Sealing strip for split open top cap of rail wagon

A railway freight car and sealing strip technology is applied in the field of sealing accessories for the split roof of railway freight cars. , the effect of dustproof sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

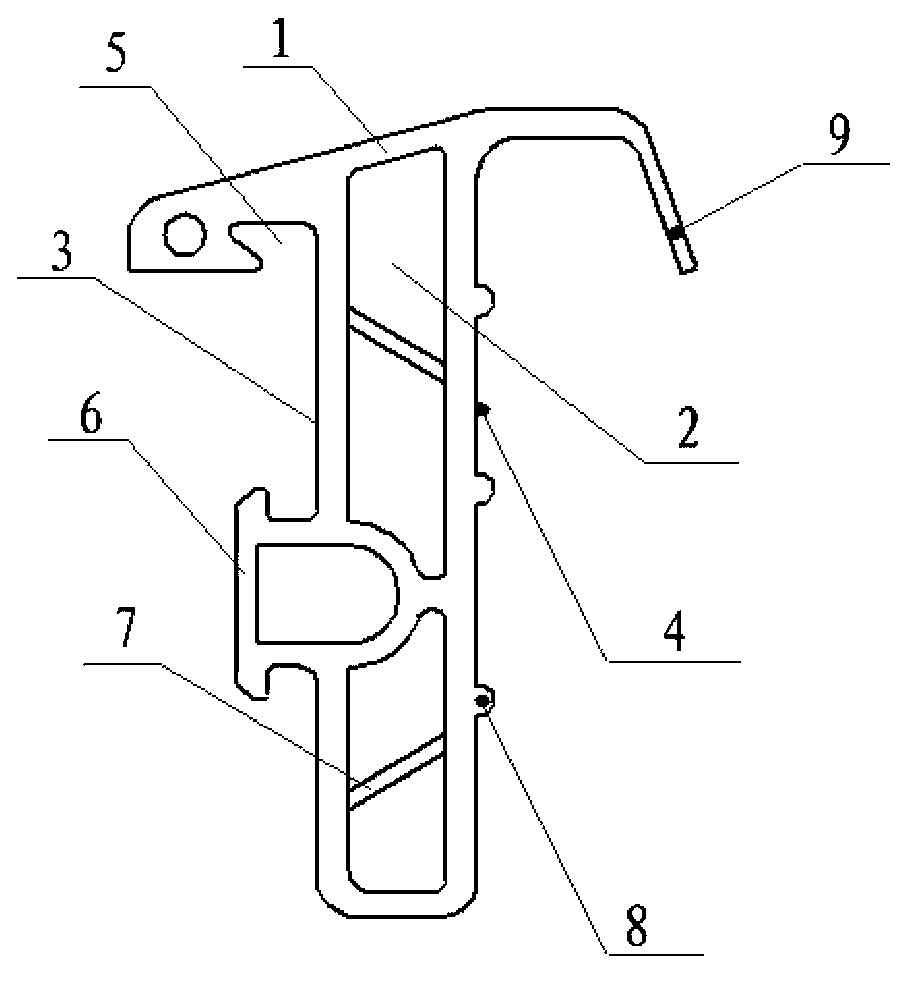

[0016] like figure 1 The sealing strip shown is made of flexible material rubber. The cross-section of strip top 1 and strip body 2 is a T-shaped structure. On the left side 3 of the bar body, the right end of the bar top is connected to the obliquely downward skirt 9. The strip body 2 is a hollow structure, and several buffer rods 7 are connected between the opposite sides of the hollow structure. The right side surface 4 of the strip body 1 is provided with several horizontal elastic rods 8 , and the elastic rods 9 are arranged at intervals on the right side surface of the strip body 2 . The advantage of the hollow structure is that it saves material and increases the elastic space of the sealing strip. The buffer rod 7 plays the role of strengthening the structural strength of the sealing strip and buffering and adjusting the external pressure in the hollow structure.

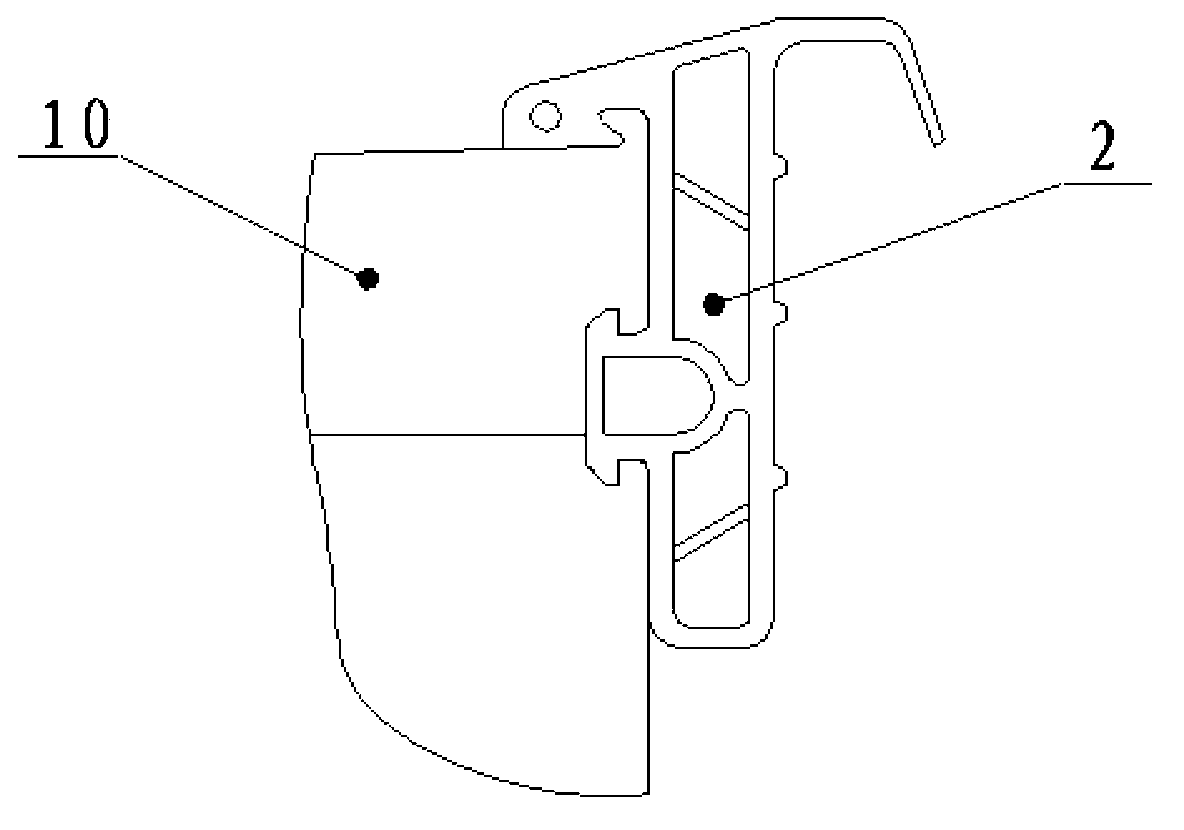

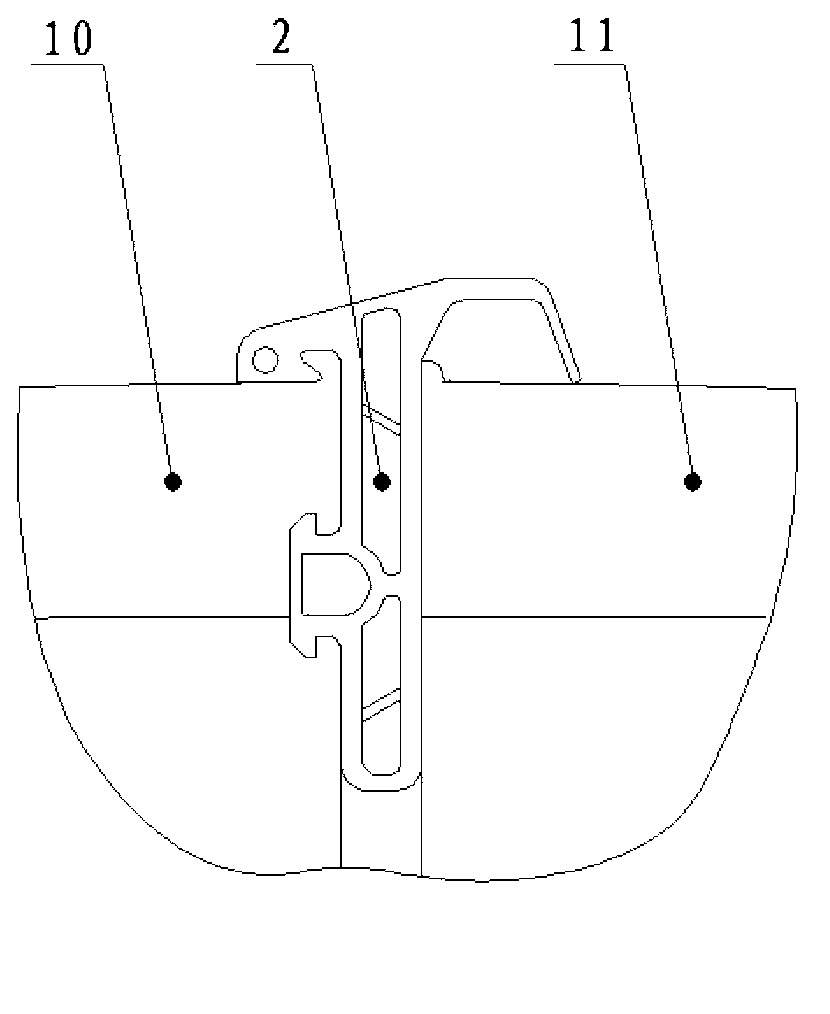

[0017] like figure 2 As shown, the sealing strip is installed on the left top cover 10 of the split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com