is arranged in the cavity, and the adjusting rod 23 is provided with a gradual change groove 23.1, one end of the gradual change groove 23.1 is larger and the other end is smaller, and one end of the knob 26 passes through After the assembly hole 24.1 is connected with the adjusting rod 23, the steam pipe joint 22 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com